GavinO

Members-

Posts

58 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Store

Everything posted by GavinO

-

New Duffle

GavinO replied to GavinO's topic in Purses, Wallets, Belts and Miscellaneous Pocket Items

-

New Duffle

GavinO replied to GavinO's topic in Purses, Wallets, Belts and Miscellaneous Pocket Items

I got my sewing machine fixed, and managed to get through the set of colours I wanted to finish Purple blue -

Good idea! I have moved to Canada from Europe, my other machine is a domestic Bernina 1130 from the 80s (I use for linings/other projects or very light leather work)- it is hard to get people who are willing to repair it when needed. Would be good to be a bit more self sufficient Macremb- thanks so much for this info, super detailed and useful!

-

Thank you Michiel, your advice is well appreciated. I was kind of getting to this conclusion but opening up machines just makes me nervous. It is fixed for now and the repairman was very re-assuring so hopefully it is sorted for a while

-

Hi all, I have had my Adler for about 4 years with absolutely no problems. However, I think I pushed it past its limit of thickness it can sew a couple of weeks ago and it threw the timing off. The repair main fixed it but it happened twice thereafter and he has now given up. I made the layers I was sewing much slimmer and managed a good few days of sewing but it just went again. This time though, it was during an operation it absolutely could do before the problems started- reasonably thick layers and zipper, perhaps the needle hit the metal of the zip and that threw it out. I have another repair guy coming tomorrow, I am worried the damage I have done has now made the machine more delicate than it was. I will talk to the repair guy about it but I wondered if anyone had any experiene with this, or tips. It is getting expensive to have repeat repair man visits, so is there a way for me to get a more permanent fix? Or is it a relatively easy thing for me to fix if it happens again so I can just manage it myself as and when it happens? I am fairly uncomfortable getting into the mechanics of my machines because I don't feel like I know enough, but if it is a matter of a slight re-arranngement and tightening then maybe it is time for me to learn.

-

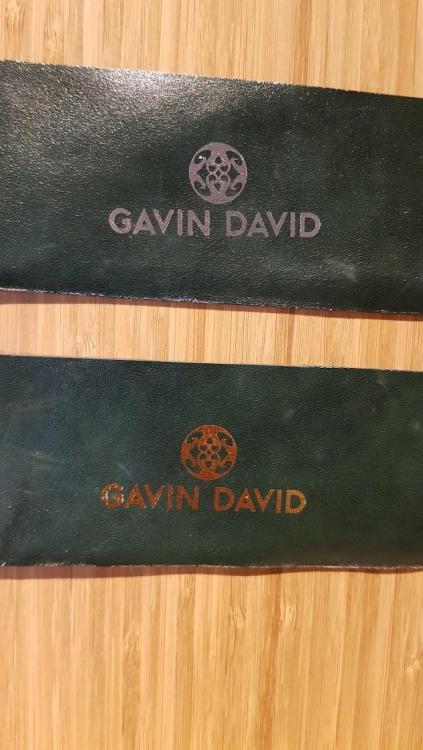

Hi all, I posted the last duffle I made last summer. Since then I have finished french school, got a new logo and I finally managed to design and source the straps I wanted with a supplier. Making this shape in 4 other colours to launch on etsy/my own website as soon as I can. Any critiques or feedback welcome.

-

I finally got my logo and stamp sorted! I ended up going with leatherstampmaker.com in the end and they were great. Very clear and easy service and I am super happy with the end result. They were also a fraction of the price that Tandy were trying to charge. I will use them again and I would recommend them to anyone looking for a stamp.

-

Hello, I have the Tandy hot foil printer, the older model no longer in stock. I am working on a brand logo and while I am happy to pay for my logo design to be made into a stamp, it is too much (400 dollars a pop) for each letter of the brand name for just a change of font away from Times New Roman. Are there any other sources for stamps that will fit my machine out there that won't cost so much? As always, any help much appreciated! Gavin.

-

Oh i just found this video- I understand it now. Do you have a sorce you would recomend? I und

-

Thank you! Thank you! So is sewfoam a generic term or a brand? Something like this: https://www.amazon.com/Bosal-493-36-R-Form-Fusible-Stabilizer-36/dp/B01I06AD48/ref=sr_1_1_sspa?dchild=1&keywords=sew+foam&qid=1610674306&sr=8-1-spons&psc=1&smid=A307EOO7SO3VAU&spLa=ZW5jcnlwdGVkUXVhbGlmaWVyPUEyUUhESFM4UE5QQkRRJmVuY3J5cHRlZElkPUEwODMzNTAwM0RNWjBRUEFTSUc5MCZlbmNyeXB0ZWRBZElkPUEwODA3MTQ4Mjg1VFdENTA3U1dNWiZ3aWRnZXROYW1lPXNwX2F0ZiZhY3Rpb249Y2xpY2tSZWRpcmVjdCZkb05vdExvZ0NsaWNrPXRydWU= ? Thanks, Gavin.

