All Activity

- Past hour

-

Tandy Leather. Nickle Plate Wide Double Cap Rivets.

RWentz replied to Allen Hiltbrand's topic in Leatherwork Conversation

You might take a look at weaver leather's rivets i have had great success with them. - Today

-

spring flowers and good food

chuck123wapati replied to chuck123wapati's topic in All About Us and Off Topic

My sanity has always been questionable lol. So i watch my share of your tube videos and ran accross a guy who makes wild clay pottery. So now I have to learn to make some pottery. I found about four different types of clay so far and am testing them all out. Man, i have dirt and mud everywhere lol. But i think i found decent clay and have made some test pots. dont quite know how i can use clay and leather together, but I'm thinking. Next week, maybe do some rock hunting too. Lots of Jade, agate, fossils, and even opals close by. -

Nakajima 321L is this worth the $1400 price tag?

kgg replied to leatherforge's topic in Leather Sewing Machines

The problem that arises is when sewing multi layers like seams where seams cross etc. The more layers adds not only thickness but the layers can slip around when you are using a drop foot machine. No one machine will do everything. A flatbed machine is good for sewing flat items like belts / wallets etc. A cylinder bed machine is good for sewing items like bags etc. You can turn a cylinder bed machine into a flatbed machine by installing a flatbed table top attachment. The most common new industrial sewing machines for leather related sewing these days are compound feed (needle, presser foot, feed dog). I have a Juki DU 1181N walking foot machine for when I sew items that are less then 5mm (~3/16") thick and with thin thread (V69, V92) as my Juki DNU-1541S really hates thin stuff particularly if I use V69 thread and it has a tendency to want to suck fabric down into the needle plate. I would suggest taking a sample of your stuff to a brick / mortar store using the thread size you would like to use and give a few machines a go. As a note if the: i) Flatbed -- Juki DU 1181N would work for your stuff they cost about $1500 new. ii) Flatbed -- Juki DNU 1541S about $2500 and a clone like the Cowboy CB 1541S about $1600 iii) Cylinder Arm -- Juki LS-1341 about $5200 and a clone like the Cowboy CB 341 about $2400 A lot is going to come down to how thick your wallet is. Buy Once, Cry Once kgg -

Seiko STW-8B Seam length and presser foot height -

Constabulary replied to Zonker62's topic in Leather Sewing Machines

The Juki 562 / 563 manual is probably the closest for your SEIKO STW8. See attachment. Can you post pictures from the underside of your machine maybe the stitch length has been limited for what ever reason. Juki 563 562 Manual.pdf -

Hook to Needle Distance: A Compromise

Constabulary replied to friquant's topic in Leather Sewing Machines

You probably have to play with the needle bar height. Have you checked the NB height / needle - hook timing? Procedure should be mentioned in your manual. If it was me I´d probably try lo lower the NB a tiny bit so you will have a bit larger thread loop. But thats just me from a distance. Hard to tell what it going on when not in front of the machine. -

maninabluebox joined the community

-

looks good, hope you have fun with this machine and it suits your needs 😃

-

AlZilla started following CAMOGA C400 Leather Splitter

-

The edit window only lasts a short time. Go ahead and list it in a reply. Someone will probably add it back to the original post so it's there, too. Thanks

