-

Content Count

347 -

Joined

-

Last visited

Posts posted by JJN

-

-

Here is some advise from someone who has bought and sold many items. It is the owner of the item who needs to set the price. Your seller is hoping your offer is higher than than what he thinks it is worth and doesn't want to leave money on the table. Don't try to impress him with how high your offer is. You cannot go lower once your offer is set. You can always go higher if needed. Know your high limit and be prepared to walk if the price exceeds it. Insist he gives you a price and negotiate from there. Good luck!

-

@leecopp, thanks. I'll check it out.

-

Can you post a photo of your machine? Not sure what a Ferdco baby bull is.

-

3 hours ago, Wizcrafts said:longer type 3L belt to match.

Shorter belt?

-

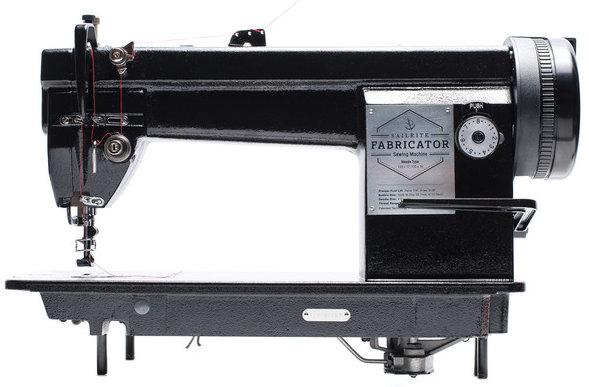

@JudyB, from the casting, it looks like it is based on the Mitsibushi LY2-3300. It may actually be made by them. Sailrite changed the balanced wheel and maybe some other parts.

-

-

-

@Bert51, can I give you my email so you can send it to me? I'll send you a PM.

-

-

I picked up a Singer 16-188 yesterday (c. 1948-1950). The price was right, free. I read just about every post on here to learn more about it but the links given for the owners manual at singerco.com are no longer working. Does anyone have a copy they can upload here or email to me? I read that the manual has limited information, so any other sources for how to adjust this thing will be helpful.

Thanks!

-

Please post a photo of how you have your machine threaded.

-

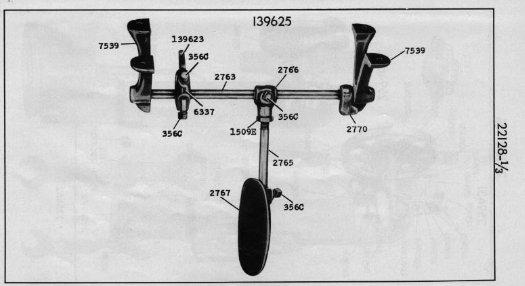

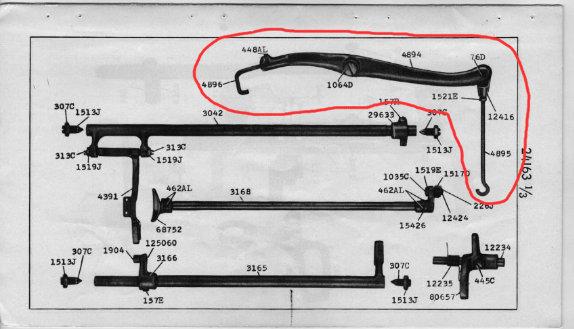

I always enjoy sewing on my Consew 206RB but have never been happy with the knee lift. I messed with it trying to get the highest lift with fair results and the cast iron finger on the bell crank has a gritty feel to it. I don't have the stop on the lift bracket and the lever slips past the bell crank if I go too far with my knee. I ordered a 'roller' bell crank from @Gregg From Keystone Sewing and installed it on my machine. Wow, I love it. Smooth action and higher foot lift. I should have done this long ago. I will order another one for my 206RB-1.

The photo shows the original bell crank setting next to the new one I installed.

-

Although Kobe is calling this machine an LS-1341 it is actually a copy of the Juki LS-341. Definitely not a 1341. The 341 binder that @Constabulary links to on Ebay may fit this Kobe machine.

I have a Juki LS-1341 and have been trying to make a binder for it. The Juki OEM binder mentioned above is no longer available. It used to cost around $600 when it was available.

I have been working on a simple binder for my 1341 but I cannot get the binder very close to the throat plate. To do it right I need to get another throat plate and feed dog and machine some material out of both of them so the generic binder can get close enough to do a decent job. I currently use a Consew 206RB flat bed as my binding machine but it is very clumsy when binding bag interiors.

