nylonRigging

Members-

Posts

478 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Store

Everything posted by nylonRigging

-

Soft cutting boards really sucks the sharpness edge off the blades, I use a lot of the Poly. cutting boards and razor knife everyday. from what I understand the #1 Best Cutting Board materials is .. Acetel Copolymer . Delrin is another but more expensive. .

-

Nice Vid. .. I going to save link on that one. You really make visibility to parts, and to the order of completion with that one . .

-

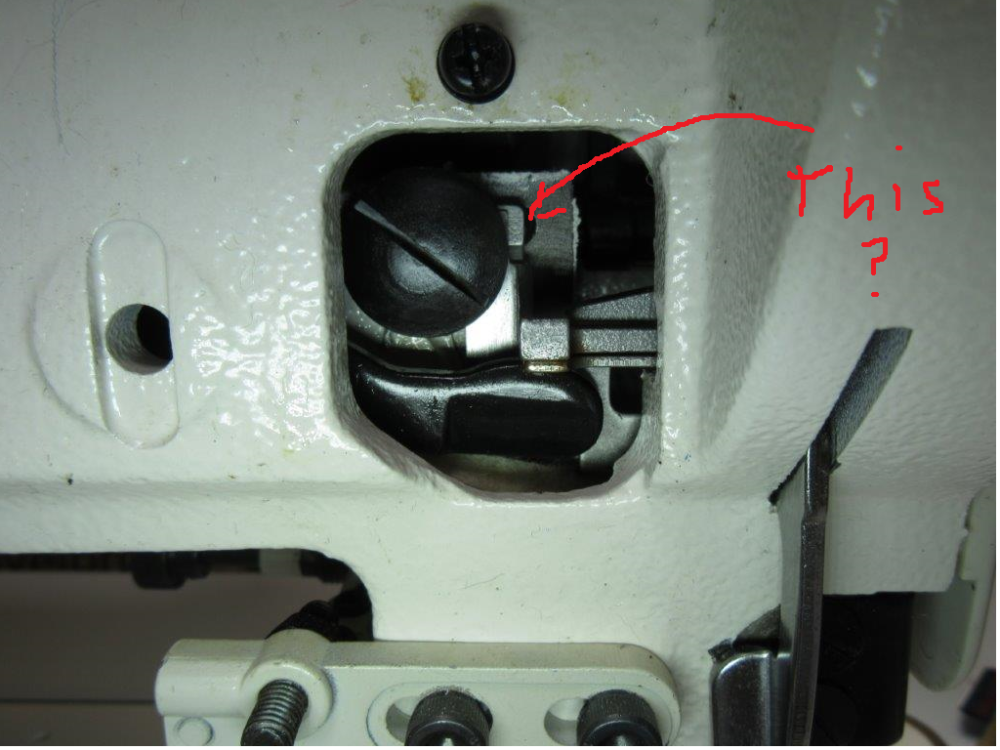

Not quite sure what you saying is Loose ? , is that what talking about a ( not quite in focus ) about 2:00 position next to the large flat-blade bolt head ?Inside the small back-side cover plate on mine. What I have in that spot ( in casting Hole ) but it is held in place, and mostly hidden by the linkage of the presser feet Lift Lever. I can just get my tiny screw driver blade to contact it, and when I push on it . It is slightly loose, but has some spring retention behind it that is pushing/holding it in contact with back of the lift lever linkage, when lifting it . ( I not 100% positive ) but, ( when manually lift the raise-feet lever ) . ' It ' , is what travels up against and pushes against the inside ( Tension Release Pin ) inside behind your thread route Tension Disk Assembly. It is all half hidden, but with the small back cover Off, and If you take Open the main front of Head cover to also make more light and see threw it all. You can kind of make better sense of it all by looking at it all work when you move the lift lever up and down . How is your Tension release working ? when you lift up and down with the raise presser-feet lever ? I never really paid attention to that small part you talking about . All I really know about what is behind that small rear cover plate. Is the hidden adjustment screw that you need to get loose to adjust Outer Presser feet height . Adj.Screw is hidden behind the presser foot lever linkage. and you got to lift presser linkage and look upward to even access see it. Juki did a good job hiding that one. I will check latter to see if I can find the 1541 parts book to see what that might be. . Here is Pic. of what I got, Mine just slight different on my 1541S , but I think ?, see what you talking about . -

-

I use one all the time. It can be easy dumbed down to sew 138 size nylon thread, but that is about as light as I have taken mine for thread size. The artisan model you quoting I bought and setup 95%+ of the time for just seam-binding using 138 on thicker edges to bind using 1" type2 heavy nylon tape, and it does really good with lighter #138 for that large shuttle system and machine. I am under-working that 3200 machines stroke and power,. but I always like to ask sew machines to do less than the suggested factory Maximum load. I basically never tried to sew thinner items with the Artisan 3200 because I have a lot of other machines to sew thinner materials that are setup and tuned for that job . it sewing..." light work "2-3 pieces of paper". I seriously doubt that. you can try ?, but I don't think the machine would do that thin unless you really changed out a plethora of things, Dog, small hole Needle plate, Feet, choices of 794 needle size, and really work playing with tensions ..etc. .. ( imho ) you don't buy that machine to sew thinnest of material. That's not what the machine was design to do. there so many other lighter and cheaper-$ machines already do that job well . .

