-

Posts

850 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Store

Everything posted by MtlBiker

-

Duh (smacking myself on the head!) for some reason that second menu choice just didn't register with me. Thanks! I just started sewing a year ago (during Covid isolation) and I've been slowly learning and working my way up to making things from leather. It's too expensive to play with until having more sewing experience. The same place I linked to also has "European Vegged Tanned" leather... I don't know if the price is good, average or high... 1 sq. meter (converts to about 10 sq. ft.) of 4-5 oz leather costs $130 Cdn.

-

I'm a total novice when it comes to buying leather and it seems I would have to buy from an online source without seeing the leather first. Which makes it even more difficult for a novice. I would be machine sewing small belt pouches to begin with, maybe to hold a leatherman or a little metal credit card holder I have (think about 6-8 credit card thickness). I'm not sure what kind or thickness of leather I should be looking at. I guess veg tan leather would be the right choice? (I did buy a couple of used leather coats at a thrift store and took them apart for the leather but I find it's really too thin for what I want to make.) I found a source online which is here in Quebec Canada (as I am) but when they list the leather with the price they don't specify how much leather that price gets you. I'm guessing it's some kind of industry standard that you all know, but for a beginner it's all just unclear. Here's the leather source I found. They list two "vgni" (???), one 2-2.5 oz and the other 3-3.5 oz. I guess the thicker one would be more appropriate for what I want to make? And once I do get some leather, I guess I'll also need a burnishing tool, dies, and I have no idea what else. What tools/dies/glues/etc. would you consider the basics that I should start with? Thanks very much!

-

I just might have you beat with that... I have a set, model no. 1000, that was given to me by my step-father (more accurately my mother's second husband, as I already living on my own then) FIFTY years ago! No kidding. When I saw this post I searched for my set and didn't find it until just now. I'd added a couple of really small torx bits so the case doesn't close properly and I use elastic bands to keep it closed. Real nice little set.

-

Please Help!!! Techsew 2750Pro Servo Motor SS-1221-P

MtlBiker replied to Stefanie1982's topic in Leatherwork Conversation

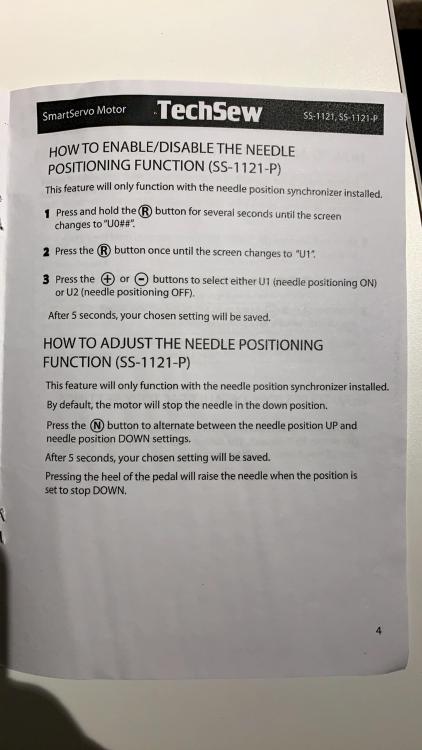

@Stefanie1982 I found my servo manual and I'm attaching a photo of the page that explains how to engage and set it. I hope that helps. I'm also attaching a photo of my 2750Pro which shows the speed reducer installed. It may or may not be something that you or your husband can install. But the cost is about $150 Cdn on the Canadian Techsew website. I've never used the machine without the speed reducer but I'll tell you, I love it! It really allows me to sew as slowly as I'd like. I hope this is of help to you. -

