-

Posts

685 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Store

Everything posted by celticleather

-

The 'strap cutter' is actually a 'ranging machine', and as Ray says, it was designed to cut heavy leather (or rubber) soles. We used to have one at the shop, but the gears broke (cast iron!) and the handle went missing, so I dumped it last month when we moved shop. I should think it would be difficult to use it to cut belts or straps . . . the cut is not very controllable. It was only intended to 'rough-cut' the soles, which would then be trimmed to size after attaching to the boot. Our machine would also leave rather unattractive 'railway lines' on the underside of the material.

-

You're right, Ray! Dad had one at the shop, and used it exactly as you described. It also served to wring out the excess mulling liquid before attaching the sole to the boot, and at the same time 'plated' the sole, rather like that huge monster we saw at Baker's tannery. It's ages since I saw one, but I recognise the WHB plate . . . we still use WHB equipment in the shop today! Just imagine what that hefty brass roller would cost today! Who says nostalgia is a thing of the past?! Terry

-

Well done, Ray! Your research bears out my suspicion that these tools were old-stock Barnsley originals. It's good to see that they are making their way back into circulation. It seemed a bit unlikely that they were knock-offs, since the market is pretty specialised, and on a global scale, pretty small! Opening that warehouse must have been like walking into Aladdin's Cave! Terry

-

Bearing in mind that George Barnsley & Sons ceased trading many years ago, I would suspect that any Barnsley items being sold as 'new' or 'unused' are probably old stock, made by the company before its closure. I don't think anything has subsequently been made bearing the Barnsley name, but as I said earlier, knives of the Barnsley pattern are still being produced by Colin and Roger Barnsley of Woodware Repetitions. These knives have the Woodware Repetitions name on them. It's difficult to say whether the quality of the Barnsley knives diminished before their closure, or whether this may have contributed to their decline; I don't have anything with which to make a comparison. I would agree with Ray, that in ranking I would put Dixons (and old Osborne) higher than Barnsley. I discovered that the old Barnsley factory was a favourite haunt of photographers, with more pictures at http://www.flickr.co...57608626780966/ http://www.whateversleft.co.uk/?p=161 http://www.pretentio...Sons%20Ltd.html The site of their building has now been redeveloped as a housing estate.

-

We still use Barnsley tools in the shoe trade, and I can testify to their quality. The company ceased trading as George Barnsley in the early 1990s, and their stock was absorbed by a company called Woodware Repetitions - still in Sheffield - which is owned by Colin and Roger Barnsley. They now seem to specialise in woodturning tools. We recently bought a couple of new leather knives from one of our local stockists, and they were the traditional shape and quality, but now stamped with the Woodware Repetitions name, so it seems that they are still making some leather-related tools. There are some poignant photographs of their old factory at http://www.28dayslat...ead.php?t=30363.

-

In my opinion, if you want to produce quality hand-sewing, in a truly traditional fashion, you definitely do need a pricking iron. You don't necessarily need a vast range of stitch sizes - I do most of my work at 8 stitches per inch. Joseph Dixon have a good range of English-made pricking irons in a variety of sizes, from ½" to 1½" widths. You would probably find that 1" wide would be good for most applications, and these are only $58.00 (plus shipping, which would be minimal). http://www.josephdix...ing.html?page=4

-

You're right, Ray - but luckily I was on the other side of the bench! Terry

-

In the course of moving my workshop, I found the original instruction booklet for my wooden strap cutter (which I'm still using!), that had slipped down behind a bench, sometime since 1972. I've posted it here as a pdf file, for the benefit of anyone who may find it interesting/useful. Perhaps it hasn't changed over the years . . . I'd be interested to know. It's a bit yellow and grubby, but I guess if I'd spent 37 years behind a bench . . . Strap-cutter.pdf Strap-cutter.pdf

-

There's a pretty useful online tutorial at http://www.bowstock..../saddstit0.html, but as others have said, the only real secret is to practise!

-

I've never come across such a lightweight bridle leather - at least, not in the UK. The lightest I've seen is 4-5oz, and there's a tannery on eBay that sells it over here - item number 330369280857.

