nylonRigging

Members-

Posts

478 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Store

Everything posted by nylonRigging

-

Looking For My First Sewing Machine In/Around Portland, OR

nylonRigging replied to Radam's topic in Leather Sewing Machines

I live just west of, and pretty close to Portland . There is a lot of sporadic machine turn over here in the NW area. also Lots of small sew shops tucked away, and also people sewing . If looking for a good clean used I see them popup all the time . You can run across some nice clean machines on the Portland Craigslist if check at it regularly . I not doing Facebook, but I here there some machines come up in the for-sales there also . . -

Bottom stitch is loose - Sailrite Ultrafeed LS

nylonRigging replied to CarrieReneHall's topic in Leather Sewing Machines

Also, double check the tension you winding thread on your bobbin winder . things happen, and bobbin winder gets looked at very little when you working repetitious day after day. . -

( Don't Oil Anything ) .. till you blow all sand and grit off everywhere real well with a air compressor .Use a Vacuum Cleaner or Shop Vac to suck out all the open hole spots and just generally everywhere . Being stored and pretty Dry is a Plus for you right now . If you Lube it only going to attract and flow the grit into places you Don't Want, while making it a real job to clean, rather than looking like a pretty easy job right now . .After you get it all blown off with Compressor, then you can do an assessment if the sand/grit is actually going to be a problem . It probably Not. If only sitting for a month, most likely all the contaminant is just laying on top surfaces only. Also.. that is a Real Nice cherry looking Consew Head for it's Age. It older Made in Japan and, ' It is a Keeper ', so get it cleaned up. .

-

what @constbulary said .. best guess is that the aftermarket Teflon press foot you running there. The foots 'shank angle forward' and hinge be totally out factory spec. That aftermarket mass produced generic Foot probably runs like a champ on a drop-feed with zero needle-bar walk/swing. but you stick it on a needle-feed motion and you are screwed. Also, forget about the Dial SPI numbers. what does the actual SPI Stitch per Inch measure on the material ? . I don't have a Juki DLN needle-feed , but I have a Juki LH needle-feed and the most I can stretch out is 5 per inch on thin material. Reminder of.. that it a pendulum/swing walk with the needle bar, so thinner material will give you a Max. on the SPI. .

-

So you saying have 2 issues ? Your needle not entering cleanly with the Feed Dog needle slot. hitting the Dog on it Walk/stroke? . Also Needle is banging the top of Press Foot ? If your machine sews great laying down stitches. and as long as your Needle stroke is timed well with entering Feed Dog ?. My 1st 'guess' off top of my head .. is You have Max out to far SPI, stretching out the stitch length, more than machine is capable . Or.. The Press Foot is not the proper length with it's needle slot to short length .? Slot is to short to match your your needle bars walk/stroke lenth. .

-

Cut a few . Nicest, cleanest, best way is to Cut on a Table Saw with the saw using a finish blade. You will be surprised how perfect and smooth clean the cut will be, even on the outside rubber bumper wrap. You can use hand circular saw, but you need to c-clamp a guide on table to run the blade guard against to keep circular saw moving in a straight square clean cut. You can clean-up any roughness with block sanding. . edit add: . Is that head and drive set-up just setting on-top a table ?. your cylinder bed machine, looks cantilever hanging the weight out over one side of table top . I would take time to determine all angles of maintaining good stability before removing any of the base it all mounted to. .

-

Oil level window - issue leaking oil

nylonRigging replied to Xanthe's topic in Leather Sewing Machines

it would good to know what machine model you asking about ? , are you asking about a underside of head view window reservoir on gear box ? , Or you asking about view window on upper Head of inboard reservoir ? , Or other ? . -

Motor pulley belts to the Large pulley reducer, Small pulley reducer belts to machine hand wheel . 1st align smallest pulley reducer to sew heads hand wheel pulley, and drill, and bolt down . Then move drive motor to the align to the Large pulley of the reducer and drill and bolt down . Also, don't forger that you always have option to flip-over the Servo drive to Right or Left, as you have option to switch drive direction on the controller. Edit Add: .. that extra small carrier pulley on the bottom of the Sew Head for factory drive belt routing . Do you actually need this now ?

