Gymnast

Members-

Posts

287 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Store

Everything posted by Gymnast

-

I think this could be problematic to use the VFD to provide power to the controller. Then you need a filter too. But I guess, that the power to the controller part may already be taken from one phase only. This could be checked. What is the input voltage specification to the machine?

-

I have read quite many posts on motors to sewing machines. But I have never seen this being tried. Actually it should also be possible with a clutch motor to do this and afterwords engage the clutch all the time. The VFD do not come with a system to connect to a foot pedal. So you need to make something extra for that to give control input to the VFD. Then I think, that the servo motors to sewing machines are quite cheep with motor and drive in all. So to install a VFD can be a more expensive and troublesome solution.

-

Thanks Wiz. Yes I know of the Speedy Stitcher, and I have got its cousin, the "Sewing Awl", and I have used with waxed thread for several small repair jobs and from before I got sewing machines. Interesting. So what you write here is that the tension back then was not controlled by the brake function on the roller, but by the number of turns. And then the roller was free to turn with no friction there - Am I right? But I guess, that these kind of waxed threads are not used that much anymore with the sewing machines. But these Wheel tensioners are still being prefered on the heavier machines. Thats why I got the theory, that it might very well have the reason due to twisting problems. Thanks Jimi for the links to other information on the 45k and 45b. Yes, this way the thread go from a top dics pre tensioner to a lower main Wheel tensioner on the face plate seems to have been repeated on many machines.

-

According to this link from The Thread Exchange , the recommended needle size is 180 to 230. So 140 needle size is a very little needle for that job. Are you able to obtain a balanced stitch and get sufficient upper thread tension? I (and I guess others) would love to see a video of you sewing this and view the stitched result (top and below in detail), because it is quite remarkable to be able to do this. The machine may have a special way in the timing.

-

I have noticed, that many of the heavier sewing machines have got a wheel type tensioner as main tensioner and one or more pretensioners of disc type. I suppose the wheel type tensioner have got an advantage by not creating much twisting of the thread as the disc type do. The higher thread tension a heavy machine needs should cause more twisting problems, if a dics type tensioner was used as main tensioner. Do you know of heavy sewing machines, that uses disc tensioners as main tensioner? What is the correct name for this wheel tensioner type? I "borrowed" this picture from @constabulary of a Singer 45k tensioner. I hope it is OK for me to use it. I plan to make a revision of the video in the start with the extra information I got here from you. If you have got a picture of a more modern Wheel tensioner, I would love to see it and use it.

-

Juki 341top thread breaking when backstitching

Gymnast replied to twotrees's topic in Leather Sewing Machines

In this video I have explained a Little about the "hard point" in the sewing cycle with reference to a modification of the hook used. In the video you can also see exsactly the same happen with a machine there sewing plywood. https://youtu.be/80WASgbKIX4 When you reverse, and the needle and thread pass Down in the previous holes made, you have left lesser Space in the hole, and therefor the friction to the thread gets higher. This can eventually be so high, that the thread breakes near the hook thread U-turn. You may go up a size in needle or deside to use a heavier thread. You do use a leather point needle - right? -

I am suppriced by the fact, that you are able to sew a size V277 thread with a 140/22 needle. Can I ask you to be a bit more specific regarding thread type and needle type?

-

I would buy this 5-pack of capacitors: Link to Amazon And then use 3 in parallel.

-

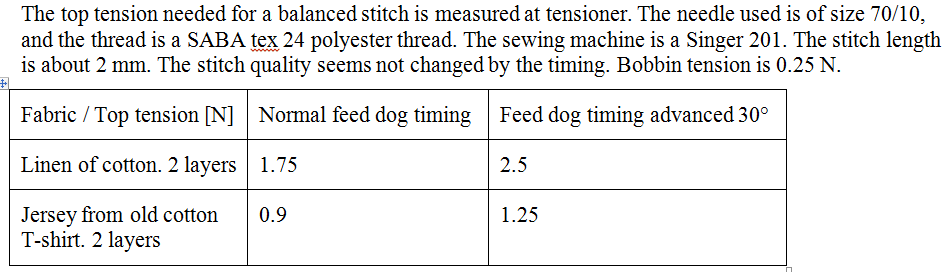

Thanks Bob. Thats exsactly what I did with the Singer 201. I checked the Singer 237, and it do not have this possibility of adjustment, because the excentrics for the feed dog stroke and the hook movement is a part of the steel shaft it self. So not all machines can be adjusted for that. I tried to sew two kinds of garment with my Singer 201 with and without the forwarded timing of the feed dogs. I was not able to see a change in stitch quality. But I saw a significant change in the required tension from the top tensioner to get a ballanced stitch: When you look at the timing diagram above in thread start, you still do have some movement from the feed dogs after the take up levers is at max. Therefore the movement of the feed dogs are involved in the final stitch forming and tension on the top thread in the fabric. With the changed timing, the feed dogs have finished the movement when the take up lever is at max. Therefore this may require more tension from the tensioner. I guess that the sewing machine designers wanted, that the feed dog movent got involved here in the stitch forming, but I am still not sure why.

