All Activity

- Past hour

-

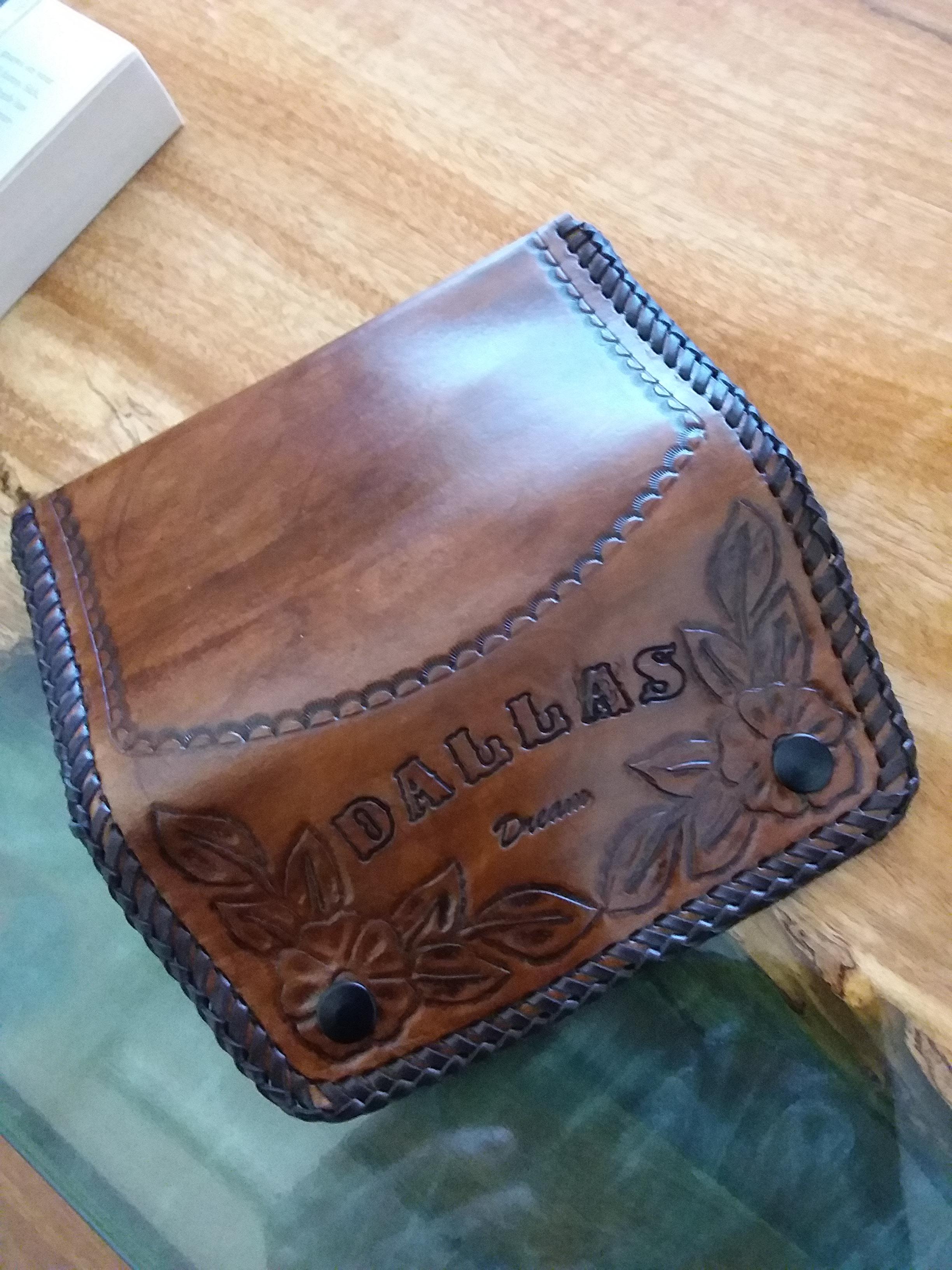

The seller knows nothing about saddles - Inheirited. What year was this carving popular? What type of tree was usually used? And just for fun the approximate retail price the saddle sold for, I am going through my old western horsemen but in 2/3 of the time Tex Tan is advertising belts or stores that carry their saddles

-

That looks nice but I don't think it would be a good burner. No holes for airflow to the charcoal

