Gymnast

Members-

Posts

287 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Store

Everything posted by Gymnast

-

Perhaps you can lent one from your local auto repair shop, or they may help you. A puller is a standard Tool for them.

-

Thanks for your reply, zuludog. I did actually try Google and YouTube for information. But I have not yet been that succesfull regarding carpet edge binding and edge whipping. That is why I desided to ask in this forum, because I think some leatherworkers might have found some good information in some uphostery forums, that I did not find by Google. After searching more I did find this forum about flooring, and perhaps they can help: https://thefloorpro.com/

-

I am looking for some adwise regarding upholstery work and in areas of carpet binding like this: What other kind of internet forum would be a good ressource for information?

-

This is an indication to me, that the check spring may not operate, as is should.

-

You are right. According to this list, the bobbins are the same: https://www.thethreadexchange.com/miva/merchant.mvc?Screen=CTGY&Category_Code=sewing-machine-bobbin-style-info The overall dimensions from data on the internet seems to be 11.8 x 20.6 mm. However, when I measure on the bobbins that came with the machines, I do see other differences. The inner diameter to the axle is different, the Berninas are 6.0 mm. The others are 6.3 mm. On the Bernina bobbins the tube forming this inner diameter extents more out from the surfaces of the spool. When you sew with low lower thread tension, such small differences can make a difference.

-

Recently I inherited a Bernina 910 machine. I do like a Singer 201 a lot. But sometimes I read and hear reviews of a Singer 201 to be the most silent and smooth sewing machine ever made. Well, when you have tried a Bernina, the Singer 201 sounds like turning on the blender. But hopefully I will never have to buy spare parts for the Bernina, because they seem very expensive. The Bernina 910 have got a shuttle hook. I took two pictures of it side by side with the modified Singer 237 shuttle: When I look at the machining of the thread U-turn area, I think the Bernina is made quite well, as should be expected from a Swiss product. Many of the dimensions are very close, and I can use the class 15 bobbin in the Bernina. I can also put in the Bernina shuttle into the Singer 237, and it seems to fit, but it is NOT the same: The thicknesses of the flanges are very different, so the race gate will not hold on to the shuttle as it should when interchanged. With the Bernina shuttle in the Singer 237, at some point the needle hits the shuttle. Would you consider the Bernina shuttle a Class 15 shuttle?

-

Sailrite ultrafeed LSZ-1 stitches come with different tension.

Gymnast replied to climent's topic in Leather Sewing Machines

When you have got a Sailrite Ultrafeed LSZ-1, then I like you to read the thread below as well regarding class 15 shuttles. If you have got one shuttle hook with edged thread U-turn and one with smooth U-turn, then you could verify this issue better than me. But from from a theoretical point of view: High friction at this thread U-turn can make very high tensions in the upper thread, that might alter the lock position of the previous stitch. So in this way this tension from hook shuttle can compete with the tension for the tensioner applied by the thread take-up. Higher lower thread tension from bobbin may then be one way to solve the problem, because then you need to increase the tension from upper tensioner, so it will win in this competition. I suppose that the friction to thread at thread guide edges will be of variable nature. -

Sailrite ultrafeed LSZ-1 stitches come with different tension.

Gymnast replied to climent's topic in Leather Sewing Machines

Many issues can cause this to happen as already suggested above. And it might not be just one of them. The machine have got no pretensioner and therefore one issue more is thread twisting problems forming kinks or unstables position of thread to tensioner. I have seens the same problems as you several times, and my good help was the use of dynamometers to measure the upper and lover thread tension. It narrows down where to look for the problem without a lot of test sewing. I like spring dynamometers best: -

Thank you for your answers kgg and Mark842. I just like to say, that this low speed torque, that you like the motor to have for heavy leather work, is a matter of the electronics, and not the brushes. A brushed DC motor can provide high torque at low speed, if it have got internal sensors measuring the speed and electronics control the motor current, so same speed is maintained. But it is my impresion, that all the brushed DC motor servo drives sold for sewing machines do not have this kind of electronics build into them. I saw this supplier selling 4 types of servo motors looking like my Picture above. And the seller argue, that they perform different. Brushed DC motors with no extra Electronics can of cause have smaller differences in torque/speed caracteristics. So if someone using this kind of motors says it have good low speed torque and easy controlled speed, the electronics for it may be inside. https://www.sewingmachinegallery.com/best-sewing-machine-servo-motor/