Please Help!!! Techsew 2750Pro Servo Motor SS-1221-P

MtlBiker replied to Stefanie1982's topic in Leatherwork Conversation

I've got the same setup, having bought my 2750Pro only in early December. But I bought mine with a speed reducer (it was an option) and that really does allow for very slow stitching... just about 1 stitch per second. And the NP is working fine on mine also. I set my machine up and haven't looked at the settings since I did that. But if I'm not mistaken, there's a button combination on the motor that allows you to set the NP to on, stop with the needle up or the needle down (I like mine to stop with the needle down). Don't you have the manual for the machine? Maybe @Techsew Ron will see your post and comment about both the speed and NP. If you didn't buy the speed reducer maybe you still can. And maybe there's another way to slow the machine down some more. On my other machine (Consew 206RB-5) with the kind help of the folks here, I managed to get that machine sewing much slower just by reducing the pulley size on the motor (plus then a new belt). Maybe that's an option. I'll take a look at my manual when I get home. -

Just wanted to follow up as I received the Sailrite magnetic guide I mentioned (link a couple of messages up). It's GREAT! It holds much much better than the magnetic guide I'd been using. It's not easy to push it out of position with a heavy assembly. Here's a photo of it on my Consew 206RB-5. The Sailrite one is on the right and the "large" one I'd been using is on the left. No comparison. I should have ordered one months ago.

-

I recently started using Affinity Designer (and Photo) on my iPad Pro and I find they seem to offer pretty much the same functionality as Illustrator and Photoshop. And the files work on either program. I'm doing a little pattern creating with Designer but haven't yet gotten heavily into it. I'm not quite sure what you are asking about subtracting the lines from the shape, but might it work for you to have the lines on a separate layer? You can hide/show layers at will, and also change their opacity. I hope this helps.

-

Mark, I was just teasing you about the lack of thread! Meant it to (hopefully) get a laugh from you. Is that upholstery vinyl or leather you were testing on? The needle is going to leave holes in either, so you may as well have left the thread in place for your test. That way you'd see if the tensions are correct. I'm pretty much a beginner at sewing myself (only having started since Covid) but I'm having a ball (and making lots of mistakes) but one of the things that took me by surprise is that colored thread generally needs different tension adjustments than black thread. I've found that red, white and blue (which is what I use other than black) work well with the same tension adjustment while black needs different tension. So when you say your machine is already set up for v69 thread, keep that in mind. You know about the drop test for bobbin tension? While holding the bobbin thread in your fingers with the bobbin hanging down, very gently bounce the bobbin. If the thread comes out too easily and the bobbin drops, you need to increase the bobbin tension. If it doesn't come out easily enough, you need to loosen the tension. And with experience you'll learn what is right. I don't know if more experienced people do this, but I have one bobbin that I use only for my black thread (normally v92) and another that I use for white, red and blue. And changing from a color to black (or vice-versa) generally needs a top thread tension adjustment also. Cheers!

-

Welcome! And that machine of yours really does sew slowly. But... (with you saying you're a beginner, etc.) uh, did you perhaps forget to put thread in the machine?

-

I have one of those "large" magnetic edge guides and for me it doesn't work well with heavier assemblies... too easy to move it out of place while maneuvering 2 layers of 21 oz canvas plus 2 of 1000D Cordura. Maybe my 206RB-5 doesn't allow the magnet to hold as well as it might if the needle plate were larger. The rippled paint finish on the body is probably not allowing the best hold. Anyway, I was going by memory of the cost of the Sailrite Deluxe 5 1/2" Magnetic Sewing Guide... it's actually fairly reasonably priced at US$32. Of course with shipping and dollar exchange rate plus taxes, it costs us Canadians a lot more. But I just ordered one. I've been wanting one for awhile now.

-

I bought one of those flip up adjustable edge guides online... I think it was from Amazon but it shipped from China. The description listed a bunch of machines it would work with, including the Consew 206RB (mine is a 206RB-5) and I was very disappointed to find that it did NOT in fact fit the machine. I have one of those guides on my Techsew 2750PRO and it's quite nice, but even though it came with the machine, it doesn't quite fit right as the laser light and wiring for it is a bit in the way. So what I use mostly is just the presser foot for 1/8" and 1/4" seams and a magnetic guide (Dritz) for larger seams. I'd like to buy/try the much longer magnetic guide that Sailrite sells, but the guide plus the shipping cost and dollar exchange rate makes the cost about $120 Canadian (yes, I'm in Canada). So I've got it on my wishlist, and will probably order one when/if I can add enough other items to my order to help spread out the (very high) shipping rates that Sailrite charges. Maybe once the border opens up again after Covid, I'll order one for US delivery and pick it up on one of my trips to the States. But who knows when that will be. SIGH

-

Thank you Keith! There hadn't been any replies here to my post but you helped me figure this out by private email a month ago. Cheers!

