-

Posts

35 -

Joined

-

Last visited

About xnikolaos

- Birthday 03/05/1961

Contact Methods

-

Website URL

-

Profile Information

-

Gender

Male

-

Location

Greece

-

Interests

Photography, DIY, fishing.

LW Info

-

Leatherwork Specialty

Quality control, Alloy steel precision castings, Alloy steel forgings

-

Interested in learning about

leather working

-

How did you find leatherworker.net?

internet

Recent Profile Visitors

The recent visitors block is disabled and is not being shown to other users.

xnikolaos's Achievements

Member (2/4)

-

Fortuna model10A bell knife sharpener stone

xnikolaos replied to richco's topic in Leather Machinery

https://www.tecon.it/en/skiving-knife-grinding-wheels/ In this address you will find everything you need for knife sharpening wheels. But first you have to disassemble the mechanism and do some simple diameter measurements to find what you need. There are 2 types of wheels. -

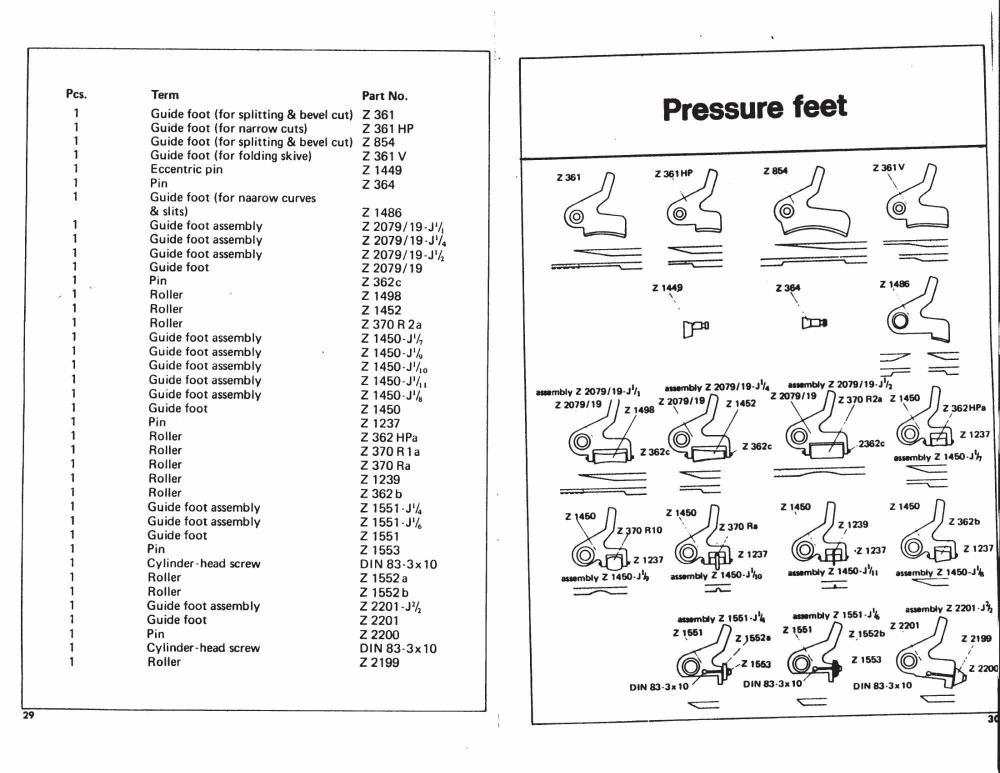

Some data from CAMPBELL RANDALL model 10A, showing how the spare parts are used. Applicable to all similar skiving machines.

-

Recommended stitching machine for new shoemaker

xnikolaos replied to JAM's topic in Leather Sewing Machines

This type of sewing machine is a single needle, high-speed post bed sewing machine (post to the right of the needle) with driven feed wheel and roller presser and synchronized needle. Is used in Europe only for upper sewing. #46, #69, #92 (TEX 45, 70, 90) . It is a TAKING TK-591 TAIWAN (GOLDEN WHEEL CS-8810 Chinese clone). Similar to PFAFF 491. Very well made (TAIWAN TAKING) with ball bearings everywhere, almost no oil needed. -

I agree with FDC. Either way you will need a portable vacuum cleaner for the surface of the machine. The built-in vacuum extractor would be necessary for a large volume of daily work and especially for the flying particles of chrome tanned leathers that can cause allergies in some people.

-

Hi Andy. I have a few alpha machines and one is exactly like yours. There is no manual for this model because the company has been closed for a long time. The closest manual is from FAV. I had to repair them little by little and I have a lot of experience. What you have to pay attention to are the screws and nuts that are a mixture of metric with the SINGER system, outside of normality. Tell me what you need so I can send you (FAV manual etc) and where to buy cheap and good consumables and some spare parts.

-

All bell skivers with the number 801 in the model name are made almost identically in China by at least two Chinese companies and marketed under different names around the world. Some aftermarket companies put their personal touch by changing some screws or modifying the threads (metric to imperial). You can't go wrong with buying them,. They use simple construction materials such as cast iron for the body and simple carbon steels without heat treatment for the rest of the parts. They are durable and easy to maintain because all the moving parts that receive stress are their ball bearings (From 10 to 14 cheap, common, ball bearings.). If you know how to change a worn ball bearing, then you will never throw it away. Most of the consumables are common (bell skiver cutter, stone feed wheel, presser foot). The reason people call them FORTUNA clones , I think, is these common consumables. They are not actually clones. Best cheap solution is to find a used old FAV, ALPHA, SAGITTA, Italian skiving machines. I bought mine in Greece for €50 each. The old FORTUNA skivers of the same type are not good for poor amateurs like me, because they use plastic materials, at least one, which shows problems over time and there is no spare part. Unless you want to give a small fortune to FORTUNA Germany for their wrong design.

