All Activity

- Past hour

-

Started to get back into leatherwork after almost 10 years of on and off practice. I’ve made myself anything from holsters, belts, to knife sheaths. I still wear the first project I did 10 years ago around my waist (with a few new holes poked in it). A few of my rifles have been missing a sling for a while, So I decided that would be a good project to restart with. Not perfect, but certainly makes it easier to climb the Appalachian hills. ~9-12oz veg tan, some lined some not, no sewing machine, fiebings black dye, el cheapo amazon chicago screws, big box swivel attachments

-

Chrome tan - I wanted something with at least a 5 in the weight like 5/6. My overall favorite was anything with a shrunken grain since that tends to be heavier. Customers with no cost constraints - shrunken grain bison. I can't remember the exact cutting size. I gave all my templates and patterns for purses, bags, home decor, etc. to an up and comer years ago. Tooling leather - something with an 8 - 7/8 or 8/9 weights cut from lower side or mid belly-between the flanks remnants from those weights or split to 8 oz from skirting leftovers. They were 2 inch strips as I recall. Pretty sure I rarely cut many strips from a whole fresh side, just remnants mostly.

-

This is really well done! I like how you tapered each piece symmetrically. The tooling is great! Leaves on one side and wood chips on the other. Great attention to detail.

-

Nice...I use actual shell casings that I cut down...

- Today

-

Belt extension, tooled English bridle

BlackDragon replied to DoubleKCustomLeathercraft's topic in Show Off!!

Great way to save the project! Just the other day someone asked for a belt, when I ask for the belt size they said "about 30inches". I told them I couldn't make their belt if I dont have the correct measurement. I instructed them how to measure their current belt and it turned out to be 34". People are pretty vague when you're trying to get product info from them. What color do you want? Brown. What shade of brown? Like wood. What type of wood, like pine or mahogany? Yes- 4 replies

-

- belt

- belt extension

-

(and 2 more)

Tagged with:

-

Ferreol joined the community

-

Hi everyone, I'm starting to think about a project that consists of sewing wool fabric (approx. 400gsm) with thick linen thread (diameter: 3mm). The aim is to use linen for decorative purposes but also to avoid synthetics. Given the thick diameter of the thread, I'm considering using an industrial leather machine. I have read quite a lot of advice by @Wizcrafts, particuarly on the following post: I would love your opinion on what you would recommend: Is an industrial machine (like the Singer 45K) recommended, or is it "too much"? My main challenge is finding a machine able to "accept" a 3mm or 4mm diameter thread, so I don't know if I should consider only heavy-duty leather machinery or if other options are possible. If the 45K or equivalent is too much, what "more gentle" option would you recommend? Would you recommend waxing the thread, specifically for sewing wool fabric? Many thanks for your advice, Clément