-

Interesting idea. Thank you. But as all my (meager) experience so far is with fabric and webbing, my idea for a small belt pouch was to stitch two pieces right sides together, leaving an opening, and then turn it right side out. I'm not sure if with cardboard inside I'll be able to do that. I want more stiffness yes, but not so much that I can't do this. I don't have a pattern to work from (just trial and error) but what I had in mind was a doubled back piece with belt loop on the outside back, a doubled front piece and a flap piece with a snap installed. Not too difficult using fabric, but I'm not sure if this would work with even thin leather. Learning experience... Here I come! Okay, I've got a lot more to learn... I'll have to research what bag stiffener is (thinking it's just a stiffer interfacing, such as Decovil Light) and I certainly don't know (yet) what bonded leather is. (BTW, how did that suede turn out?)

-

Thanks very much! I'll give it a try then.

-

I'm totally new to leather working, and relatively new to sewing in general, only having started since Covid. Anyway, I have some calf's skin (?) leather that's quite soft and thin. I also have salvaged some leather from leather coats that I bought at a thrift store. I want to start experimenting with it. Before going out and buying perhaps more appropriate leather. If I want to make a little belt pouch using the leather I have, is there a way to stiffen the leather? With fabric I'd just apply a fusible interfacing... Can the same be done with leather?

-

I just bought some Nomex thread, believe it or not for making oven mitts. Anyway, American and Efird has a thread called ANESAFE (using Nomex) which is available in Tex 27 to Tex 90, in white and colors.

-

Can you post a photo of the machine?

-

I've only been sewing for a few months so obviously the stuff I don't know would fill a book but I'm really confused about the different thread size specs... For a little project I want to do, I need a thread that's pretty resistant to high heat... won't be flames, but high heat. I understand nylon and polyester wouldn't be good choices. So I've found a Canadian supplier who lists Nomex thread, but I don't understand the spec they quote: 30/3, with 3,000m per spool. I'm familiar with v69, 92 and 138. But what's 30/3? Is it comparable size/strength as v69, v92 or 138? Thanks for any help.

-

Trouble getting started with Seiko STW 8 help please

MtlBiker replied to bigsig11010's topic in Leather Sewing Machines

Uwe, I respect your vastly greater experience and knowledge than mine, but I really wonder about what you said regarding that pin. You did say that there's wrong information being repeated all over the place and that's probably true. But as I said, it was the Consew dealer who showed me how to thread my machine and I would expect that he knows how. Plus I just checked a couple of Youtube videos about theading the 206RB and they also show and say to wrap the thread over that pin. Here's one of the videos. If you really think that shouldn't be done, I'll give it a test when I get home after work tonight. I'd just hate to have to readjust all the tensions again since I've got everything running so well now. -

Trouble getting started with Seiko STW 8 help please

MtlBiker replied to bigsig11010's topic in Leather Sewing Machines

Geez, so I've been doing it wrong ever since I bought my 206RB-5 a few months ago. And it was the DEALER (Eastern Canada distributor for Consew) who actually showed me and told me that the thread needed to go around that little pin. And as far as I can tell, it's been working just fine that way. (I had absolutely no experience with industrial machines at that point, nor really much general sewing experience.) I guess I'll have to try without wrapping the thread around that pin. -

Trouble getting started with Seiko STW 8 help please

MtlBiker replied to bigsig11010's topic in Leather Sewing Machines

Hi, and welcome. I'm just a beginner myself so I may be totally off-base with my comment but on the photo that shows how you've threaded the machine it does look wrong. But it is a little hard to see the exact detail from your photo (could have been a larger photo)... When you bring the thread to the upper tension disc, it looks like you have the thread arriving at the 2 o'clock position (which is right) an then going counter clockwise and coming out at about the 7 o'clock position and going to t he second tensioner. If I'm seeing that right, then you do not have it threaded correctly. At the top tension disc the thread has to enter like you are doing and going counter-clockwise, all the way to about the 4 o'clock position and around the little pin that's there. And from that point, down to the second tensioner entering clockwise at about (guessing) the 4 o'clock position. From there up around to the spring and most probably you'd have to give a tug there to get the thread to pop over to the inside of that. I hope this is of help. -