- 11 replies

-

- pedal

- speed control

-

(and 1 more)

Tagged with:

-

I hope some of you can help me with at question about servo motors. When I read about servo motors for sewing machines, there seems to be a Group of motors, that looks like this: I think they are called DC motors with bruches. I got a question concerning the torque/speed caracteristics. In this video below, Stephen Feldmeier compares two kinds of servomotors. The other seems to be a bruchless DC motor. https://youtu.be/SOyQtt3eDLw Stephen mention, that this bruched kind of DC motor may be considered the "older" kind of servo motors for sewing machines. Do you agree with that statement? It seems like this kind of motor do not have electronics and speed sensors, that try to keep a constant speed of the motor. The torque/speed caracteristic have a slope, so with a constant setting on the food pedal, the torque drops off slowly when the speed is increased. It is the same way most older domestic sewing machine motors react to the foot pedal position. Do you agree to this statment regarding motors with this apperance?

- 11 replies

-

- pedal

- speed control

-

(and 1 more)

Tagged with:

-

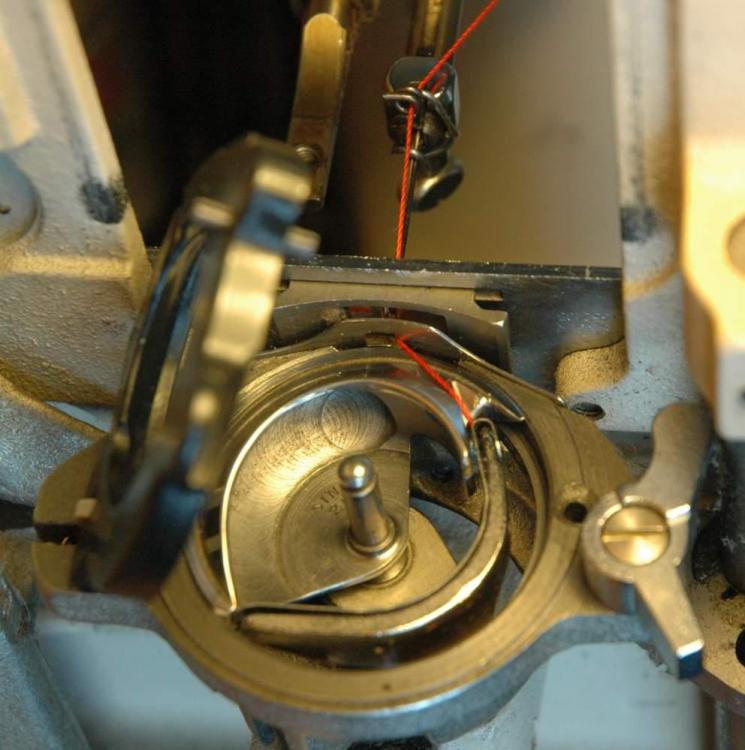

Thanks kgg for clarifying this subject and the specifications for this class of portable machines using the class 15 shuttle. My point is, that some of these machines actually might be able to handle a thicker thread and materials if this thread U-turn area of the shuttle are better rounded. When sewing heavy materials very slowly, I have noticed, that the required torque to drive the sewing machine vary a lot during a sewing cycle. Maximum torque is required when the needle eye passes the heavy fabric in upwards direction. At this point the shuttle (some people call this the hook) pulls the upper thread downwards at high speed. And a high friction force is added to the thread passing at both sides of the needle in the "narrow" hole in the fabric. Sometimes the machine is forced to a complete stop at this point. So I am sure, that the thread tension in this part of the sewing cycle can be very high. Therefore I think that the smooth passing of the thread at this U-turn should be of interest, if you sew with thicker thread and heavier fabrics.

-

I am interested, in this subject. However I do not have the skills in leatherwork needed. But I could help on some specific technical issues. I did a few videos myselves, and almost nobody choose to see them. So I would like to know more about how to make people interested. Some youtubers make a living making videos. So this is perhaps another perspective on this subject.

