-

Posts

284 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Store

Everything posted by DwightT

-

I've always tried to use the concept of ""put you tools back in the same place so that you can find them next time". My problem in the garage though is that every so often my wife gets a wild hair and decides to reorganize, and it takes me several weeks to get used to her new system. So far she hasn't touched my leather tools, so I can't blame her when I can't find one. /dwight

-

Looks great. Maybe someday I'll take on some painting / dying like that. For a closure, how about just a tooled leather strap and buckle? Tool and color it to complement your current design, then you could possibly attach it to the back of the case or just leave it unattached like your current bootlace. /dwight

- 10 replies

-

- coloring

- floral carving

- (and 4 more)

-

Used to do the river skiing thing when I was a kid, but we didn't use bungee cord or a barrel. We just used rope to attach the ski to the middle of a bridge. As long as the rope was long enough we could launch from the river bank. Been more years than I want to admit since I last did that. /dwight

-

My Second 22 Pouch

DwightT replied to Brokenolmarine's topic in Gun Holsters, Rifle Slings and Knife Sheathes

Looking good. And thank you for the idea of gluing two pieces together for the sewing. I have to do some edge stitching for a project that I'm working on, but the holes keep tearing out because I'm using old leather. This will solve that problem for me, plus give me another tooling surface where I can add some additional customization. /dwight -

Laserjet toner is essentially composed of polymer beads that are "fused" to the surface of the paper with heat. I'm not exactly a chemist, but I would imagine that the acetone breaks the bond between the paper and the polymer and lets it settle onto the leather. Once the acetone evaporates the polymer adheres to the leather. I'm guessing though that it isn't a strong bond, and over time the toner would wear off. Inkjet ink though really is ink that has absorbed into the fibers of the paper. The developers of the inks have actually put a lot of R&D time into making those inks stay put even when they get wet, so it's not surprising that you couldn't find something to make them transfer. As interesting as your laserjet process sounds though, I think I'll stay with the transfer film method. Since I can see through the film I would imagine that it would be easier to align the pattern on the leather piece. I may try your process on a sample piece though just to see how it works. Thanks for the description. /dwight

-

I'll ditto what Tequila says. I print it out, then trace over the image with a pencil onto transfer film. One of the advantages of this is when I'm transferring the image to the leather is that I can see through the film to verify that I've hit all the lines, and to line everything back up if I missed some. But tell me more about your laser-printer transfer process. I used to work in laser-printer development (I wrote the low-level code for some control panels) and I have a laser printer in my home office (retirement gift). I'm not too sure about using acetone on leather, but if the process works without damaging the leather it might make my life easier especially with small projects where I've scaled the image down. /dwight

-

Yes. The dice cup I made a while ago was actually a trial run for this. I had thought about just making a sleeve, but I felt that having a base would make it stronger. Plus it gave me a place to put my "Handcrafted By" stamp. /dwight

-

I'll have to give the Carve Ezz a try. Once I got away from that edge it hasn't been too bad, but it definitely doesn't carve or punch like new leather. Part of it was probably how the leather was stored. In my case it was rolled flesh side out and tied with a cord. The roll has been stored in the garage for the past ~20 years, which means that it has been subjected to hot/cold cycles. The leather that was in the outer layer seems to be in the worst shape. I was just going to leave it be, but then I decided to go back and finish the edges. I applied several thin coats of tragacanth gum, burnishing between each coat. I have a wooden burnishing wheel that mounts in my drill press, so it makes it fairly easy to cure the gum. Looks a bit better now. /dwight

-

My son was recently promoted to vice-principle at a local high school, so I got a Yeti Coffee Cup for him and made a leather koozie for it. Still not my best effort (I hate the border), but I'm still experimenting and re- learning as I go. The whole thing is filled with symbolism for him: I made it, the rose is for his mother (she loved roses and always had a rose garden), the purple of the cup is for the pancreatic cancer that took her from us, and the silver on his name is one of the colors for his new school. Overall he is happy with it, so I'll ignore the flaws for now. /dwight