-

If you don't mind buying from the UK, Joseph Dixon make very good quality pricking irons. http://www.josephdix...ing.html?page=4

-

I use a couple of these - which are pretty good so long as you label the drawers - otherwise they are a nightmare! Available from http://www.maplin.co...?ModuleNo=29163

-

Hi Rhona This was just a one-off job, and since it was a year ago, and I've heard nothing from him since then, I assume he must have got fixed up by now. Thanks for your interest! Terry

-

Hi Alberta I have a Singer 29K table, and recently let another member have the dimensions and some pics. I've attached them here. Measurements are as follows (in millimetres) A=115mm B=80mm C=45mm D=25mm The length of the arm is 312mm (this is the short-arm version) I have also traced around the inside of the slot, and the result is on the attached pdf. The file has been reduced to 50%, so if you print it out and photocopy or scan it to 200%, you should arrive back at original size (or just get the measurement back to 318mm by whatever means!). Hope this is what you need. Terry (celticleather) slot.pdf

-

Here's my BUSM A1, that I bought a few months ago for a very reasonable price. It came complete with spare shuttles, bobbins, about 90 assorted needles and a manual! It hadn't been used for about 20 years, and was a bit stiff to turn; I stripped it down, cleaned out accumulated wax and thread balls, and it runs like a dream. Unfortunately it didn't have the original stand, so I've had to adapt an old Singer treadle stand, but it works well.

-

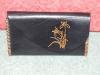

I've attached a pdf of a very basic iris design that I created a while ago for the front of a clutch bag, and a picture of the finished bag. If it's any use to you, you're welcome to use it. Terry iris.pdf iris.pdf

-

Weird hardware - need to find a supplier urgently

celticleather replied to UKRay's topic in Suppliers

Ray I wonder if this is a clever combination of the two-legged Lift-the-Dot post as at http://www.bresco.co..._Fasteners.html and the Prym-type press stud cap on page 7/9 of http://www.prym-cons...c/0H09003dG.pdf . . . or maybe something along those lines! Terry -

What is it?! Geo. Barnsley tool.

celticleather replied to mynholme's topic in Leatherwork Conversation

It is indeed a nailer, used for driving nails from the inside of a boot, down into the heel block to secure the heel block to the upper. It's mostly used for tall boots, where it is impossible to reach with a conventional hammer. As dirtclod has suggested, the nail is dropped into the side tube, the ball is raised, allowing the nail to drop down into contact with the shoe, and the ball is then walloped down to drive in the nail. -

Have a read through the tutorial on handstitching at http://www.bowstock..../saddstit0.html, particularly the figures 11 to 18. It is important to be consistent in the way that the threads pass through the stitch holes. I would recommend using a pricking iron to mark the stitch spacing, and a diamond awl to make the stitch holes. As well as marking the stitch spacing, the pricking iron also predetermines the correct angle for the awl hole. Above all, remember that good, neat handstitching doesn't just happen . . . it takes practice, practice, practice!

-

I guess by 'bevelling' you mean the concave cutout in the handle of the cutter (see indicated on pic). This should be on the left-hand side of the cutter, as on the picture. I've had the wooden version of this for over thirty years, and it's still going strong!

-

Ray I've taken a look at Angster's tutorial, and I see that he does actually dip the mug, and then pours melted beeswax into it, swirls it around and tips it out. This is repeated a few times and builds up a coating of wax on the inside. This is a pretty similar process to using brewer's pitch, except that I don't dip the whole mug into the pitch. It may be that this is all that's required to re-wax this girl's mug, but I can find out. If you're prepared to have a go at it, I can put you in touch. Max - Thanks for the tip about Angster's tutorial! Terry

-

I've had an enquiry from a person whose roommate has put her leather mug through the dishwasher . . . and it now needs re-waxing! I don't use wax to seal my tankards, and I wonder if there's anyone out there (preferably, but not necessarily in the UK) who would be able/prepared to do this for her? If so, please drop me a PM with your email address, and I'll put you in touch. Thanks guys and gals!

-

When you make a cut, is the colour the same all the way through the thickness? If so, it is almost certainly veg tan. Chrome tan is usually grey in the middle of its thickness. When moistened, try striking an impression into the surface. If the impression remains sharp when the surface dries, it's veg tan.