-

Posts

710 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Everything posted by BearMan

-

Hi Max, It looks like I'm getting in kinda late,,, but here's a picture of something I made,,, that I'm sure you could make yourself!,,, Take Care,,, Ed

-

Floral Notepad Cover

BearMan replied to BearMan's topic in Purses, Wallets, Belts and Miscellaneous Pocket Items

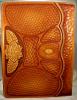

Hi Everybody, Thanks for all the wonderful comments!! I forgot all about this post,,, so sorry about taking so long getting back. Yes,,, that is SLW, intertwined. Basically I just Overlaid the letters, Duchess font, Resized them, & then just had to redraw a couple areas,,, slightly. I won't find out how the Daughter likes it, until April 1st, when she gets it for her Birthday. I really like designing the Basketweave sections on the back. The whole thing was designed using a cookie tin lid. All the Radii (archs) are the same,, except for some small areas, just to join the archs. Thanks again,,, Ed -

Thanks Bobby, Ben & Outcast, Ben, yes it is a 10 oz Amboyna Burl maul. I've been saving that piece for a while, until I did something special. In the next ones coming up, I'm making a "Set" of Bolivian Rosewood mauls,,, I'm thinking 18oz, 15oz, maybe a 12 oz, & a 10oz. I also, am working on something for everybody that likes the "black" mauls. But,,, I'm getting way ahead of myself,,, as I haven't even done any testing with that yet, & yes they will have exotic wood handles. I'm even working on some "BearMaul Keyfob" mauls. A Little maul for your key ring, still using all the same materials,,, sooo you could actually use it,,, if You had some small enough tools,,, hehehe. I'm hoping to have most all of these done before the 15th. Wish me luck,,, Ed the"BearMan"

-

Hi Everybody, Here are a couple Custom Mauls, I've been working on lately. I have some more in the works, that are even more special. Very functional works of Art, is what I'm going for with these,,, & the next batch coming up. They are all still made with all the attributes, as all of my mauls,,, just more distinctive. I hope you like them,,, can't wait to show the next ones,,, Ed the "BearMan" Opps,,,, ran out of room for more picturs,,,, More to come,,,

-

Hi, It's been a while since I've seen anything from you. But it looks like You're coming along pretty good. I see improvement with each new project. Your stitching is looking lots better,,, but You may want to work on the edges a little more. If You haven't seen it yet,,, Bob Parks, "Edges" tutorial will help a Lot! Keep up the good work! Ed the"BearMan"

-

Floral Notepad Cover

BearMan replied to BearMan's topic in Purses, Wallets, Belts and Miscellaneous Pocket Items

Hi Everybody, Thanks again! Pete, I don't always do it the same way,,, but usually, the front & back piece is pretty mush the same size as the Notepad,,, plus the width of the stitching seam, on three sides. Then the spine cover, I cut one edge to match the pattern, plus a little reveal, then wrap it around, to get the width, with matching the pattern on the other side. Of course, it's a good thing to add in a little "fudge" factor,,, don't want it to be too small. Make any sence?? But, you may want to check in with Bob,,, he does a lot more Binders than I do, so I'm sure he'd have better insite into those,,, & most everything else too. Rusty, it's 5oz/6oz from Zack White's Leather. I've had good luck with them, & they're close enough, so that I get my orders withing 2 days. Troy, all the colors are done with mostly Fiebings Spirit dye. In this case though, after I applied the colors, I had to tone them down somewhat, with some finish & antique. -

Floral Notepad Cover

BearMan replied to BearMan's topic in Purses, Wallets, Belts and Miscellaneous Pocket Items

Thanks Clay, Storm, Bobby, Ben, & Bex, Thank You all so much for the wonderful compliments! The Muted colors have grown on me. So I guess the customer was right after all,,, hehehe The "Rapid Repeater",,, (I kind of hate calling it that), really did make the stitching go faster, & a lot more uniform. The design, was an effort on my part to revive some of Ketchums, & Porja's inspired designs. Also, the flap that holds the notepad in, is 5/6 oz Horse hide. If any of you haven't used any of that yet,,, you might want to. Horsehide is a finer grain, & somewhat tougher skin, that is Very smooth. It also takes an edge like glass. Horsehide is a little tougher to tool , & cut,,,, but it's no worse than some of the cowhide being marketed out there. If you want to try some, make sure you get the "Soft Rolled" if you are planning on tooling it. Horsehide has been used for a LONG time. Some of the best holsters use it. If you use it, be aware that it darkens quite a bit with oil,,, & it doesn't take dye quite as well. As far as being Busy,,,, well,,, I really need to be, as working on "stuff" helps keep my mind off the chronic pain situation I live with. Distraction is a good thing,,, at least in my situation. Several battles with large animals, a couple "sprint Car accidents, & standing on concrete for 30 years just distroyed my back. Thanks again everybody,,,, Ed the"BearMan" -