-

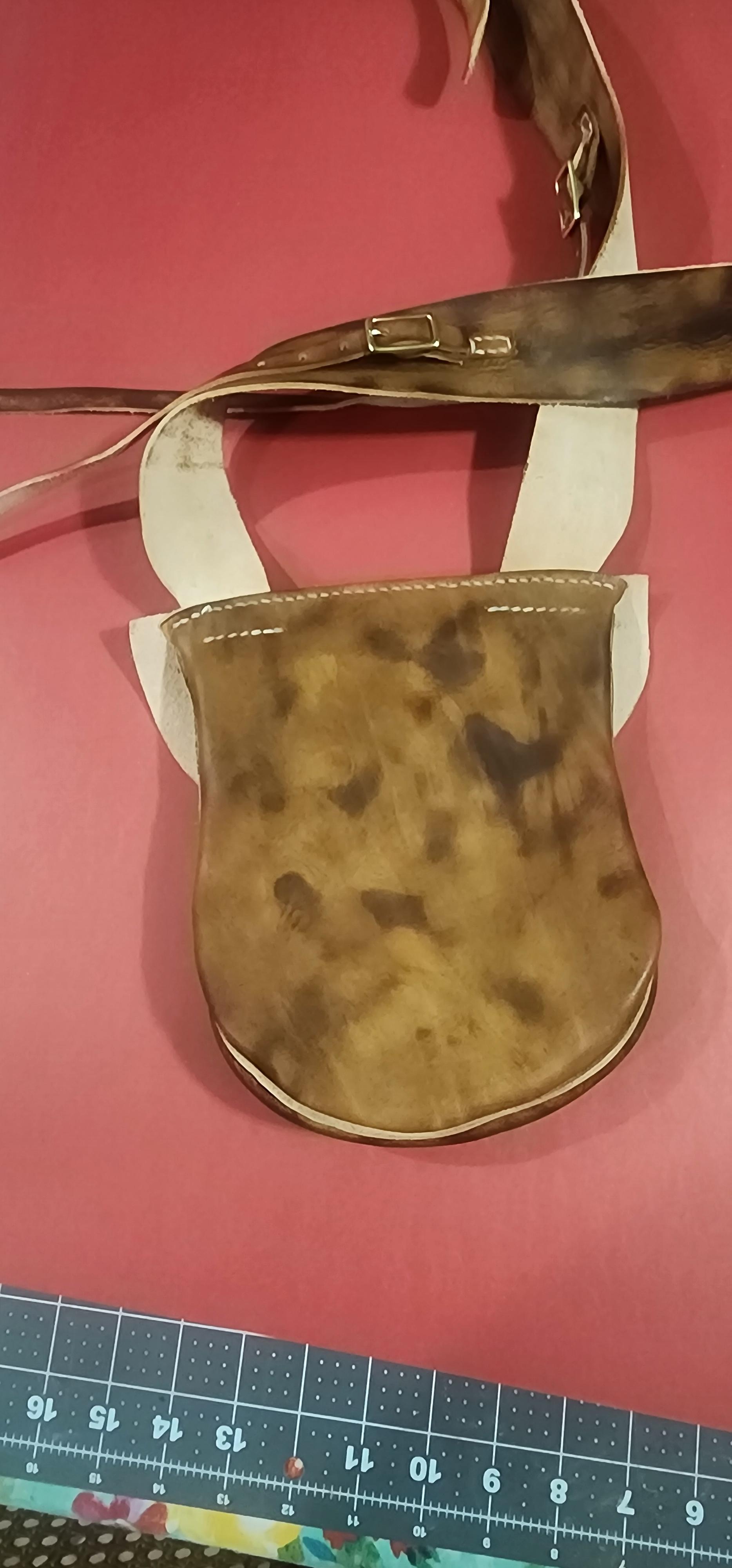

This was a different project for me. Ive always every to make a shooting bag just for the fun of it. I finally got around to it. I got creative in trying to make it appear aged. It was kind of nice not having to worry much about being perfect on a project. The rough edges and things add to the effect.

-

This post is informative of the consew t1919 performance envelope:

-

Bags are best done with a Cylinder arm machine while flt items like belts are best done with a Flatbed machine. A good all rounder to cover off round or roundish items and flat items would be a Cylinder arm machine like a brand name Juki LS-1341 or clone with a flatbed table attachment. There are quite a number of clone machines available at various price points. The thread V69 T70 is the largest thread your Domestic sewing machines typically can handle and pretty much the bottom end of what an industrial sewing machine can use. A Cylinder arm machine like the Juki LS-1341 (~$5000 USD) or clone ($2300 USD) can handle just over 3/8" thick leather which will cover off your projects. kgg

-

You'll need to get a proper walking foot machine, then get #18 leatherpoint needles in the "system" that machine uses. For instance, my Singer 111 and 211 machines take system 135x16 leather point, and 135x17 round point needles. I tend to hunt for titanium coated needles because I sew through leather tape or glue on a lot of jobs. Titanium coating helps prevent clogging of the eye of the needle. I also keep Goof Off and a dauber close by to clean the crap off the needles when they do get full of tape residue!

-

Belt extension, tooled English bridle

Mulesaw replied to DoubleKCustomLeathercraft's topic in Show Off!!

The disappointment and annoyance of suddenly having to deal with producing a product that doesn't live up to your own quality goals is exactly what is so hard to accept. Knowing that suddenly instead of a flawless product out there representing your skills, there is something completely different that you know ytou could have made better. The only good thing is that usually those who see it will still think it looks amazing, They don't know how it looked from the start, but it is still not much of a comfort to me.- 4 replies

-

- belt

- belt extension

-

(and 2 more)

Tagged with:

-

Can I ask what thickness you use for the chrome tan & the veg tan? Any other tips you may have would be appreciated. Thanks, and again beautiful workmanship.

-

Belt extension, tooled English bridle

DoubleKCustomLeathercraft replied to DoubleKCustomLeathercraft's topic in Show Off!!

It's something I think we all end up having to deal with at some point. I've had my share of "improvising" several things. It usually end up being a complete hassle, and disappointment because it wasn't part of the plan. Sometimes it'll look really nice and sometimes you wish you could just throw it in the fire pit. I hate improvising because it usually doesn't look like the quality I like to represent. Miscommunication is probably the biggest culprit. I know with belts, there's no standard to measure. Some makers measure one way while others measure it right...Oops I mean measure another way lol. Kids are the hardest because they're growing, and sometimes it's fast. I've only made a couple belts for kids. Not many people want to spend hundreds on a belt for a kid that's going to outgrow it. I add length so that holes can be added while they grow. And I know the belts I make will last a lifetime if not abused- 4 replies

-

- belt

- belt extension

-

(and 2 more)

Tagged with:

-

While browsing Youtube for videos of English saddle construction, for some very strange reason this suggestion popped up. I speak very limited Spanish, so I can't make out what kind of straw that they use, and I think the saddle might be for the horse mounted person in a bullfight arena, but I am not sure. The interesting thing is that the saddle is built without a traditional tree. All the stiffness comes from straw. There is also some interesting decorations, that I guess are traditional. Definitely worth watching.