-

Ya, you need to swap-out your 1/4" , to a ( 3/16") gauge needle setup for 3/4". But it pretty easy to do, if you ever decide to do it . Double-needle does look good though, It presents itself well in trimming out items with the 3/4" on raw exposed edges, pockets and things . So... I just planting the seed now in back of your Brain ...LOL Even the old Singer 112/212 'needle feeds' are pretty common, easy to find, and a lot of people overlook them in searching out a compound feed, Needle-Gauge sets are common found, and cheep for them. Just grab an old 112/212 when you run across one. Clean it up, set it up with a Raw-Edge 3/4" binder . The old Needle-feed Singers do a Very Nice job with both fabric and Leather. People really overlook them and never give them enough credit over compound feed with Leather. BUT they do an outstanding job . Here a good example in Pic. using needle-feed machine binding edge on leather. I just cut a scrap strip off 3/4", off some nice soft supple black leather, and threw it under one of my Needle-Feeds set-up for 3/4 raw edge binding . Also trimmed same cut of Black with some raw-edge Nylon grosgrain 3/4" . - -

-

You want some changes in making crawling low RPM speed to an already built and working Top table drive set-up . There is going to be some sacrifice to make something new work, like changes, moving things, drilling a couple new holes..etc . Like i said no biggie just drilling and moving things around on the table tops. and was just an alternative thought on using Box reducer , but sure it would probably work. Normally pulley reduction or the box style speed reducer are under-table mount. But the Box style is a 'stack' together with the drive motor. Rather than the pulley reducer that is off-set alignment to one side of the drive. So.. Instead of hanging motor off the bottom of the box style speed reducer under the table . You just reverse, mount Box style reducer to table-Top, and then drive motor on-top of box speed reducer. Take motor OFF . Align and mount Box . Mount motor on-Top of Box . Buy new V-belt to fit the new length dimension . Also you might try just buying another more powerful servo drive unit, that has enough low RPM power to move slow with little effort. Just a swap out with your existing servo drive and controller . - That hand wheel on the machine right now looks nice. and It looks to have a little weight to it also which is nice. but If wanting to change it out . I would just call Artisan. ( i think ? ) ask, talk to ' Chester ' , if i remembering right name from last time I ordered parts from them. Ask him if they could hook you up with a larger diam. Pulley/hand wheel to that model . .

-

For adding a speed reduction pulley that is meant to run offset to the side . You have to move the motor and you will also loose your belt-bobbin wind . It no big deal really to move things around and just drill new mount holes in table tops . If not wanting to move and re-drill a few holes, Possibly ? , is it possible to run a 'Box' style reduction system . ( Pic. Attached ) . Just reverse from hanging under, to stack on-top of table . I have never used a Box reducer style, only the traditional under table pulley reduction, But there a few people here that use one that could chime-in if it possible to box-motor stack on-top of table rather than underside . That does look like a 'Well Thought Out' , top table motor drive set-up that Artisan sent out to you. Did you just order this machine new from them ? . If you call and ask what machine design/model that Artisan Labeled this from . You could possible get a larger hand wheel.pulley ordered for it . - -

-

I would not put so much of the decision on what drive each machine has under the table. But would make the decision on the condition of the Head. ( me ) , drive motors come and go, and can easy be changed out. Machine Pic's would help a Lot . Both are solid workhorse machines / The older Head is no doubt the 111w115., and it most likely does not even have reverse . If the Pfaff was pretty clean Head, and not beat to hell. I would take the old 145H3 on my 1st choice. .

