All Activity

- Past hour

-

You really looking at compound feed machines (needle/feed dog/presser foot) move the material along which the machines you have mentioned are. For flat items, think of wallets/belts, are best done on a flatbed machine like a brand name Juki DNU-1541S or a clone which the Consew RB is and both are able to handle up to 3/8" thick material. For round items like bags, seats a cylinder arm machine is a much better choice like a brand name Juki LS-1341 or a clone and able to handle up to 7/16" thick material. . You can sorta kinda turn a cylinder arm into a flatbed machine by installing a table top attachment but you can not turn a flatbed into a cylinder arm machine. The cost of brand name machines like Juki can be expensive that is why a lot of people go with clone machines like Consew, Cowboy, Cobra to name a few. There are quite a few clones available at various price points, just depends on how deep your pockets are.

-

@Thadrick I moved your post to Gun Holsters, Rifle Slings and Knife Sheathes. It seems to be the best related forum.

-

@eLeM 800 pixels in the longest dimension is quite adequate and recommended. Most devices members use don't display much higher resolution and it is a favor to users on the fringes of the internet that suffer from low download speeds.

-

Tell us about the leg bags. Boat seats are typical "upholstery" which works great on a flatbed walking foot. But when you start talking bags then you have gussets. And if you've ever stitched a stiff gusset on a bag with a flatbed machine you will wish for a cylinder bed or post bed. 😀 What type of images? What is the filesize? Sometimes there are filesize restrictions, so scaling the image down to 1000x1000 pixels gets it under the bar.

- Today

-

In my opinion 1000$ for a machine that is so old is way too much. I own old pfaffs and Adlers, but I am using them as hobbiest and with a lot of love for old iron. It's great machine with some limitations (small bobbin), but with limited documentation and limited access to parts which are often very expensive. The worth of the head is max 300$, 500 if you really want this machine. Tables and old motors are practically not worth much.

-

Hello everyone, I’m new here from South Korea, and I’m facing a big problem with redyeing my custom-made dress shoes. I hope someone can help me figure it out. I bought these dark brown (actually closer to medium brown) shoes two years ago, along with other pairs in black and light brown. Compared to the others, this pair of dark brown shoes seems to have some sort of transparent coating or sealant, like Resolene or Saddle-Lac. Still, I was able to polish them Unfortunately, last year the right toe got scratched. I used sandpaper to smooth out the surface, thinking I could restore it by applying Saphir Shoe Cream (Crème Surfine, Color 05: Dark Brown) and later by wax to make them mirror shine. The surface became smooth again, but the shoe cream didn’t cover the scratch or recreate the coating anymore. When I applied Saphir Renovating Cream (Crème Rénovatrice, Color 05: Dark Brown), it just looked like paint sitting on the surface instead of blending into the leather. After polishing a few times, it simply came off. So, I tried acetone to deglaze the shoes and remove the original finish, planning to redye them dark brown. I used Fiebing’s Pro Dye, applying three coats with one-hour intervals by brushing, allowing it to penetrate Afterward, I left the shoes to dry for 24 hours in front of a fan. I buffed them with a white cloth for 10-15minutes and they seemed fine. Then I applied Saphir Renovateur Cream (Conditioner), hoping to polish them well after coniditioning them. The photo below shows the shoes after dyeing. I am indeed quite satisfied because it looks great. But here coms the problem: when I buffed the newly dyed shoes with a dry or damp cloth, they were fine. But whenever I applied any type of cream (Ex: Renovateur, Crème Universelle Leather Balm, colored shoe cream, etc.) or wax (Ex: Saphir Pâte de Luxe) with water, there's huge ruboff: the dye bled heavily and even reverted to the condition before dyeing. That means I couldn’t polish do coating on them by waxat all. I ended up removing the dye completely with acetone again, which took a lot of time. Interestingly, even after deglazing, the leather surface was still very smooth, almost as if dye couldn’t penetrate it properly. I ran a small test by applying just Saphir Shoe Cream and letting it dry. But again, whenever I applied any cream product, the dye bled. This was unseen on any other shoes I have. I've been extremely frustrated and trying to figure out the root cause but without success. Should I simply wait longer (2–3 days) after dyeing? Or should I apply something like oil or water to the shoes before dyeing? Or with this type of leather, does it require any special treatment before dyeing? Or would it be necessary to apply sealer such as leather sheen or Resolene on shoes? I originally wanted to ask the shoe company, but unfortunately, they are no longer in business. I’d really appreciate it if someone could point out what I’m doing wrong or give me some advice. Thanks a lot!