Top thread breaks when removing work

MtlBiker replied to MtlBiker's topic in Leather Sewing Machines

Just to follow up, thank you again for your kind help! You got me on the right track to solve the problem. As far as I can tell, it was a combination of two things: First I was probably a bit lazy in using the knee lift all the way... there's a pronounced stop/resistance near the top of the lift and I guess I was usually stopping right there. But if I push past it, it raises the presser foot even more and releases the top tension. The other thing was that I hadn't readjusted the bobbin thread tension when I changed back to black thread. So to compensate the upper thread tension was really tight. I'd gotten so used to simply changing between red, white and blue threads (same type and weight) without having to change the tension that I forgot to change for the black. Now it's much much better. No quite perfect yet (I still sometimes break the thread) but day and night better. Thank you again. -

Top thread breaks when removing work

MtlBiker replied to MtlBiker's topic in Leather Sewing Machines

Thank you! I'll check what you suggested when I get home tonight. One of the first things I did when this started happening was to put in a new needle. Problem was still there. I also doubt there are burrs on the top tension discs as there was no problem at all with the red, white and blue threads. Unless the stiffer black thread would show up that problem and the others wouldn't. I'm suspecting it's user error. It just could be (and I'll confirm tonight) that perhaps I was being lazy with the knee lifter and maybe, just maybe, I wasn't lifting the presser foot all the way up... maybe just enough to pull out the material. Newbie mistake. I will check for that. The other thing it could be (again per your suggestion) is that I've got the tensions too tight. I don't think I readjusted the bobbin tension for the black thread when I switched to it. I'd gotten used to (for the last month) being able to pop in the white red or blue threads and not having to change any tensions. But the black IS more stiff and I probably should have loosened the bobbin tension. Great call on your part! I'm sure your suggestions will help me solve this. Thank you very much, kind Sir! -

Lately I'm having a lot of trouble with my Consew 206RB-5 breaking the top thread when I try to pull the work from under the presser foot. I've replaced the needle (#20) and checked that the threading is correct, and I really can't figure out what might be causing this. But I am very much a relative newcomer to sewing. I didn't have any trouble with the v92 blue, red or white bonded poly thread I'd been using for the last month, nor with the black thread I'd been using before that. When I changed back to the black thread a few days ago I did have to readjust the top thread tension (black thread always seems to require different tension settings than white, red or blue threads and I don't know why that is either). Before trying to pull out the work I always turn the hand wheel so that the arm (not sure what it's called) is at the top and I raise the presser foot usually with the knee lifter. This has always worked fine hundreds of times. But now almost every time I try to remove the fabric, my top thread breaks. What could be causing this? What should I check? Thanks for any help.

-

Thanks so much for the further info! I just wasn't thinking of drilling into the flatbed part of the machine (duh!) which is why I couldn't see a use for the right-angle drill. As far as custom making some kind of mounting for the right-angle binder attachment I have, with my lack of experience with binders, I don't think I'll tackle it. I don't even know exactly where the binder attachment needs to be positioned for proper binding, so wouldn't be able to make a mount in the proper place. I wish I could see a properly set up machine in operation and then I'd probably have a better idea. If I can find one of those binder throat plates and feed dog, would the holes in the plate be correct for attaching the binder in the right place? I'm talking fore and aft, not side to side which could probably be adjusted. Is installing the binder throat plate and feed dog something complicated? Is it straight-forward, or is there some careful adjustment needed? I'm asking because I wonder how convenient it is (or isn't) to switch back and forth from regular sewing to binding. I've often heard that some people dedicate a machine to binding (I certainly wouldn't be doing enough of it) which makes me believe it might be somewhat complicated to set up.