MacB

-

Posts

28 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Store

Everything posted by MacB

-

Hello Trox,

I read that you have a Service Manual for a Pfaff 345. I recently bought an OLD Pfaff 345 VR 132 B S for about 13 Euro :-)))

It works fine (except that the Feed Dog has no Teeth at all and is smooth as baby skin) but it is s beatuy. Since I have to clean all parts, some kind of manual would help. I already asked in Pfaff Germany (I live in Austria) and they can't support me anymore ...

BTW: An old black Pfaff 335 VR 132 B H2 S ia also coming my way :-))

TIA and greetings from Austria.

-

Hi, is it possible for you to post this: ??

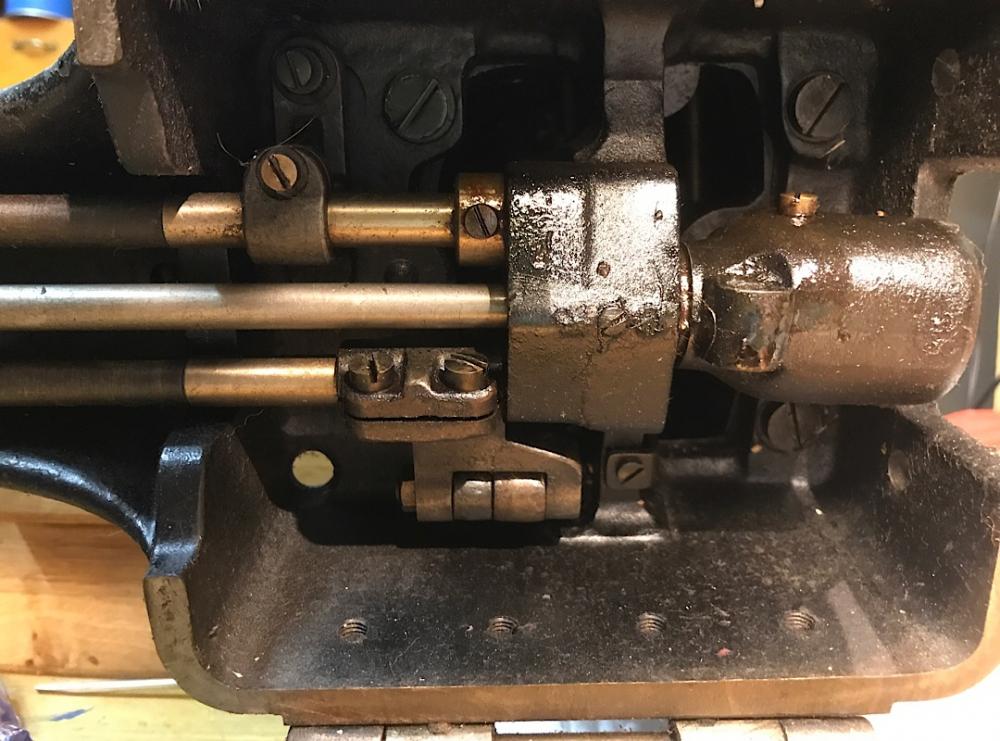

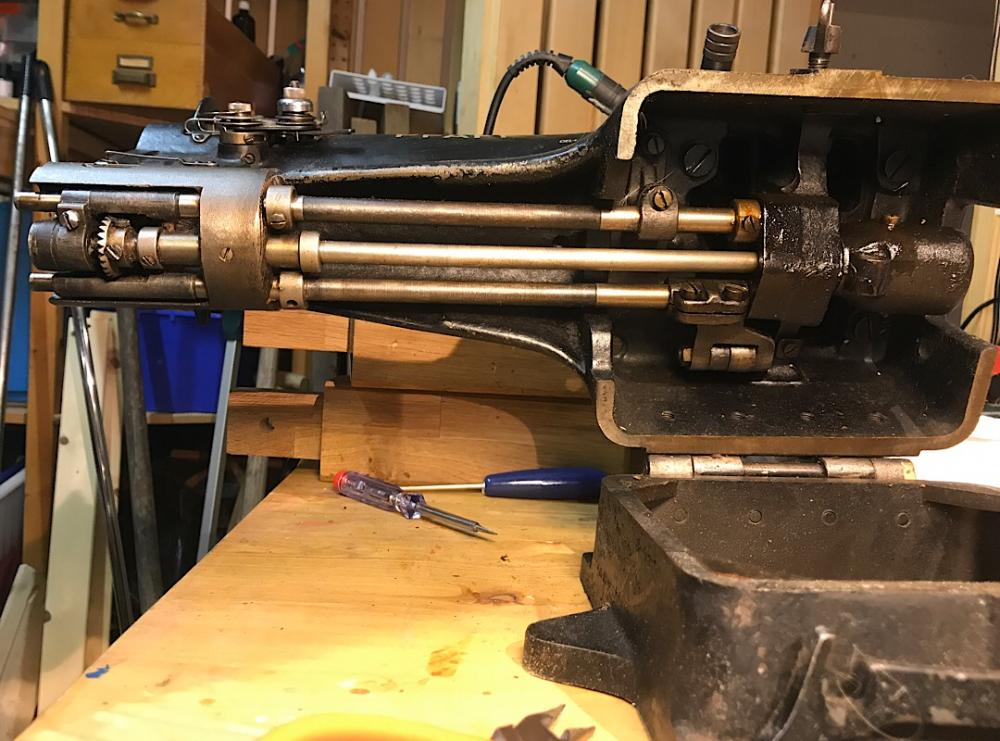

QuoteThen there's the question of how to stamp them. I'll post some pics of a homemade stamping machine I made out of an arbor press if anyone wants. If you already have an arbor press, it costs less than $50 all in to make if you have access to scrap materials, a drill press, and taps/dies.

That would be very nice!

cheers