-

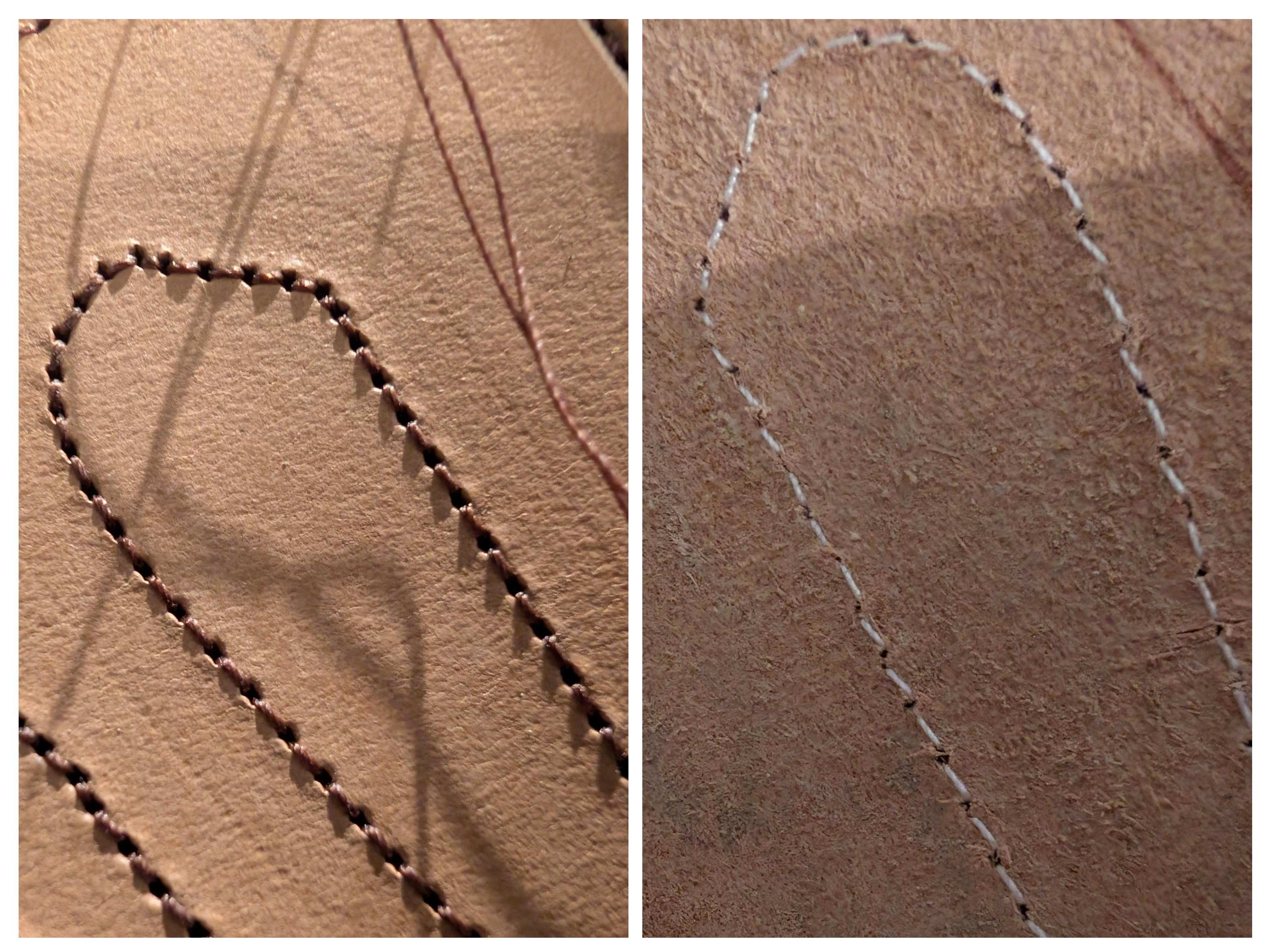

Thank you for all the information and help. This is how it's currently sewing. The white thread is thinner than the brown but it's the only other thread that was a contrasting color to see if my tension was right.

-

mansirani joined the community

-

Seiko STW-8B Seam length and presser foot height -

Zonker62 replied to Zonker62's topic in Leather Sewing Machines

Hi! Thanks for the replies. F&R are exactly the same and there's a beautiful reverse giong in its path. I will post a video so you can see and diagnose but I was looking for something written, 'cause both Seiko/Consew manuals are scarce on the tuning... -

Luna Liberty joined the community

-

Markdor9613 joined the community

-

Nakajima 321L is this worth the $1400 price tag?

leatherforge replied to leatherforge's topic in Leather Sewing Machines

Thank you so much for your response! I had a suspicion that this machine was very old and overpriced. I think that you have confirmed my fears and saved me some travel time. It's a good call to buy a machine made by a company still in business. I don't think that you "need" a walking foot machine to sew leather depending on what you're sewing. In this case I am looking for a machine that can sew soft to semi-soft temper leather for bags, garments, and accessories. Nothing super thick. I have seen needle feed machines used with great success for these purposes. I was hoping to find something that would make sewing zippers into leather reasonably smooth. What kind of machine would be adequate for that do you think? -

I really like this one the best. Clean, neat, great color and excellent tooling and stitching. Something I would carry myself.