-

Ah ha! Now this looks intersting. Where would you normally get this?

-

Oh wow that's loads! Will check them out for sure. Just saw this, will have a look and feedback

-

Hi all, I am looking to experiment with quilting leather. I use old/discarded/surplus upholstery leather so it is a little lighter and has a bit more movement than some of the traditional craft leathers. I am inspired by the style and details of vintage cars so I would like to reproduce that kind of lush voluminous bulk that you get in something like those old car seats. I have done a little - just put some fleece in between the lining and the leather and sewed it down. While the result feels nice to handle it doesnt have the nice chunkier relief I am looking for. Is it a matter of a bulkier layer? Or I need to create non flat channels and stuff them then sew it down/seal it in maybe? I don't know how to quilt with standard quilting fabric, and I amn't looking to make patchwork, more just sewing shapes to get volume and shape (like classic Chanel bags, but I want to experiment with different shapes too) Any help much appreciated! Gavin.

-

Goooood point. Thanks for the reminder. Any tips for sourcing within Canadian borders? I am in Monéreal

-

I have the Tandy Pro and don't have any real complaints. Sometimes a leather piece doesn't take the stamp but I put that down to the quality of the leather rather than the printer. It takes a bit of getting used to, to get the 'knack' and I have nearly messed up a couple of pieces but if you are ready with a damp sponge or cloth and can see the problem and act right away you can correct it without ruining the leather. It is my first and only foil print machine so I don't have a basis for comparison. I do find the stamp sets to be very expensive. I have a set of 4.5mm but want to get the 6mm set soon and sort out my logo on an individual stamp and that is going to knock me about $800 for that-eek! I did find these guys when I was surfing about looking for a Die Cutting Press https://lwleathers.com/ - might be worth a look. Tandy isn't selling their die cut press any more (or they are just out of stock) so for that I am between these guys or etsy sellers from the far east which I am a bit hesitant about.

-

Awesome, I will dip into these

-

Thank you! I will have a look into it and compare. I also want to do an order with them just to see what the service and products are like.

-

Hi, I havent dipped into YouTube loads for leatherwork videos, but I do like Bedo's channel: https://www.youtube.com/channel/UC84XCkIspEOw3cxv3IISvMA He is more focused on shoes but when he does work on bags I find it super interesting (it shows what classic big brand name bagmakers do in their construction which is cool) I have also found some real crap videos out there, so if you have an interesting or useful faves in general leatherwork or bagmaking I would love to see them.

-

Bonjour Adonis! Loving your work. I moved to Montréal from the UK in February. Would love to pick your brain on where you get your materials and tools from! Gavin.

-

Hi there, I have just come across 'Rocky Mountain leather Supplies' online. As a recent transplant to Canada from the UK I have been spending a lot of time working out my new suppliers. I have been quite reliant on Tandy but I like the 'Rocky Mountain' stategy of picking and supplying different products from around the world as well as their own label goods. I am thinking of buying the sanding kit as I am finding the manual sanding pretty labour intensive and would love to speed it up. If anyone has this or any good alternatives I would love to know what you think https://www.rmleathersupply.com/collections/machines/products/rocky-mountain-summit-edge-sanding-and-burnishing-attachment?variant=29972344209517 Gavin.

-

Hello, I make my own bags and accessories, some of things that work for me: Stiffeners- bag base. In the UK I was using Buckram material which is most commonly used in millinery I believe- it comes in various weights (I use thiiner for small leather goods, heavier for the base of a bag) . For the overall structure of the bag I stock mostly to craft foams and interfacing (like pellon etc. that you have listed) as I don't find leather needs too much support to sit upright (thin buckram can be good to get it to stand up without too much weight- this is a recent discovery for me!) Piping wise- I tend to use vinyl when I make my own piping as it is a bit thinner and a lot of my designs can get bulky quickly. It's flexible and easy to sew around curves and there is all sorts of colours. I guess this only works if you are working with a contrast design aesthetic though) I haven't used much reinforcement tape but I will have a proper look at the links you put on there-I should probably consider using it myself!

-

Hi there, I managed to order a set of nylon bonded coats indutrial from A&N trimmings when I lived in London. They don't love doing small single orders, you kind of need to get the right person on the phone and they check then and there what is available. https://www.antrimm.co.uk/threads The threads are great! I am still using them. There was maybe black and white threads only in the various leather supply shops in London but these guys were the only ones I could manage to get the right stuff in a range of colours without being a full corporate customer.

-

New leather sewing machine- I am down to two

GavinO replied to GavinO's topic in Leather Sewing Machines

Hello, Just a wee update, after a bit more back and forth and more research I have settled on the Durkopp Adles 69-373. Mark at muary sewing machines had a model in better nick and for about £300 less than what I found in Wimbledon. He has re-furbed it, I tried it out in his shop on Tuesday and having it delivered tomorrow. I am excited, I will let you know how I get on with it I just tried to attach a pic of it but it is too big sadly! Gavin. -

New leather sewing machine- I am down to two

GavinO replied to GavinO's topic in Leather Sewing Machines

Hi Matt S, Yes the price i am quoting includes VAT. Though now I am registered as a sole trader I am not sure how that will work- just e-mailed my accountant so thanks for the prompt! Re: W246- what is the advantage of a 4-motion over a 2-motion feed dog? Just more stability? I understand the bobbin sizes. I called Maury yesterday and spoke to a guy called Mark (who seems to be referred to as 'the governor'!) Seems really affable and knows his stuff, and I don't think they have any of their own clones so he seems pretty impartial. I am going to go meet him tomorrow afternoon and try out a few machines and hopefully then it is final decision time! (Unless he opens another can of worms I wasn't aware of- very possible as that seems to happen every other day the more I research) Side note- have you been to the sewing machine museum? I went once a couple of years ago, but I feel i would appreciate it more now so I may well re-visit. Gavin. -

New leather sewing machine- I am down to two

GavinO replied to GavinO's topic in Leather Sewing Machines

Hi all, Thanks for the quick feedback, this forum is great. Tomsmith85717- Nope, definitely not a mechanic and don't plan to be. I want to be more knowledgeable but really my focus is product. From what I can find on the Alder 69-373 it seems to be able to handle upholstery fine (I have sewn some samples of sofa leather and doubled a belt over and it handled it totally fine) on industrial-sewing-machines.co.uk it says; In terms of parts and servicing and getting parts the mechanic at Wimsew seemed confident that it would be unlikely I would need them (as they service it all before re-selling) and that the parts for this were easy to get (might be the case for getting a Euro brand in England?) However, same stands for the Chinese clone in question. Which brings me to.... Matt S- The W246 is the very one I am comparing against! Given what you are saying here I am leaning again more into the Adler. Wimsew is local to me, I am based in Tooting, I can walk to them in twenty minutes. I talked to Tysew on the phone and they were quick to get me onto their Tysew clones, although i did find a couple of decent reviews for their machines online it seems they are the same things as the 'Wimsew' versions, though they claimed superiority, naturally. Again, just a bit quick to recommend one model, and they must be working to better margins on their own-make clones so are encouraged to sell them up as much as possible. The guys at JT Batchelor in Islington recommended Maury, I haven't been yet but maybe I will give them a call (even just for a price comparison) The £1590 price for the adler includes servo motor, year warantee, delivery and installation and talk-through set-up which seems very reasonable given i can see versions of it going for £1850 on ebay. Kgg- In terms of weight/appropriate machine dynamic, I guess it is the same answer as the quote above. There are not really any accessories for binding/cording etc. which is the same for the particular Wimsew I have been looking at. The foot is slim and to the edge so would work like a standard zipper foot anyway I think, and I am not sure I need cording or binding per se. I guess all I am looking for is a leather workhorse that can pull my bags and accessories together (though it looks like belts are now a possibility) confidently. However, I don't know much about cording or binding and what they might be used for, so perhaps I am closing myself off to techniques without realising it. I guess the flipside to that point is that a straight stitch workhorse is all i need for now, until I get up and running and ready for more advanced techniques, I could re-invest later. I am loosely assuming that machines with these features would generally cost more, so there is budget to consider too. The Adler in the shop, though old, is serviced and has some new parts on it (the threading plate on the front has been replaced etc.) Maybe I should find out how old it actually is (if they know) Thanks guys, Gavin.