jeeperaz

-

Content Count

195 -

Joined

-

Last visited

Posts posted by jeeperaz

-

-

Since I made this post, I have ordered 3 or 4 times from Weaver. I did have to send in my Texas sales tax exemption form before they would send me my order. I have had noting but a great experience from them. By having my sales tax number, I have cut my production cost in half. Just as an example, I was paying 3.50 for a halter snap at a local shop, I now pay 1.39 for the same snap. The retail markup for hardware is unbelieveable. I understand it, but am glad I don't have to pay it anymore.

How fast is there shipping? Earlier last week, I ordered from them for the first time and haven't received any type of shipping confirmation. Do they even do that?

-

I have been working with leather for 9 years now and am self taught. I have had the problem of the blue and black spots on my leather after wetting. I know it is from contact with metal. I have always tossed my projects unless they needed to be dyed black. I recently found this site and have read about the oxolic acid but I cannot find it local and I do not have enough time to order any. Is there anything else I can use to remove these spots?

Do you have a hardware store close by? Typically all of them sell wood bleach which is usually plain Oxalic Acid (check the label before purchase).

example of the most popular brand:

http://www.highlandwoodworking.com/savogranwoodbleach12oz.aspx

-

oh the music on that site.... just awful.

But with that said, it is a great resource.

-

My new years resolution was to get going on my leather projects, the first being a custom wallet. I posted earlier about getting my old singer 31-15 sewing machine to work with leather. I used it last year and was able to sew some leather with the guidance of an old shoe repairman in his shop. He sold me the machine when he suddenly retired, and I have had a hard time just getting over this initial hump of threading the machine properly. I was able to get an owners manual from the Smithsonion museum, no less, because this clunker was made in 1912!

Only one person responded to my post, and since then I discovered my needle was in wrong. Now I can at least sew blue jean material, but not yet leather. I feel however, like I'm almost there. I bought some new needles 16-100, and some thread to match at the local joanne fabric store. When I try to sew these two thin practice pieces of leather together, it just puts a nice row of holes in the leather, but the thread goes nowhere. When I try on 2 thickness of blue jean, it works OK. When I try it on two double thick leather folded over, it almost works, but the stitches are all messed up. I gave up for now, but will try using various tensions and maybe a couple of different kinds of thread. If anyone has been down this road before, I would like to hear from you as to exactly which needle, which thread, how to adjust it, and whatever it takes to make a wallet.

Is it OK to try to sew using only the hand wheel and not the motor and go extremely slow?

I wonder if you still have the wrong needle(s). The singer 31-15 uses system 134 needles. These systems will also work: 135x5, 135x7, 135x8, 797 and DPx5. Make sure it is a leather point needle.

Go to an industrial sewing supplier in your area and they should have the correct items. Also, get some size #69 bonded nylon thread to go with size 18 needles (like Luke said). Often times, the machine will behave better if there is a slightly lighter thread in the bobbin but #69 will be fine top and bottom.

Tell us more about the needles you are using? What other numbers/letters are on the package? Joann's fabrics likely would not have had the proper items needed for that machine or your project.

Also, when starting to sew, hold both threads back behind the project for the first few stitches. You can sew without the motor but why? Just practice for a bit and you'll get the hang of the motor speed. Get some old manilla folders or card stock and practice without thread. You can also put a tennis ball under the foot of the machine to help control the speed.

I know what you are going through because I was there not too long ago. I bought a 31-15 and had never sewn a stitch in my life. It took me a while to figure out the machine, the needles, the thread, tension and timing. Now it sews beautifully.

-

Do vendors typically offer better prices at the shows than their normal phone or internet sales?

-

-

Tooling/carving is not where my interests are... but I like it. I like anything with a chiefs head.

What type of artifacts are you into? I used to collect prehistoric southwestern pottery but got out of it about 10 years ago

-

OK folks, since it is Christmas and I am still unemployed I am dropping the price for everything down to $100.00 picked up.thanks.Dave

That's a pretty good price.

Did you put it on your local craigslist? I would think it would sell pretty quickly there if you advertised "industrial, leather sewing machine".

31's are great machines.

-

is there any reason that you can't just use a compass for circles, a ruler for straight lines, and a piece of posterboard? Use it as a template, poke your holes with the spots and when they are spaced and lines up, place it on your project .

Maybe I don't really understand your question and problem but if you could elaborate a bit more then we can help more.

pete

You understood right. These are the type of ideas I was looking for.

Lars,

Tandy has (had?) a craftaid for laying out grids & one for laying out bling/spots. Your nearest tandy should be able to help you & maybe show you how if you're close enough to stop.

russ

Thanks. Fortunately, I have a Tandy about 1 mile away. I'll see what they have.

-

All,

I need help with laying out spots. Just trying to eyeball where the next spot goes is not working for me.

I'm trying to layout your basic decorative shapes like diamonds and circles... or even a straight row of spots, but my spacing and alignment is crap.