-

LWcom link to older thread / similar discussion . - https://leatherworker.net/forum/topic/95016-roller-foot-could-you-and-would-you/ -

-

What do i do now. Why there is no edit option.

-

Didn't know that. Thanks for sharing I ordered a bottle of Dark chocolate Fiebings Low VOC this morning. I'll report back once it arrives and let everyone know how it looks. I think with a deeper brown that doesn't have any orange tint, I should be able to dilute it and get a nice light brown. Thanks everyone for chiming in!

-

You forgot to post the price. It is required.

-

You should tag or quote the user you want to correspond with as not all users have properly setup their notifications. To tag, type the @ symbol followed by the user's screen name and pick it from the popup box. Like this @Radam you have someone interested in your clicker press, see above.

-

Since you want a steel rule die bender, I split your post off its initial location and moved it to the Marketplace > Wanted. This is where it belongs.

-

I have not used that needle system, but for my machine there are at least two names for the needle system. So if the needle packaging includes the needle system you're after, I would tend to believe it. Also I found this old post that has a little bit of info on 7x3: https://leatherworker.net/forum/topic/1830-needle-help/ If you do end up going with an alternate needle system in order to get the size/point you are after, at least it's only the needle bar height that needs to change. (Much easier to adjust than hook timing on my machines at least)

-

Scoutmom103 started following Hook to Needle Distance: A Compromise

- Yesterday

-

AlZilla started following Hook to Needle Distance: A Compromise and Consew 206RB-2

-

@Phil Royce I moved you to the Marketplace. We also require location, shipping info and a picture for machinery. Rules are linked here, FYI: https://leatherworker.net/forum/forum/71-items-for-sale/ .. Thanks