Floral Notepad Cover

BearMan posted a topic in Purses, Wallets, Belts and Miscellaneous Pocket Items

Hi Everybody, Ever had a project, that just seemed to fight you ALL the way??? Well,,, here's mine!! hehehe But I think I finally won!! It's a Notepad Holder for a friend's Daughter. He told me he wanted "Muted" Fall colors on it. After getting the front tooled,,, & started the dyeing process,,,, I soon realized that even as hard as I was attempting to get "Muted" colors,,, they were still to bright for him. Soooo what I did was,,, after I got done with the dyeing,,, & it dried completely. I kind of Scrubbed it with my NeatLac replacement, which I knew would remove, some of the Depth of colors. That helped,,,, but it still was a "little" too bright still. Soooo I smeared on a good coat of Antique,,,, & kept wiping it off until I got the colors, that I knew he was wanting. Of course I topped it with some Tan Kote, over the Antique. The coloring process, only took about 15 hours of work. About 2 1/2 times longer than normal. I had to make the spine cover 2 times. I made the inside flap a second time when I found out his Daughter is a Real estate Appraiser,,,, that uses a calculator "all the time". Of course, while working on this,,, I just had to make the "Rapid Repeater",,, & make 3 more Mauls. So,,, needless to say,,,, I'm glad this battle is over! Now,,, just 10 Mauls to make before the 15th,,,, Ed the"BearMan" -

Hi Josh, Congrats on the new shop!! Thats a Great stamping stone,,,, & it looks like a "BearMaul" on top!! By the way,,, I had a friend once that carried his round knife like that,,, He's called 2 finger Slim now,,, hehehe J/K. Congrats,,, I know how nice it is, getting a new shop set up. Ed the"BearMan"

-

Kate, You & Ben are just too sharp!! I've got a roller type gate planned, that would be adjustable, with the roller small enough so that the work could pivot around it. I have some little bearings that would work just fine for that, they are about 3/4" around, & I could mount it on an adjustable post. That will be handy. Ed

-

Hi John, Ben, Ray, & everybody else, Thank You all for such wonderful comments!! I made this because I was tired of having holes that didn't line up perfectly, front to back. After using it , I realized just how much easier it is punching holes now. Ben, I had thought about making a foot operated lever,,, but I just don't have the room for a stationary machine right now. That would be Very "handy" though! Once I get a chance, I'll post all the dimentions,,, if anybody is interested. Thanks for looking,,, Ed

-

Hi Everybody, Here is something that I've come up with, to help with making stitching holes. It's basically the same action as a drill press, except that nothing turns. The "throat" area is about 13", so that I can reach most things that I stitch. The "awl" part is an old Osborne, that is just the right size when using a 517-1 needle, that I use a lot of the time. As you can tell, it's pretty basic construction. The only partially challenging part was making the pivot hole placements correctly, so that the awl would go straight without any angles. The area where the awl goes through, is covered with cork, & that whole section is replaceable. That section can be lifted out & turned to reposition a good area, so that they wont have to be replaced as offten. I've only punched about 2 feet of holes with it so far,,, so far it's working great. I'm going to be putting in a "stop", to keep the arms from going too far, & pushing the awl through the base,,, that will be easy. Well,,, there it is,,, what do you think?? Ed the"BearMan" P.S.,,, please don't pay any attention to the background,,, it's been one of those weeks,,,

-

Full Spectrum Lights, & Block Heaters

BearMan replied to BearMan's topic in Leatherwork Conversation

Hi, I got the lights at Big Lots, They are on sale today, fot $15.00 for the desk lamps, & $19.99 for the floor lamps. -

Hi Everybody, It's been a little while since I've posted. Just wanted to give an update on a couple things. A couple months ago, I installed a new stamping block heater. My old one lasted about 10 years. What I use is a Water Bed heater, with a thermostat. I was able to find one almost exactly the same size as my block. The way I made my bench, the middle of my stone is open, only the front & back edge, are supported. That way, it makes it easy, to install the heater. It's basically just held up against the stone with a piece of plywood. It takes about 45 min, to an hour to heat the stone from about 50 deg. up to about 80 deg. Makes for some very comfortable tooling. Secondly, yesterday, I bought a "Full Spectrum" desk light, for my tooling bench. I never knew, just how much one of those helps!! If you don't have one,,, GET ONE!! I'm headed down, to get another, for my coloring bench. & maybe even a spare. The colors, & definition, in every situation, just Pops!! Now that I'm actually able to see,,, I'm sure my tooling will get better. If there is such a thing as a "Must Have" list, both of these should be on it. I hope this helps,,, they really have helped me. Take Care,,, Happy Tooling,, Ed the"BearMan"

-

It looks by your post that you must be near Columbia?? I'm in Beaufort, sc.