-

As I mentioned in my intro post a few weeks ago, I'm returning to leather work after a 30+ year hiatus. I have a bunch of tools and stuff from back then (along with some really old tools that I inherited from my grandfather), and I have most of a side of leather that I bought probably 40 years ago. Recently I finally got around to trying my hand at making a dice cup following the instructions in "The Art of Making Leather Cases" book and I cut the leather for it from that old side. For the most part the leather took the tooling OK, but when it came time to do the stitching I ran into some problems. Basically the leather was very stiff along one edge (what had been the edge before I cut it from the side) so I had a hard time in getting the awl to go through. The awl was freshly sharpened so I know that it wasn't from using a dull awl. It was just very hard to push through that edge and it ultimately stretched the leather to the point where I couldn't get a clean joint. I'm still mostly happy with the project, but if I do any other projects with that leather and I have to sew it, I'll pre-punch the holes with a stitching chisel. /dwight

-

I'm stealing that idea. I'm also working in a small space, so your shelf unit will help me to get my tools organized. I love the way that you tilted the tool block to make it easier to see the stamps. /dwight

-

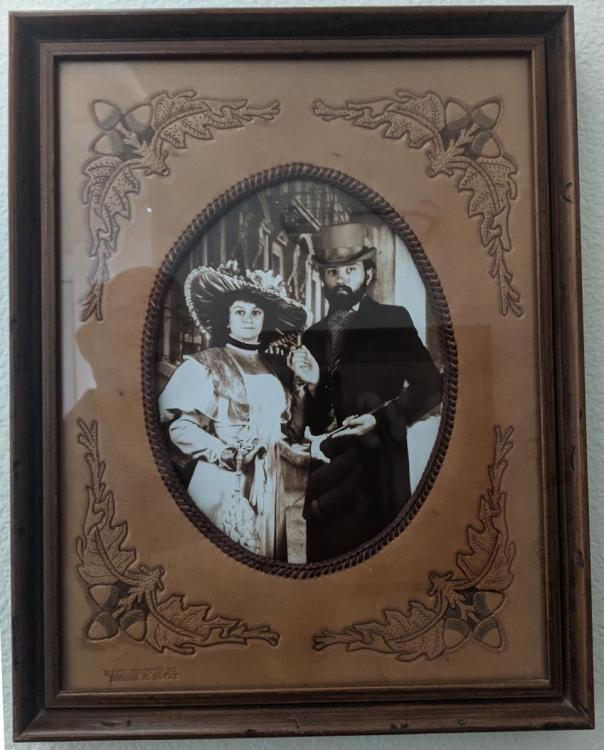

Just for grins, here are some of the things that I did back before my hiatus. Maybe I'll be able to get back to this kind of stuff again. This was the panel on a briefcase that I used for many years. The briefcase eventually fell apart, but I liked the panel (even though it got fairly well stained over the years), so I kept it. Maybe I'll figure out something else to do with it some day. This is the clock that's in my office. I did several of these back then for family and friends, and I still see some of them being used today. This was a photo frame for an old-time photo my first wife and I did when we were first married. I lost her to cancer in 2010, but I'll keep this photo forever.

-

Yeah, when I was signing up I tried for the username 'Dwight'. The site told me I couldn't have it. There aren't a whole lot of us out there. /dwight

-

Hello all and Greetings from Meridian Idaho. I'm not completely new to leather work - I used to do a fair amount of leather tooling (mostly belts, wallets, and purses for friends and family), but until recently it had been something like 30 years since I last swung a mallet. However even back then I wouldn't consider myself to be any type of expert. Now that I've retired I've decided to get back into it again. So far I've really only done a practice round to get used to the idea of tooling, and made myself a wallet from a Tandy kit. I'm not completely happy with the wallet (it's a bit thicker than I would have liked and next time I'll use a different style of letters), but it will do the job for now. One of the things that I want to work on is leather cases. I ride with the Patriot Guard Riders to stand flag lines at the funerals of veterans and I'm thinking about making a leather flag case. I have Volume 1 of the Stohlman book on cases, and I'm thinking of a case based on the fishing rod case in that book. However I'll probably start with the Dice Cup described in the book just for the practice. I look forward to getting (and maybe eventually offering) advice and feedback on hopefully many leather projects. /dwight