-

Phil Royce joined the community

-

Hook to Needle Distance: A Compromise

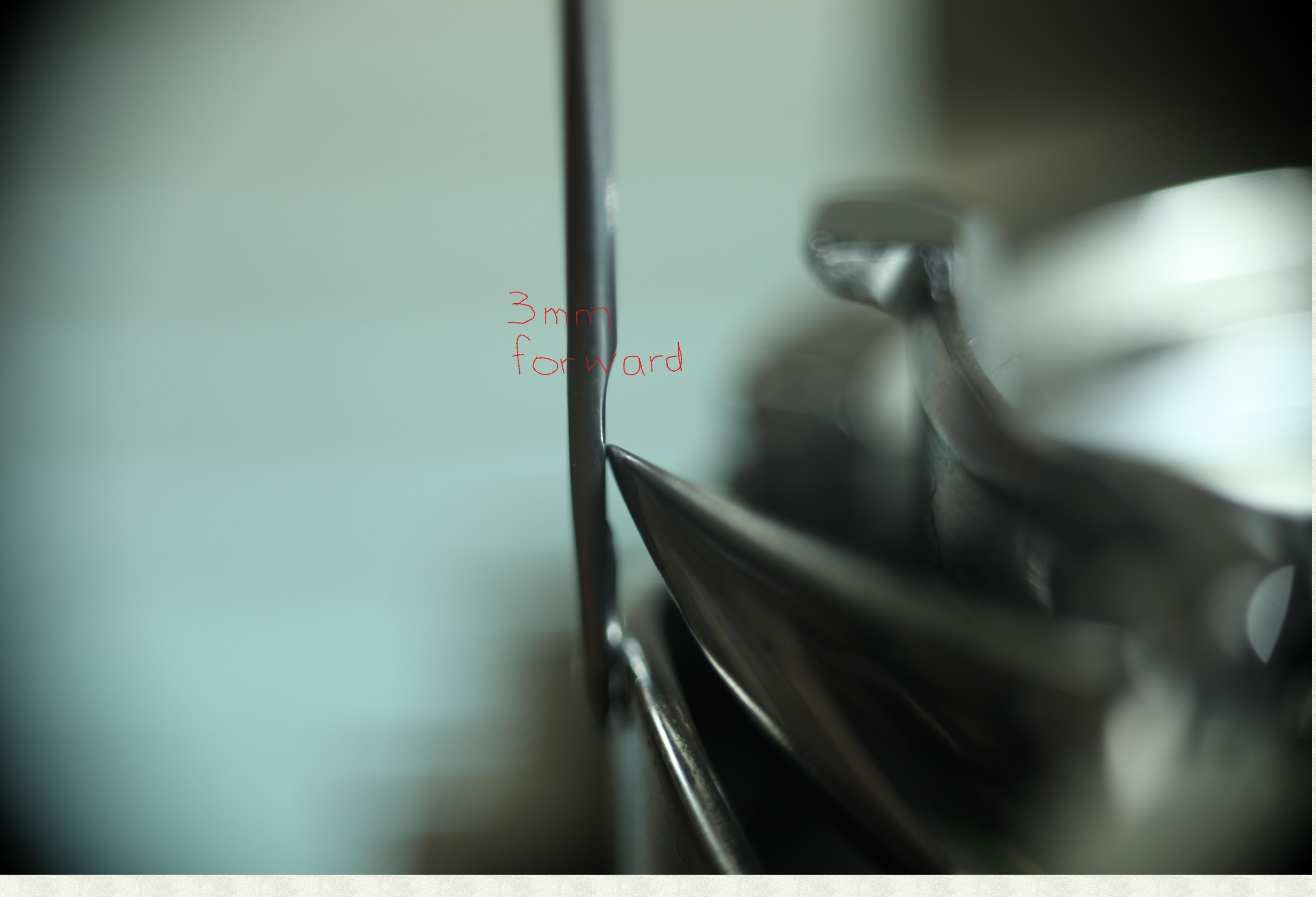

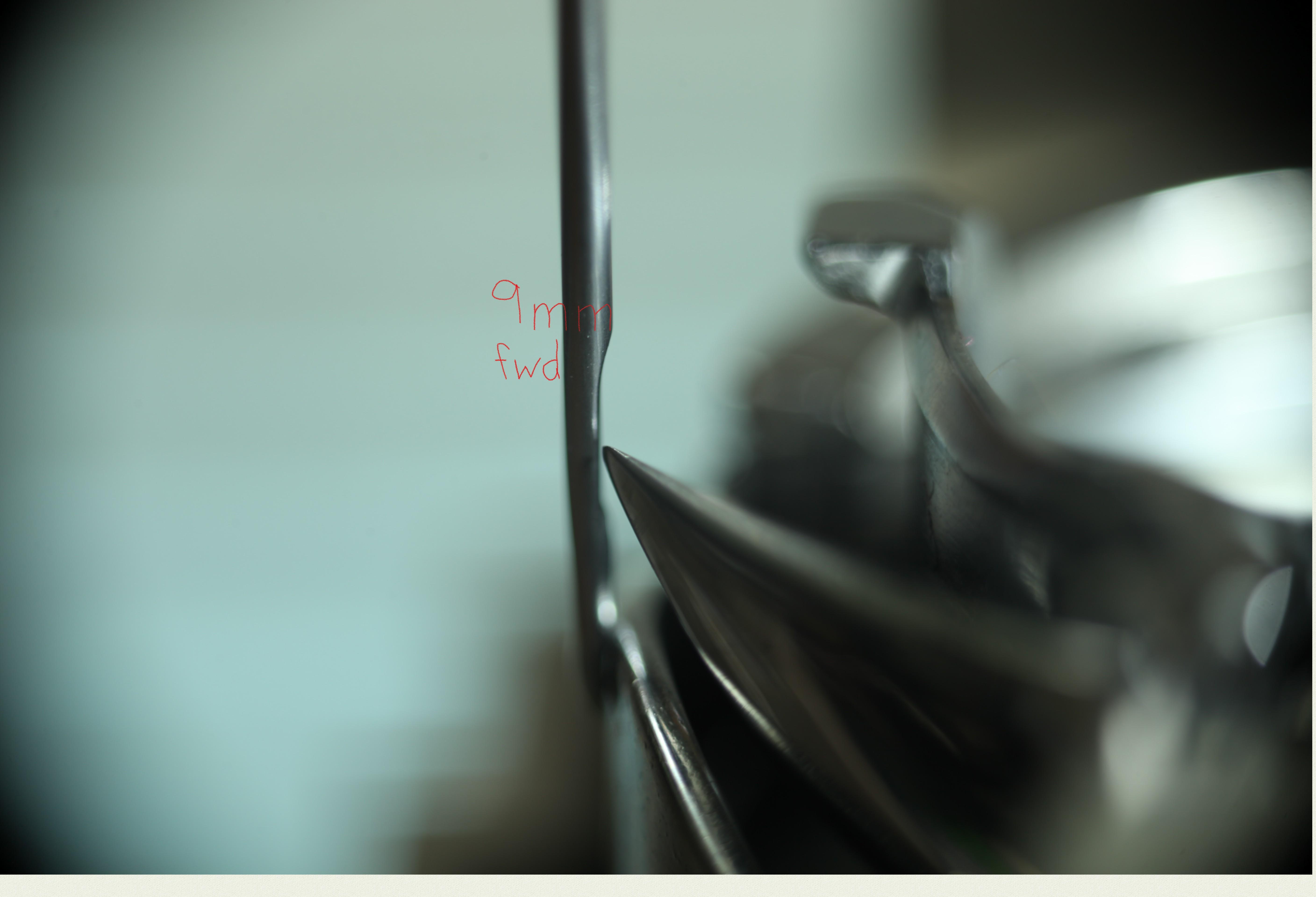

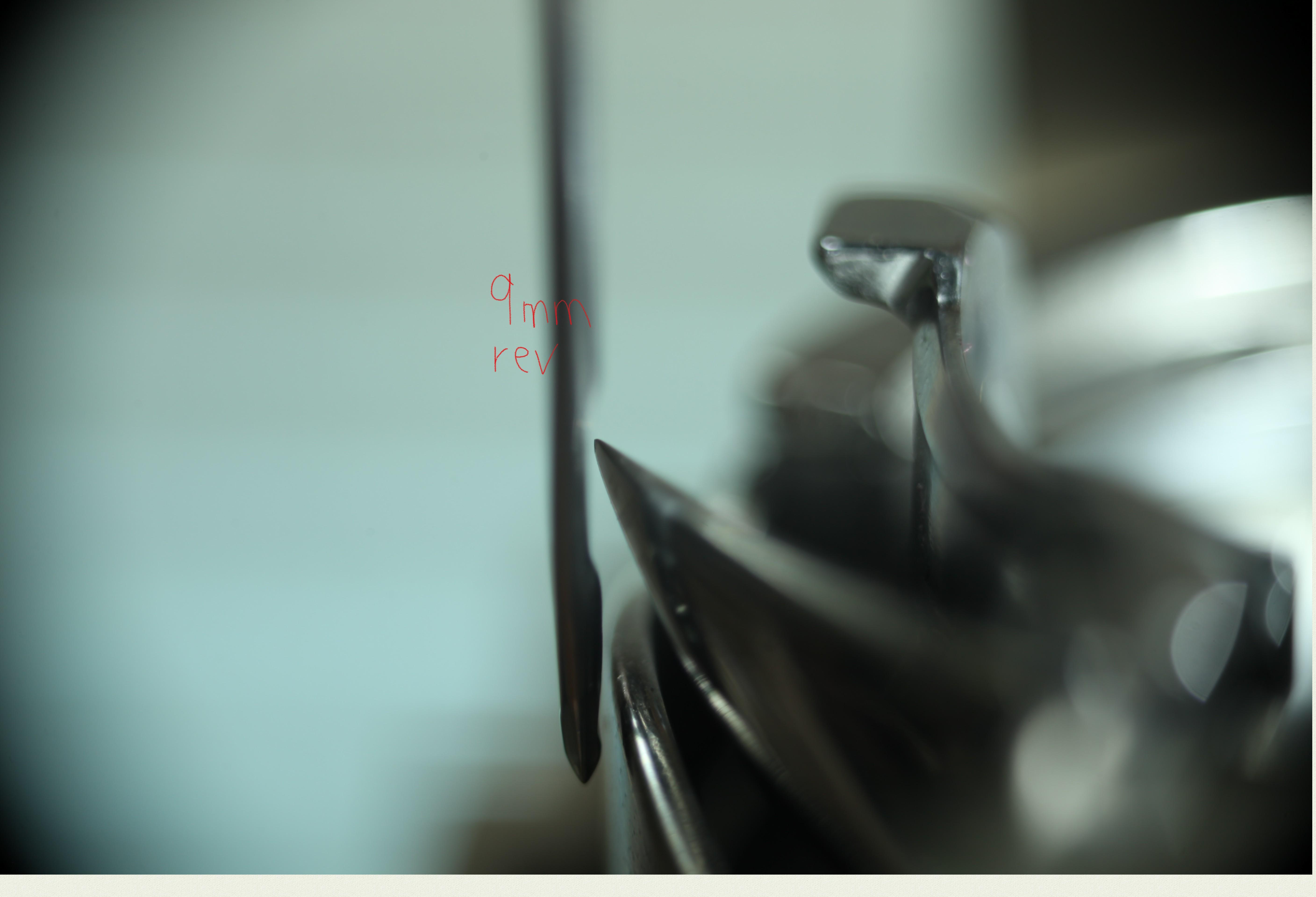

friquant replied to friquant's topic in Leather Sewing Machines

Original question, continued... I spent some time moving the hook saddle over to reduce the hook to needle distance. The Juki 341 manual says to make the adjustment with the stitch length set to 3mm, but the Juki 341 has a maximum stitch length of 6mm. One could interpret this at least two different ways: A. Set stitch length to 3mm, or B. Set stitch length to half of the maximum. (The Jianglong 341 that I'm actually working on can make 8mm stitches) Here are photos after my hook to needle adjustment, with stitch length and forward/reverse shown in red text. You will notice that long stitches in reverse prove to give the largest hook-to-needle distance, and I conjecture it was this large hook-to-needle distance that previously had the hook only catching one or two strands of the UNbonded thread. Since the adjustment, it seems to be doing fine with long stitches in reverse. (Not bisecting