All Activity

- Past hour

-

I've seen a slow-down in several other forums. It doesn't seem to be limited to this one.

- Today

-

Swiss Saddler Clam Drawings

ClaimedVacancy replied to ClaimedVacancy's topic in Leatherwork Conversation

The only scaled drawings i have are the templates i posted earlier. Everything else has been in the moment, and it mainly boils down to what can i free hand and what can i not. So the do not free hands are the arms, two side panels, the cam, and all of the placement holes minus the screws that go into the fixed arm. There is a fairly high amount of drilling on structure depending on how square all the wood is! For me i didn't square the two side panels, and what i’ve noticed is I’m off about 1/16” or less. I think the reason is because i went off the template and not on structure when drilling and that tends to go bad sometimes. If i had squared the arms to the side panels, and used the template holes as a guideline i wouldn’t be off anywhere. The stationary arm bolt hole is also off by 1/16 to 1/8”. This is causing the jaw misalignment. Best advice at this stage is SQUARE your parts to each other, but separately first. Overall, it’s inconsequential and can be alleviated. Mainly talking about the jaws. What ill end up doing is cutting the jaws while closed until i have an imaginary square. Ill then glue in a harder block of wood. Cut right through the center of that, and finally shape the two blocks to match the contours. For progress report #6: I got many of the screw and bolt holes drilled and fixtured. The base is square now, and next will be jaws and getting the dowels installed to hold the upper spring. Spring will be installed after the jaws are fixed. Somewhere in between ill get the base plate squared away and fixed to the body. You can see that the cam is off as well inside. This is because the movable arm bolt hole is off, and some of that is under shaping on one side. Ill fix that later.- 19 replies

-

- swiss leather tools

- swiss army leather

-

(and 2 more)

Tagged with:

-

Well, Boss Lady has the bots that register to spam us pretty well down. For the moment ... Posting activity here of late has been pretty quiet, even with a steady trickle of new users registering. Even a few short years ago when I first joined there was so much activity, it was hard to keep up. Maybe it's just seasonal. I don't know, maybe after 20 years, most of the questions have been answered.

-

Paddle holster question

wizard of tragacanth replied to DoubleKCustomLeathercraft's topic in Leatherwork Conversation

Frank, thanks for the tip on searching. It worked for me and I found a couple of things. Double K. In my perusing paddle holsters, I realized that a paddle is a very compromised design from the git-go. With diligence and experimentation, I'm sure you could work out a design but I am wondering why your customer could not be better served with a flat-back, snap-on design? It would be easier to execute and much more secure. It would take a little more time to don it, but I think it would be worth it for the better stability and security. However, I do not know his needs. Something like this Don Hume design -- https://www.donhume.com/index.php?main_page=product_info&cPath=65_5&products_id=837 -

Long time lurker first time poster

misty vale leather replied to misty vale leather's topic in Member Gallery

Thanks. -

Long time lurker first time poster

chuck123wapati replied to misty vale leather's topic in Member Gallery

welcome !! -

Paddle holster question

chuck123wapati replied to DoubleKCustomLeathercraft's topic in Leatherwork Conversation

I've made paddle holsters for phones. Double the paddle side and keep the rough sides out so it won't slip as badly. I also ran some rivets along the top to keep the bend in place. -

picking a leather Conditioner

DoogMeister replied to stampingdelight's topic in Leatherwork Conversation

There are bound to be as many opinions to this as there are responders. My preference is Feibing's 4-way care. Easy to use, predictable results, and it is available at a decent price. -

Thanks for all the positive vibes. I just hope she loves it.

- 11 replies

-

- shoulder bag

- sedgewicks leather

-

(and 1 more)

Tagged with:

-

I'm on another forum that was inundated with bots. They put a Captcha to verify you're a human at the login and that eliminated just about all bots. I don't know what's involved to do that but it is one solution to the problem. Maybe it would be a good idea here.

-

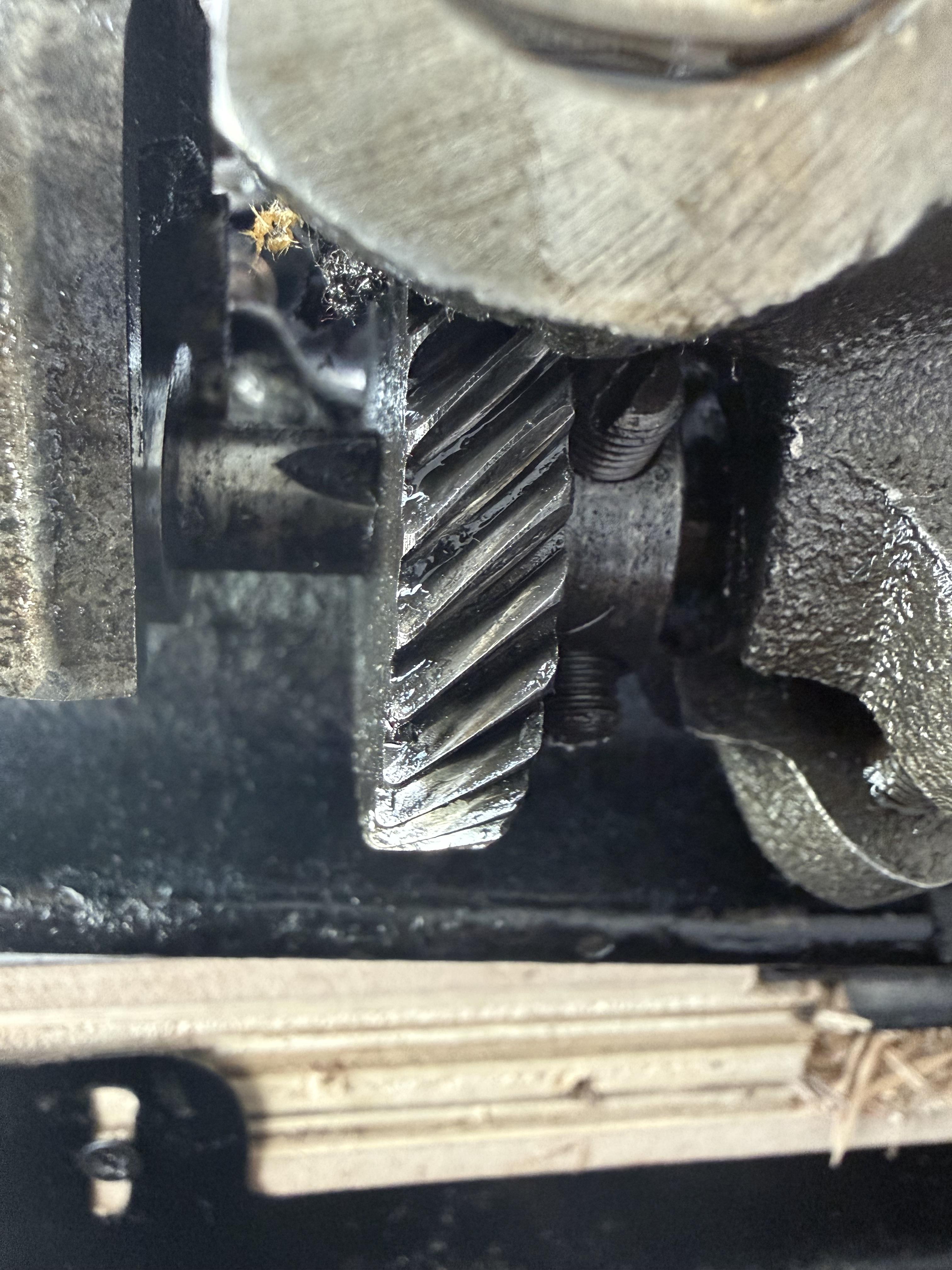

I think I'm making it worse. I got the left needle dialed in. I stitch with heavier fabric and multiple layers and everything was clean and good tension. I took a look at the right needle and noticed the hook timing was off a little. I followed the steps in the video to adjust the hook timing. But when I loosened the two screws for the big gear, it didn't move freely along the shaft the way it showed in the video. Now I can't get either hooks to rotate properly. I attached some pics and videos to show what I'm dealing with. This is really starting to get frustrating and time consuming.

- 13 replies

-

- singer 112w

- double needle

-

(and 1 more)

Tagged with:

-

Nice tool holder. I like that kind of organizing. I see you have marked them with stamps. Maybe you could rub some antiquing across the top so the numbers show better. I keep many of my drills on a shelf behind my drill press in similar blocks. I also have blocks to organize many of my leather tools in my various tool boxes. They're made mostly of different hardwoods, depending on what was on hand when I made each one.