-

I will try that. Yes, it is a possibility, but I consider it to be a rather costly operation in time and effort. I am not quite sure of the history of garments here and how early stretchy garments were produced in large quantities. I know that in the past 40 years much more cloth are made of stretchy fabrics. The Singer 66 I got came from factory in 1930 and the design goes further back. It do have this late timing of feed dogs anyway. I think, that a normal streight stitch machine is not that good for stretchy fabrics. Zig zag or double needle is better. And some computer machines make special patterns. I guess that sergers are common to be used for stretchy fabrics today. I got this link with the information, that a fashion designer started to use jersey in 1924: https://www.fulgar.com/eng/insights/jersey-fabrics

-

This can have many reasons, and I just name two which is not said already. If the fabric in some way are lifted when the needle goes up, then you get skipped stitches. The foot needs to hold the fabric down in a firm way. You may also look for the distance between the hook and the needle. I think you want it to be about 0.2 mm, but I suppose a manual or others expierience may give you the right distance. If the distance is too big, you get skipped stitches. If it is too Little, the hook may hit the needle too much, when the needle is a bit bended.

-

Thanks for your answer. I do not think, that it is possible in an easy way to adjust the feed dog timing of the Singer 66 "just a Little". If you see how I adjusted the 201 in the video, you got the same kind of grove in the shaft for the pinol lock screw on the Singer 66 (I suppose the Singer 15 got the same). That means, that if you just do a little advance of timing, the pinol will move the eccendric part back into the factory timing again. To avoid that I think you need to advance the timing at least about 25 degrees. But I guess this will be in order too, unless I should look out for something I do not know about yet.

-

This is a general question, that relates to a more "normal" sewing machines with ordinary drop feet (not walking foot). Most people with some knowledge of sewing machines know about, that the timing of the hook in relation to the needle is important. But the timing of the feed dog are not an issue in the domestic sewing maschine service manuals, that I have seen. I have checked the five sewing machines i got, and they all have a similar timing of the feed dog, and it seems to me that the timing is about 30 degrees late. I think that the designers of sewing machines must have a reason for that, I just like to know why. For domestic sewing machines, there may be some jobs of soft fabrics of high thickness, that a user may like to use the machine for. But this seems not made possible by the chosen timing. I made this video about the issue. I hope someone here may have an answer to the question - why the normal feed dog timing is like that? The cover picture of the video shows the measured position of the feed dog of my Singer 201k.

-

I got leather needles in size 22/140 from a German supplier 6 years ago. I still got them, but the supplier still sell them: https://www.ebay.de/itm/Nadeln-130-705-LR-140-er-zum-LEDER-nahen-20-NAHNADELN/112170380582?hash=item1a1de02d26:g:71sAAOxy63FSzw2n This is the Photo of the needle label I got:

-

How thick a thread do you expect this Chinese patcher can sew?

-

Who is an European supplier of heavy beehive springs?

Gymnast replied to Gymnast's topic in Leather Sewing Machines

I looked at the College Sewing website and found another beehive spring with a picture of a spring that looks more heavy: https://www.college-sewing.co.uk/1422-beehive-tension-spring-seiko-sk-6f-132k6.html I guess the base diameter of the spring to be 18.5 mm or about 23/32 inch. I suppose that all behive springs to sewing machines have that base diameter - am I right? Then the steel thread diameter should be about 1.35 mm based on measurements on the photo. The tension spring is supposed to be used on a Seiko SK-6F or a Singer 132K6. -

Who is an European supplier of heavy beehive springs?

Gymnast replied to Gymnast's topic in Leather Sewing Machines

Thanks for this lead. I will try to contact them. I have a local spring manufacturer too, that I have used for something else. Perhaps I should ask him too about this type of spring. When I look at the picture, the spring seems not that heavy to me. But I should ask them about the steel thread diameter. I managed DIY of two tension springs from the steel of two hooks like these: http://lesamisducircuitdenivelles.be/g/Women's-Inline-Skates/ For me a spring needed bending and adjusting with plyers for 2-3 hours to get an acceptable result. The diameter of the thread I used was 1.55 mm. So I can make it happen again, but I just liked to know if such a heavy spring is a normal replacement part - and it seems not to be. In the tensioners I got, the domestic springs can make a reliable thread tension up to 3 N. Using the spring with 1.55 mm thread, I can get a reliable thread tension up to 9 N. -

It seems to me, that there should be a supplier of heavier beehive tension springs in Europe or perhaps China or Taiwan. They may be used for Consew 206RB or similar. I found this supplier in USA, and the spring seems heavier by its looks and naming: https://bobbinusa.com/walking-foot/tension-spring-extra-heavy-juki-seiko-consew-walking-foot-sewing-machine/ And this from Australia: https://www.sewingmachinesaustralia.com.au/shop/buy-spare-parts/consew/consew-2202012-05-16-04-19-16/tension-spring-heavy-duty2012-05-16-04-43-42_24.html I have been fooled once by a supplier just stating, that it was a heavy behive spring, but it was infact as a domestic beehive tension spring. I measured the steel thread diameter of domestic sewing machines to be 1.0 to 1.2 mm. I guess the thread diameter of the heavier springs should be 1.4 to 1.6 mm.