-

There bunch of different zigzags out there . Just looking threw my local Craigslist today. there is few used Zigzag's for sale . old Singer 20u . Consew CN205R . Tacsew T-199RB . Juki LZ-586 . I used to have a old Singer 107W and it was a real good machine and those made to last forever . I see those old Singer 457's around for sale once in while also . .

-

Are you sure, that it walk-foot ? . I found only One, 10 year old Vid. of a ( Rex 345-2L ) on YouTube . It really a crappy poor video, but If you go all way to 6:40 in the Vid. . It clearly shows it's a common High shank foot, Bottom-Feed Industrial . - 345-2L -

-

I got to say, this forum never fails to offer info to pick-up on. I never really paid much attention to M-Bobbin sizing. of my machines running 3 of them use daily are M-bobbin . ( 2 ) consew ( 1 ) juki . I just buy the same M-bobbins that I use in All them. They all seem to work satisfactory sew great, but when I get some time I will put a Mic. to some of them and check size variation. .

-

got your PM..and will get that out to you. .

-

just my opinion. on small size like lining for Wallets and such. I would probably do a supple lighter denier weight Nylon like maybe (example) a 70 denier Taffeta. Taffeta has a nice look to it on the finish presentation side of the fabric. Taffeta not a urethane back-coat. So it better to hotknife cut to be clean and cauterized edge. Urethane back-coat nylons fray little on the scissors cut edge. but Urethane back-coat is going to add a little more weight and stiffness to the fabric lining. As you move up in larger sizes in Bags increase little heavier deniers in Nylon inner lining, and if want to add a little extra protection to the Bags use a urethane backed for controlling any messes or spills from bleeding threw to the outer. I probably stay under a 100 Den. on the small wallet items, and probably not over a 300 to 400 Denier max. on the larger bag linings, Larger outdoors/sportier larger bags maybe a 400 Den. pack cloth or even 500 Den. urethane backed. 'Cordura' is just a licensed brand name, but if it is Cordura. It is US mill primo quality from Brookwood or maybe Kenyon. Some of the import nylons are ok though. 'me' I just try to stay away from Polyurethane and stick with Nylon. If you want to check-out some nylon Taffeta on those wallets. Just PM your postal info, and I will throw a chunk of it in a bigger envelope and mail it to you to look at/cut try. .

-

Bump this 202RB Thread up, so I can mark it to find it again latter on, as I picked-up a free 202RB today that was in storage. don't really have anymore room for another machine, but you know what happens when someone says ..." if you want to drive here, come and get it '. ....lol There does not seem like to much info about 202's. but Tons on on 205, 206.. So ( I assuming ? ) the 202 is older predecessor to these RB's. .

-

Recommended stitching machine for new shoemaker

nylonRigging replied to JAM's topic in Leather Sewing Machines

That last Pic....LOL .. looks like you chain smoking and stitching all day with that ashtray and burnt butt's. I have the china clone of that machine design 7" post, It is pretty solid and smooth feeding. I use mainly for bag bottoms. Reverse would have been nice, but really it is no biggie to just backstitch without. . -

OK...Probably Not cause of this particular 'noise' problem.. But I had a weird ( high pitch whine ) sound coming from a machine when sewing a few years back. The more RPM's I put into the drive pedal, the louder the whining was. So I spend many minutes trying to isolate the part of sew machine the problem was coming from. So Turned out. That it was a 'Radio' that was making the sound... LOL .. I always have the Tunes ♫ ♫ playing in the background on a old Sony sport radio up in corner of the shop when sewing. For some reason on that one particular day, the servo drive on that one machine that was plugged-in wall on same circuit as the Radio. The Servo transferred a 'whine' to FM Radio channel, and it was bleeding some frequency interference, and that what I heard every time I picked-up the RPM's on that one machine. .

