-

Posts

20 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Store

Everything posted by 3DReefer

-

Agreed. It may delay the liner coming loose but the stitches will get torn up pretty quick and look worse than a loose liner when they do. It appears you either apply a second layer of glue before you stick the liner on to give it a better bond (barge and most contact adhesives actually normally advise to do 2 coats, letting dry to non tacky between each coat, to each surface). Also your stitch to edge distance could be reduced by probably half, which will increase the hold the stitches have on helping prevent the edge from coming free. Normally i aim for 3-4mm stitch to edge distance, with same distance between stitching lines if do double as you have. As well as what is your edge finishing process? A good slicked edge then finished with beeswax and canvas should do a really good job at creating a stiff edge that has the liner and exterior leather sealed together with the wax and be long wearing.

-

Thats how Barry King makes his maul handles as well.

-

One big issue with this.. Borax and leather are like mixing vinegar and baking soda.. Leather has a slightly acidic pH level of 4.5. Mild dish soap, on the other hand, possesses a basic pH level between 7-8, and other general cleaners, such as Borax, usually find their way to around a basic 10. The contrast between leather pH levels and the cleaners’ during contact damages leather fibers and can weaken its integrity over time. This leather pH damage is typically characterized by – you guessed it – cracked and dry leather. Just stick with alcohol to thin your dye and simply hit with neats foot and conditioner when your done, or you can even pre oil the leather and give it a day to absorb and dry before dying the project. (normally one of last steps as finish project anyhow for 99% of people for the long term health of the project.)

-

6 slot bi-fold

3DReefer replied to Albob's topic in Purses, Wallets, Belts and Miscellaneous Pocket Items

I tend to avoid opposite directional pockets, as once they stretch and wear in, the cards in the downward facing pockets want to fall out. The design works ok with long wallets since the card pockets wear in much slower in comparison to a smaller wallet where many of the cards may see multiple uses a day and wear the pockets in faster. -

Dragon Vanity Tray

3DReefer replied to stormdevil's topic in Purses, Wallets, Belts and Miscellaneous Pocket Items

not a bad price at all for that size laser honestly.. equipvalent machine from commercial vendors that dont even offer any better build quality or options run 3x that expense. -

Dragon Vanity Tray

3DReefer replied to stormdevil's topic in Purses, Wallets, Belts and Miscellaneous Pocket Items

amazing work! -

Hit the gear cog in the lower right of the video. A speed setting is there allowing you slow it down to 1/4 speed even Only if using for regulation play

-

I would so end up like 1 or 2 stitches off center no matter how many times I check and it not fit just right once got around it lol.

-

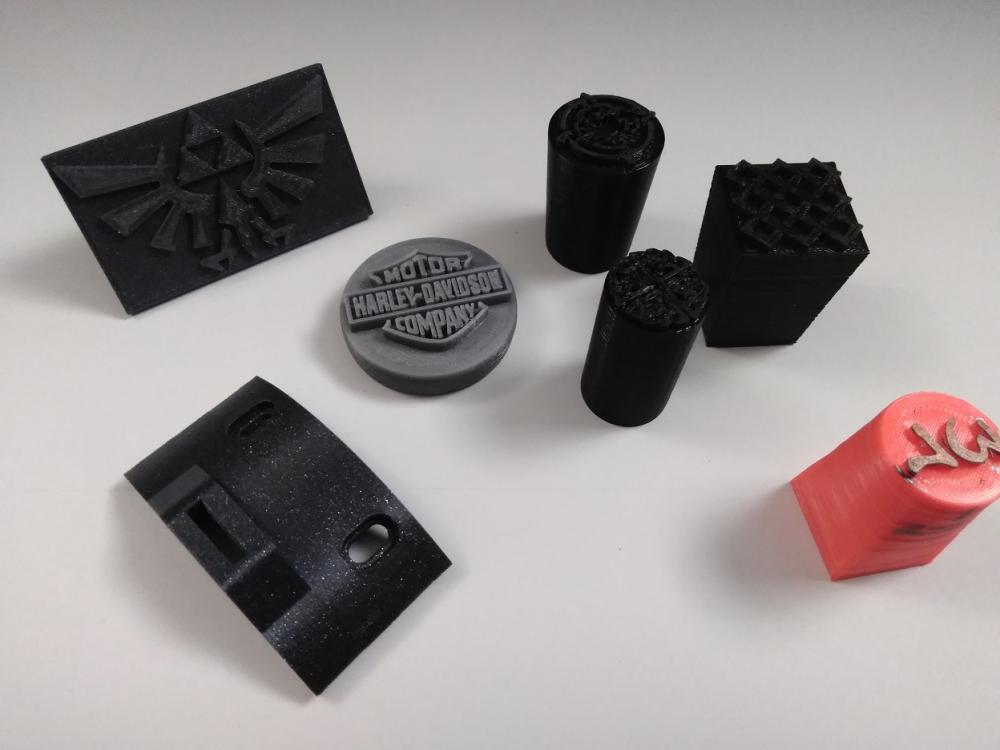

Heading to dragoncon 2018 so needed something to hand out for easy promotional items that wont just get tossed out like a business card or trinket. So keychains it is. Function and fashionable. Stamped using 3d printed stamps (post has 5 pics in the link provided since over the upload size here). The skeletal dragon was designed by my girlfriend and just happen to match the theme needed. Bunch of my other work on my instagram as well if curious.

-

Oooooo what sls machine you have? I'll probably never be able to justify the investment even at current prices.

-

Snap-N-Slide OWB Holster CZ RAMI

3DReefer replied to IngleGunLeather's topic in Gun Holsters, Rifle Slings and Knife Sheathes

Gorgeous. Personally id want to see a lot more trigger gaurd imprint tho to hold it in. Doesnt appear much friction to keep it stable. But beautifully done. -

It is and isnt. It requires a net connection every couple of months to recertify your login and license, but can be ran offline also. For a while I didnt have internet and ran it, only connecting when it told me it wanted to certify licensing via my phone. When it does get an internet connections it just will sync all your new designs to the cloud server. It in no way requires a constant net connection like any of the browser based ones will. Designs and autosaves updates (done every 3rd or so change to design which is really nice) are all done locally and then sync to the cloud only when you do an actual save point or close the program. If there isnt a net connection, then it just syncs the next time there is.

-

Sketchup is ok for visualizing. Its mesh creation and export of stl files tho is horrrrible. I can always tell when someone sends me a stl that was created in sketchup as its full of errors and particles that i have to run thru clean up programs a few times usually to hopefully fix.

-

Tinkercad is good, onshape is ok if you dont mind the files being public (you have to pay their subscription to have private saves), fusion 360 is free when register it as a hobbyist. It all depends what you want to do for modeling? I prefer fusion 360 as i 3d print all my templates and custom stamps. Also great way to make molds for wetforming or fitment for things like phones or even helping to get wallet pockets wore in while wait for them to sell by printing card blanks.

-

If you prefer live interaction there is many many many of us leather workers on Twitch nowadays. Here is a short list. Be it armor, cosplay, or EDC items, or anything in between, we have it covered. twitch.tv/SymbiArt twitch.tv/parkersandquinn (over 2 decades of leather experience) twitch.tv/Moriku twitch.tv/GOIcraft twitch.tv/MidnightArmorInc twitch.tv/firebirdleather (bdsm and theater style leather goods) twitch.tv/PaxEtCorio (aus based maker of high end leather goods) twitch.tv/TaarnaCR twitch.tv/RyanJames3049 twitch.tv/baconboyrlz twitch.tv/suchikuchi twitch.tv/Bjornsworkshop (armorer, cosplayer, and creator of anything leather) twitch.tv/eye_make_stuff twitch.tv/Anjhe (UK based creator) twitch.tv/Peeper49 (piratey stuff and EDC) twitch.tv/Director_Koala twitch.tv/ProteanProjects (mixed media artist) twitch.tv/gyokuon (amazing japanese carver) twitch.tv/3dreefer (<-- hey thats me, newbie doing anything and everything i can to learn the art, a local to Wiz and Dan @ RW Custom Leatherworks) twitch.tv/evacathrin (horse tack and saddlery) twitch.tv/cavegeekart (pyrographical maps and portraits) twitch.tv/w1ndage twitch.tv/Starschlock (Battle ready Armorer) twitch.tv/thevoidcollector

