All Activity

- Past hour

-

It sure is. I checked out the hard copy once from the library-easily 3 inches thick! He’s got some beautiful button knots in there.

-

I have a fairly new Singer . . . table top portable machine . . . it will do embroidery and a bunch of other stuff . . . I bought it with the eye on the 90 day "send it back if it don't work" idea I had with the seller. I was looking for something that could sew two layers of suede or maybe 2/3 oz veggie tan. When I use it . . . I mostly use carpet thread . . . and it has surprised my britches off at the things it has done or will do. Anything in a shirt or light jacket . . . it'll handle it . . . no sweat. I used it to put my E-6 Navy patch on my short sleeve white shirt. Name tags . . . and the like are a piece of cake with that machine. I wanted to add to the group . . . the below picture . . . mostly for jackets and stuff . . . biker work . . . etc. I live between two towns of of 45K and 35K . . . with lots of police, military reserve, national guard, etc . . . and from the research I've done so far . . . I'd have it all to myself and the little old ladies with their thimbles. Plus there is a huge Harley place a 1/2 hour away . . . and 5 different state prisons plus three county lockups . . . and all them folks need patches sewn on. I wouldn't make a living at it . . . but at a minimum of $5 for the first one and 10 bucks an hour for the rest . . . I was looking at a nice extra few bucks . . . and I don't have to create anything here . . . just stitch the dude down. Most of it hinges on two "interviews" I have to do with a couple of dry cleaner shops. If I can become their supplier . . . I'd be looking at maybe a 100 a month average. May God bless, Dwight

-

Need to sew patches . . . help!!

Darren Brosowski replied to Dwight's topic in Leather Sewing Machines

- Today

-

Option 😄 Clutch Motor See the parent article: Choosing a Motor Online mostly you will see clutch motors disparaged as a thing of the past, going too fast, with little control. Yet there are ways to tame them by slowing them down and getting better at feathering the clutch. 1. What is a clutch Just like in an old school automobile with a manual transmission and a clutch, a clutch in a sewing machine motor allows the motor and the sewing machine to move at different speeds. The pedal motion is opposite that of an automobile though— on a sewing machine you press harder to achieve full engagement, and let off to stop. 1a. What is the clutch made of The clutch typically has a cork surface pressing against a steel pressure plate. 1b. Why do they go so fast Not all clutch motors go the same speed. A clutch motor is typically run by an AC induction motor. The no-load speed of the motor is determined by the input frequency (typically 50Hz or 60Hz) and the number of electromagnetic poles (how the motor is wound). The clutch motors I’ve seen are either 2-pole (about 2800rpm @ 60Hz) or 4-pole (about 1400rpm @ 60Hz). Notice one is twice as fast as the other. You want the slower one. 1c. How to reduce the maximum speed Here are some ways you can reduce the maximum speed of the machine when using a clutch motor: Get a 4-pole motor instead of a 2-pole motor. Buy a 45mm motor pulley (the pulley that goes on the end of the motor) for about ten dollars. Add a gear reducer (about $110 for 3:1 belt gear reducer) If it’s a 3-phase motor, reduce the input frequency using a VFD 1d. How to get better at driving it If your clutch motor is hard to control, first slow it down so that its maximum speed is actually of use to you. That is, so that on your long straightaway runs you can comfortably be full on the gas. Then take the clutch apart and clean and sand lightly the cork clutch and the pressure plate. Figure out where the oil hole is for the actuating lever so you can oil it so it releases smoothly. Experiment with varying levels of spring tension on the actuating lever. Experiment with how much leverage the treadle has against the actuating lever, and find what works best for you. Practice with short stitch lengths, since this will be more controllable at first. Wiz recommends greasing the clutch surface, but I have not tried that yet so I don’t have any data. 2. Is a Clutch Motor the Right Motor for Me? Choose a clutch motor if: You already have a 4-pole (1400rpm) clutch motor You like driving manual automobile transmissions You appreciate the extra challenge You are good at adjusting things You don’t want to use a needle position sensor You are going to gear it down anyway You have a 3-phase clutch motor (allows using VFD to slow it down)

-

Thanks for the kind words-means a lot! After wet-forming, I used Weaver's 'leather firmer', since I want my holsters to be as stiff and sturdy as possible. After that, there's a dip in Resolene, and that's the entirety of the finish. The clip is mounted to slotted posts mounted under the reinforcement piece wrapped around the mouth of the holster. Larry

-

Problem using a TandyPro Deluxe Leather Splitter

DieselTech replied to Coloradoguy's topic in How Do I Do That?