-

Juki 1541s noise and wheel hard to turn

nylonRigging replied to Dbz456's topic in Leather Sewing Machines

You saying it .."might have been dropped". but you probably would notice some paint damage or some dings ? . The Inner-Foot and the outer-Foot, Have clearance ? Not rubbing together binding when the inner foot cycles back-forth/Up-Down moving inside the outer Foot ? nothing visually tweaked to see ? Also saying it was sitting for long time ? but if no surface rust it probably just pretty dry on the lube. I have picked-up machines that sat for more than a couple years not running, and non of them was dry enough to sound like that. But.. wow the sound it making on the Vid. is definitely pretty rude. Like BAD Dry or something Binding . -- I opened the front cover of my 1541s and looked to see/understand what you describing . So, you saying that the chatter/binding is both ? . When lifting Inner and outer feet, with using Knee-Lift . And Rolling by hand w/ no belt connect . When you hold your fingers on both the Foot Bars just above both inner/outer Feet . Lift the Knee-Lift Up/Down and Roll the machine by hand . ( do you feel ?) . Is that hard chatter transferring down and, 'feeling it' vibrating hard on your fingers ? When Rolling by hand . Looks like in the Vid. ? , that the Hard chatter/binding is mainly happening after the needle plunging bottom, and moving in the up-stroke, with also the Outer-Foot lifting. . -

Singer Twin Needle sewing machine

nylonRigging replied to LomaeArts's topic in Leather Sewing Machines

- 6 replies

-

- singer

- double needle

-

(and 1 more)

Tagged with:

-

Singer Twin Needle sewing machine

nylonRigging replied to LomaeArts's topic in Leather Sewing Machines

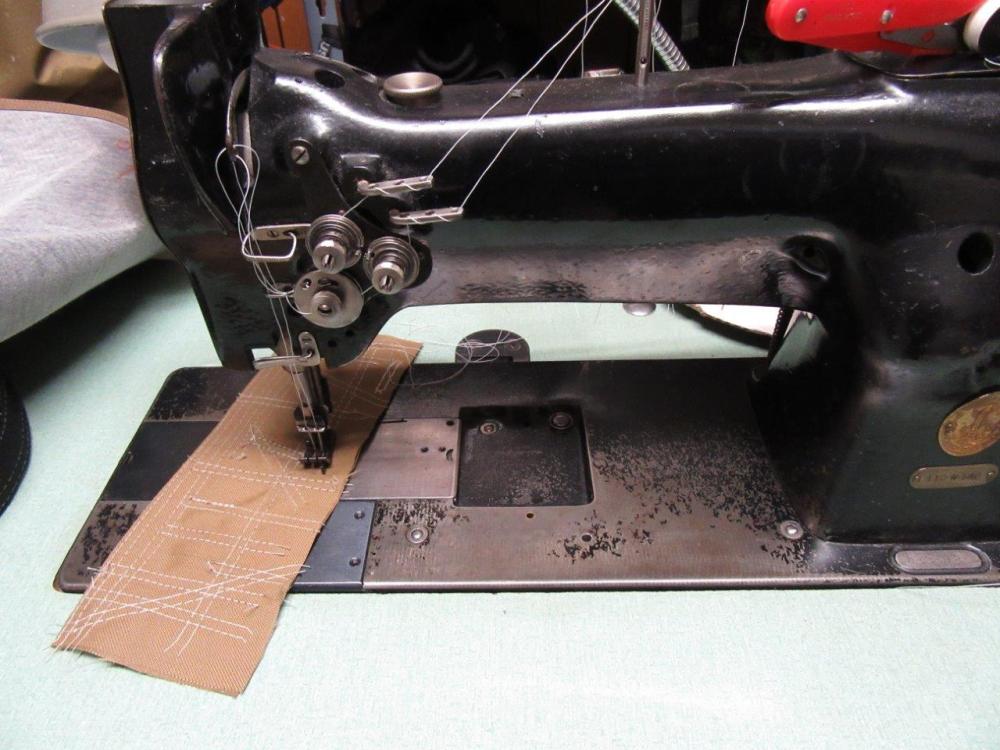

It's an old 112 W needle-feed. It's pretty old , looks well used . I got one in the back that still runs like a champ. .- 6 replies

-

- singer

- double needle

-

(and 1 more)

Tagged with:

-

Sieck 269-373 Tension trouble

nylonRigging replied to LimaZuluTango's topic in Leather Sewing Machines

Ya there something funny going on there with the routing choice that machine is giving him . If you look at a Pic. of a Durkopp Adler 269 . That this machine copies . The thread routing goes over around the Top and down around of main Knob tension, and makes WAY better use of the main tension. . -

Sieck 269-373 Tension trouble

nylonRigging replied to LimaZuluTango's topic in Leather Sewing Machines

OK, Not sure if proper routing ? . just throwing ideas out there .. but from your Pic. it looks like you not utilizing full benefit of your larger tension-disks/knob on that thread routing . Look like it needs to be using more tension surface area. As it is right now, looks like you only using maybe 25% surface of that main tension knob . But right now, your not getting much thread surface on that main Tension Knob Disks with routing that you doing . I don't know why ? , it not with what choices given you on that machine . If yiu look at a Pic. of a Durkopp Adler 269 . The thread routing goes over around the Top and down around of main Knob tension . Is it possible maybe ? , to take that routing as it comes around that main tension knob . Take that thread over more L-side to the 'thread guide' . To then take thread routing down to the Take-up spring routing . I Not sure if that Thread Guide that is above your take-up, has 2 holes, or it just open wire guide ? . Route .. Main Knob --> L- to tension guide --> down to take-up --> then back up threw thread guide . . Or ? .. can you ( flip-over ) that thread guide that is above your take-up . From pointing Left , to pointing Right ? Then come off that main tension knob with thread . to thread guide . down to Take-up . Then come up from ' take-up spring' routing thread up threw the other thread guide that is below the safety guard . . -

Dont understand ? you say ..." can’t get a stitch to stick! " are you talking about tension ? Might try a Titanium plated needle, as they tend to be slicker surface and better for sticky and needle stays cleaner. Are you sewing threw that really sticky ( peal and Stick ) Velcro ? that adhesive backing is pretty gawd awful 'GUMMY' especially that 3M brand . in general almost never buy and avoid that adhesive Velcro product, and just use rolls of sew-on . I would suggest not even using that sticky-back Velcro. I always sewing Velcro and keep hundreds of yards always on hand of different size/color. Like you saying, the fluffy 'Loop' side sews easy, looks good . but Hook is different animal, Going sewing around the boarder edge of Velcro Hook always looks great, But In general though anytime you sewing right on Top of Velcro Hook is hard to make look good because your feet are on-top of tiny 'unstable' flexible pillars .Stitches never look consistent pretty . .

-

- The 211 parts to covert back is easy found,and cheep to do . but me.. I wondering what material stitching the original 112 owner was doing with this set-up ? That a sham to just toss aside the prefab. foot/dog setup work that is on it. It was built and added to do a specific job on the old 211, and 'probably does it very well' . .

-

Cant really see the feed-dog . Is that just one large dog ? Is it a Needle-Feed / drop-feed walk ? . I never seen a heavy large single-needle foot setup like that before on a 211. It's interesting.. A different (side angle and rear ) Pic.of the feed and foot would be good to see. .

-

211W155 Is this part supposed to move

nylonRigging replied to TomWisc's topic in Leather Sewing Machines

Those screws are tiny...LOL . If can't round one up . I got a screw can mail you. I wont miss a screw. I replaced both bobbin assembly on my old double needle singer about dozen years ago, and threw the old in a box just for that reason of loosing or breaking...etc. 'cheep insurance' Robbing parts off the old trash. . -

I like the size, shape, design, the finger cutouts for 'Grab Bag' . and you should digi. pattern it. That bag can be no-sew primitive Grab bag, or easy go different directions for the maker. It could be sewn, plus use the lacing and rivet points as added accent, or even with lining, pockets, removable shoulder strap...etc. .

-

Soccer Ball Production -

-

Binding issues with cylinder arm machine

nylonRigging replied to ThomasBH's topic in Leather Sewing Machines

Setting-up Binders is never easy, and it hard to get into specifics on doing a setup to Bind with internet forum pic. and not actual seeing, and with not having hands-on the binder and machine . Getting the correct Binder, and with Binder in proper set-up . That goes with equal detail with seating-up on the positioning of Binder to the presser feet, also the shaping of the feet to accommodate the binder position to Needle for feeding materials. Plus a few other things. After that it's all about building your personal technique for Binding. Sounds like your saying, your biggest struggle is getting the binding material of choice to track out the binders throat nice even with feeding material ? , and the Pic. of the, 1"/25mm Binder to me ?, looks like that binder is for thick edge, it looks to have a pretty tall open throat height . your 1st choice on binding is, 1" wide, type lll grosgrain ( tape binding ) ? ( for me/just my opinion ) .. On thicker edge materials, ( exposed, finish look ) and using 1" wide Binding for a wrap. My 1st choice is a type ll, #4082 herringbone . Binders throat height around the 12mm size . And for ( exposed finish look ) for the thinner edge binding, 1/8' and thinner edge. I always go with a 3/4" wide type lll #5038 grosgrain . also the binders throat height around the 5mm size . . -

New apprentice with new tools!

nylonRigging replied to SpartanCarry's topic in Leather Sewing Machines

ya .. a nice Magnifier for sure , and also some 'soft' super-fine grit emery cloth for smoothing Hooks and also need something to remove nick's on needle plate, and other sharp spots ..etc. that you run across. edit add: Besides a nice tool carry box for repair and cleaning . Also I seen some repair techs. run a hang-harness/ chest mount that has a lot of common small hand tools at easy reach . Also...LOL you will be cleaning and blowing out a lot of thread and fabric Lint and oil everyday, If a machine is run for 8 hr. shifts it's incredible the amount of filth they accumulate. .