-

Taking a harder look at that sailrite offering on that bias binding, It 'probably ?' is quality weave for outdoors/marine environment, Poly for better UV life . it's double fold edge, so that is extra cost for them from the Mill. but the asking retail is pretty high-$ . Buying off the Ebay is hit and miss,and lot of middle-man reselling. but I have run across some deals though in the past. - Ya if you buying 1 roll at time on-line off ebay/amazon then you are kind of stuck. when I buy binding and tape, I always buy no less than1-k yrd. @ a time, and that is really not that much tape, as I goes pretty quick. On a color I use all time, I have had done custom color orders with 5-k yrd. and that will last me about 3 years average. and when ordering from a mill, you really don't even begin getting any price cuts unless you start getting 10-k plus+ Yrd. . Good mil.spec.Nylon 3/4" typelll runs ( I paid ) anywhere from .22 to .26 yrd. it all depends if you ordering from a Mill, or getting from a supplier with them having order drop-shipped from a mill. - Ya herringbone-bias nylon lays down, turns and tracks good . Bias weave always flex's better than the straight line weave of grosgrain. Financially...LOL, you might want to move away from that sailrite Bias binding . ( PM sent to you ) . - The grosgrain and bias look different, turn different . ( me ) i determine which, by the needs of the Item. ( i think ) Nylon Gross grain makes a visually nice presentation for finished edge trim like small items, pocket front edges..etc.. The herringbone-bias I use for heavy thicker outside seams of bags, or bigger items. It all personal preferences. .

-

Nice.. you are starting to work some binding, and working on building technique with laying down some stitches. the more you run binding, the easier it going to get for you, especially learning the little Idiosyncrasies your machine does with stitching and feeding it. What you aying on that 'thinner' material you taping , and you using single-needle. If you turn radius with 3/4"width grosgrain typelll 1a, Instead of 1" wide . You are correct. The 3/4" will lay and turn nicer with less wrinkle distortion . Same for that Bias 1" the weave with single-needle. Bias always turns substantially tighter than the Grosgrain weave will . If you go 3/4" on that Bias, It will do some real tight turns and lay flat smooth/nice . But.. you are getting the synchronized swing set-up and eventually working. So you will be able to just swap-out different size throats for taping width changes. Dude.. 136-$ for 100 yrd. roll of 1" polyester bias is pretty SICK . I cant believe that price is correct ? . I pay usually in the .32 to .34 per yard for 100 yrd. mil.spec 1" Nylon 4082-1 herringbone-bias . The price for the Grosgrain is little high, but 'is what is' if you just picking up a roll or two occasionally off the Amazon . .

-

Man that a cheap price to start building a setup . . All the binder throats are sold separate In different sizes for the width of binding you using .. All you do is just take Off/On with the two screws on end of arm, and that good for you so you can move back-forth from maybe 1/2 or 3/4" for your thin stuff. to 1" and wider for thicker binding . . Your compound feed should do a very good job binding, it just a different feed with certain characteristics. Your clipped into a hole on the Dog and your swinging synchronized to the feed motion . you just have to learn to set-up and then build a technique by just binding different edges/shapes/thickness .. all binder size throats sold separate sizes/widths. just take out 2 screws and swap the tapes . If you have different size feet cut/shaped married to that size Tape, then you swap them also. .. PIC. -

-

Your Pfaff 1245 is not a common machine for finding Synchronized-swing binder set-ups . for your compound feed that would really be the thing for you to get hookedup with trying to do a correct professional set-up . If you had a 335 you be golden they common for aftermarket . I dont thing KHsew in Hong Kong does one either, and only one I see offering syncro-swing parts for a 1245 is Italian . Offering Dog/plate, Feet, and Bracket is this one.in link below---> They List parts model #'s of... 145 / 245 / 545 / 1245 1245/syncr/swing/bind - Edit Add: Well I lied to you...LOL . I logged-into KH and looked around and, they Do offer for Pfaff 1245 . I bought things from KHsew before and they are 'very' good quality machined aftermarket parts, and super Fast on the delivery to. KH/1245/swing .. https://www.khsew.com/index.php?route=product/product&path=141_143_250&product_id=383 KH/1245/Dog-Needle Plate .. https://www.khsew.com/index.php?route=product/product&product_id=374 -

-

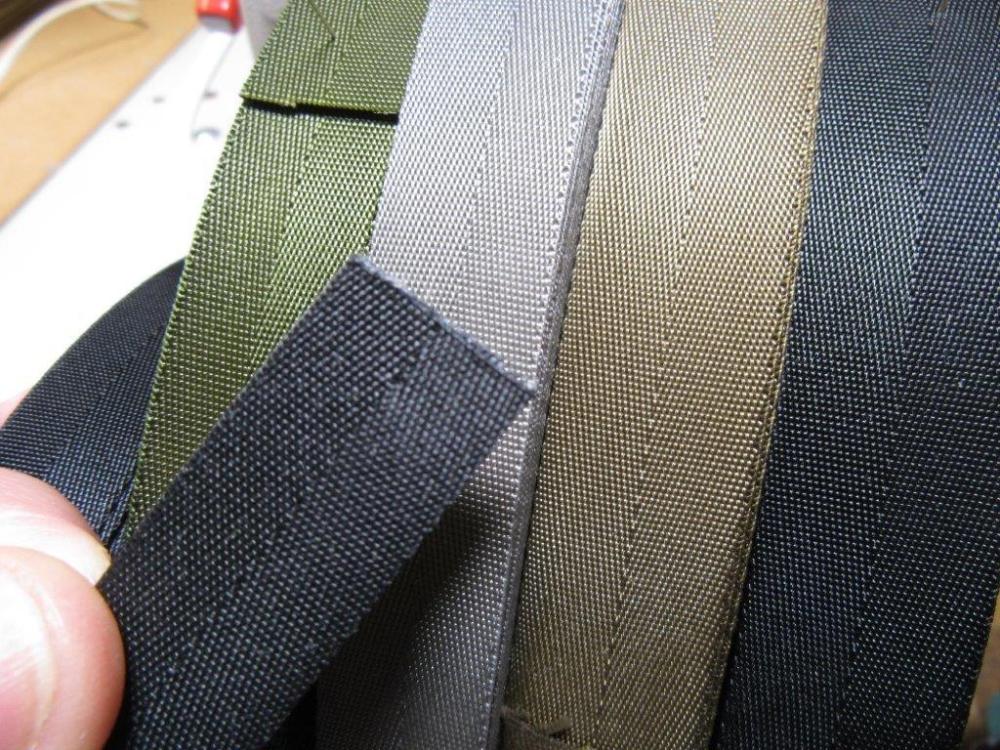

Double-Needle does leave a great finish look for edge binding . Also you talking about 'Sailrite' for binders ? and I think their main machine line is all Drop-Feed Walkers, and they push binders for that system. That a little different Feed than your Pfaff Compound-Feed machine . The Non-Walk feed of the inner foot and Needle shaft of Drop-feed walk is easier to set-up a simple stationary Binder on positioning it right in there tight to needle. AND .. have you ever thought of just getting an old Singer single-needle or double-needle Like an Old.. 111 112 or, 211 212 in a ( Needle Feed ) to learning on for Binder set-up, and Binding ? . Needle-feed does a nice job for binding. People pass over the old needle-feed Singers all the time when looking for a old compound-feed, and most are sold pretty cheep. Needle-feed does a great job binding. the old Singer feet, dogs, plates are plentiful and cheep. Setting up Binders on them is a little more forgiving and easier learning curve. Everything you build on your sew binding technique from that will translate over bigtime for latter down the road. along with setting up other binders. . I cant edit/add anything to last Post I made, I guess I timed-out for that. For a mil-spec Nylon Herringbone/bias . I pretty sure it's a ' Mil-W-4088 ' . I use that for years and it tops for way it feeds and finish presentation. Also it Never Hurts to just ask suppliers to mail sample of binding materials if you not sure what it is, for you to see if it is what you want to use before a larger order. Pic. of some of the 3/4" and 1" ,on the Mil-W-4088 Nylon binding, and the weave look. - -