-

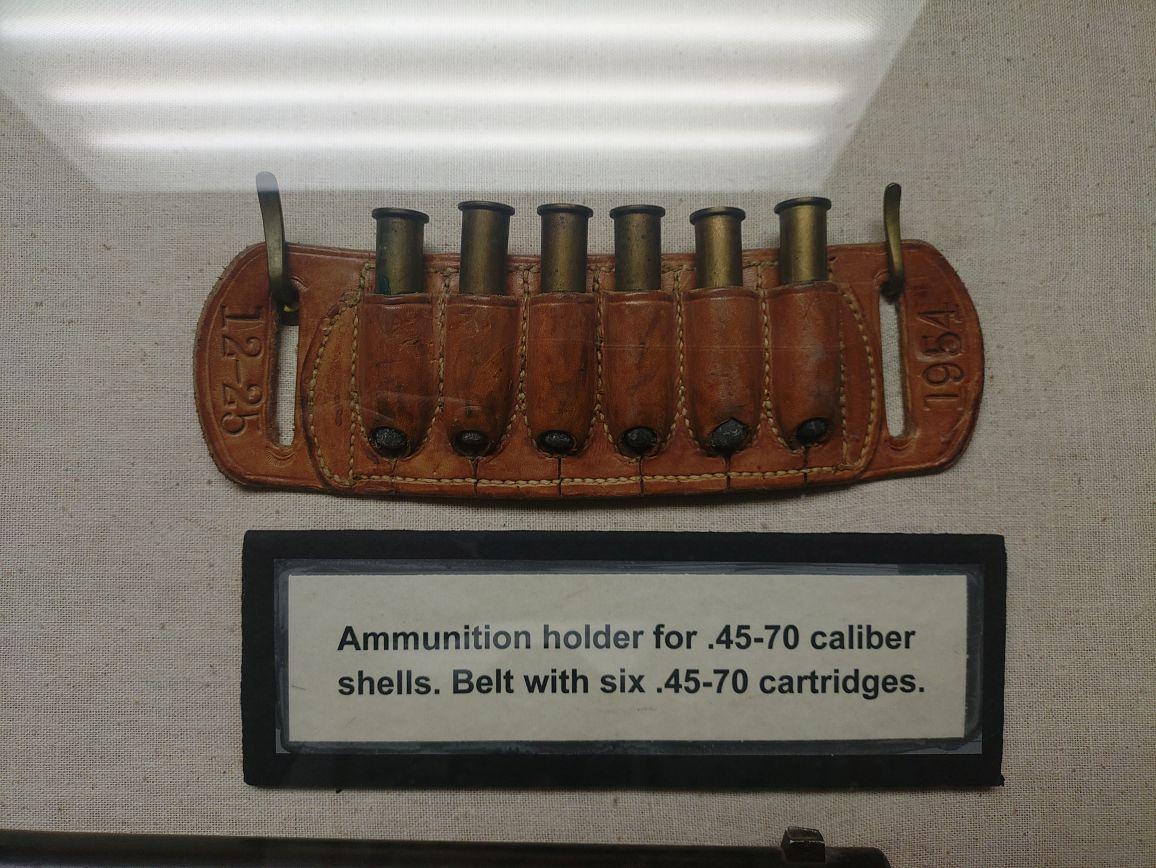

As I was fiddling with paper trying to work out a pattern, I think it will require an oval punch? I'm in the middle of another project right now or I would get right after doing one of these, starting with strait wall cartridge first and then working my way to a bottle neck . My theory would be that the punched hole would be where the bullet and neck could poke through for bottle neck cartridges ? Museums are awesome for ideas. Those Ole timers were brilliant.

-

ammo holder

chuck123wapati replied to Thadrick's topic in Gun Holsters, Rifle Slings and Knife Sheathes

looks like a round punch was used and a cut under it to relieve the wrinkling isssue with wet forming these small pockets. Use some scrap leather and quit with the almost-as-good stuff to work this out. just do one pocket first and pin you leather down along the sides, then measure about where you want your punched hole at the base punch it out cut a slit to the end and then wet it and form around the end and pin it down until dry. there will be over lap on the slitt you cut when dry cut straight down through both overlapped tag ends to get that straight clean cut at the bottom. use thin leather! The hole and slot thing is a really good way to solve that wet froming problem, very cool indeed. If you can't figure it out, then later today I might do one and show the pics i have a trap door on the wall and could use a good cartridge belt for it. -

shoestareve joined the community

-

Many walking foot machines have a bracket the adjust for left & right movement of the whole needlebar assembly.See the attached pic there are 2-screws behind it to loosen & hold it against the bracket & re-tighten if you need to.

-

At school we learn to cut liner a bit larger than the leather panels to glue it to. That way you have extra space to apply glue so that the glue extends to the very edge of the leather. Afterwards the excess liner is cut off. We also always stitch edges so that the liner doesn't come loose. If liner and leather is properly glued together and cut to the exact same size, painting the edges shouldn't be a problem. I've painted edges with three layers (outer leather, salpa reinforcement, and pigskin liner) without a problem. If stuff doesn't exactly line up you can start with a coat of filler before applying the first coat of edge paint.

