nylonRigging

Members-

Posts

478 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Store

Everything posted by nylonRigging

-

Please help, thread is too tight when pass bobbin

nylonRigging replied to Orrrmygod's topic in Leather Sewing Machines

Is there such a thing as that ' little Post ' being a blame for ..." my machine not sewing correct" ? Just now, I just went out and checked after seeing this Thread Post . I walked out to shop and looked at an old 211 singer that I have sewed with for 20+ years . The old 211, The R-side thread tension has that 'post' like in your pic. of that machine . and The L-side has no 'post' on tension mechanism . So 2 tension spring-discs, with 1 being routed over the post, and 1 not . The R-side thread has always been routed that way ( over the little post ) for all these years of sewing and it sews like a dream ? . -

Needle Sticking in Leather

nylonRigging replied to ValkyrieEquine's topic in Leather Sewing Machines

Are the Ti-nitride coated needles slicker than standard needles ? always used silicon on the heavy thread cord and works great . But I ( have not ) tried the Ti coated needles yet and wondering if anyone uses ? . -

Adler Chandler model 190 - thoughts - experience?

nylonRigging replied to plinkercases's topic in Leather Sewing Machines

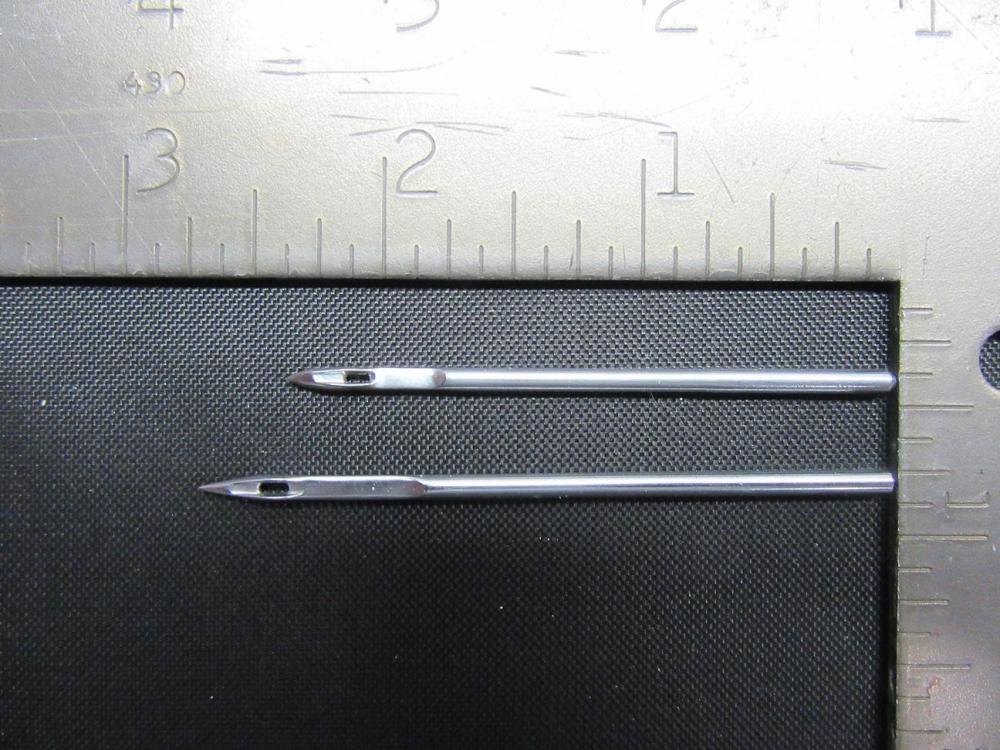

I need to rephrase that ( wimpy ) . It smaller shorter, than the #794, But It is still pretty ridged with a thick shank . It just wont punch the depth like the 794 will . I just remembered I had old one laying in the magnetic straight-pin box . So here is a pic. side by side . 328 & 794 , Scarf side-up . -

Adler Chandler model 190 - thoughts - experience?

nylonRigging replied to plinkercases's topic in Leather Sewing Machines

I sewed with one several years before selling, Pretty positive from memory Yes correct on the needle size #328 and was bit wimpy smaller than 794 . the cylinder Bobbin was smaller also . using #346 was pushing to much but it did #277 well . ( mine was bottom feed model ), 1/2" thick was about the limit, but for just a bottom-feed it actually sewed very well and smooth . . also it a pretty solid machine and there is/was a crapload of import clone machines floating around made off the parent machine design . -

Etui rasoir fermé.jpg

nylonRigging commented on beaulama's gallery image in Gallery- Our Leatherwork

-

Difference between using a Larger Pulley vs. Speed reducer?

nylonRigging replied to tofu's topic in Leather Sewing Machines

Much More than just aesthetics and what is pleasurable to the eye . And it's great to have electronic speed selection with Servo drive motor, but there is more to it, than just the end result of RPM desired . I can electronically select my RPM command on motors to turn any speed I want . So why add additional pulley's and belts in-between the 1 tiny pulley drive, and the 1 Large machine handwheel pulley ? The addition of the pulley reduction in-between the drive motors and machine drive shafts . whether you put it under table or above table for 'aesthetics' appearance . ( I interpret it ) Reason is, It delivered more Lb/ft energy to the Needle for a end result, Using less energy required from drive motor to make that Needle crawl threw the Thick material resistance you give it . Question ? . ( For example ) on one of my tables with pulley reduction under-table . You have a 13" Diam. handwheel with/10" diam. pulley, and with belt, going down to a 1.5"Diam. pulley off the Servo drive with electronic speed select . So why do I need the additional pulley/belt reduction inbetween the drive motor and the machine drive shaft to punch 346 threw 12 pieces of webbing ? . -