-

Need supplier of needles for vintage Singer 111W113

Gymnast replied to jjs111w's topic in Leather Sewing Machines

As far as I can see, a 135x17 have a "but to eye" length of 38.9 mm The 190 needle have got 44.5 mm so it is 5.6 mm longer or 7/32 inch longer This is a supplier: https://www.thethreadexchange.com/miva/merchant.mvc?Screen=CTGY&Category_Code=NDL-190 -

I suppose I earned this reputation And based on the number of people seeing this video, I am not the only one.

-

I made a video about this comparison of these two vintage presser feet one normal foot and one food with a notch. I included a little more explanation and drawings than given above. I suppose the result is significant for those of you using a sewing machine without a walking foot. I did not make a comparison to a foot not hinged. People in this thread rightfully rejected the first results when the feet was not exsactly the same. I suppose and hinged foot may easier climb a "hill". But do you see a reason when to chose a hinged food and when to chose a non-hinged food?

-

It seems that Big Dog Forge on youtube did try what you like to do, and the result there is impresive to me considering the price of the parts. This chineese patcher seems able to handle pretty thick stuff. Big Dog Forge do also need to use his hand on the wheel now and then while stitching, so the speed control is not perfect there, but much better than the other videos using the domestic motors with no extra speed reducer. I like a controlable speed down to 10 stiches/min, but I suppose it is just me.

-

Interesting project with this Chinese patcher. I just looked at two youtube videos, with the use of some domestic sewing machine motors on this patcher, and the speed control seems not that convincing. One of them used a very bad pedal that have 3 speeds (off, half speed and full speed). With such a domestic motor, I think a speed reducer may help. I am not sure, that the motor that you suggest have that good speed control, but it ramps up the moment like on a domestic machine. This video indicate the difference of a brushed servo motor and a brushless servo motor: However I do feel somewhat nervous, that the high power of the servo motor may damage this small patcher machine. Perhaps that you should use a belt that can slide with ease.

-

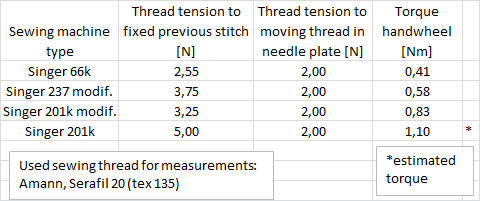

I have tried to make a small video about the modification of this class 15 shuttle hook. It got no more information than already given above in text above, but I suppose the message get better clarified: https://youtu.be/80WASgbKIX4 And then I continue my reputation on being a nerd on measurements and numbers: After the modification above, I tried to make a measurement set-up to give some figures related to the thread friction in the shuttle area. It looks like this: One end of a thread is attached to a digital dynamometer with no movement and the thread goes down through the needle plate and around the hook. This end simulate the thread attached to the previous stitch. The other thread end is attached to a moving spring dynamometer and it simulates the thread comming down the needle grove through the needle eye and to the hook. When I advance the machine and the hook, you see the indicator of the spring dynamometer move down, and you can measure the two thread tensions. No needle was used. The thread length was adjusted, so the position of the hook at measurement corresponds to a needle eye position of about 3 mm above the needle plate. The difference in the two thread tensions indicate how much friction is applied by the hook thread U-turn, but also some other friction. Furthermore I measured the torque on the flywheel by removing the belt and by use of another dynamometer. I tried this test set-up on three vintage domestic machines, and got these results: I am sure, that the improvement in grinding the edges of the class 15 shuttle hook could have been measured this way. So the figures above is only after the modification. I did also try the measurements with thinner thread, and then the thread frictions became less significant.

-

What is the right bobbin thread tension?

Gymnast replied to Gymnast's topic in Leather Sewing Machines

Well, now people that like to share these bobbin tension values can do it. I use these spring dynamometers, and I think the most significant benefits have been to diagnose tension problems faster and fix them. It it is much faster than a lot of test sewing. I have had problems with tensioners giving variation in tension including once with a shuttle tensioner. When you search this forum and look for problems with tension or helpers suggesting wrong tension - I think you get over 1000 posts.- 28 replies

-

- thread tension

- lower thread tension

-

(and 1 more)

Tagged with: