All Activity

- Past hour

-

I was hopeful ...

-

What’s the maximum thickness the Singer 29K71 can handle

AlZilla replied to JRodriguez's topic in Leather Sewing Machines

Well, here's over a hundred references, maybe the answer is buried in there. Were it me, I'd let the buyer decide for him/her self so I don't get blamed for any problems. https://leatherworker.net/forum/search/?q="Singer 29k71"&quick=1&updated_after=any&sortby=relevancy -

What’s the maximum thickness the Singer 29K71 can handle

JRodriguez replied to JRodriguez's topic in Leather Sewing Machines

Thanks for your reply. That’s what I found too. It doesn’t stitch when I tried it with 2 pieces of veg tan leather together 8mm Thick. -

Introduction In the custom craft industry, a hot stamping machine is an essential tool for enhancing product appeal. Whether for leather goods, creative gift items, or premium brand packaging, the hot stamping process adds distinctive texture and visual impact, helping products stand out in a competitive market. With the growth of the custom market, consumers are demanding higher craftsmanship quality and personalization. As a result, creators and workshops now place greater emphasis on a machine’s performance, stability, and ease of operation. Among today’s most discussed models, the Dream Factory hot stamping machine and the MAXITA EC-27 hot stamping machine are frequently compared. The Dream Factory is praised for its modern design, convenience, and beginner-friendly features, while the MAXITA EC-27 wins professional users with its high precision, strong durability, and excellent value for money. This hot stamping machine comparison will explore both models in detail—covering product background, key technical specifications, build quality and design, functional features, and user suitability—to provide clear guidance for both hobbyists and professionals choosing the right machine for their needs. 1. Product Background Dream Factory – Brand and Market Positioning The Dream Factory hot stamping machine is known for its versatility and beginner-friendly design. With an emphasis on affordability and ease of operation, it is ideal for beginners and small to medium-sized studios. Its applications cover basic craft materials such as leather, paper, and plastic sheets, offering a balanced set of features for entry-level needs. MAXITA – Brand and Market Positioning MAXITA specializes in delivering high-precision, high-stability hot foil stamping solutions for professional workshops and brand manufacturers. The MAXITA EC-27 is one of its flagship models, equipped with an industrial-grade Omron temperature control system, red-dot laser positioning, and an enlarged sliding worktable—designed for users who value efficiency, consistency, and professional-grade performance. 2. Core Parameters Comparison Item Dream Factory MAXITA Appearance & Finish Simple structure, strong design sense, excellent build quality Dual-base design with modern aesthetics, stable metal structure Machine Positioning Versatile for manual/semi-automatic stamping machines High-precision digital control leather stamping machine Temperature Control Knob mechanical control Omron high-precision digital temperature control system Positioning System Positioning card ruler Red-dot laser positioning + positioning card ruler Holder Font Holder + Stamping Holder Letter Holder + Logo Stamp Worktable Fixed type Push-pull sliding type Applicable Materials Leather, paper, plastic sheets Leather, paper, PU, and other materials Size & Shape Compact model Medium-sized, larger working area 4. Appearance and Craftsmanship Highlights Dream Factory Materials & Structure Body made of brass and powder-coated steel, offering durability and a vintage aesthetic. Support base crafted from SUS 420 stainless steel, ensuring a flat, warp-free surface. The thickened design provides excellent stability. Functional Design Equipped with a swivel column for precise and repeatable stamping at the same spot, with flexible operation. Height adjustment knob is simple to use. Alignment guide paired with a quick-release mechanism allows accurate workpiece positioning. Quick-release attachment interface enables easy switching between different tools, such as movable type, die molds, or punching tools. MAXITA EC-27 Structure & Materials Steel frame with walnut wood accents and matte black powder coating, combining durability with modern aesthetics. Solid steel base with high dimensional stability, paired with a precision sliding work platform for both durability and accuracy. Functional Detail Design 16×20 cm elevated work table (optional 20×30 cm table) provides extra space for handling finished products such as bags. The platform features a high-precision sliding rail system with lockable positioning for improved efficiency and safety. Modular aluminum alloy body allows easy assembly/disassembly and portability. Positioning & Temperature Control System Built-in infrared (laser) positioning system for accurate alignment and improved stamping precision. Equipped with Omron temperature control system (a well-known industry brand), capable of maintaining temperature fluctuations within ±5°C to ensure consistent stamping quality. 5. Functional Details Analysis 1. Temperature Control & Heating Stability Dream Factory: Wide temperature range, suitable for general crafts, but temperature fluctuations are more noticeable during continuous mass production. MAXITA EC-27: Uses an industrial-grade Omron temperature control system combined with a high-power heating core, delivering excellent temperature stability and maintaining precision even during prolonged operation. 2. Positioning Accuracy Dream Factory: Primarily relies on scale marks and manual visual alignment, suitable for projects with low positioning accuracy requirements. MAXITA EC-27: Equipped with a built-in red-dot laser positioning system, achieving ±0.5 mm precision — ideal for brand logos and intricate patterns. 3. Mold Replacement Convenience Both Machines: Feature a detachable holder for quick swapping of logo stamps and letter stamps. 4. Operating Comfort & Stability Dream Factory Operation Feel: Compact structure, short press travel, easy to learn, ideal for beginners. Worktable Experience: Fixed or simple push-pull table is convenient for small items but somewhat limiting for larger pieces or frequent position adjustments. Stability: Moderate weight makes it portable, but under high pressure, slight vibrations may occur, affecting extremely high-precision work. MAXITA EC-27 Operation Feel: Smooth sliding oversized worktable provides ample space for placing and removing workpieces. Worktable Experience: Sliding table moves steadily and includes a positioning lock, enabling fast workpiece changes in batch production. Stability: Solid structure with heavier weight ensures virtually no vibration during operation, maintaining consistency and comfort in long sessions. Summary Dream Factory: Lightweight, portable, and easy to master, but less stable for extended or high-precision work. MAXITA EC-27: Solid build, smooth sliding operation — ideal for batch production and long-term use. 6. Best Choices for Different User Types User Type Recommended Model Reason Beginners & Craft Hobbyists Dream Factory Elegant appearance, intuitive operation, quick to learn; suitable for occasional small-batch production of leather, paper, and similar materials, with low requirements for temperature and positioning accuracy. Brand Studios Focused on Display Appeal MAXITA EC-27 Dual-base design with strong visual appeal, perfect for studios prioritizing brand image in stores or showrooms. Budget-Conscious Users Seeking High Value MAXITA EC-27 More affordable than Dream Factory without compromising on functionality; stable performance suitable for multi-material processing. Professional Workshops & Mass Production Manufacturers MAXITA EC-27 Industrial-grade temperature control, red-dot laser positioning, and large sliding worktable — ideal for high-frequency, long-duration batch production, especially where product consistency is critical. Conclusion The Dream Factory machine provides a well-rounded entry-level solution, equipped with essential features suitable for basic craft projects and occasional use. In contrast, the MAXITA EC-27 Stamping Machine offers advanced technology and robust construction designed to meet the demands of professional, high-volume production environments. When choosing between these models, consider your production scale, required precision, and budget to select the machine that best aligns with your business goals and craftsmanship standards. References Omron Corporation. (2023). Technical Explanation for Temperature Controllers. Retrieved from https://www.ia.omron.com/data_pdf/guide/53/temperature_tg_e_6_4_csm231.pdf Dream Factory. (2025). Product Overview. Retrieved from https://dreamfactory.com/products MAXITA. (2025). EC‑27 Hot Stamping Machine Specifications. Retrieved from https://jinglinmachine.com/products/maxita-ec-27-hot-foil-stamping-machine

-

- hot stamping machine

- dream factory

-

(and 2 more)

Tagged with:

-

Sounds good, thank you. I appreciate that.