I think your blade is not quite sharp enough. Plus if the blade is dull & you are taking a big bite/cut you are actually stretching the belt some & resulting thinner/thicker cuts on the sides of the belt. -

Problem using a TandyPro Deluxe Leather Splitter

TomE replied to Coloradoguy's topic in How Do I Do That?

My older Tandy Pro splitter doesn't have the additional depth locking screws on both ends of the roller. It seems that the strap is getting pinched on either edge and drawn up towards the blade in the middle. I don't have an idea why that would happen. Does this occur when using different parts of the blade? Have you tested different leathers of varying thickness/temper? Is the roller centered on the edge of the blade? Also, I don't understand the need for the 2x4 clamping the strap. When I split straps I don't have any pressure on the strap entering the splitter. I am careful to pull the strap through at a consistent angle, slightly lower than horizontal. -

Here's a manual: https://www.manualslib.com/manual/505004/Pfaff-145.html#manual Here's a guide to the numbers and letters: https://leatherworker.net/forum/topic/89283-an-introduction-to-the-pfaff-numbering-system/ Here is a good video by Uwe on timing in general: https://leatherworker.net/forum/topic/36127-pfaff-545-safety-clutch-and-timing/page/2/#findComment-442262

-

Problem using a TandyPro Deluxe Leather Splitter

fredk replied to Coloradoguy's topic in How Do I Do That?

I think your 2 x 4 is giving too much localised pressure. Giving it more pressure to cut deeper in the centre than the edges Can you try a wider lever bar? -

Tall Post Sewing Machines?

RockyAussie replied to Cumberland Highpower's topic in Leather Sewing Machines

Mine is not great compared to most of my other machines for sitting at but I use an adjustable high stool which is close to standing height. That means the knees are not a problem as they barely go in under. I have an adler post as well that is set on an angle like the picture posted by @nylonRigging but that is how I bought it set up. I would be somewhat concerned about how the oil falls down and through on the tall post to do that without checking every oil hole for proper lubrication. -

