All Activity

- Past hour

-

If you go to google . . . search video: concho belt you can watch videos for the next several hours May God bless, Dwight

-

Its not quite as bad as that....you can still have handguns if you are a member of a shooting club. Roger

-

Thank you both for your help. Will definitely give hotter water a try. I've only used plain tap water that was fairly cold. Will hotter water make it harder to sew? I'm only making about 4 pairs of holes near the fold so I'm just brute forcing a sewing needle through. Will I need to pre-punch the holes before using the hot water? The idea of giving my little duckies "armored" beaks is a hoot and will make for a great 'story' for them.

-

Good lookin work . . . but how in the world did you manage to hang on to a 1911 when your government played bad boy and burned all the guns??? May God bless, Dwight

- Yesterday

-

I made a couple of knife sheaths for various knives.....a pancake for my work knife, an SOB for a tracker style knife I made and one for my old Mora... The pocket in the SOB carries a diamond sharpener, ferro rod and assorted bits and bobs... Roger

-

-

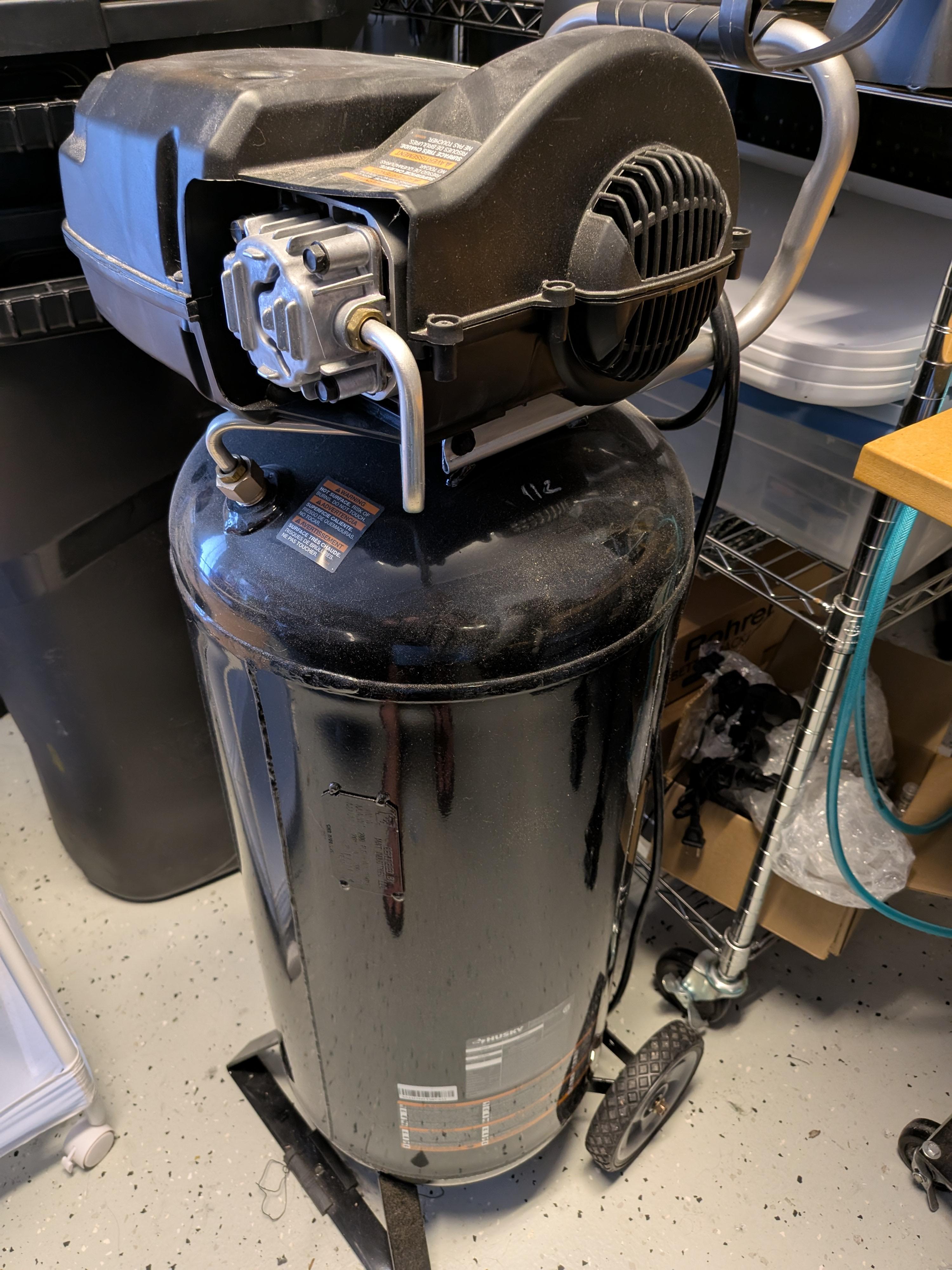

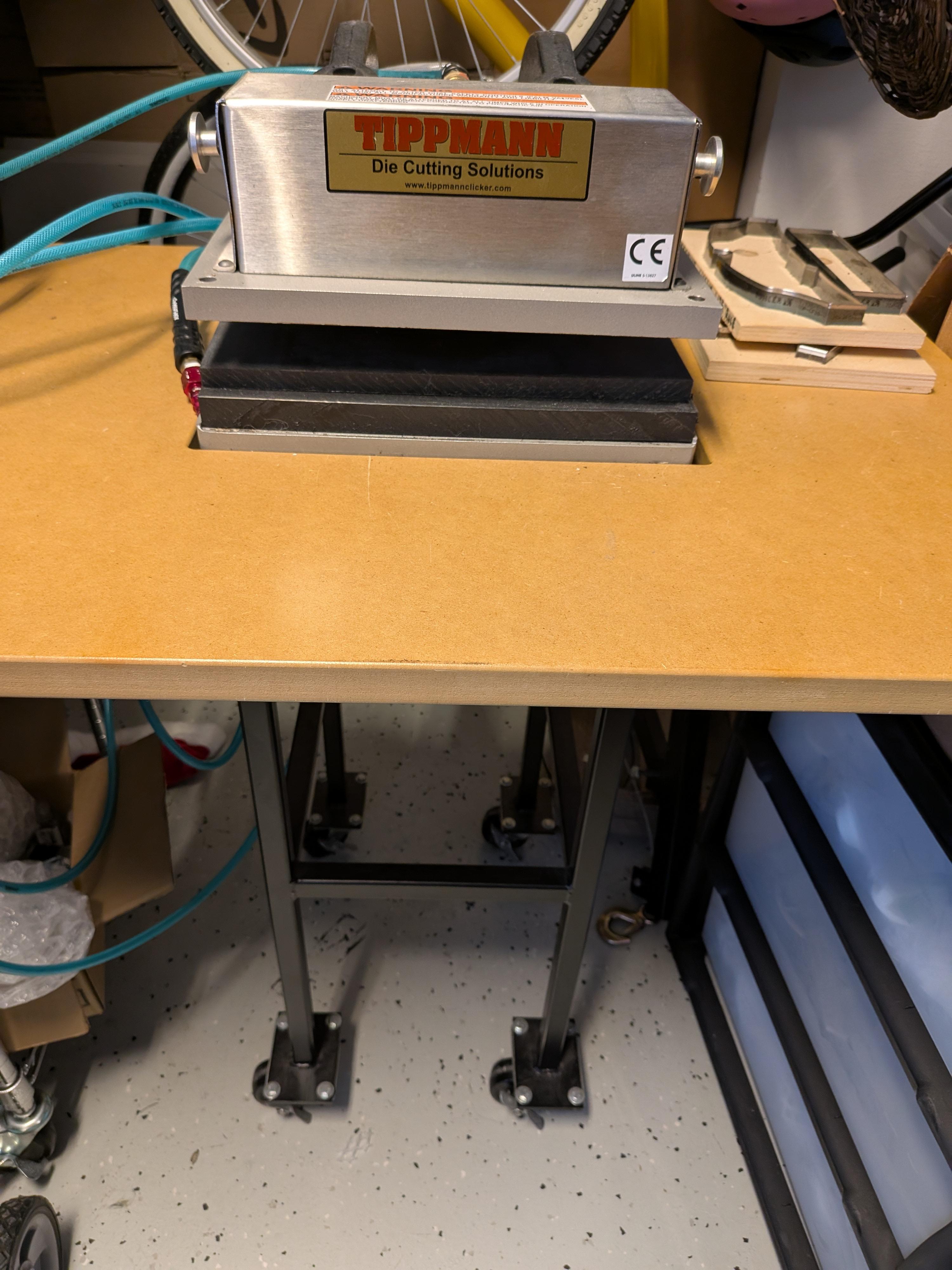

Selling my Clicker 700 that was used for one project only (a couple hundred foam presses). It’s been sitting since, so I’m moving it along. Machine is fully functional and in excellent condition. Package: Clicker 700 press Matching stand C201H air compressor + hose (ready to run) Why this setup? Turn-key—connect power/air and go. Ideal for leather, foam, gaskets, and small-batch production. Clean, reliable, and barely broken in. Price New: $4,500 Asking Price: $1,900 OBO Location: St. Petersburg (Tampa Bay, FL). Local pickup preferred, but I can palletize for freight if you arrange shipping. PM for additional photos, a test video, or to come see it run. Facebook Marketplace Link for photos: https://www.facebook.com/share/175oYsma25/

-

I made some pouches for some mates in the Big Game Rifle Club..... I use girth elastic to hold the rounds, some are spaced for double rifles and the pic of the cases gives you an idea of the sizes... Roger

-

Thanks for that; gotta' track some of those down. Larry

-

Did you see the add at the top for Ohio Clicker Dies?