-

Show & Tell: 3-D printed corner supports for sewing table

3DReefer replied to Uwe's topic in 3D Printers and Lasers

@koreric75 unsure if it will fit the other models as it was designed one off with the CB4500 at the RW Custom Leather shop. I am assuming for factory production speed and design they dont vary much tho. The stamps show have been thru my 1 ton armor press countless times without sign of deforming, the test samples I did for RW didnt hold up AS well originally with their 4 ton press, but once i used a different, tougher PLA type it has held up great. The WL one i also color with sharpie and press it to leave my stamp on chrome or oilled leathers that wont take a stamp. Sorry for the slow response.. seems i need to play with notification settings. -

Show & Tell: 3-D printed corner supports for sewing table

3DReefer replied to Uwe's topic in 3D Printers and Lasers

Never underestimate the usefulness of 3d printing. I trace all my templates into fusion360 with splines and extrude them to 1.5mm thickness to have quickly reproducible hard plastic templates instead of worrying that the edge of a cardstock one may have lost its dimensions. This also means i can also scale any project quickly like a coin purse template becoming an identical small bag. While costing pennys in comparison to having acrylic templates made. I also print my own stamps where the detail level allows me, 4 perimeters with 35% infill has survived months of use in my 1 ton harbor freight arbor press, as well as occasional smacks with the deadblow and poly hammers. RW Custom Leather has a 3d printed stamp that has been in use many times in their arbor press (think 4 ton) with 100% infill without any signs of deformation using polymax PLA. (key note as can see by the harley davidson stamp in picture.. dont forget to invert the X when printing so it is correct when stamping.. oops) To answer the question of accuracy, a 3d printer, even the cheap as hell ones (i have 4 printers, from $150 Anet A8, $330 Creality Ender 4, to the $1000 SeeMeCNC RostockMAX v3.2) can be accurate way beyond anything leather could ever ask for. My printers are accurate to within .05-.1mm, well within anything that would be needed to accurately print blue guns, or absolutely anything else you could want to wet mold. Finished printed parts easily sand if need to be modified. Personally i use PLA for all my leather print needs. In the second picture you can see i also printed a throat plated for the Cowboy 4500, which is now in possession of RW Custom Leather for their needs. The final was printed in white Polymax PLA. -

40W Chinese Laser - Engrave and Cut Leather - Discuss

3DReefer replied to Billy Hell's topic in 3D Printers and Lasers

OK so.. first off check out newer machines not the same that you have been waiting 4+ years to pull the trigger on. For example the glowforge and a large number of the machines within the beginner market are only 40w, which with proper focus and speed control will happily slice thru 7-9 oz leather, let alone any engraving desires. The tech has came a long way in even the recent year and most of your worries have been updated by even the cheapest of chinese companies. Water temp should never be felt by hand anyhow (what is that accurately going to tell you?? Use a digital probe). Also with the speed at which your work will be getting cut it wont even have time to heat up the water cooling system even. Yes it smells, ALL lasers cuts should be done with proper filtration/ventilation in place and turned on. Your literally burning flesh, it will smell as such, but isnt intolerable either. I know many leather workers that use lasers daily in their work, many of which (including myself) stream live on twitch quite often and can answer any questions you may have. On the software side anything that will create an svg image can be used for most laser cutters. Be it corel draw, inkscape, etc, so dont think Mac uses are left out at all. 99% of lasers use an svg file for the tool path generation. Although some may require a secondary program to create the gcode, but that can easily be found also with a few minutes of google. Inkscape has laser plugins to generate gcode for example.