Search the Community

Showing results for tags 'industrial machine'.

-

$1200 OBO located in Orange County, CA less than a year old. Runs great and has only been used a handful of times. I upgraded to a Servo motor. It also has a table. We are moving and I unfortunately can’t take it with us. The FY335A is a Medium to Heavy Duty Walking Foot Cylinder Bed with Compound Needle Feed or (Unison Feed) Lockstitch Sewing Machine with an “M” size Big Bobbin and end of the cylinder Big Size Rotating Hook mechanism. The FY335A machine includes a lever-operated stitch length mechanism with a reverse feed regulator for back tacking and stitching in reverse. Some additional features of the FY335A include a semi-automatic lubrication system. The machine sews thread from size z-46 up to size z-207 in the needle with up to z-138 in the bobbin. SPECS Sew up to: 7/16" Thread Size: Up to 207 / Reverse feed Speed, Max (SPM): 2500 Presser Foot Lift by Hand: 5/16" (8mm) Presser Foot Lift by Foot: 1/2" (13mm) Needle: 135x17, DPx17 Needles System Stitch Length Max: @4.2 SPI (6mm) Cylinder Diameter: 1-31/32" (50mm) Work Space: 10-5/32" x 4-11/32" (258mm x 110mm)

- 2 replies

-

- sewing machine

- industrial machine

- (and 7 more)

-

Hey folks, I'm having a problem, hoping someone can help. In forward stitching the tension is perfectly balanced, but when I reverse it the upper thread is very tight. Any ideas why this happens, and what I can do about it? The forward/reverse stitch length balance is perfect, so I've eliminated that as a reason. This is on a Singer 591, but if you know about this issue on any machine I'll be interested, since it's a problem I encounter a lot in the machines I work on (this case is just particularly bad). A video of the issue is here: https://youtube.com/shorts/jY-ETcKG2AM?feature=share I used a lightweight cotton so that the issue would be obvious, but it bunches with lightweight leather too. Machine: Singer 591 D300AD Thanks, Alaina

- 6 replies

-

- industrial machine

- tension problem

-

(and 1 more)

Tagged with:

-

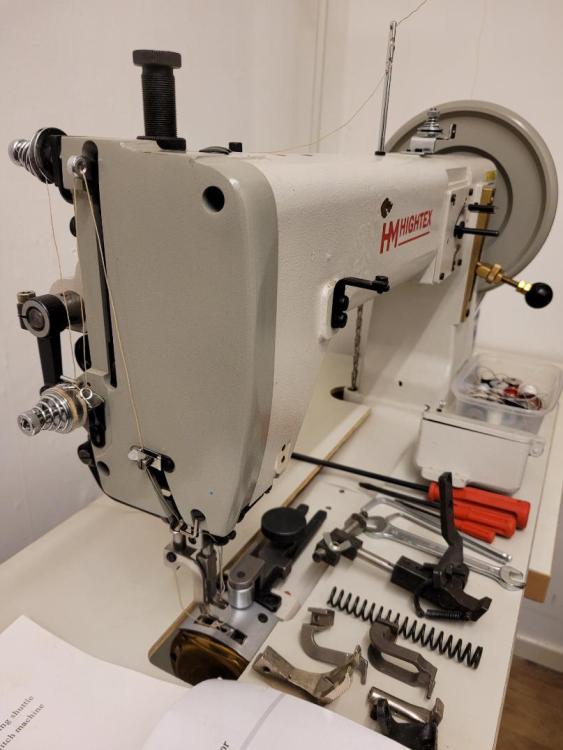

Due to health issues I'm no longer able to continue with my leatherworking business so I'm selling my beloved CB4500. It's Hightex branded but identical to the Cowboy machines available in the States. I bought it from Franklins in the UK in autumn 2019 for making dog collars. Covid hit at the worst time and that business never took off so it's only made the odd guitar strap and journal in the last 5 years. I've maintained it well with regular oiling in all the right places and it runs as smoothly and fault free as it did when it was delivered. I've only ever stitched 2 layers of 2.5mm veg tan at most. It has the standard speed reducer fitted so can sew at super slow speeds which is why I bought it in the first place. If you are looking at this you're already know that these machines are absolute monsters and will stitch through just about anything. The torque is unbelievable. It comes with removable table, drop down stitching guide, sliding roller guide, all the original tools and top oil reservoir. It also comes with at least 10 empty spools, 3 packets of various sizes of needles and a box of bonded nylon threads in various colours ranging from 20s upto 8s. There are a few marks on the table due to clumsy old me spilling dye on the adjacent bench in my workshop and it splashing everywhere. There's a tiny chunk of paint come off the front from when I removed the stick on LED light. The machine is located in Mirfield, West Yorkshire, UK. It's on the first floor of a building with easy access down a very wide flight of carpeted stairs. It will need the head unbolting to get it downstairs and at least 2 strong people. I got it up there with the help of my son. I've left it as is for now so it can be tested by the buyer, but it's only a 10 minute job to dismantle. Sadly I'm unable to offer any help lifting due to my health issues now. You will need a van ideally unless you want to dismantle the based and the table completely. It will all fit (just) in the back of a Zafira or similar people carrier. I have a couple of short videos of the machine stitching which I can send if required. (I can't upload videos here as they are too large). I'm looking for £2200 or very best offer. Please e-mail me at blackorchardleather@hotmail.com with any enquiries and I'll give you my phone number so we can discuss viewing arrangements etc. Thanks Andrew

- 1 reply

-

- cb4500

- industrial machine

-

(and 2 more)

Tagged with:

-

Hi! I'm totally new to this machine- I usually sew for a sheepskin tannery on the isle of Skye in Scotland using a one thread overlocker, and at home using domestic machines. My workplace is shut indefinitely due to bleedin covid19, but they've given me loan of a Seiko Stw 8b to see if I can make use of it if and when I go back. I've looked at several grainy manuals online for it, and I think I've neeeaarrly got it going... Its been sitting untouched in an office for ages so I've oiled it, changed the needle- I'm worried I've made a mistake somewhere threading it, and also worried the timing might be out maybe- if it was one of my machines at home I would change the needle and rethread.. any advice would be amazing! I've attached pictures of the wonky stitching and my probably wonky threading. Cheers!

-

Hello, Leatherworkers! First off I would like to thank you for your sharing your extensive expertise. I read @Wizcrafts' sewing machine thread and have been lurking around this message board for weeks. I've definitely learned more about machine mechanics and specs here than anywhere. I really appreciate the breakdown explaining the various machine types, feeds, walking foot vs add-on foot, etc. I'm a professional seamstress with a market opportunity for alterations in Irish Dance dresses. Think Riverdance. Modern show/competition costumes are constructed with a particular double pleat skirt, with extensive stiffening materials (sometimes plastic or cardboard), on thick fabrics (duck, velvet, heavy satin, sequin, embroidered). This is to create the distinctive flat, sticking-out skirt. The skirt-to-bodice seam easily can be in excess of 1/2" thick. Example of a dress here: https://irishdancedresstoimpress.com/product/dress-11916/ My kids are Irish dancers and since I have done some alterations on their costumes, as well as some friends' costumes (mostly rescues from the damage done by local tailors), I now have many requests. But I can't get that blasted double-pleated skirt-to-bodice seam through my domestic sewing machine. Hence, researching industrial machines. My goodness. I had no idea there were so many possibilities. I asked my group of specialty Irish dance seamstresses what they recommend, but no one comes even close to this group's ability to break down the why's and wherefore's of my options. I'm pretty sure I've narrowed my search to a true walking foot machine with more than 1/2" clearance under the presser foot -- though some of the seamstresses say they are doing fine with high clearance on a regular double-toe foot. Juki was originally recommended to me by a trusted seamstress, but Wiz raves about his Consew machines so much, my horizons have expanded. :-D What I'm hoping for here is maybe to connect with someone with a used machine for sale, a dealer, or any and all advice & guidance the group might be able to offer. I think I will need to buy something used to get me through the upcoming fall seasons and then save up for an "ideal" machine. I know most of my particular craft doesn't apply to leatherworking, but the best mechanical information is here. Perhaps somebody is able to "interpret" my needs, or can point me to a different group that has a closer specialty (but can also explain the mechanical pros and cons). I'm located in Jacksonville, Florida. Thank you very much for reading my message and considering my questions.

- 9 replies

-

- machine

- industrial machine

-

(and 3 more)

Tagged with:

-

I just ordered a Pfaff 1295 post bed but can't find information on what the best weight of nylon bonded thread is to use on this machine. Any recommendations? Thanks guys!

- 2 replies

-

- industrial sewing

- pfaff 1295

- (and 4 more)

-

Great machine if you can’t afford to spend thousands on a leather sewing machine. I’m starting nursing school and won’t have the time for it and I need money. https://redding.craigslist.org/for/d/igo-pfaff-545-walking-foot-industrial/7216319921.html

-

I've been scouring this site for information on industrial sewing machines. I'm looking for a machine to do rugging for taxidermy. It needs to go through 2-6 layers of 11-18oz felt and the hide (bear, coyote, etc). I have previously used industrial sewing machines for garments, so these heavy duty machines are new to me. From what I've read on this site I'd like to try find a Consew 206RB-5 (or any subclass with reverse) or a Cowboy machine, maybe the 3200. I'm open to other machines that have a reverse and large capacitity bobbin. Before I make the plunge can anyone give me some feed back on what walking foot machine would be good for me or should I be looking for something with a rolling foot? Should I find something to sew up to 1/2" thickness or is that overkill?

-

Hello! Ive run across a group of Zoje brand sewing machines, one of which is a double needle post machine which I've been looking for! I dont know anything about this brand, but I did read that someone found them similar to Adler machines, and considered them a Juki replica- anyone have any advice or information to share? Picture attached. Thanks, Erin

-

Hi! So I've been working on a relatively newer Pfaff 335 machine and it's been getting the job done. After sewing an entire colonial style jacket out of leather and suede on a commercial machine, I finally upgraded; however, I'm beginning to think I'm making life harder than it needs to be by not using the correct settings for each job. I generally use a 17/105 or 18/110 diamond point needle for most things and the forum recently helped enlighten me about materials / needle / thread combos with the charts I found. I use a flat plate and the feed dogs in the pic below. I work on wallets, duffle bags, jackets, dopp kits and a lot of random luxury items. I even make soft leather holsters. After scouring the site and the manuals, I'm having a hard time finding good resources for what tools do what with my machine i.e. If I'm making a nice, burberry or cole haan type wallet with (fill in the blank type leather) (fill in the blank weight), I'd love to find some sort of 'standard practices' guide that answers: what needle and thread would I use? if binding edges, how to operate the edge binder and how to choose the size feeder etc etc what type of leathers are --typically-- used and what range of leather thickness? if skivving, how thin? when stitching zippers, which feet to use for the machine? I realize this just gets honed with time and each project is unique depending on the tastes but there has to be a guideline? I've figured out a lot thus far but it takes forever. Any help, resources, tables and/or charts are immensely appreciated! Thanks in advance!

-

- industrial machine

- feed dogs

-

(and 4 more)

Tagged with:

-

Hi, this is my first post on leatherworker! I have an industrial machine, a singer, for very lightweight sewing (I had to order special narrow needles) so I am looking to buy a new machine for sewing thick leather, 5-7oz I have found some good machine heads on ebay, Consew 255B, Singer 211W115, and very old but apparently in good working condition Singer 111W115 (someone I worked for had this exact machine, also old but very beautiful and reliable stitching) My current table and motor are in great condition, the motor is a Tacsew, clutch, 5.8 amp. My question is...possibly a dumb one...but will any/all of these machine heads fit and run with this motor? I read your post about clutch vs servo, but still felt unsure about combining a different head with my existing clutch. Thanks in advance! here is a photo of my motor.

-

Howdy from Farmville, VA! Yes, Farmville is a REAL place:) My husband is a cowboy from TX who enjoys leatherwork, he creates mostly custom tack for our roping horses and can repair just about anything to do with leather. His Singer home machine just broke and we just purchased an old industrial SEIKO machine walking foot and cylinder arm which I believe is a CW-1. It works well but has no paperwork with it. I have been searching for days to find a manual and to try and determine what size needles I should order and what size/type of thread. My husband is old school and did a lot of his work by hand. I need help! Any and all would be appreciated:) I have attached some pics of the machine in case anyone is interested or knows exactly what we have. Thanks!

- 7 replies

-

- needle size

- thread size

-

(and 2 more)

Tagged with: