Danne

Members-

Posts

772 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Store

Everything posted by Danne

-

An idea. (The accounting rules might be a little different from here in Europe) When you buy a side you attach a little tag with Weight and price with shipping for that hide. When it's time for your inventory you can check the weight of your hides and you have an approximate value. It will also make it easier if you for example cut off the belly part. Instead of having to measure your hide to find out the size, this would be a lot quicker. An Excel sheet would be useful here also, just check the weight of your hides and update your excel sheet.

-

Brown wallet

Danne replied to Danne's topic in Purses, Wallets, Belts and Miscellaneous Pocket Items

I will certainly figure it out. I haven't spent a lot of time trying to solve it. It have only been something I have been thinking about. And I will have to do real tests on leather to figure it out. -

Brown wallet

Danne replied to Danne's topic in Purses, Wallets, Belts and Miscellaneous Pocket Items

Yes, I have tried all these methods. And the way Philip does it looks good, but you still see how the thread tends to lay on top of the other thread, and it becomes even more visible with thinner leather. Even some (a lot) of the best crafters out there seems to struggle with this also. But here is an example of what I would say a perfect backstitch. -

Brown wallet

Danne replied to Danne's topic in Purses, Wallets, Belts and Miscellaneous Pocket Items

Thank you for your kind words. I try to improve something on every project. This time it was the creasing. I have been using Regad FN2 for pocket edges, and Regad F2 for the rest of the edges (gives a more crisp line which I think looks good on stitched edges) but I wasn't really happy with the Regad F2 iron it's a little too sharp for goat leather, it either cuts/burn the finish, or the crease is barely visible, so I have changed to Dupin G1 instead, and I'm happy with the result. A couple of things on the list to improve is more consistent backstitching (It's so hard, I have searched the internet everywhere, and I have seen tutorials with decent result, but not perfect result, well kept secret?) I also plan to work on the corners, I will probably use a round awl at the corners. I also would like to slim it down just a tad (not that the wallet is bulky, but removing a couple of mm on the exterior, and also line the card pockets, but this require a splitting solution, and I will not stress with this. You have probably seen how I've had a hard time sourcing a new FAV skiving machine with the specs I want. I do like the black ones from Nippy, would match the colors of my desk/working area. We see I might pull the trigger. -

Brown wallet

Danne replied to Danne's topic in Purses, Wallets, Belts and Miscellaneous Pocket Items

Thank you -

Brown wallet

Danne replied to Danne's topic in Purses, Wallets, Belts and Miscellaneous Pocket Items

Thank you -

Brown wallet

Danne replied to Danne's topic in Purses, Wallets, Belts and Miscellaneous Pocket Items

Thank you Yin. -

Brown wallet

Danne replied to Danne's topic in Purses, Wallets, Belts and Miscellaneous Pocket Items

Thank you for your kind comment. -

The wallet from my progress post finished. Video clip: https://i.imgur.com/keYbhE1.mp4

-

Progress photos wallet

Danne replied to Danne's topic in Purses, Wallets, Belts and Miscellaneous Pocket Items

Yes, Tärnsjö is also a Swedish tannery. Real high quality vegetable tanned leather. Used to be supplier to Hermès and Louis Vuitton. Don't quote me on this, but I think Hermès and LVMH tried to push down the prices too much, and I get that in a way because supplying big fashion houses is good for your brand (The tannery in this case) But also today both Hermès and LVMH own a lot of the tanneries that produce their leather. Why do I like this leather? I really like the semi-aniline finish. It gets a patina, but not as extreme as a pure aniline leather. -

Progress photos wallet

Danne replied to Danne's topic in Purses, Wallets, Belts and Miscellaneous Pocket Items

Thank you. Exterior is Tärnsjö semi-aniline veg tan. Interior is Alran Sully. Thank you. -

Progress photos wallet

Danne replied to Danne's topic in Purses, Wallets, Belts and Miscellaneous Pocket Items

Thank you -

Progress photos wallet

Danne posted a topic in Purses, Wallets, Belts and Miscellaneous Pocket Items

Took some photos during the making of a wallet. So thought I share it here. Feel free to ask questions, or give critique. Parts cut and ready to be skived. Card pockets edge painted and creased (Regad FN2) Pocket sections assembled and lined and ready to be trimmed. Trimmed Pocket sections and finished lined exterior ready to be assembled. Top of exterior stitched. Stitching card sections in place. Exterior edges creased (Dupin G1) and ready to be edge painted. First layer of edge coat applied and drying. Waiting for the edge paint to dry and then heat, sand and repeat five/six times before melting wax to edges and polish. And some cleaning and it's finished. -

The problem is what is the right size? Today maybe you need 0.8mm or 1mm or 1.5mm for a watch strap. Next time you need the same leather in three different weights for a wallet/card holder. Also buying directly from tanneries is not an option without a splitter (With very few exceptions where you can get the hide split, but then it's the whole hide in one weight) But for hobby use a bell knife will go a long way. Nitz as example split his leather for small leathergoods with a skiving machine.