-

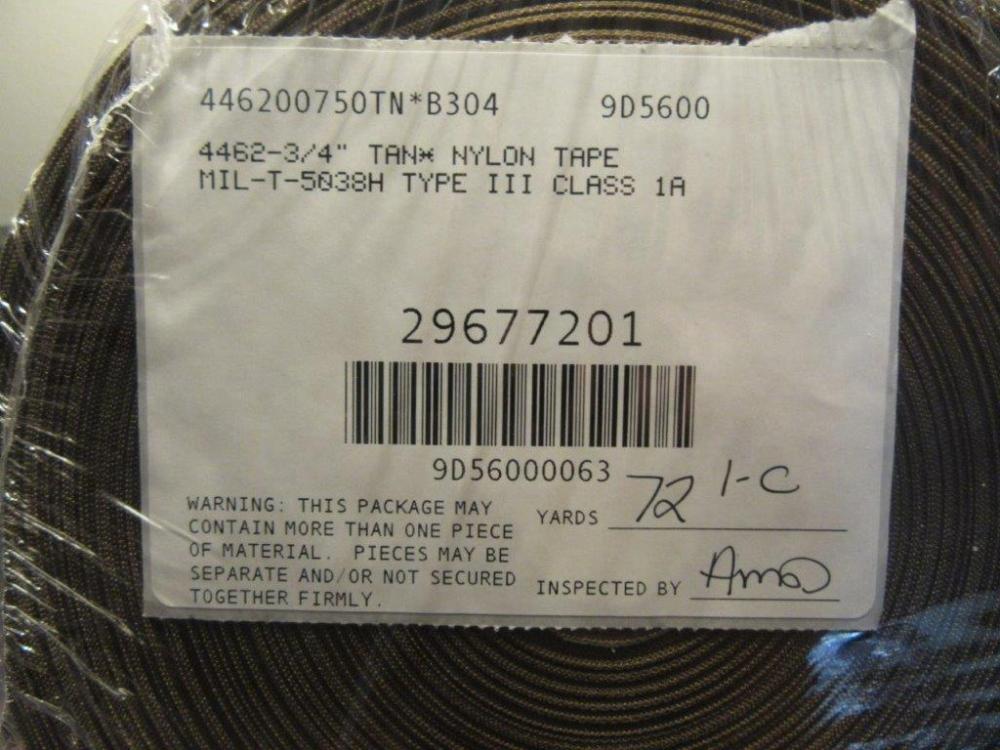

I got into all this side of things on the Para Rigging side of sewing, and to this day it still makes my head spin with the designated 'ID' Mil-Spec labeling of every individual type of webbing, binding, tapes, threads ...etc. It's a Federal Gov. and military labeling that all material must fall into a ( minimum requirement/rating ) of, size, thickness, structural breaking strength, ..etc. I think it even gets into the number of TPI requirements on the Looms that are even doing the weaving. with all this also getting into 'Berry compliance'.. Bla bla bla bla...eyes glaze over....LOL Getting into this is a 'Rabbit Hole' that you wont see daylight for a week. But like I said in earlier Post. the quality of your binding materials you use will feed and lay so much better if it mil.spec. and US Milled product. Your headaches will be minimal with binding. This plus getting the proper binder, set-up proper to your machine . Grosgrain, most common seam bind is 3/4" and 1' width tape, you want to use ' Mil-T-5038H class 1A type lll . If you do a order straight from the Mill . Here is a pic. of the common label with the nomenclature of spec compliance . -