I'm a noob at this so any tips or advice(no matter how basic) is most appreciated. Also, is there a good tool to mark where to punch or slice the slots for the prongs of the spots?

Regards, from Phoenix,

Lars

-

I got this link from someone earlier this year...

http://evergreenengravers.com/

I have no first hand knowledge of their work.

-

Does anyone know how many tanneries are left in the US?

Hermann Oak??

Wickett & Craig??

-

Just placed my very first order with them earlier in the week. Good experience so far.

-

Looks good. I had a peek last night and felt the whole site was a little small. Had another look today and it seems better but still small to my eyes.

-

I've noticed that "The Capgun Kid" is now a forum member. Perhaps we can get him to post a few pictures of is hand stitching techniques and maybe add his stitching articles to the Leatherworker.net tutorials. If you haven't read his stuff check out the links I posted previously on this thread.

Long live hand stitching!

Cheers,

Lippy

Lippy, did you send him a PM? I was always bummed that the links above were old and the pics never worked. Now that he is here... it would be a tremendous resource to have him post something again.

-

If not a timing issue then quite likely you are using the wrong needle or an improperly installed needle... but needle/shuttle timing is my guess.

As far as the manual online, I believe you are talking about this one: http://www.tpub.com/...s/14218_183.htm which is where most of the info below comes from.

There are two distinct timing operations for the 31 series machine. One operation times the needle with the shuttle; the other times the feed dog with the needle.

Timing the Needle with the Shuttle.

Insert the needle in the needle bar as far as it will go. Next compare the needle stroke to the shuttle stroke. To do this, remove the throat plate. Turn the balance wheel toward you until the point of the shuttle on its forward stroke reaches the center of the needle while the needle is on the upstroke.At this time, the needle bar should have risen 1/10 inch and the point of the shuttle should be 1/16 inch above the eye of the needle. If the needle eye is not in this position, loosen the needle bar connecting stud screw and move the needle bar up or down as needed; and then tighten the screw.

Timing the Feed Dog with the Needle:

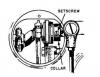

If the feed mechanism is properly timed, the feed dog should be on its down stroke and level with the throat plate when the point of the needle reaches the material. To adjust the feed timing, first lower the stitch regulator to the lowest position so the machine forms its longest stitch. Turn the balance wheel until the feed dog is on its down stroke and is flush with the throat plate. Move to the rear of the machine and take off the arm side cover. Turn the balance wheel away from you until the feed eccentric collar setscrew is visible (see attached image). Hold the collar with your left thumb.Loosen the screw and rotate the balance wheel away from you until the needle, on its down stroke, reaches the material. Tighten the setscrew.Rotate the balance wheel to check the timing. Recheck the timing of the shuttle point with the needle. When you time the feeding mechanism, you may throw the needle out of time with the shuttle.

-

If the masses begin to equate leather with cruelty then bad things are on the horizon for leatherworkers.

'Slaughter free leather' is a first step in that direction.

I won't buy from Siegel as long as they 'push' this product.

-

The GC 128-B machines that are made by Highlead are a nice little boot top machine that won't break the bank. They are generally provided with a roller foot, servo motor and a speed reducer. By the time you get all that on a 31-15 the costs are getting real close. They are also sold as a 5550B.

http://www.leatherma...log.php?item=28

Art

Singer 31-15's can routinely be had for $75-$150 on ebay.. plus maybe $50 for shipping. Roller presser and single dog feed another $50. These machines are very common and are frequently found on craigslist as well.

There cannot be an easier machine to work on as far as cleaning and tuning. I would not hesitate buying a used one as long as it looks decent.

-

Your first machine should be a post bed with a roller presser foot.... you can make a simple platform to get these machines to work as a flatbed as well. Singer models: 51w or even better a Singer 236. But Consew,pfaff, juki and others make good postbeds as well.

Don't take my word for it, read what the experts have to say about what machines are needed to make shoes/boots: Read the post from Friday, December 26,2008 and the answers from the next 2 or 3 days.

http://www.thehcc.org/discus/messages/4/1386.html?12566782253

-

Many years ago, Tandy had wooded CLOG kits.

There were a lot of patterns for the leather tops of the wooden clogs.

DOES ANYONE KNOW WHERE I MIGHT FIND A SUPPLIER TO GET THE WOODEN CLOG BOTTOMS?????

you might try this place... she states on her website to email her if you need help finding shoe making supplies:

-

Taken from another forum:

"burn a small piece(1/2" x1/2"). If the resulting ash is turquoise blue or green there is no question that chrome salts were used in the tannage. If the ash is pure grey or black(from the burnt sugars) it is a pure veg tannage.

-

Eye catching work. Nice job.

What did you use for the 'liner'?

-

Love it! Very nice work.

-

We have a post machine that is an exact copy of the Pfaff that sews smooth as silk.

I don't see anything on your website. Am I missing it?

Weaver

in Suppliers

Posted · Report reply

I did receive an invoice from them on friday or saturday and in tiny print at the bottom, it did have a fedex tracking number... which indicates that I should have it today. I can't wait!