-

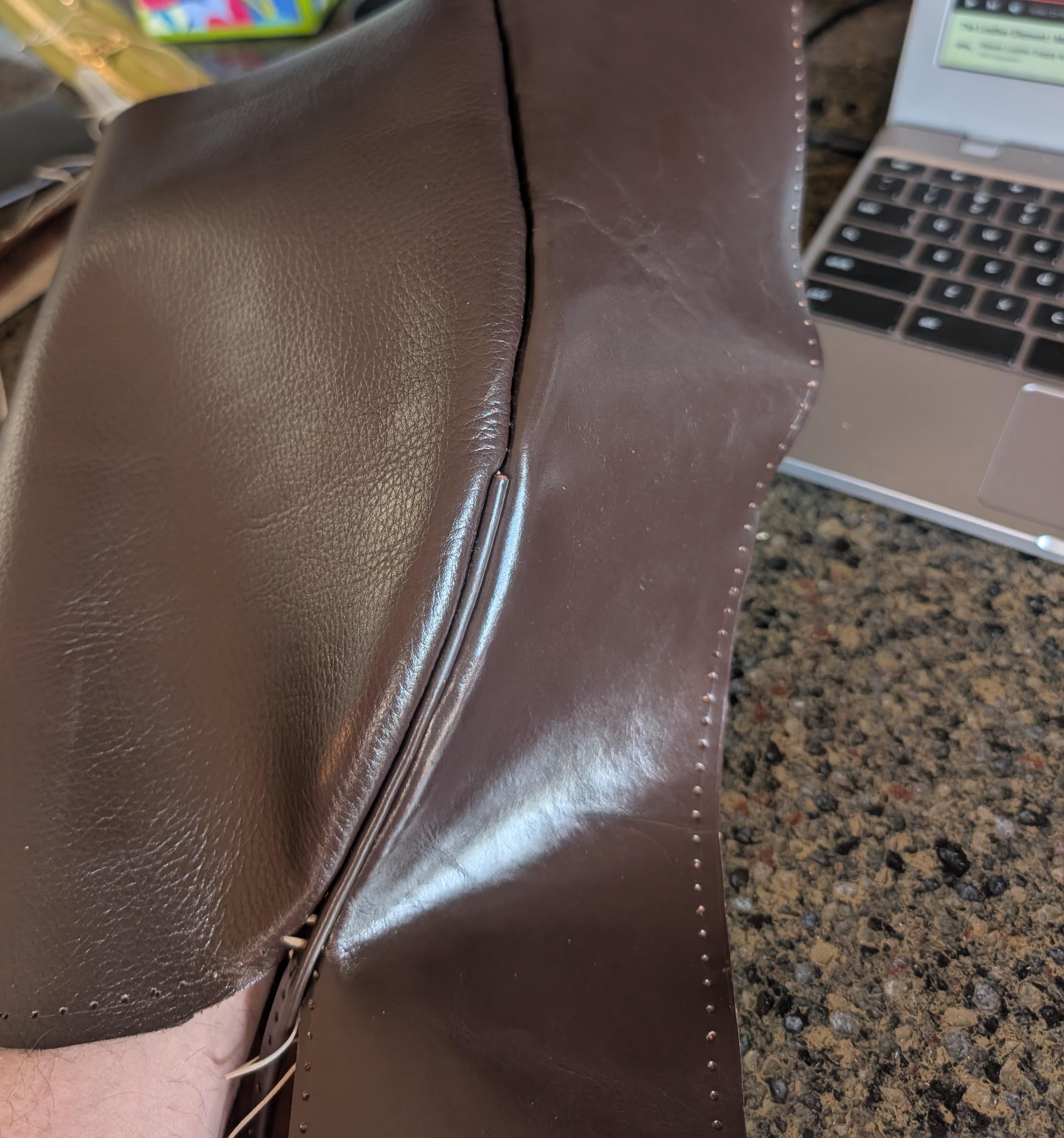

piping always. There is a reason you use it in light leather goods, actually more than one lol.

- Today

-

I'm experimenting with different ways to stitch leather pieces together. Without the piping, you can see a little bit of the stitching when I turned the panel from the gusset. When I added the piping, the stitches disappeared entirely and the leather became much more cooperative with making the curve of this bag. I didn't skive the piping, panel, or gusset. I didn't add a wire/string in the piping. I just cut a narrow strip of leather from the gusset leather, applied glue, and forced it over with a bone folder, then punched the holes. I'm working with two $10 rolls of chrome tanned leather from a local hobby shop...low end stuff. I'm working on a tribute handbag of the highest end French maker. I didn't find any already produced patterns for this design, so I created the plan myself with help from chatgpt. AI is useful in the process, but I had to make adjustments for what seemed like faulty planning on its part.