I think I will just find a Pfaff 335 with synchronized binder to use as my dedicated cylinder bed binder and leave the 1341 as it is.

-

Check out a food grade grease. It is used on food processing machinery and it is clear. I got some recently from Amazon for a stand mixer repair and was very happy with it.

-

On 4/10/2020 at 12:23 PM, palvim said:Here is the video of how I'm trying to do it. I tightened the presser foot tension to at least 3 turns.

Maybe I am seeing something odd. Not sure. In this video, it looks like the leather is slightly jerking back towards you just as the needle is about to pierce the leather, shortening the stitch when stitching forwards. Maybe someone more knowledgeable can look at this and comment.

-

-

In my opinion, #69 thread is ideal for canvas and Cordura. I don't have experience with the Cobra 18 but consider a Juki dnu-1541s. I use it with #69 mostly, but I think it will sew with #46. Keystone has this machine for around 1700 shipped. Nice machine.

-

Hi,

Here is a link to a manual that should work for that machine.

-

It appears to have some variation of an 'upper feed'.

From Pfaff website: Special high-speed sewing machine with drop feed and variable top feed. Sewing of fullness and/or sewing without ply-shift on fine to medium heavy fabrics - Shirts, blouses, jackets, blazers, soft furnishings, curtains and much more

It is not a true unison/triple/compound feed machine. From the videos I saw on Youtube, the foot lift looks pretty small. The specifications show that the needle size for this machine is 80 to 100 or 12 to 16 size. That would make the max thread size is 69. This is a machine made for light fabric, not polyester canvas. I think.

The machine in your photo has some kind of attachment under the arm to the right of the needle. It has an additional control lever. I don't know what that is.

I also looks to have special feet that may be impossible to replace or change to feet that will better fit your bimini project. I really suggest you look for an upholstery class industrial machine for your work.

-

8 minutes ago, Wizcrafts said:If I was doing production sewing I would use a positioner system, but I would not use servos that start up with a jolt.

@Wizcrafts, I agree. I have a couple machines with the Family Sew servo motor and I like how they start up. I don't have speed reducers on them, just the 50mm pulley. I will put reducers on them when I start working with leather. The SV-71 came with a Juki 1341 I bought and I am trying to make use of it. I think I will get another Family Sew and a box style speed reducer and switch it out.

-

1 hour ago, Abdo said:Thanks for the recommendation. I heard great things about Juki sewing machines. About the needle position / speed reducer, why do you recommend to get one or the other, but not both.

@Abdo, I agree with what what Wiz said above. Both the speed reducer and the NPS accomplish similar things. Better control when making stitches.

The speed reducer will slow the machine down and allow you to be very accurate placing the location of the stitches in your leather while adding torque at this slow speed.

I have a SV-71 servo motor with NPS on one of my machines. This motor does not go very slow, but I can control it using the NPS. By 'tapping' the foot pedal, I can easily sew one, two or three stitches at a time and I can stop it needle up or down. It is like driving a car, after you get used to it. I don't think about it any more, my foot seems to know what my mind wants it to do. I am mostly doing production runs of 25 to 100 pieces at a time on that machine and I feel the NPS makes the work flow faster. I am also working with waxed canvas, Cordura (nylon canvas) and nylon webbing and the stitch placement is not as critical as with leather.

Either device will work once you get the feel of it. Having both methods on one machine is overkill in my opinion. For wallets I would suggest a speed reducer.

I have made some Cordura wallets on my Juki 1541 and it works very well for that. I hope to start working with leather very soon. I am still learning.

-

I purchased a Juki DNU-1541S from Keystone and recommend this machine for what you are doing. I like that it is a genuine Juki, made in Japan. You can order it with either a speed reducer or a needle position. I would not recommend both.

-

You are not offering much information for anyone to help you. Can you provide a manufacturer or a photo?

If by chance you are considering a Pfaff 487, that is not the machine you want. That machine is for lightweight clothing fabrics and thread.

-

In the US I would say it looks like a Consew 226R. I don't know if Seiko sold as Consew or Seiko in Australia. The bottom of the bed should have the Seiko name cast into it either way.

111W155 Needle Bar won’t walk

in Leather Sewing Machines

Posted · Edited by JJN · Report reply

I think you need to have the feet and throat plate installed to make the walking bar and presser bar 'walk'. One pushes against the other. Without the feet and plate attached it has nothing to push against.

I think!