the thread anymore.) It makes sense that if you must optimize for either forward or reverse, one would almost always optimize for forward stitching. But here's another avenue I have not used but am considering: "Set the hook-to-needle distance to zero for long stitches in reverse, and use the hook needle guard to keep the hook from clobbering the needle in all other scenarios." This might get us down to zero hook-to-needle distance in all scenarios. But we'd also be deflecting the needle (elastic deformation) a little bit on all but the long reverse stitches. I'd be curious to hear how others have achieved a satisfactory hook-to-needle-distance compromise on machines that can make long stitches in reverse. -

dikman started following Adaptability for 1 hand? and Hook to Needle Distance: A Compromise

-

How to always have the hook to needle distance be next to nothing? At first I thought the thread was shredding when I stitched in reverse with long stitch lengths. (Thread is Selric brand TEX 135 UNbonded polyester) (Machine is Jianglong 341 (clone of Juki 341 but with even longer stitch lengths)) On closer inspection, the thread wasn't being torn actually, but in reverse with long stitch lengths (about 8mm) the hook was not catching all three strands of the thread. It might catch one or two. Here are some photos (recreated) of what it can look like when the hook tries to bisect the thread. Then I will continue my question in the next message..

-

Lots of youtube videos to watch and learn more about leatherwork.

-

Nakajima 321L is this worth the $1400 price tag?

kgg replied to leatherforge's topic in Leather Sewing Machines

I would run not walk away at that price. Buy something from a manufacturer that is still in business. Nakajima 321L is a needle feed machine and for leather work you really need at least a walking foot machine. The Nakajima 321L is what the old Juki LS-341 was based on, according to the info I have seen, with some changes. The first Juki LS-341's if I'm not mistake began in the early 1970's. From that the Nakajima 321L is going to be will over 50 years old. With the Nakajima sewing company being part of the Juki company since the 60's or 70's finding the different parts could be difficult. What are you planning on sewing???? kgg

.thumb.jpg.6e903dd66163ad5672f00f144058c571.jpg)