-

No. I haven't found any used ones, for sales, in Greece. I have seen them used in small shoe factories and at shoe machinery shows.

-

Silverd. According to skiving machine manufacturers (FAV, Old Sagitta, Old ALPHA) , bottom-feed skiving machines are designed to handle soft and medium hard chrome or vegetable-tanned leathers. Top and bottom feed heavy dutty skiving machines are made for hard leathers, which are usually shoe soles and some leathers of the saddlery. If we make the assumption and divide the leathers into three hardness categories (soft, medium, hard). In my experience, you need both machines for the job. I'm not a professional, but I have four old Italian skiving machines and from my experience as an amateur I noticed that I can also skive hard leathers (soles) but in a very long time and at the limits of the strength of the motors and the machine. It simply means I can't. Of course, the best answer would be given by a representative of a skiving machine manufacturing company, who supposedly has the information that a simple user does not have.

-

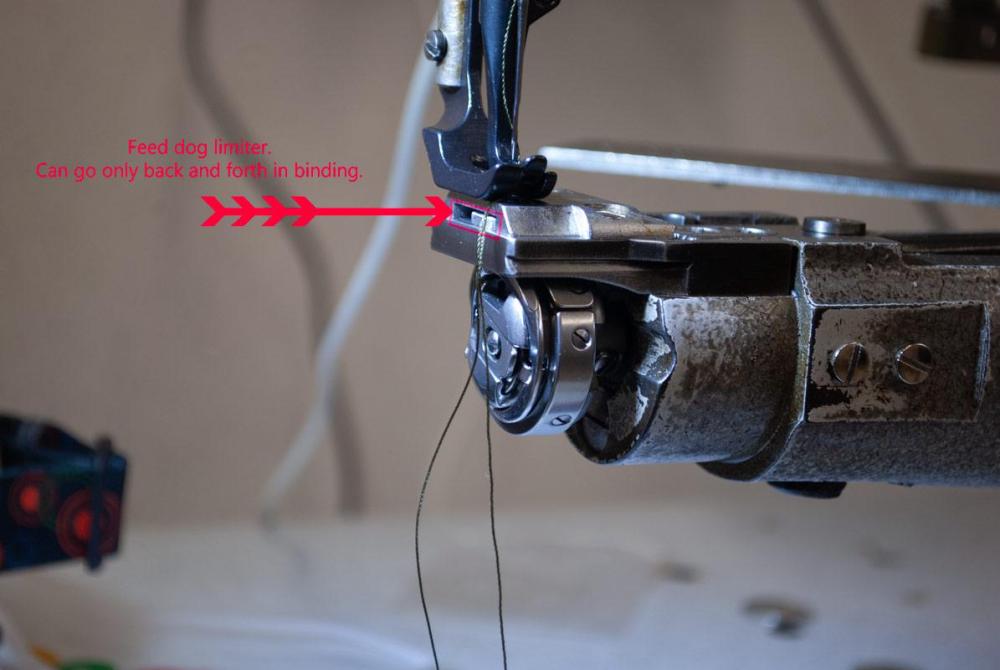

I have a similar machine SEIKO LSC8BV and use it regularly for sewing and binding as an amator. To understand if it is a machine for binding, you should turn the hand wheel, without material for sewing, as if you were sewing and observe the feed dog if it only moves back and forth ( binding) or if it simultaneously rises and falls over the needle plate (sewing only, not for binding).

-

You need to set the direction of rotation on the electric motor. At least that's how I do it. Older motors (Clutch motors) have a switch for this purpose or some reverse wiring connections.

-

Normal old type universal skivers. Bottom feed only. Good for chrome leathers , not for stiff and heavy.

-

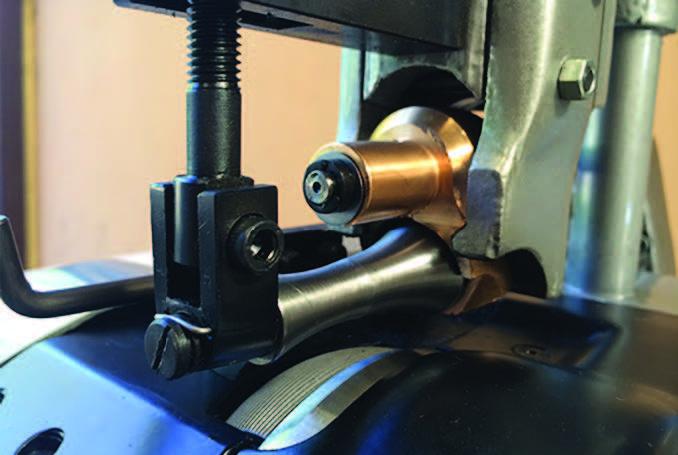

Heavy duty skivers with upper driven feed roll are machines to skive stiff and heavy materials. Example FAV ( Fratelli Alberti) CUT, CUM2, CUM3, CUM3K.

-

Yes I can send them to you but the file is larger than 1.5Mb. I think email is easier.

-

Jazznow, look at the pdf file I'm sending you. It is two pages of Italian FAV1,2 manual. It is the same machine as the FORTUNA with minor modifications. If you learn these pages, then you will understand how the old FORTUNA type skiver works. AV1 AV2.pdf

-