-

Even if the machine do work decent, what happens in a couple of years when maybe that machine doesn't exist anymore, and you need spare parts? If you can afford it, I think the Camoga Compact for 12-13000usd is a better choice. Also depending on what you make you can learn to split leather with good results for smaller leather goods with a skiving machine.

-

I don't agree. My punches from Ksblade doesn't need any sharpening, they are super sharp. And hole punches I've seen being recommended like SPC and Kevinlee is probably really sharp when delivered also. I remember when I started this craft and bought the "mini kit" with hole punches from Tandy though, they didn't just need sharpening they didn't have a cutting edge at all.

-

The edge paint applicator: https://ksbladepunch.com/product/edge-paint-applicator The only reason I bought it in the first place was because it was nice. and I have been using a cheap round awl from Aliexpress (That one that is included in most cheap leather kits) But I was surprised how good this applicator was, and the reason is because it has a turned finished so it holds edge paint really well. Of course there is no need to buy this one, a rod that have a turned finish would work just as good, but this one is nice also What applicator do you use?

-

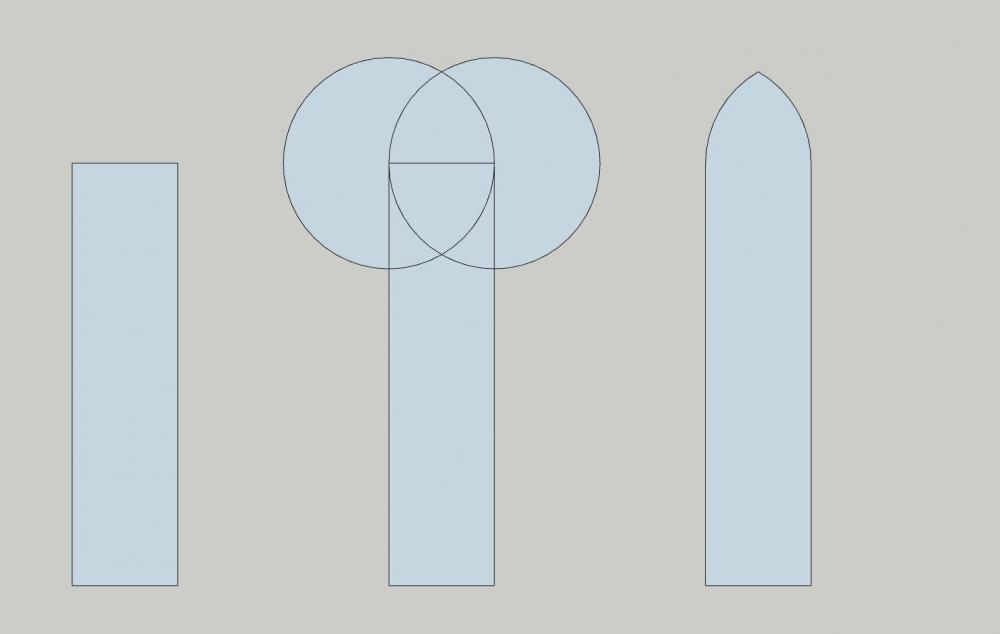

An easy way is to use Google Sketchup. 1. Make a rectangle with the width you like. 2. Two circles. 3. Erase the excess Of course you can also do this with a wing divider, either for a template, or scribed on the leather. When you cut you can either do it in multiple cuts, the first cut just slightly through the grain. Or you can "stab" your way around with a skiving knife, and sand it smooth.

-

My plan was to buy a new Fratelli Alberti skiving machine, but unless you live in US it's not possible to order it with this specification anymore. A machine without suction device is not available with two motors for some reason. And trying to buy only a head (AV2T) and two motors and belts also seems impossible. (I don't need the table) So I give up trying to buy a new machine. I will look for a used FAV AV2 and add a second motor. Any tips where I find a motor in Europe. A quality motor, absolutely not some Chinese brand motor.

-

Isn't AV2TE (Only head with dual motors?) Because the one I asked for the price is AV2ME. (Or they will ask if it's possible to buy everything without the table, because I don't need it, but from the photos I don't think it makes a big difference in price, because it's a very simple table. And from people I have talked to (Not the exact same configuration and different countries) I guess the price will be in the range of 4-4500euro. But I update here when I know.

-

After 3 years: gone full-time and moved to Siberia. Here's my progress!

Danne replied to karlova's topic in Member Gallery

Nice work. And doggo <3 -

I use "card paper" like from a cereal box. If I would use the same template a lot I would have it laser cut in acrylic.

-

I would probably need a price from someone who bought it in Europe. I looked at Campbell Randall's FAV AV2TE and it looks like they only buy the head from Fratelli Alberti, the table and foot pedal is not FAV, and so probably not the motors either. (I don't say they use low quality components, just that their might be a huge difference in price)

-

I'm waiting for answer for a new skiving machine Fratelli Alberti with two motors. (Single phase and no vacuum) I understand that the price are different in different parts of the world (I'm from Europe) but would be interesting to know the approximate price. Anyone know?