-

The binder itself looks like a plain raw edge binder. pretty sure there a difference in raw edge, and double-fold materials for binders . Do you even need to use a double-edge fold binding tape ?, factory woven edge probably is just fine for your finish seam binding . Also. I would think it harder to make a good radius turn also with using the double-fold, over using a raw edge finish . Even though it a more pliable bias weave, being 'double thickness' is going to lead to tracking issues on stitching bending tight radius . I do have double-fold attachments of different sizes for double folding cut material strips, but I never use double-fold binding materials in binding. Also 'Wawak' . have actually never bought anything from them, but they look to be a sew supply house and not an actual production Mill . I just typed the single word 'webbing' into the google search. They look to be a heavy payer-$ for brand name placement up-front covering 1st page for search findings . I NOT saying saying Wawak good/bad . I just saying they buy their materials from everywhere on the planet to then stamp their Name on for Retail Sales. I would find out if you buying 'paying' for import or domestic for your materials like bindings and webbing because there is a BIG difference in quality most times. .

-

Also add.. Turning radius is not to hard if you get the setup correctly mounted into the Feet on your machine . That is a BIG hurtle to teach yourself. Reality is that the only way to really learn how, is to just start mounting Binders to your machines Feed, and build some understanding with how positions/angle/height effects the feeding of the binding out the throat and lays. Different binding materials do turn different. Also you might be trying to turn to Wide of Width Binding, in relationship to your thickness of material ? . it does takes some practice also so you need to take it all in stride, dude I been running finish edge seam binding over 30+ years, with almost everything I sew having binding on it, and I still screw-up once in while. ( Me ).. I have set-up a CrapLoad of binders on machines, and fed many miles of binding. I seam bind almost everyday I sewing .. But.. my skill.. I only know what I do for last 30+ years. I use double-needle and single-needle, I only use raw edge binders and binding, I primarily use 'Love' needle-feeds for taping/binding . I do have and use compound feeds, but synchronized-swing set-ups . I mostly 'like using' type-lll grosgrain's, and I use Herringbone Bias binding. - OK.. I just grabbed cut some scrap to show you different material in reference to thickness of material you bind . 'Radius' Binding. using ( 2 ) R-Angle Binders. Here a 5" circle consisting of 2-piece of 1-k denier cordura. seam bound with 3/4" wide typelll with a 3/32 gauge double needle, T-70 thread . 5" radius is about as tight as I like to go with a double-needle . Single-needle with some 1/2" wide bias will easy turn even smaller/tighter radius . Then there a radius with material of 3-pieces of 1-k cordura with some high density closed cell foam in-between. So this is lot Thicker edge, and I using 1" wide type2 herringbone Bias, with a single-needle, and #138 nylon thread. - -

-

Sorry, couldn't reply sooner I been in the shop all day cutting a sewing . OK first off, I don't understand this, In the Pic. ? , I might not be seeing it correctly ? with your Tape feeding/going into Binder. You got a Raw-Edge Binder, and it looks like you got Tape folding, as it is feeding into the binders throat. - -

-

Your binding tape choices make a HUGE difference when you don't match to your specific needs . Also a lot of the cheep import binding is out of spec. crap. Try only to buy US milled quality and it really aids to better tracking, lays down better, makes your work look 100% professional. Buy your product from a good vendor selling US quality mil-spec. or just order direct, like from Bally Ribbon mill. Cheep Binders, they can lay down Real Nice tape job with using quality tape, and If the binder is setup proper on that machine. but, then just opposite. Expensive-$ Binder if setup Bad to machine, just gives you one continuous Headache after another. with your work looking like crap. .

-

When does the thread advance off the spool and bobbin

nylonRigging replied to Lint's topic in Leather Sewing Machines

Thread advances 'Comes Off' the top thread spool, after every-time the Patcher foot makes contact. Patcher Foot is the feed . The Thread advances 'Comes Off' as 'Needle Goes Up' same time the Patcher Foot feeds/drags the Thread and material behind for the beginning of next needles plunge with top thread. 'basically' .. Bobbin thread advances 'Comes Off' with every completed cycle of the Hook, and With the Needle Up-stroke pulling, and thread 'Comes Off' Bobbin . .