-

I just looked a bit more into this subject, and perhaps this is a more general problem. I think this Singer Class 15 shuttle is used at many sewing machines. I have looked at pictures of these shuttles on internet, and I think all of them are not that rounded at these edges, as I should like them to be. Some are quite sharp. I am not sure if you will consider the Sailrite or Rex sewing machines as industrial sewing machines. They do have a combined feed. But i think you would expect them to sew up to a V138 thread. When I look at this video from Sailrite, these edges are somewhat more rounded than many other class 15 shuttles, I looked at from internet. But I would not be satisfied with this. I rounded these edges to some higher radius than the shuttle I see in the Sailrite video. I cannot say how much is needed. But If I had a machine like this, I would look into that. The driver is a bit different on this Ultrafeed than my Singer 237. The 237 have a flad spring attached to the inside of the driver. The Ultrafeed have not got this spring. To do the job I used some abrasive cord like this: https://www.gesswein.com/p-2867-abrasive-cord-and-tape.aspx To polish the surface I soaked some Ø2 mm polyester cord into some scouring cream I use for cleaning.

-

I just like to share a kind of modification I have done on a Singer 237 domestic machine. With this machine I try to make sew with V138 polyester thread, and it fails (of cause). The upper thread gets damaged when I try to sew more than 5 stitches, and then the thread jam or break. So I tried to figure out why. The Singer 237 have got an oscillating shuttle, and it is a zig-zag machine. The Pictures below illustrade the modification: The modification fixed the problem, and now it is able to sew with V138 serafil 20 polyester thread. Of cause I need to increase thread tension of the machine for this to happen as well, and the machine may wear down quick. Before the modification, the shape of this U-turn was rectangular with quite sharp edges. I suppose these original edges will be all right with thinner thread and lower tread tension. However I cannot be sure, if this could be a fabrication error. I have looked at some similar new shuttles for sale on internet, and I think they some of them have got quite sharp edges as well, when I look at Pictures of them: https://www.searspartsdirect.com/product/1i5kk8lux0-0020-385/id-532096007 https://picclick.com/Shuttle-Hook-For-Singer-Butterfly-Flying-Man-Old-153009787971.html#&gid=1&pid=5 https://www.amazon.com/SINGER-Sewing-Machine-Shuttle-Hook/dp/B008MM42UM Has this area of the shuttles of industrial sewing machines for leather the same kind of issues? Perhaps you should expect some Wear on these surfaces as well.

-

Dürkopp 18 Patcher Restoration - long journey...

Gymnast replied to Constabulary's topic in Leather Sewing Machines

Constabulary, thank you for sharing your amazing work on restoring this amazing machine. I loved watching all the pictures, video and details. -

I hope, that the motor should be able to turn at lower speed than 300 RPM. It seems to be a high speed to me. This link is to a dealer of what I think is your motor: https://www.strima.com/texi-power-750-sm-ac-servo-motor-with-synchronizer/item/1047899 Another guy, DanishMan is sometimes around this Leatherworkers forum. He uses another polish servo motor from Zoje, and recommend it: https://www.sewtex.de/Motore--Gestell--Tischplatte--Zubehoer-fuer-Naehmaschinen--Stuehle--Leuchten--Transportwagen--Industriestuhl--Schere/ZOJE-TZ-ZJ750W-S-Servomotor--Naehmaschinenmotor.htmlhttps://www.sewtex.de/Motore--Gestell--Tischplatte--Zubehoer-fuer-Naehmaschinen--Stuehle--Leuchten--Transportwagen--Industriestuhl--Schere/ZOJE-TZ-ZJ750W-S-Servomotor--Naehmaschinenmotor.html When I compare the Pictures, they look the same, and I suspect they come from the same Chineese manufacturer. However important software can be different. I found and read this link to some service information on a servo motor from Zoje: http://files.zoje.com/uploads/doc/WR596 training.pdf I guess, it is the same motor, but I am not sure. But this service information reveal a motor and control unit, that is designed for sewing machines. Its is a well designed motor drive and uses a brushless DC motor. It is not just a modified industrial multi purpose motor drive. In order to control a motor like that at low speeds, you need a bit more complicated software in order to avoid too much ripple in torque. Furthermore you need to measure or estimate the temperature (by software) of the copper windings in the motor, because the blower on the motor shaft cooling the motor is not effective at low speeds. I made this thread in this forum to show off my "home made" speed control of one of my sewing machines. I did that, because I suspect, that some leatherworkers speed control are not well designed, and they should see what is possible: https://leatherworker.net/forum/topic/86489-do-you-like-this-speed-control/