-

spring flowers and good food

chuck123wapati replied to chuck123wapati's topic in All About Us and Off Topic

Have you seen a rocket stove? It's the great-grandson of you BBQ lol? its on my bucket list of things to build. -

Singer 29k58 needle timing issue - I think.

Constabulary replied to LNB's topic in Leather Sewing Machines

You are welcome! This sometimes happens when you strip the 29K´s. You are not the first and for sure not the last with this problem. 😉 Have fun with your patcher. -

sneaksnrolla joined the community

-

I've made a few simple baccy pouches. I used material called 'rip stop'. Its sort of a nylon fabric, very thin, available in many colours. I glued it to the leather than sewed the pouch up

-

Black powder double shot snake need help

fredk replied to DoubleKCustomLeathercraft's topic in Leatherwork Conversation

If the shooter is so particular about things I'd go the extra distance and use cow horn -

I forgot about the expanded aluminium; I placed that on to stop my sausages falling thru the bars. The bars hinge up to put wood or charcoal under them for burning

-

Been making baccy pouches for years. Mostly just keep them simple but put a bit extra in occasionally.

-

spring flowers and good food

Handstitched replied to chuck123wapati's topic in All About Us and Off Topic

@fredk that would be perfect for satay or marinated chicken or pork skewers , while marinades may not be 'medieval ', they'll taste real good 😋 HS -

I enjoy my pipe and cigars, so I make things useful to me. Just finished some more. The pipe tools are redone with Moose antler and the pipe rest/tool. I enjoy working with leather doesn't matter what. Love trying new things.

-

A billion thanks to you! That was it. I've aligned the cams correctly and the bobbin and needle are working together! I am very grateful for the time you spent on this. On to tuning tensions!

-

I agree with dikmann - we have a topic her about Singer SV machines:

-

Thanks for posting this. It looks very nice. Also, this is the first tobacco related project that I have been able to find on leatherworker.net. With all the leather products that I have seen on etsy I would have thought that more tobacco related products would be found here.

-

Yes it is. The Singer 153 was out first. glenn

-

How to add needle positioner on adler 669

shoepatcher replied to HarrySingh's topic in Leather Sewing Machines

Do not need the screw that I have ever found. Just the plug. glenn -

Yes it was. glenn

- Yesterday

-

Maybe it is an SV model, these are notorious for having little, if any, information available about them?

-

If it's a 144 you may get a little insight here: https://ismacs.net/singer_sewing_machine_company/model-list/classes-100-199.html

-

Black powder double shot snake need help

dikman replied to DoubleKCustomLeathercraft's topic in Leatherwork Conversation

Chuck made a good point about the powder in particular catching at the join, and don't forget plastics are notoriously difficult to glue. You might have to consider a "sandwich" layer, trapping the plastic between leather? -

MermaidMustard joined the community

-

I agree with JLS. Custom order and get exactly what you want, no compromising. I also second his recommendation for Texas Custom Dies. Good people and good service.

-

At the size needed I'd go for one to use with a press

-

Have not found a perfect match between my this machine and one of the 144 submodels. In most respects it appears to be a Singer 144w103. That is, it has ten inches to the right of the needle, single needle, 8-inch hand wheel, 7x3 needle system, with stitch length regulation done by turning a screw on the feed eccentric. But this machine appears to have the reverse mechanism from the 144w305, which is "controlled by a treadle" see this manual: https://web.archive.org/web/20190820161643/http://www.parts.singerco.com/IPinstManuals/144W305.pdf So I could call it "144w103 with the reverse mechanism from 144w305" or "a 10-inch version of the 144W305".

-

Totally appreciate your input. You bring up valid points. Yes he is picky, but easy going too, and he definitely uses some really nice high end custom shotguns, among many other types of firearms. Five figure guns that are specifically made to his measurements. I love his collections, but they're so far out of reach for someone like myself lol. I was thinking if using veg tan with leather hardener as an option. It was his suggestion to use the plastic in the first place, and handed me a couple small sheets to use. I do have to consider the thickness of it all coming together at the chargers because it's a friction mount, and I believe their original pistol l purpose was to be used with horn. I did and will tap and use matching brass set screws. I was wanting to find a better solution than plastic. I will glue, and stitch whatever I decide to go with for that reason. I made the first one in a way that build up shouldn't be bad but not impossible of course. It's going to happen some. I have to stitch it all together in a specific order to make any overlapping pieces fit as flat as possible. Making sure the overlap is like a roof, working from the bottom so that things will flow like water. Thanks for the suggestions

.thumb.jpg.327685d8c1787fa894323fed9a6b2dac.jpg)