-

Posts

284 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Store

Everything posted by DwightT

-

Beautiful. I may have to look at making myself a set one of these days. And your stitching looks pretty awesome also. /dwight

-

Nice. Gives me some ideas for some of the cigar smokers in the family. /dwight

-

Takedown fly rod/reel case

DwightT replied to GrampaJoel's topic in Satchels, Luggage and Briefcases

I finished a dice cup today using your technique (mostly) for the base. I'll need some more practice, but I have to say that I like the process and the results much more than the flush base that I was doing. I started by cutting a circle that had a radius that was about 3/8" longer than the circle that I would have used for a flush fit. After skiving and wetting, I did some initial shaping over the Campbell soup can that I was using as a mandrel. I then inserted it into the tube, smoothed the fit and stitched it in. Next I cut off the excess (about 1/8"), and finished the edge as normal. As I said, I think it looks a lot better than what I was getting before. /dwight -

Takedown fly rod/reel case

DwightT replied to GrampaJoel's topic in Satchels, Luggage and Briefcases

Thanks. Seems so simple that now I feel like an idiot for asking (but the only foolish question is the one that isn't asked). I was thinking that you would have to have cut a dart in the inner rim to get it to fit properly. I didn't even think about wet molding. Haven't done any yet, so it just didn't come to mind. I'll be trying that in the next day or two on the next cup that I do. Thanks again. /dwight -

Carved Holster

DwightT replied to Bawarrior's topic in Gun Holsters, Rifle Slings and Knife Sheathes

Beautiful work. Especially with the lifter. I have got to get more practice with that tool. /dwight -

I also did the "social" media thing for a while. Originally it was a convenient way to keep in touch with my daughter when she moved to the other side of the country. But with the way it has devolved over the last few years and as Chuck mentions the total narcissism that it seems to breed, I've pretty much given up on it. This forum and one motorcycle related forum are about the only types of online discussion areas that I'm involved with any more. /dwight

-

Small workspaces almost require some level of neatness. Otherwise there wouldn't be any room to get any work done. There is actually only one can of NeatLac. The other can is NeatLac Thinner. Basically acetone. I bought both of them way back when I was in high school, long before the digital age. There is about a third of the can of the NeatLac left, and it is actually still good. I don't use it too often though. It doesn't seem to work well with the gel stains that I use. /dwight

-

Takedown fly rod/reel case

DwightT replied to GrampaJoel's topic in Satchels, Luggage and Briefcases

Hi Joel - I'm looking at the recessed base disk in this photo: In the dice cups and bottle totes that I've been doing I've been using a flush box joint: It works, but I think that having a recessed bottom like yours would be better, plus I would be able to do a better job of finishing the edges. Thanks /dwight -

Takedown fly rod/reel case

DwightT replied to GrampaJoel's topic in Satchels, Luggage and Briefcases

Beautiful work. I like how you did the base with the recessed bottom. Can you describe how you do that? Do you cut a dart in the rim? /dwight -

Lets hear it for small workspaces. My tool rack is based on one that I saw in the forum - I think it was brokenolmarine. Works well for me. /dwight

-

That is gorgeous, and high quality workmanship. Good job! /dwight

-

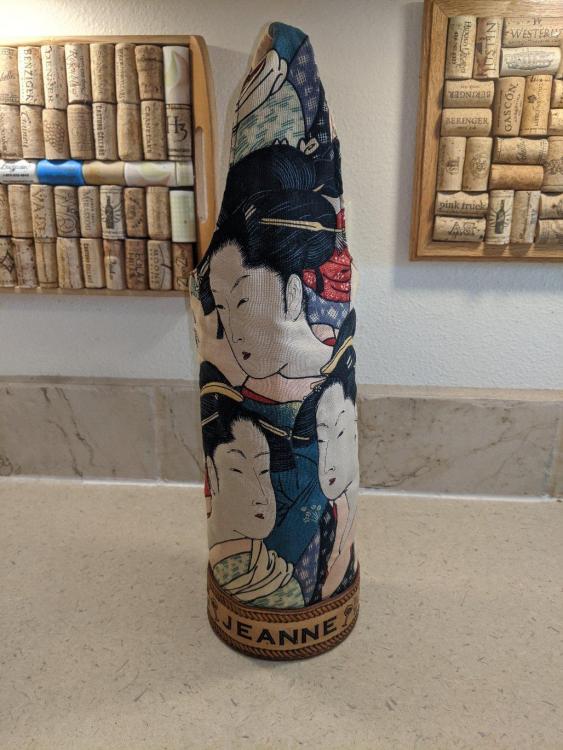

Wine Totes

DwightT replied to DwightT's topic in Purses, Wallets, Belts and Miscellaneous Pocket Items

Thanks for the kind words. We came up with a few different designs during the process, some more successful than others. With 7 kids between us and all their spouses, doing these bags gives us a way to give each kid something fairly unique for Christmas. Right now she is working on a patchwork leather bag using my chrome-tan scraps (that's what prompted her to organize my scrap bin the other day). It should be interesting once it's complete. /dwight -

When I got back into leatherwork a few months ago, my wife felt threatened because she thought family and friends would like my stuff more than her quilting (poppycock). So we came up with a way to collaborate by combining her quilting with my leather and including our mutual interest in wine: quilted wine totes with a tooled leather base. It's been a lot of fun working with her on the design and fabrication. /dwight

-

Thanks a lot. Now my wife wants me to make a couple for the Barby doll collection that she keeps for the grandkids. /dwight

-

Welcome from Idaho. You'll find lots of good info here, often just from digging through the archives. Lots of friendly people ready to answer questions and give advice too. Looking forward to seeing your work. /dwight

-

I have to confess - when I got back into leather a few months ago, I sorted my scraps into veg tan and chrome tan bins. That was the chrome tan bin and since I haven't really done much with chrome tan... Most of that is from the bag of scraps that I inherited from my grandfather. My veg tan bin has a bit more in it. And I can't believe that I'm really in a discussion comparing the size of scrap bins. Seriously? /dwight

-

I'm going to have to try one (or two, or three) of those and play with it, but I would think you would do a "faded" bevel where you start heavy at one end of the line and fade out towards the middle. Then you fade in on the other side, ending heavy at the other end of the line. But I think Handstitched is right: most of the effect will come from proper coloring & shading - which is something that I personally am horrible at. /dwight

-

'Crocodile Dundee' inspired hat band

DwightT replied to fredk's topic in Clothing, Jackets, Vests and Chaps

That's not too bad then. I've had some hats where things like that added significant weight and by the end of the day my neck was screaming in pain from holding it all up. Regardless the hat stilllooks great. /dwight -

Hello from western Idaho. As has been stated, lots of good info here. It's pretty amazing what you can learn from the people here. Welcome to the forum. /dwight

-

'Crocodile Dundee' inspired hat band

DwightT replied to fredk's topic in Clothing, Jackets, Vests and Chaps

That looks awesome. Have to ask though how heavy it is. Seems like all those antler tips would add a fairly noticeable weight. /dwight -

That was exactly my point. Half the time I'm not looking for a specific piece of leather. I'm usually looking for inspiration for the next project. /dwight

-

I should have known better. My wife wanted some leather for one of her projects, so I handed her my scrap bin. Next thing I know she has sorted my scraps by type and size. This completely goes against how I look for scraps. /dwight

-

Finished the suspenders finally!

DwightT replied to YinTx's topic in Clothing, Jackets, Vests and Chaps

Absolutely stunning! -

I can agree with that. I would like to see a simple list of the person, their location, and the tool/service that they offer. Beyond that prices and other specifics can be negotiated at the time of order. No need to have multiple posts showcasing every tool that you may offer. I think just a single entry in the list should suffice. But that's just my opinion. /dwight

- 10 replies