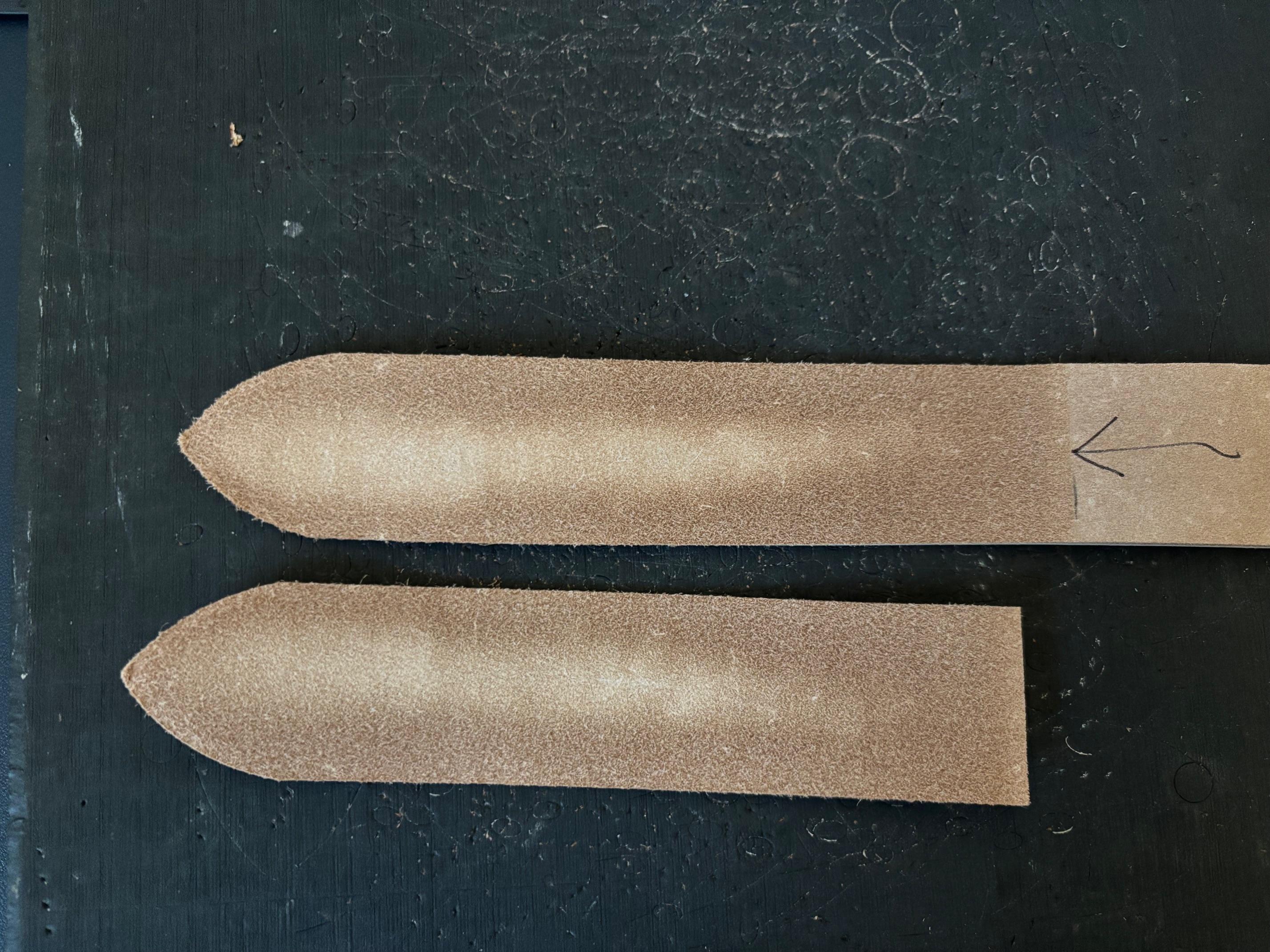

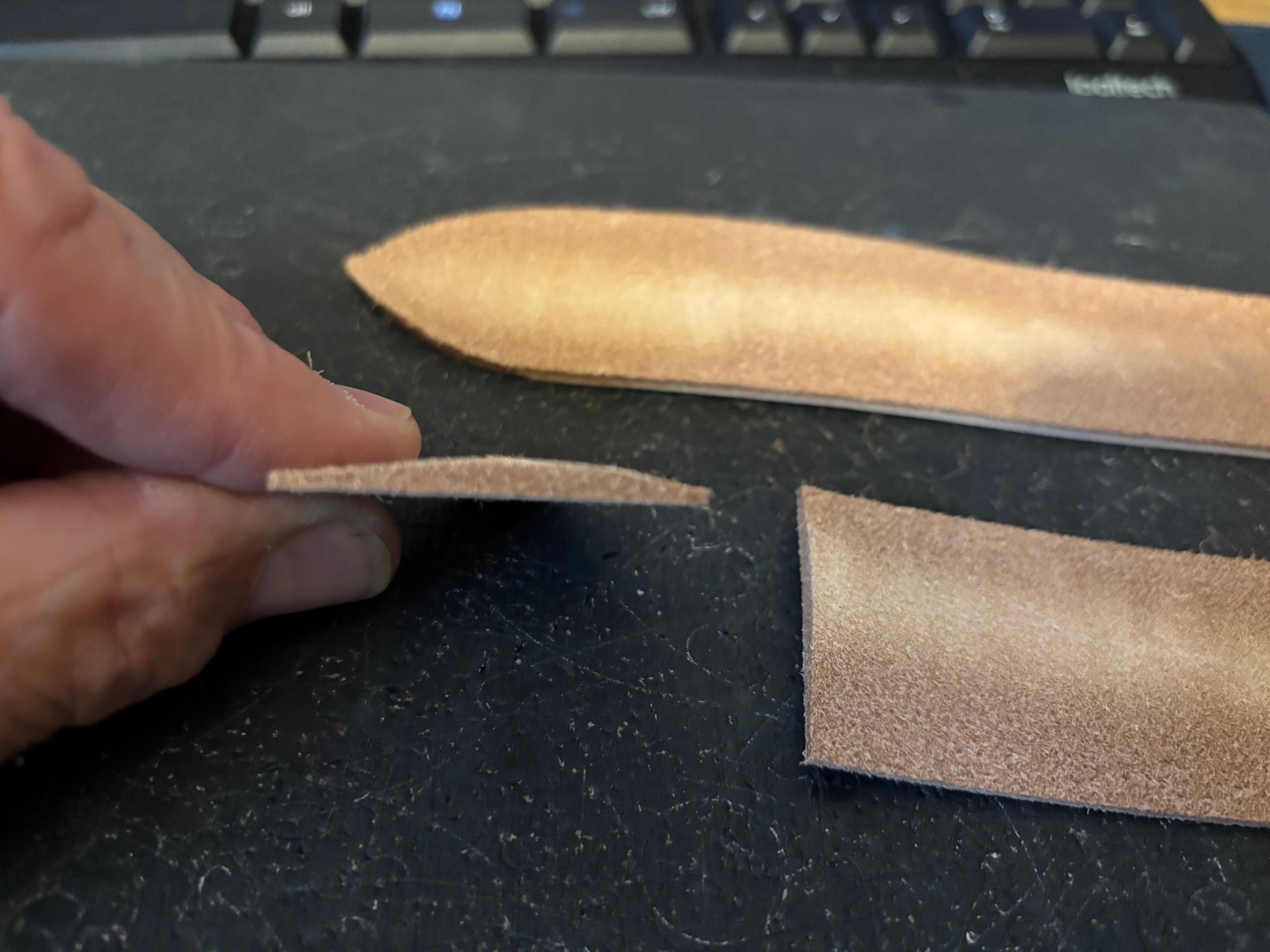

I posted a similar question back on May 18 in this forum and got some good tips, but I'm still having trouble. I purchased the TandyPro Deluxe Leather Splitter a few months ago. My problem is, when I pull belt straps through to skive 7" at the buckle end, I am not getting a flat cut. It is cutting too deep in the middle of the blank, see photos. The light area on the end of my blank in the photo is cut too deep, I cut a cross section of the waste piece and am holding it in my hand in the photo, you can see how bad it is cutting. These are the steps I am taking to do my split/skive: First, I sharpened the blade a LOT from how it came in the box, and kept the edge very flat. I set the roller at the depth I want at both ends and tighten the two lock nuts I start my cut while pressing back on the lever, cutting slowly for about 1/4" to 1/2" until the blade gets to depth I stop and tighten down the roller with the large nob Then I use a short piece of 2x4 to hold down the bar and the blank behind the roller, so the blank follows the curve of the roller from behind and slightly below Then I pull the blank through slowly. And it screws up the cut. What am I doing wrong? Previously, and before I started holding down the bar and belt with a piece of 2x4, I'd split through the blank entirely and ruin belts. I'd appreciate any tips or comments to correct this problem, thx!

