SolarLeatherMachines

-

Posts

248 -

Joined

-

Last visited

SolarLeatherMachines's Achievements

Member (2/4)

-

Where are you located?

- Show previous comments 2 more

-

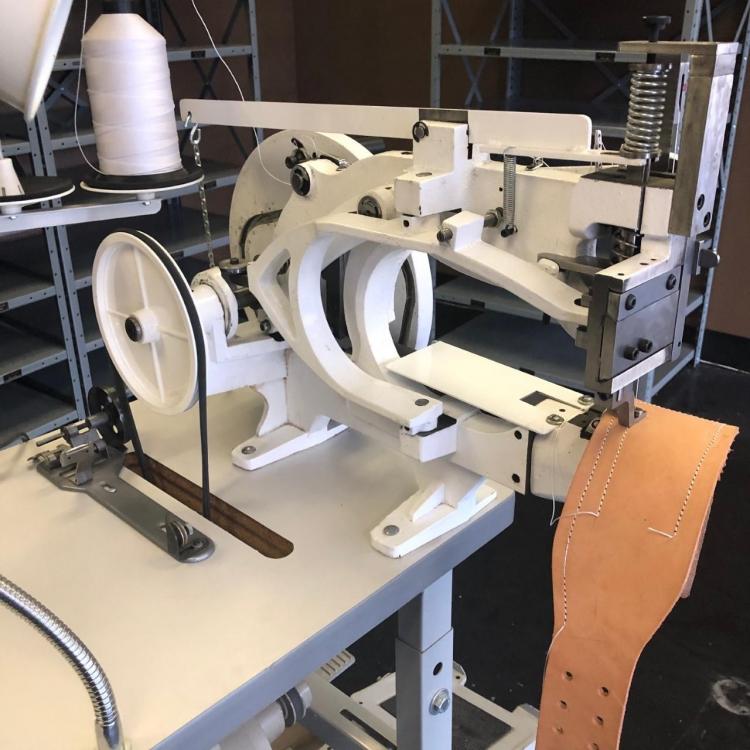

I bought that 6/6 from you a few months back! I bought this Ferdinand in Dallas last week! Had I have known, I’d have stopped by!

I do have a clicker I need help with! But it’ll be a week or two before I could even think about getting into my pickup and brought up there!See where this one is bent? Do you have anything used you could sell? Would need one good screw as well!

-

I closed my shop on January 3 of this year. The Trump tariffs killed us. But I can privately service your machine. I still have all the tools required.

Just drop me a line when you're headed this way.

Just drop me a line when you're headed this way.

Also, I don't have that part. Maybe contact City Sewing in Dallas, or Texas Sewing Machine in Fort Worth. Or MAYBE Campbell Randall down by you.

-

Ok, yes, I knew you were closing/moving when I picked up the Ferdco 6/6 from you!