-

@bruce johnson is the man to ask about the older tools. We're gonna waive the price rules until we have further conversation so we can get this man's tools into appreciative hands for a fair price.

- Today

-

Thank you for the tool tip on setting them and also for indulging my random question.

-

That's a handsome bag with a nice finish. I like the stitching, the handle, and how you attached the shoulder strap.

-

I opened up the VFD and disconnected the fan. The VFD has thermal protection, currently set to trigger at 90 degrees C, so I'm not worried about overheating it with the low duty cycle I'll be putting it through. Here's a video to show the sound level without the fan vfd-sounds-new-bearings-no-fan__small.mp4

-

Ariadne Leather joined the community

- Yesterday

-

If you've already spent the time to research prices you're comfortable with, maybe you could use them here? Let's let BossLady weigh in since I tagged her.

-

I understand. I actually made a similar post on another subreddit last week that required prices, so I based them roughly on recent eBay sales averages. That said, I’m not sure how my tools condition compares, and since most buyers will likely take multiple items, individual prices might not matter as much.

-

I am downsizing and need to figure out how to price of the the leather that I'll be selling. Some side, I've had for years. While still perfectly usable, in some cases I don't even recall exactly what they sides are <lol>. But, I'll figure that one out. My main need now, is to figure out how much to ask for various partial sides of Latigo. Most are in the 10 ounce range and the belly edge, of course. So any suggestions on how to do it and be fair?

-

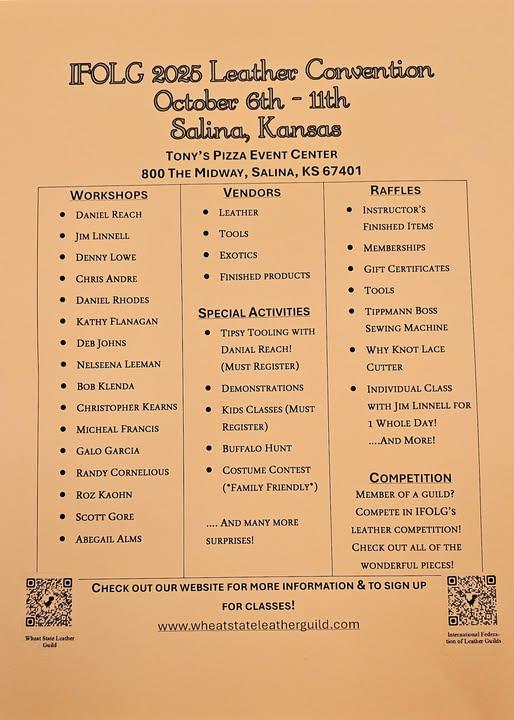

The 2025 International Federation of Leather Guilds show is scheduled for October 6-11th at Tony's Pizza Event Center in Salina, Ks It is hosted this year by Wheat State Leather guild. For more information please see the attached flyer. Or go to Wheat States website at www.wheatstateleatherguild.com

-

Holster between the belt and pants

AlZilla replied to AlZilla's topic in Gun Holsters, Rifle Slings and Knife Sheathes

Oh, yeah, I remember this from the stitching question. Very nice. I thought that belt loop was odd but didn't make the connection. No, I've been spending my time tearing servo motors apart. We're also on the tail end of a heat wave and no a/c in my craft room. I definitely need to pick a gun and get on this. Maybe my PK380 would be a good candidate. -

Very classy, I can see a lot of work (and leather!) went into it.

-

Man, you have you a massive amount of work into this. The challenge is that we normally want prices but this is kind a different situation. Let's tag the BossLady in here and see what she thinks, I'm sure it's happened before. @Johanna?

-

What’s the maximum thickness the Singer 29K71 can handle

AlZilla replied to JRodriguez's topic in Leather Sewing Machines

Here's a manual that says the foot rises 3/8" of an inch, so less then that: https://leatherworker.net/forum/applications/core/interface/file/attachment.php?id=149218 -

Hey everyone, I'm selling a bunch of vintage and antique leathercraft and cobbler tools that belonged to my dad. I put together a full numbered list of the items, and matched each one with a picture in this Imgur album: https://imgur.com/a/AjGKXD3 Each photo has a number in the description so it's easy to reference. The images are in the same order as the list. My dad bought a cobbler/leather shop in the 90s from a guy who had it since the 50s, and he had bought it from someone who started it in the 30s. So some of these tools are seriously old. One of them dates back about 165 years. A lot of them haven’t even been used in 30+ years. My dad’s close to retiring and I really don’t want to get stuck with all this stuff, so I’m trying to sell it now. I’m not in the trade myself, and I don’t have prices set so feel free to send me an offer for anything you’re interested in, whether it’s just one tool, a small bundle, or even the whole collection. Just keep in mind shipping is extra. It already took a ton of time just to identify and photograph everything, so figuring out prices on top of that was a bit much. If you want more pics or have questions about a specific tool, just ask me. I’ll help however I can. I'm in Montreal, Canada. I can ship almost everything — the only stuff I’d rather not ship are the bigger machines like the Singer 29K60. But if you’re seriously interested, we can see if there’s a way to make it work. I broke the list down into four parts: items in good/new condition with known brand/size items in good condition without brand/size info items in bad condition items I couldn’t identify (some might not even be for leatherwork) Here’s the full list: Mitutoyo 141-133 IMS-12" Inside Micrometer Rod Set, Not Complete Durex industrial 27-piece letter ⅛” letter stamps square (“J” missing) Pincers Cutter tool 10” Lasting Pliers with hammer tool Pincers Cutter tool 8” (3) Pincers Cutter tool 7” Cantle Pliers Pliers Cumbrian Made in England Cutting Nipper Eyelet Leather Punch/Driver Wiss Inlaid No. 20 Scissors Jeweler or Machinist Hammer with screwdriver C.S Osborne Draw Gauge Stitching Awl Wood Chisel Fuller (2) Singer 29K60 Singer 291U3 Landis Shoe Finisher Landis 5 in 1 Antique F.H. Smith MFG CO The Universal Press Punch Eyelet Hole Punch Machine Press (2) Shoemaker's Anvil Bench Vice Auto Soler Heel Wheel C.S OSBORNE #0150 ⅝ Strap End Punch (English Point) Kraeuter #27 11/16 Arch Punch Tool Kraeuter #27 ½ Arch Punch Tool C.S OSBORNE #500 3A Grommet Hole Cutter Kraeuter #27 ⅝ Arch Punch Tool C.S OSBORNE ½ Round Punch Tool C.S OSBORNE #245 3/16 Belt Punch Tool Kraeuter #350 Size 4 Rivet Setters C.S OSBORNE #151 1 ¼ Bag or Oblong Punch Tool Rare W.M DODD C.S OSBORNE #151 1 ⅛ Bag or Oblong Punch Tool Made between 1856 - 1861 C.S OSBORNE #216-3 Plain Grommet Inserting Dies C.S OSBORNE #216-2 Plain Grommet Inserting Dies Split-Head Magnetic Tack Hammer Singer C312 Scissors Set-Square Revolving 6-Hole Leather Punch (2) Maun Industries Spring Punch C.S OSBORNE #21 Size 5 Creaser Large C.S OSBORNE #21 Size 1 Creaser Large C.S OSBORNE #21 Size 3 Creaser Large C.S OSBORNE #21 Size 5 Creaser Small C.S OSBORNE #21 Size 3 Creaser Small C.S OSBORNE Double Line Creaser Size 2 C.S OSBORNE Double Line Creaser Size 3 C.S OSBORNE Double Line Creaser Size 4 Gomph Space Marker Size 8 Gomph Space Marker Size 5 Gomph Space Marker Sizer 7 Cat’s paws Rubber Heel 15-16 Twin Grip Brand New (2) Cat’s paws Rubber Heel 12-13 Twin Grip Brand New (2) The following items have no brand and/or size on them 55. Belt Punch Tool 56. Belt Punch Size 10 Tool 57. Oval Drive Punch 58. Knife 59. Digit “1” Stamp 60. C.S OSBORNE #21 Size ? Creaser Large The following items are in bad condition 61. Arch Punch ¼ 61. C.S OSBORNE #151 ¾ Bag or Oblong Punch Tool 63. C.S OSBORNE #245 5/16 Belt Punch Tool 64. C.S Osborne #147 Size 2 (⅛) Round Punch Tool 65. Priory Size 4 Belt Punch Tool Made in England 66. Belt Punch Tool Made in Japan No Size or Brand 67. C.S OSBORNE #147 3/16 Round Punch Tool 68. Priory Size 5 Belt Punch Tool Made in England 69. C.S OSBORNE #245 3/16 Belt Punch Tool 70. C.S OSBORNE Chisel The following items I don't know what they are. Some may not even be related to leather. See the images on imgur

-

Adler 205-370 - help an old man who screwed up

councilman24 replied to councilman24's topic in Leather Sewing Machines

This is the only machine that has this spring loaded shuttle race. Unless Adler's new one, 969 I think, does. -

Adler 205-370 - help an old man who screwed up

councilman24 replied to councilman24's topic in Leather Sewing Machines

Not that I can find. Found one on setting neesle bar height bit not on turning shuttle timing. I figured it out and it's sewing but don't know what I don't know. -

Hi everyone, I’m selling a SINGER 29K71 on behalf of a retired cobbler. I’m a shoemaker in Australia and I only have used my 29K71 for leather used in shoemaking, probably maximum 3mm thick. A person wants to buy it but they’re asking about the maximum thickness that this machine can stitch. The information I found on the net says 8mm. I tried to stitch two pieces of veg tan leather together (8mm) total and the leather doesn’t even move. The needle is going into the same position all the time. The machine stitches nicely on a lighter weight leather (2mm) but not with 8mm. Can someone’s share their experiences please?

-

Adler 205-370 - help an old man who screwed up

Goldshot Ron replied to councilman24's topic in Leather Sewing Machines

Weaver has a good video on Youtube for timing your 205. -

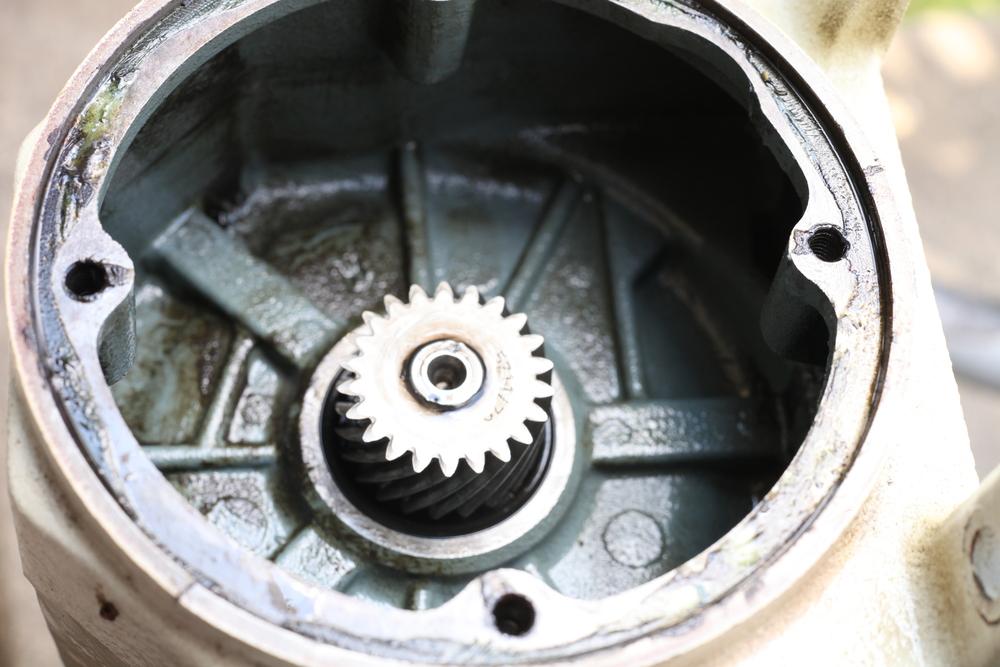