-

Hi Tina,,, It's been a long time since we've talked,,, But I just had to jump in here. It's very obvious that your Daughter, has some inhereted Talent! I'm sure that with some tutaledge from you,,, we all better get on top of our game!! She deffinately has the eye for detail,,, even though I can see some of your insite applied. Great Job!! Looks like She will be needing a good set of tools for herself soon! Happy Tooling,,, Ed the"BearMan"

-

Bobocat, Absolutely stunning! Eyes are always the hardest thing to get right,,, & you did a Great job!! That's the way eyes shold look. Ed the"BearMan"

-

Hi Ben,,, & King,,, Yes,,, I just had to. I guess this means I Mauled myself??? hehehe I'd be ashamed to show anybody the ones, I've been using! hehehe I even, still have & use the one that Bob Dellis helped me with,,, soooo many years ago. But, I will be adding more from time to time, to replace the differnt weights,,, until I get the assortment done, probably a 10 oz, a 13oz, a 17oz (which this one is), & a 19-20oz. That should be about right for me. Ben,,, I'm sure you'd like this latest one,,, the balance is Perfect! I see, a LOT more Madrone Burl in my future! I think it's going to be my wood of choice. If anybody wants something darlker,,, I'll stain it,,, even purple,,, if they want,,, hehehe Take Care,,, & thanks for looking!! Ed the"BearMan"

-

Hi everybody, Well, I finally turned in my "round 2 it", & made myself a maul. Yes, it's the old "shoe Makers Son" situation. I've been wanting to try some Madrone Burl for quite some time. Madrone Burl, is a very light wood, that is extreamly hard for it's weight. It polishes very nice & has a very tight grain structure. But, the main reason I wanted to try it is, that by having the wood, a very light weight, the weight balance, shifts farther up the head. What that means is that, it will give a bigger impact, with less weight. Just in the little bit that I've used it, it feels pretty nice. This one is 17oz. Here are a couple others I've finished in the past month or so. One is Bolivian Rosewood, & the other is Hububali. Ed the"BearMan"

-

Thanks, Doc, Adam & JL, It seems that everybody likes the curved Basketweave. If I remember correctly, it seems that there was a good tutorial here on doing the curved Basket weave. It can be somewhat of a challenge,,, but if you keep everything lined up, & plan your spacing, you can do it. I would start with a gentle curve, & then progress, to a tighter curve. To do complete circles, you will need 3-4 basket weave stamps, of the same design, that get progressively smaller. Some of the best I've seen, have been by: Phil LeDuc , Little John France , & Don Berglund. Thanks, for the compliments,,, Ed the"BearMan"

-

Hi Everybody, Here is the Bible cover I tooled in my " Improvised" Warm shop. As you can see,,, it is covering a Very thick Bible,,, a heavy one too. All the colors are done with Spirit dyes, & there is some airbrush fading on the back & side. You can't really see it in the picture, but the oval area around the Cross, has some Pearlescence finish on it, to give it some added pop. The basket weave on the back is curved. The person wanted a handle, so this is what I came up with. I added some rare earth magnets on the flaps, just to add a little more strength. Also,,, I almost forgot,,, the Book Mark, has 3 faceted Garnets,,, Jan Birthstone. Sooo what do you think?? Thanks for looking. Ed the"BearMan"

-

Hi Tim & Odin, I may hate to say this but I've been using Rubbing Alcohol for about 30 years now, to thin my Spirit dyes. Tim when you say it ruined something,,, what happened? I've never had any problems at all,,, now you've got me wondering. Here are a few things I've done using Rubbing Alcohol thinned Spirit dyes. Ed the"BearMan"

-

Hi Everybody, I remembered that I hadn't sent any pictures of an Address book I did a few weeks ago. Yes, it has Black for the background,,, but that just helps to make the other colors Pop out. It's all done with Spirit Dyes. It has a pen holder attached to the inside flap, putting it right in the center of the book,,, that's why it's curved like that. The back is just some plain Tri-Weave. It's made from some 5-6 oz leather, with some pigskin lining. Thanks for looking. Ed the"BearMan"

-

Airbrush survey

BearMan replied to UKRay's topic in Dyes, Antiques, Stains, Glues, Waxes, Finishes and Conditioners.

Hi Ray, I just got in an airbrush, to replace an old one I had. It's a HF # 95810. It's a Double action, with seals that will stand up to use with Lacquers, Solvents, & Acrylics. Right out of the box, it worked perfect. After using it on a book cover project, I took it apart to clean it. I found no residue to clean! After I get done sraying, I always flush it with rubbing alcohol. It would appear, that all the holes the color goes through, are smooth with no burs to trap color particles. Over all,,, I'm very impressed. It seems to be as good,,, or maybe better than a Paasche, double action airbrush I borrowed from a friend. For the price, I don't think You can beat it!! I got the airbrush, & a 10 foot braided hose, & with shipping it was $35.00. I hope this helps,,, Ed the"BearMan" -

Professional Oil Dye

BearMan replied to azrider's topic in Dyes, Antiques, Stains, Glues, Waxes, Finishes and Conditioners.

Hi,,, May I ask why you are using the Oil Dye? Basically, that's the Fiebings dye with oil in it. I've never really had any luck with the oil dye. I use the regular Spirit dye. If I add oil, I do that seperately. As far as getting an even application. The best way is to use an airbrush, that makes it nice & uniform. You can get it pretty uniform by first wearing rubber gloves, & using a piece of shearling about 3" square Very wet with dye,,, & moving very quickly. This makes the color very intense,,, so if you want it a lighter shade,,, cut the intensity with alcohol, or thinner. But,,, the airbrush works a Lot better.