-

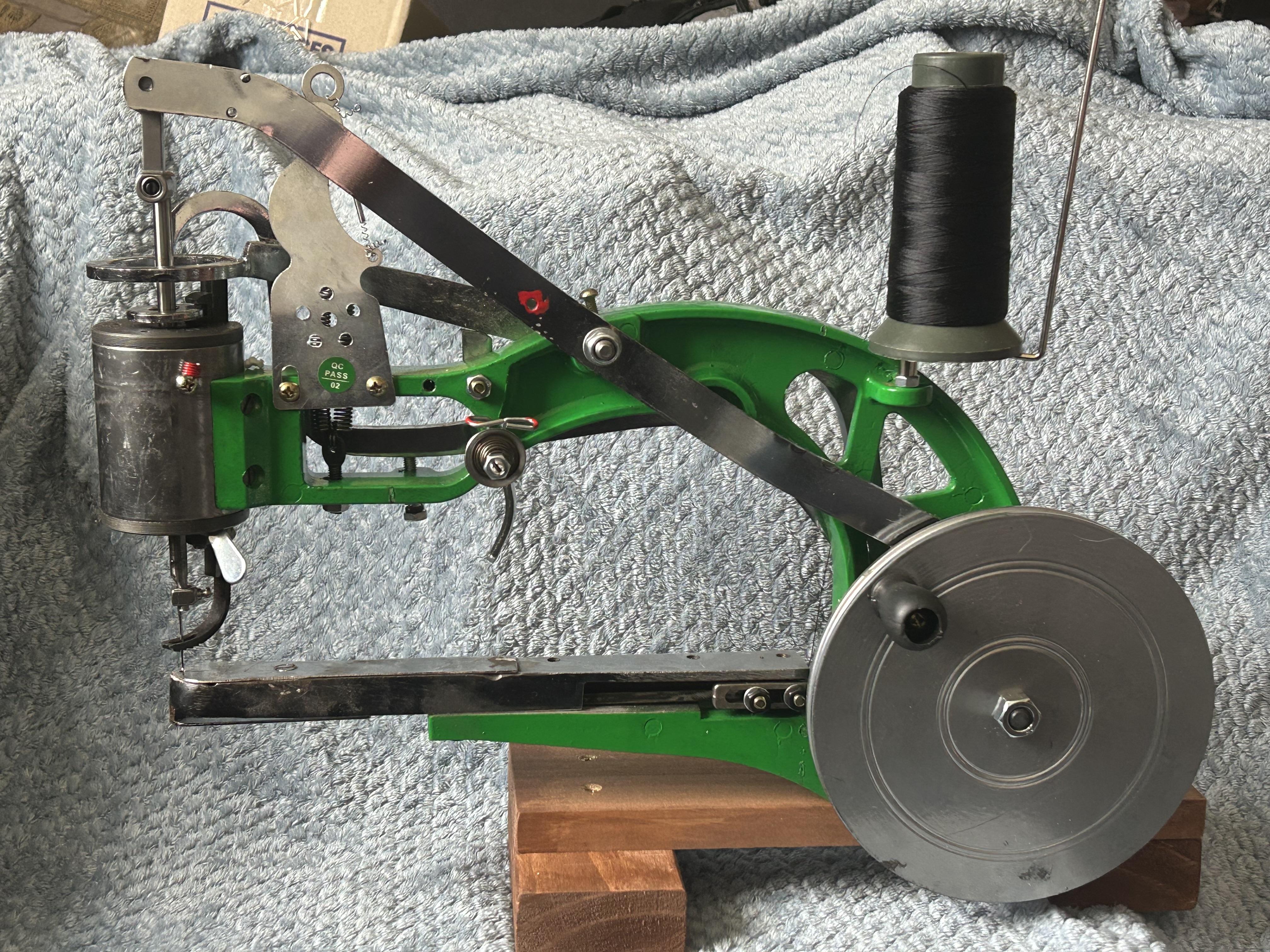

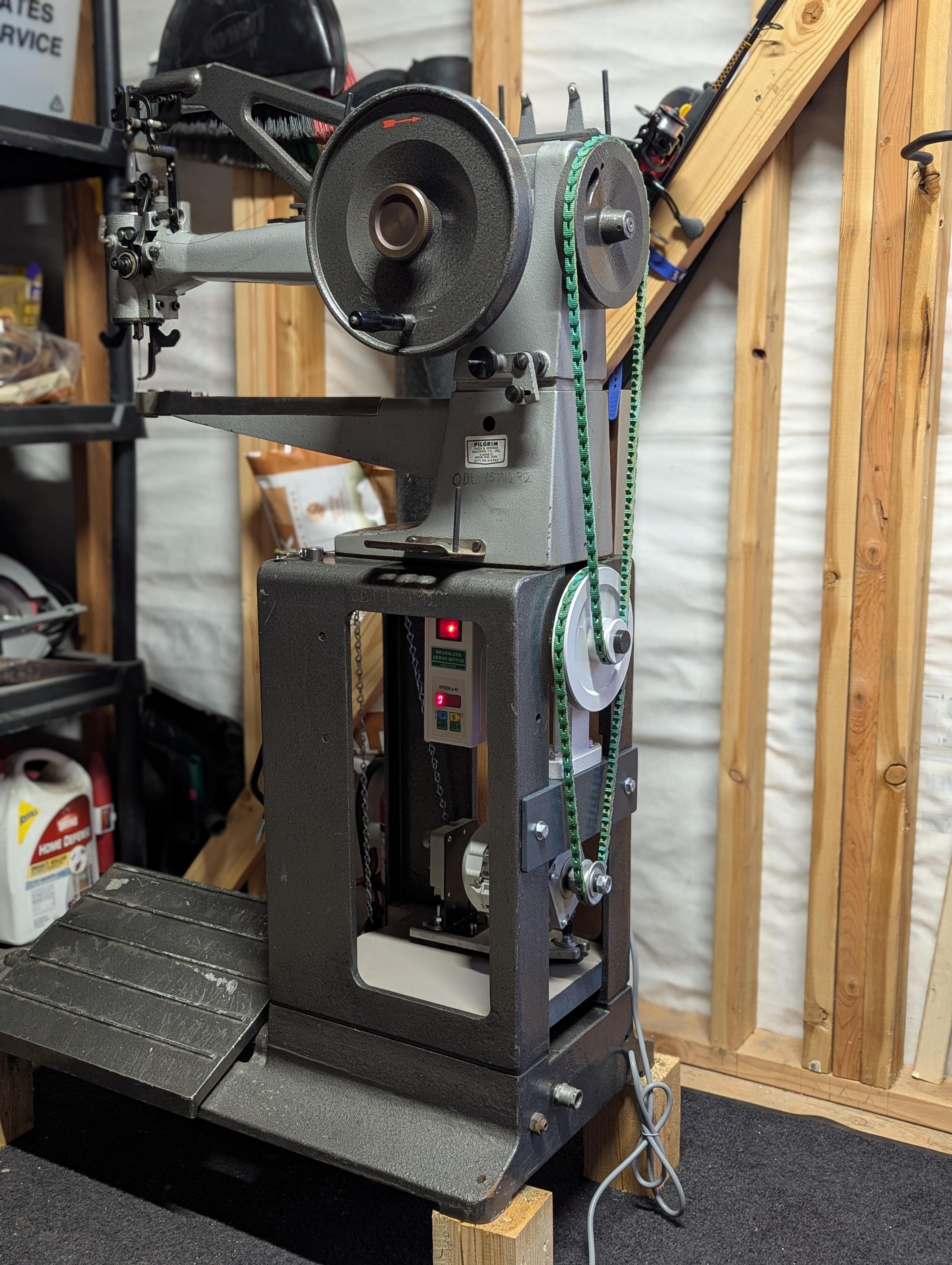

A couple weeks later and she's pretty much squared away. A thin plastic washer in between the motor side pulley and the casing got rid of the clunk I was complaining about earlier. There's still a lot of play in the hand crank but I'm not going to worry about it. I still need to finish up the bobbin winder and tall spool placement. The O-ring for the bobbin winder didn't come with the machine and I can't justify paying $25 for the "bobbin winder rubber" from Landis. BTW, a new shuttle costs $400!?!?! I have two, fingers crossed I never have to pay for a new one! I ordered a new servo motor with needle positioning sensor for my Consew and moved its servo motor over to this machine along with a 3:1 speed reducer. I had to make a couple custom mounts and platforms but enjoyed working through the process. While doing some testing, the machine was running about 32 SPM which is exactly what I was hoping for. I did get some belt slippage when not giving it a running start on some thick leather. I'm wondering if a rubber v-belt would do better than this adjustable fiber chain belt that came with the machine. It was very convenient for setting everything up but it seems to be more "slippery" than what a v-belt would be. Eventually I may get some low profile wheels but for now I think it'll just live on the floor. Thanks for the advice and feedback!