-

My boss likes to break needles off at the top. Took me a while to figure out the problem until I realized that the top of the broken needle was stuck inside of the needle holder not allowing the new needles to set correctly (too long). Check to be you don't have a broken needle inside the carrier.

-

Those are Chicago Screws the work out very nice.

-

Final offer $2500.

-

SynergyWiz joined the community

-

Selling my Clicker 700 that was used for one project only (a couple hundred foam presses). It’s been sitting since, so I’m moving it along. Machine is fully functional and in excellent condition. Package: Clicker 700 press Matching stand C201H air compressor + hose (ready to run) Why this setup? Turn-key—connect power/air and go. Ideal for leather, foam, gaskets, and small-batch production. Clean, reliable, and barely broken in. Price: $1,900 OBO Location: St. Petersburg (Tampa Bay, FL). Local pickup preferred, but I can palletize for freight if you arrange shipping. PM for additional photos, a test video, or to come see it run.

-

What’s the maximum thickness the Singer 29K71 can handle

Mulesaw replied to JRodriguez's topic in Leather Sewing Machines

The feed mechanism is not really super great when it comes to thick stuff, so in addition to setting the adjustment on the back to H like @CowboyBob says, it also helps a lot to push/pull gently to help the object through. It also depends on how much pressure you keep on your presser foot, if it is pushing hard, and there is a lot of friction between the leather and the sewing machine, it can be hard to move just by the feed mechanism alone. I'd say 8 mm is a good figure, you can go a bit thicker, but not always with great success. In my view it is a fantastic machine, but again, my work is mainly repair job, and it is really great at that. Brgds Jonas -

I need only a few, simple clicker dies. I would like to get dies made and sold by US companies. Where should I look for good quality dies at reasonable prices? Also looking for a 4-ton clicker press. Any suggestions? Nick

-

Alternate take: safety-clutch-adjust-animated.mp4

-

The safety clutch on my Singer 144W was tripping too easily, so I decided to investigate. Here's a video showing how to adjust the preload. safety-clutch-adjust-calm.mp4

-

Rather then you fiddling with a new machine be it a demo unit I would go bring back the machine to the seller and ask them why the 794 needles don't fit and have them correct the problem. kgg

-

Thank you so much for the explanation. All the needles are the same length except the one that doesn't hit the bobbin cover. I backed the screw all the way out, and the long needles are still too long. Unfortunately, the needle that works best doesn't have a size designation on it. The thread I'm using is 346. I should add that I bought this machine from a well known seller of leather goods. They didn't have any in stock so they sold me the demonstration model. They, rather than Tippmann, might have supplied the oversized needles.

-

According to their manual Page 13 THREAD SPECIFICATIONS: Breaking down what "794s Serv 1 230 ...... SM 53-5 " means i) the 794s Serv 1 denotes the needle has a chisel point tip made for leather sewing ii) the 230 denotes the size of needle. Here is a good reference chart for the thread size vs the needle size needed ( https://www.tolindsewmach.com/thread-chart.html ) iii) the SM 53-5 is the Tippmann Boss part number for the needle. You can order these directly from Tippmann using their part number or from other vendors just by specing the needle system, needle size and shape of the tip of the needle. The needle system (794) denotes the length of the needle. All 794 will be the same length. Are all the needles the same length when you put them side by side?? It maybe as simple as you don't have the screw holding the needle backed off far enough. Otherwise I would call Tippmann. kgg

-

It does cuir bouilli, literally Boiled Leather, sometimes using a hot wax bath

-

I'll endorse Fred's answer. From experience, the hotter the water, the harder the end product will be. If you have plenty of leather, it might be worth experimenting with a range between hot tap water and boiling water. I think the hot water trick played/plays a role in making leather armor.

-

Only hot water from the tap, and not too hot at that Boiling hot water will really harden the leather but will make it shrink by as much as 20%, in uncontrolled directions

-

Lovely and so much detail on that paint job. Good to know that's an option. Thank you for all of your suggestions!