Johnny

Members-

Posts

34 -

Joined

-

Last visited

Profile Information

-

Gender

Male

-

Location

Indiana

LW Info

-

How did you find leatherworker.net?

Google

Recent Profile Visitors

4,914 profile views

Johnny's Achievements

Member (2/4)

-

Here is what I have, I added a chain from the rod (91-000 078-15) to a foot peddle I fabricated from sheet aluminum.

-

Let me look tonight, I took mine off and made a foot peddle. What part are you looking for? Johnny

-

Here is a manual that covers the 146 Johnny Pfaff 145 545.pdf

-

Minimum and Maximum Thread Sizes for Pfaff 145?

Johnny replied to ethereal's topic in Leather Sewing Machines

-

Minimum and Maximum Thread Sizes for Pfaff 145?

Johnny replied to ethereal's topic in Leather Sewing Machines

I have a 145 H4 that use's 190 Needle System, it sews fine with #207 Both top and in the bobbin. I have never used any thread smaller than #92. Not sure about #277 thread that might be pushing the limit for these machines. I used to sew mostly belts with mine but don't use it much any more once I got my CB4500 setup with the narrow needle plate. Here is a belt I made using #207 thread and a size 24/180 needle. Johnny -

how to lay out your measurement on a pair of chaps

Johnny replied to hickok55's topic in How Do I Do That?

Springfield Leather YouTube channel, here is a link to part 1 of 3. Johnny -

Pfaff 145 h3 reverse stitch length shorter than forward

Johnny replied to ThomasBH's topic in Leather Sewing Machines

Thomas Can anyone confirm what the 145 H3 needle bar height should be set to? Mine has 20mm at bottom, again my machine is a H4 it has 14mm pressor foot clearance. Once I had the timing right I was able to adjustment the eccentric to correct the reverse stitch length. One thing I might add to adjusting the eccentric is to place reference marks on it to keep track of the direction and how much I moved it, do little bit at a time. Don't give up these are great machines! Johnny -

Pfaff 145 h3 reverse stitch length shorter than forward

Johnny replied to ThomasBH's topic in Leather Sewing Machines

Thomas 1. Can anyone confirm what the 145 H3 needle bar height should be set to? My machine is a H4 and uses 190 needle system. I can give you that dimension if you want it when I get home. 2. Should I adjust it to be exactly 2mm and not touch the scarf? The needle bar should rise 2mm (for a C model machine) and should not touch the hook about .1mm clearance. 3. Timing for 134-35, 135-17 needles. If the only difference is the 1mm length then set the needle bar height using that needle. I probably would start with the recommended needle system for your machine. 4. Will any of the above adjustments actually affect the forward to reverse motion of the stitch length? In my case I could not get the reverse stitch length correct, I checked and made adjustments from the setup document and then I was able to get the reverse stitch length fixed. My needle bar height was way off and I am amazed it even sewed. Try this with a fine black marker place a line 1.5mm above the top of the eye of the needle and install it then bring your needle bar up 2mm the tip of the hook should be at the black line if not loosen the needle bar screw and adjust it so that it is. I am wondering if the reverse stitch length is not correct because of the welting foot and not having a regular foot installed? I have an extra set of pressor feet if you want I could send them to you and you can send them back when you get yours. I am happy to help if you like send me a pm and I will give you my number maybe be easier to help over the phone. Johnny -

Pfaff 145 h3 reverse stitch length shorter than forward

Johnny replied to ThomasBH's topic in Leather Sewing Machines

Thomas What is the complete number of your machine located on the brass tag (mine is 145-P-6/1-216C H4LMN)? I would get a regular set of pressor feet, eBay has several sets at a reasonable price. Start with a new Needle (just to make sure the current one is not bent), I believe your machine should use the 134-35 Needles. Section 3, setting up your Needle Rise height, 3.2.6 the hook point should be just past the center line of the Needle this is important for the other adjustments. Section 4, check your Needle Bar height and adjust if required. Section 5, Needle to Hook distance, this one takes some patience to get just right. Section 6, Needle Guard easy one but important. Now would be a good time to check the alternating foot, foot motion, feed dog. Check to see if the machine sews good in forward. Now go back and adjust as above for your forward/reverse stitch length. Send me a PM I have a parts manual but its to big to attach here. Johnny -

Pfaff 145 h3 reverse stitch length shorter than forward

Johnny replied to ThomasBH's topic in Leather Sewing Machines

Thomas This is as close to a service manual that I have found, not sure where I got it from. I have used it many times to keep mine running smooth. Johnny PFAFF 145-545 Setup.pdf -

How to setup SewQuiet 5000 Servo on a Consew 227R

Johnny replied to TheFatBob's topic in Leather Sewing Machines

TheFatBob I have a manual for one, it is from Keystone Sewing Machine Company. Johnny SQ5000Instructions.pdf -

I enjoy leather working but with a full time job already its more of a hobby right now, I mostly make western gun rigs and belts for Cowboy shooters. Last year I made several sets of holsters and belts for a Cowboy who supplied me with his own stamp, I didn't charge any extra and I actually gave him a discount because of the quantity he purchased. He was happy with the quality and continues to buy from me. I say make them, a happy repeat customer is all ways nice to have. Just my 2 cent's Johnny

-

Pfaff 145-h3-6/C LMNP, Good for leatherwork?

Johnny replied to Rickyjd5's topic in Leather Sewing Machines

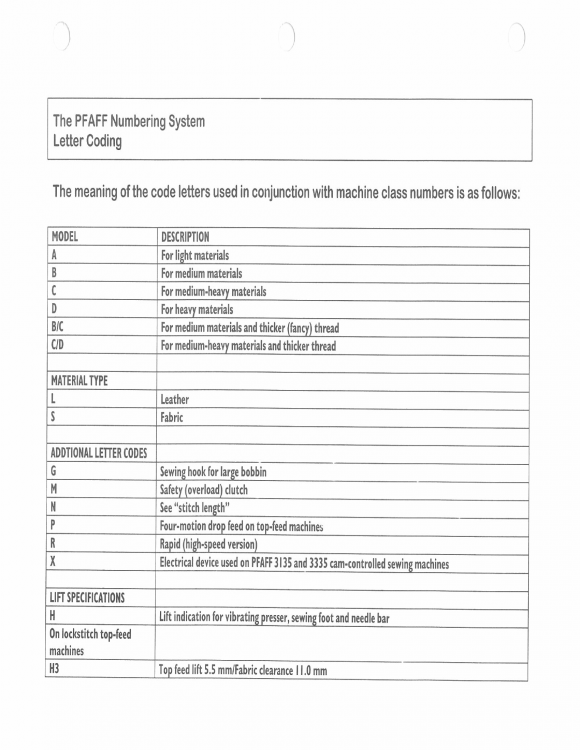

This may be of help. I really like the one I have, it would be fine for wallets and clutches. Not sure about spare parts being available so check it before buying it. Johnny -

hugocrafts I have a 145 with H4 lift, the machines are very similar.

-

hugocrafts Have a look on page 3, I found it very useful when working on mine. 145-545 Setup.pdf