-

Not really a fan of rough out, but man you really made it look great!

- Yesterday

-

Adventures in watch strap making

dikman replied to dirk87's topic in Purses, Wallets, Belts and Miscellaneous Pocket Items

Well, my efforts were not exactly a success. First leather I tried cracked at the fold for the pin. I then tried kangaroo leather as it is thin and tough, unfortunately it is still too thick, next I tried some chrome-tan as it's thinner but two different types proved to be too soft at the fold. I finally got a piece to stay in place around the pin but it has too much stretch to use as a watchband, I don't think buckle holes will last long. The problem, I finally realised, is the watch, it has recessed parts in the body where the pin/strap fits which severely limits the thickness of the band material. Probably why they use synthetics for all the bands for these I guess. Ah well, it was an interesting experiment. As I have a strap hanging off one side of the watch I'll use it as a fob/pocket watch instead. Me hats off to you, Jim of Calgary. -

Bnorton49 joined the community

-

Anyone taken a cheap servo motor apart?

friquant replied to AlZilla's topic in Leather Sewing Machines

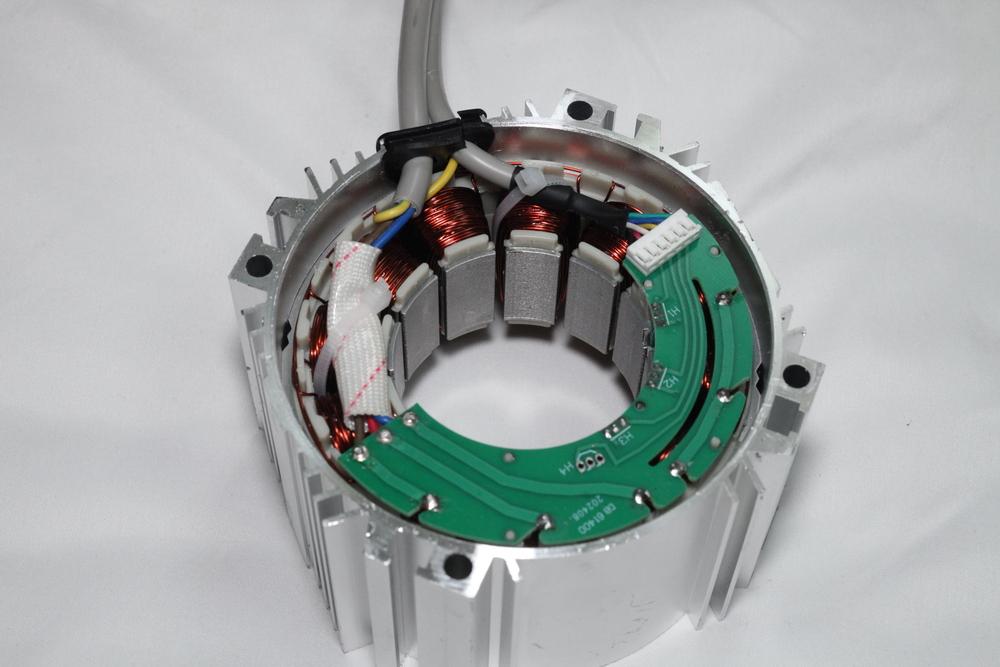

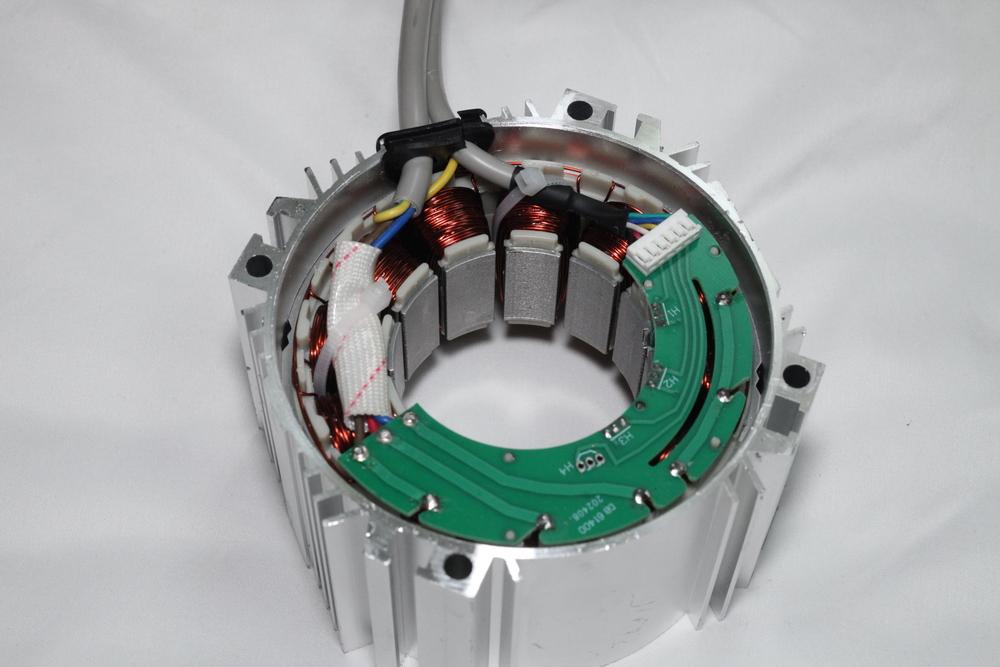

This is the stator and rotor from my "stitchman" digital servo. Only took about fifteen minutes to get it apart with a #2 philips on the screw gun, then a screwdriver and wrench to pry the plates off. Those permanent magnets are no joke! -

Universal motors are all brushed. My universal motor came with extra brushes even. About half the digital servo motors I see advertise as being brushless---the others don't say. I took the motor apart today on my "stitchman" digital servo and verified that it has no brushes. If anybody has a digital servo with actual brushes inside, I'd be interested to hear.