Difference between using a Larger Pulley vs. Speed reducer?

nylonRigging replied to tofu's topic in Leather Sewing Machines

There must be a upside benefit reason, as multiple pulley and belt reduction placed between motor and machine have been around long before I was born and sewing . . -

My chinese cobbler patcher arrived

nylonRigging replied to Yankee63's topic in Leather Sewing Machines

it is a rough machine . But I do see your points . there is something to be said for the truth of.. " less is More " . Less complicated purity . . -

Difference between using a Larger Pulley vs. Speed reducer?

nylonRigging replied to tofu's topic in Leather Sewing Machines

There probably someone here more Tech. that can articulate better on the mechanical science definition . I think the main thing of importance is efficiency . Amount of power put in, related to the amount of power received at the end result. like you say, It does take up extra space with addition of another belt and pulley . I have a couple of tables with common used setup (under table ) pulley wheel reduction between motor and machine . The power felt sewing is so much stronger than when just using a single changing of one pulley and a belt size . Multiplying pulley's . By adding another pulley and belt in-between the drive motor 'clutch or servo' , and the sew machine hand-wheel pulley . The 'torque and the power' is pretty strongly and plainly felt with even using the slow RPM or even in higher ranges of speed . . -

My chinese cobbler patcher arrived

nylonRigging replied to Yankee63's topic in Leather Sewing Machines

Does not sound like the machine to own from what you just described ??? . I am sure it a fine tool and adequate machine for shoe cobbling on the streets of communist Vietnam or China . But not sure about Investing your time in the lowest common denominator . old saying of ..."putting lipstick on a pig ". . -

Need adhesive to hold leather patches on hats..

nylonRigging replied to thatgriffguy's topic in Sewing Leather

Adhesive . I use 3 things for quick stick for hold in place before stitch . Small dab of glue-stick hot gun, and use the softer silicone sticks . . different sizes of, Basting Taps . . Loctite, spray adhesive #200 /middleweight bonding . -

That is some 'solid' MacGyver'ing right there . I giving you a Big thumbs-up on that print pulley . I seen it done ( printed pulley ) on ( the Larger Pulley ) with a under the table gear reduction and the guy swears it works perfect . What material you printing with ? The material will probable work for long time if you keep the friction/heat down with turning a low RPM . I see in your forum profile you from Sweden . So I don't know if you get the old 80's 'MacGyver' episode reruns there for the DIY reference ....LOL .

-

Nice Find .. That a keeper, one of the rare good deals on the craigslist to be found , the sew machine Gems are there but you have to be vigilant on the hunt . I have looked for few years in my regional area and made several trips to look at machines offered for sale on craiglist . I have bought only ( 2 ) machines over the years of looking that were 'happily' well worth the time and energy . A lot of over priced junk on craiglist there but good machines can be found. I got a sew friend that also keeps craiglist eye-out and sends me link of machines that are worth a look . I just was looking at another machine that popped up last night, in my AO that you rarely see ever come up on the craiglist . Is a 1942, 7-31 that looks ( from the Pic's. ) to be all there and working order . .

-

This is a great read on this Thread, well worth the time to take and go threw . 'competent' sew tech. like ( Eric ) are harder to find now days ( never met him ) . Reading this thread makes me feel SOooooooo Grateful to know a couple techs formal trained by years of machine industrial sew repair, that I can get my machines to when I have been pushed to my limit on sew machine repair knowledge . Up here in NW. Oregon, years ago it was a sew mecca at one time especially outdoor/sporting . Now, 'Real Techs' are slimmer pickings, I know 2 that will do mobile, and one that I can drive over and drop off a machine . But I can imagine that it would really suck and be stressful to say the least if you lived in area that had No competent sew repair locally that you could count on when there is trouble that you cant find answer or fix for . .

-

...LoL . .HaaHAHAHAHAHa .

-

consew breaking top thread on 4 layers not 3

nylonRigging replied to wilsonintexas's topic in Leather Sewing Machines

What (wizcraft said ) .. slow down the rpm on moving through the thicker thicker materials and trying small adjustments like recommended . ( i no expert ) and It really hard to diagnose stitch problems without actually having hands-on and sitting in front of machine . So I will throw my guess in the mix . unless I missed it somewhere ? . your saying it just a 'Bottom-feed' Consew ? , but what model is it ? , and the needle 135x5 or a 135x17 or bigger ? You saying with 4 loose pieces of material, the top thread breaking, but how thick of a stack is it with 4 pieces ? this--> Assuming you already have proper Pressure-foot tension and thread tensions on Top and Bobbin thread ? , and also using the proper Needle size/length for your material ? I think your statement ..." I can rotate the machine by hand and all is fine ". is the giveaway . Your just asking your Machine to do to much . You may just be pushing the machine and needle to it's design limit, Plus . If just Bottom-feed model and not Needle-feed or Walk . with stacking the 4th piece of material on ? . And Nothing wrong with Bottom-feed and I still run 2 of them daily . Sometimes it is just plain hard for a Bottom-feed with keeping good tension and stitching on thick multi-layers . that is where a needle-feed or walk shines . hold multi layer materials firmer with stitching motion for no deflection and holding proper presser and thread tensions . . -

( imho ) if looking for that edge over a everyday 550 watt, 4amp servo drive . Go for a ( Consew CSM3000 ) it a 750 watt and pulls 6amp, and It really improves the low rpm torque when your just bumping the needle threw some heavy or stiff materials with staying very smooth on the slow rpm light pedal pressing . it also has a couple accessory plugs for future position sensor .. with speed control on the on/off switch .. ' like your asking for ' . and break is released for easy moving of needle with hand . .

-

sent you PM ....thanks