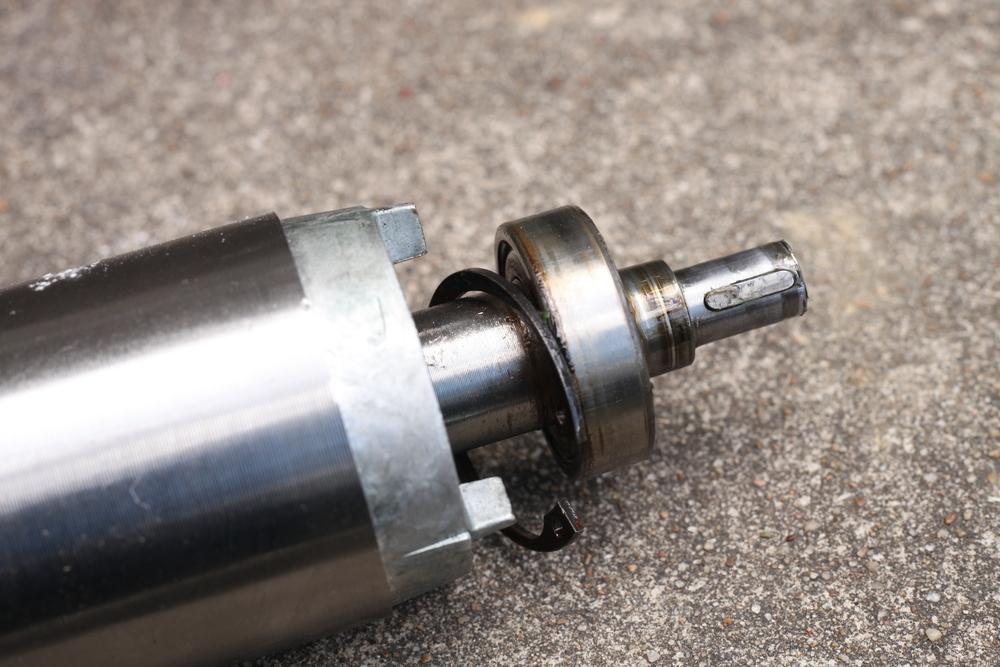

Here's how to replace the bearing on the gearbox end of the motor shaft. There is a big circlip on the motor side of the gearbox. (There will be a photo later) Make sure you remove that before you do any pounding This first image shows the gearbox after you remove the four cap bolts and pull the cap off. This model has two dimples in the shaft to mushroom it out to keep it on. I moved the dimples back inline with the shaft using punch, then used a 1/4 inch drive socket extension and a sledgehammer to drive the shaft out. Here is the bearing that needed replacement the most. Note the large circlip behind it---that's the one you have to remove before you do any pounding. Now that the bearing is out of the gearbox, I used a 3-jaw puller. By the way, notice the paint on this one is white. This is a second gearmotor (same make and model) from the same ebay seller. This time better paint, but still needed a new bearing. I replaced both bearings on the motor shaft, both are size 6203. I did not replace any bearings at the gearbox output shaft. They turn smoothly already, and they get a lot less revolutions than the motor bearings! Good news is, this motor runs semi-quietly with the new bearings. (Makes an oompah sound like you might imagine used as a movie sound effect in an eerie movie) I'll be replacing the motor shaft bearings on the other motor soon.