-

Use contact cement to glue the two pieces together. It will make everything stay together longer, and make stitching easier. I try not to have any "square" stitch lines. Ovalsare more appealing to the eye. On the sweat shield (back part where the grip rests) I wound trim back so that your hand can grip the grip without interference. You're off to a good start. Nice thing about leather, it lasts and ages well. Keep it up.

-

Belt extension, tooled English bridle

Mulesaw replied to DoubleKCustomLeathercraft's topic in Show Off!!

Ouch, having incomplete (or false) information to start out with is so frustrating. And I thjinbk you made a nice save! I promised my son to make a set of chaps for Christmas for his good friend (a farrier who does western riding). I was told that they should just be exactly like those that I had made for my son the year before, I asked if he really was the same size etc, and yup, just make them the same. Turns out that he would have liked his legs 4" longer.. I had to improvise to make it look decent, and I was pretty fed up with the project since redoing it was much more trouble than just making them correct the first time. But lesson learned 🙂- 4 replies

-

- belt

- belt extension

-

(and 2 more)

Tagged with:

-

Just as an addition here. They do make a 45 acp rivet like the shotgun shell. I know it's got the 270 winchester rivets on Amazon, but i think the 45 acp was from weaver or tandy. You'll see it on this holster.

-

Hello, Thank you all for your feedback. Currently I make wallets, keychains, and coin purses which are all hand sewn. I primarily wanted to move to a sewing machine to hopefully expand my inventory with tote bags, belts, and other accessories. I work with 2-3oz leather currently but will need to go thicker for various projects. The thread that I attempted using was Thread # 69 T70.

-

I recently posted a tooled belt that I made it is English bridle leather. Well my client gave me his pants size instead of his belt size. I didn't question this because I had made him a belt for his son recently and thought he had given me his belt measurement. Y'all know what they say about assuming. Another lesson learned, question everything. He told me 30" which I thought was a little short but he does have a smaller frame. I verified twice before I cut the blank to length and went to work. When I delivered it to him, it was way short. About 4" too short and this belt was 100% personalized, difficult to tool and a lot of work went into it. If the personalization wasn't on it I'd have just made a new belt and sold the shorter one. So I told him that I would figure something out. This is the second time I've had to extend a belt. The other was a short simple extension. That was years ago, and I have learned a few things since then. Which sometimes makes for more work, but I'm the end it's higher quality. After looking around a bit online reading some information and looking at pictures on this site, I decided to go with a stitched billet extension over the buckled billet extension that adds a second buckle and set of holes. Two buckled on one belt looks funny to me. I didn't have any more English bridle to work with. I purchased the strap and used the cutoff (about 12") to practice carving since this is my first time working with english bridle. I tried to color match as best I could with what dye colors I work with. I added some tooling the the extension to help blend the build together. I think it came out decent, and the extension is mostly hidden when the belt is worn. My only complaint is the color difference but I know he'll be happy with it. Buckshot isn't perfectly centered anymore, but it's really close still. Hermann Oak English bridle strap (weaver) Hermann Oak holster (veg) tanned side (weaver) extension Weaver's Water Buffalo for lining Jim Linnell's montana inspired belt pattern. He's an excellent leathersmith and artist. I don't do his work justice but I love his patterns Solid brass Chicago screws and rivet on the extension Stainless steel roller buckle (weaver) Ritza 1mm cream thread, hand stitched Feibings Dark brown antique with Feibings leather balm

- 4 replies

-

- belt

- belt extension

-

(and 2 more)

Tagged with:

-

Very nice DOMESTIC sewing machine not suited to leather work. Since you are interested in that machine which costs north of $3000 USD you can afford a proper machine capable of sewing leather. You need to tell us what you want to sew, belts, wallets, bags, holsters so you can get good suggestions on the machine that would suit your needs. kgg

-

Well, what you did was right, because it came out clean.

-

That's why I did the welts one piece at a time, so they stayed flat. I also used one side as a guide for ALL the holes, so I didn't end up with a copy of a copy of a copy.

-

I've often thought about seeing up a press of some kind to punch my stitch lines. It's hard to keep the angle right when working with odd shapes so I gave up on that idea pretty quick.

-

Bags can be hard, they're time consuming and they use a lot of leather. I have made a few purses and a laptop bag. I prefer not making them so I price any bag items extremely high in hopes of not getting the order. If they still want me to do the work then it's a good payday. As an example, the laptop bag was a $1200 profit for me after materials not including my time though. I rarely charge for design/build time unless it's a one off piece, like this. It was made from bison with veg tan lining for support, a divider inside, external pocket and pen sleeves. Kept the natural edge on the flap which made for a really sweet look. By far my best bag.

.jpg.b1d7d520168f228540746fbbff18fdb4.jpg)

.jpg.7bed408001a37305d5935d1fe7d4b9aa.jpg)

.jpg.71a5bcc5dc754dd565ccbb80d197935e.jpg)

.jpg.755993baf52505cee0c999261d21d2d4.jpg)