-

Congratulations with your machine. Did you buy the machine for sale in Hvidovre? I just read some forum treads regading needle positioner. Most servo motors have problems in using a needle positioner, if you also use a speed reducer on the machine. It is not quite clear where the limits are. One reported, that with a gearing below 5 from servo motor shaft to handwheel shaft, it was possible to use a needle positioner.

-

Thank you mikesc for helping to find what I search for. I searched for "servo motor" but got so many threads, that it became meaningless, and therefore I started a new thread. Now I found this 9 month old thread, that I might have continued. But I will look more into the matter. https://leatherworker.net/forum/topic/82673-ho-hsing-g60-servo-or-what/ It seems to me, that most leatherworkers are satisfied with the servo motors they got, but a few like to see a wider speed range and the positioner to Work with the step Down gear. I have tried to make a case about using a better food pedal, but I do not think, I had any luck there

- 11 replies

-

- pedal

- speed control

-

(and 1 more)

Tagged with:

-

Stitching issues on a 3200 with 5-6 oz veg tan

Gymnast replied to BDAZ's topic in Leather Sewing Machines

Thank you Wiz, for explaining this to me and the historic background. I suppose you mean, that you still need a pretensioner with disks in order for the roller main tensioner to operate. -

I have seen the Enduro servo motor still using a slotted optical switch to provide input signal like all the references from 2012. It was also an Enduro servo motor, that was used for the the very popular "how to" video SWFLholsters made: https://youtu.be/X6CCxv3i4No Depending of what kind og sensor is used, and how the interface is made, it might be possible to make a retrofit solution by using an air pressure sensor instead. In this way it may be possible to use a pedal like me. When you look 10:30 into this video, you see the slotted optical switch, and 3 wires are leaving it for the motor control. If this is a standard component with a type number on it, I should like to know this type number.

- 11 replies

-

- pedal

- speed control

-

(and 1 more)

Tagged with:

-

Stitching issues on a 3200 with 5-6 oz veg tan

Gymnast replied to BDAZ's topic in Leather Sewing Machines

Thank you very much for explaining this to me. The video you found from Solar Leather do also have provide high quality instructions about the check spring. -

I think a Photo would help me to help you. You can get problems like this if the pressure on your presser foot is too low, so the fabric is lifted in parts of the sewing cycle. Did you check needle size or swap needle?

-

Stitching issues on a 3200 with 5-6 oz veg tan

Gymnast replied to BDAZ's topic in Leather Sewing Machines

Yes, it is some kind of illusion to me :). I think I watched 5 other videos on youtube regarding this subject now, and they all looks equal and as on your machine. They all seems to me like the thread do not go between the discs on the main top thread tensioner. So I hope I can learn something too. With the pretensioner Ryan in the video clearly indicates, that the thread must be pulled in between the discs. But he do not show the same regarding the main tensioner. Are the tension discs different on the main tensioner? Do the thread go around the discs near the outer perimeter of these discs? I normally see the thread commes in around the post, that may be only about 1/4" diameter, and I do not see this happen here. -

Stitching issues on a 3200 with 5-6 oz veg tan

Gymnast replied to BDAZ's topic in Leather Sewing Machines

When I look at your Picture AND the video I refered to above, it seems to me that the thread is not put between the tension discs of the tensioner. I take that from the direction of the thread from the pretensioner. The thread rides on the top. It should be pulled in between these discs. -

Stitching issues on a 3200 with 5-6 oz veg tan

Gymnast replied to BDAZ's topic in Leather Sewing Machines

I did also look at the youtube video https://youtu.be/MHQBvaNkcRM I think the upper tension should be high enough to move the check spring at any time. So to me it means the upper thread tension is too low. Perhaps the lower thread tension is too low as well. Do you have any Means of measuring the thread tension? The Picture you have above, is that from before or after the stop on the check spring was changed? I would like the stop be lower than on the Picture to make Space for more movement of the check spring.