-

Done this only a few dozen times so far. Mark the bottom centre on all parts. I measure the curves on the stitch line with soft bendy ruler or tape from that centre each way, then cut a bit long. Then test fit it with clips and mark it. Then glue liner on if im using . Then test fit it again, just to be sure, then I'll fold and stitch or whatever the tops of the gusset. I'll finally glue it and stitch. Been caught a few times where the front and back panels join up slightly uneven with the gusset. Only takes to be a couple mm off the stitch line to change where it ends up. Gets way easier once you get one right and make a template

-

Sallow leather crafts joined the community

-

ammo holder

bruce johnson replied to Thadrick's topic in Gun Holsters, Rifle Slings and Knife Sheathes

Looking at the picture there is a slit below each bullet loop/pocket. I am sure some bit of leather was removed at the bottom like a "dart" in patterning. The cut edges were then butted up and that allows some of the loop to form and still lay flat around the ends of the bullets. Cool design work and once you work out the patterning for the cuts, it probably falls together much easier than you think. There is going to be some wet forming to make a tight fit, but the design will make that a whole lot easier. -

Definitely wet formed to an extent but the bottom part of the loops are nicely designed and sewn down to the end of the cartridge. Sometimes that kinda stuff floors me with our ancestors designs. They were brilliant.

-

Yeah, I just tried paper and it won't form properly. It kinda looks like piano keys when laid flat though. Obviously wet formed to an extent?

-

Ah yes. On other machines, this is called the needle guard. Its purpose is to prevent the hook from stabbing the needle. Whereas the hook is very hard and fairly brittle, the needle guard is soft and malleable. You can bend the needle guard out of the way just a smidge, move the hook saddle closer to the needle so the hook point rubs a little on the needle, then bend the needle guard back so that the needle guard pushes the needle to the side just a bit as the hook comes by and the hook point just misses the needle. Here's a video by Uwe, known as "Stuffing the Hook" And some references: https://leatherworker.net/forum/topic/47477-211g155-do-i-have-the-wrong-machine/page/6/#findComment-304044 https://leatherworker.net/forum/topic/65973-video-how-the-hook-catches-the-thread-loop/#findComment-428831 https://leatherworker.net/forum/topic/65973-video-how-the-hook-catches-the-thread-loop/#findComment-428844 https://leatherworker.net/forum/topic/65997-video-sewing-veg-tan-leather-on-a-consew-225/#findComment-429071 https://leatherworker.net/forum/topic/131796-singer-211-u166a-walking-foot-problem/page/3/#findComment-785084

-

Your needle is probably to small for the T135 (V138) thread in thick/grabby leather. You should try using a #24 needle. Here is a link to a good thread size vs needle size chart: ( https://www.tolindsewmach.com/thread-chart.html ). kgg

-

My bestest guess is, the bullet holders were sewn in place then soaked in water and the bullets forced in, basically wet-moulding the holder

-

carl22 joined the community

-

1/8" craft foam is a pretty good stand in for prototyping leather. Your imagination is probably as good as mine about how to make it happen.

-

The hook washer as it’s called in the parts book, is the large flat washer that sits under the hook, it has like a finn that extend at 90 degrees upward just below the point of the hook. i can’t figure out what it’s function is, but the needle is rubbing on it, and I don’t think it supposed to be this way. I’m an automotive mechanic by trade, I have no previous experience in sewing machine. when sewing multiple layers of upholstery leather, it all goes well for about 12 inches, then my string frays and breaks. (135 thread, 160 needle, 5 stitches per inch, pressure is ok)

-

If this is your rookie effort, I can't wait to see what's next!

-

Ive seen many ammo holders on here in the past but this one stumps me. I found this in a museum and couldnt help think that this design would work perfectly for bottle neck rimless ammo. My question is how the heck did they cut the outher loops like that to get things to fit ammo and yet look so clean? How can a person reproduce this to fit bottle neck ammo? Just use a bunch of leather and try till its right? Where are the measurements taken from? Anyhow? anyone know of any writeups on this design?

-

Exactly, just tweak the stopping point until it stops with the tension arm all the way up. I'd have to go sit down in front of a machine, but it should be pretty close to the moment the needle is all the way up.

-

RoboAdonis joined the community

-

Trust the machine. (not the motor haha) To understand when is an appropriate time in the stitch cycle to pull your material free, you can stitch slowly (handwheel!) with the bobbin cover removed. I both start and end my seams with the takeup lever at the top of the stroke. Depending on which model of digital servo motor you have, there may be adjustment within the menu to configure how much rotation happens between what the servo considers Needle UP vs Needle Down. I suppose in my wildest dreams a needle positioner might default stop for needle down a little after the hook point grabs the thread. Then when I heel tap it would first rotate to where the takeup lever is at its highest point (to lock the last stitch), then reverse ten or twenty degrees and come to a stop when the needle is at its highest position so it's easy to pull the material out. ☺️

-

@kiltedkrafts As they don't have serial numbers i don't think you will ever know . All i can say is that it is pre world war 2 because the factory was bombed. Vihl perderson took over production after that and made them under their name . Both machines are identical and parts are interchangeable . Needles are still available from the link below but to get parts means to buy an old machine and cannibalise it. https://www.leffler.com.au/pederson-needle-ltr-for-309-machine/

.thumb.jpg.6e903dd66163ad5672f00f144058c571.jpg)