-

https://dn790008.ca.archive.org/0/items/TheAshleyBookOfKnots/the ashley book of knots.pdf Over 600 pages! That's a lot of knots.

-

Aleathermaker joined the community

-

Ditto!

-

Stitch strength heresy - Lock vs Saddle

Cumberland Highpower replied to AlZilla's topic in Sewing Leather

Ok. -

Tall Post Sewing Machines?

Cumberland Highpower replied to Cumberland Highpower's topic in Leather Sewing Machines

Hey I like that. I guess that's the "Slant 6" of the sewing world? -

I'm wondering if the minimum speed issue is to decrease heat. I've read that 300 is where heat dissipation is adequate (maybe for sustained operation?). Possibly 200 is banking on the user not staying at 200 for longer periods? I've also noticed that some of these cheaper motors have actual cooling fins on the outside of the body, where others just have undulations cast into them. My current motor with a 100 rpm minimum start speed has the cooling fins on the case. I'll have to start noticing if there's any correlation. Also, based on my recent disassembly of a cheap servo, the fan built into the end is just flat paddles running next to the closed end of the motor. No circulation at all. I think a small computer type fan blowing on the motor housing would really up the cooling game. It's on my to do list, even though with my low volume of sewing, I don't think heat is going to be an issue.

-

And maybe there's a distinction between brushed and brushless.

-

The top thread on a machine stitch saws back and forth something like 50 times. Remember that the tension arm way up at the top of the machine is letting it get pulled around the bobbin each rotation and then yanked back up. I was surprised when I first heard it. You are correct about the bobbin thread having an easy time of it. I'm glad this post finally got some traction.

-

Well said Fred.