-

Antique Tools - Edge Channelers; Anyone else use these?

MarshalWill replied to alfredleatherworks's topic in Leather Tools

Those are really interesting. Nice find. No, I don't have any channeling tools. That said, there's nothing like old well-made hand tools. My grandfather was a contractor who worked on the Winchester House from about 1900-1920. I have his tool chest and many of his hand tools. Some are leather tools and others are woodworking tools. I love to use them. Good, old tools just work right. Samalan, those boxes of old tools sound amazing. What a treasure. Even the boxes. -

Hello everyone, my name is Stephen. My wife and I run Misty Vale Leather in WV https://mistyvaleleather.square.site/ We create WV/Appalachian themed leather goods. While I just got my wife into the craft about a year ago, i've been involved for about 10 years now. Even though i've been making things for quite a while, i'm relatively new to the business side of things. I'm hoping i'll be able to pick sone if your brains on marketing and business questions. I've utilized the site many times in the past when i've run into unexpected problems that I couldn't figure out, and I have always found it an absolute wealth of information. I figured it would be even more helpful if I could actually ask questions, and I thought it would be nice to maybe help someone else out with their questions as well. In the regular world I'm a teacher so sharing information and helping others learn is kind of what i do. I've learned a lot from viewing old archived threads and I'm looking forward to not only learning more but also sharing some of the knowledge i've gained over the years as well.

-

I think I'm making it worse. I got the left needle dialed in. I stitch with heavier fabric and multiple layers and everything was clean and good tension. I took a look at the right needle and noticed the hook timing was off a little. I followed the steps in the video to adjust the hook timing. But when I loosened the two screws for the big gear, it didn't move freely along the shaft the way it showed in the video. Now I can't get either hooks to rotate properly. I attached some pics and videos to show what I'm dealing with. This is really starting to get frustrating and time consuming. Video Project.mp4 Video Project 1.mp4

- 13 replies

-

- singer 112w

- double needle

-

(and 1 more)

Tagged with:

-

Paddle holster question

FrankHester replied to DoubleKCustomLeathercraft's topic in Leatherwork Conversation

Try this search in a search engine-- "site:leatherworker.net paddle holster". don't use the quotation marks though. -

Paddle holster question

wizard of tragacanth replied to DoubleKCustomLeathercraft's topic in Leatherwork Conversation

I knew that my suggestion was not a perfect answer for you but it was "an" answer if nothing else was found. Actually I am surprised that you found anything with the search function here. I have rarely found answers using it. Good luck. I will be following this thread as I am curious as to what you find. Nick -

ok I take it that any leather conditioner will clean the leather & they should help restore oils lost over time. was just looking to get some and never new so many where around so thought to see if all should be about the same if made for leather.

-

Thanks for the response. Albuquerque is about a 9–10 hour drive for me. If you happen to travel anywhere closer to Utah (I’m in the Salt Lake Valley), that would make this much more doable on my end. Otherwise freight likely pushes it past what I can responsibly spend. Let me know what regions you typically cover if you could. Thanks

-

That is very helpful, thank you.

-

Yes, I double checked the threading. When threading I go off the manual (which is not that good) and a youtube video. The tensioner on my machine seems to have these little notches that I'm not sure is part of the threading process. The video I followed didn't mention it. My left needle seems to mostly dialed in. I will be checking everything again and testing on different fabrics next, then move on to the right needle. Thanks for the 139 manual, I will take a look at it before I start any of my next steps. I would mention that since my machine is needle feed (slightly moving towards the back of the machine when going down)and doesn't have the timing marks on the needle bar, it was a little difficult getting the exact lowest point of the needle bar.

- 13 replies

-

- singer 112w

- double needle

-

(and 1 more)

Tagged with:

-

"Sheriff of Cochise" rig

billybopp replied to fredk's topic in Gun Holsters, Rifle Slings and Knife Sheathes

It makes perfect sense, but ... getting dressed must have been a PAIN! LOL -Bill -

"Sheriff of Cochise" rig

chuck123wapati replied to fredk's topic in Gun Holsters, Rifle Slings and Knife Sheathes

Looks like all his leather came from the same guy. -

"Sheriff of Cochise" rig

chuck123wapati replied to fredk's topic in Gun Holsters, Rifle Slings and Knife Sheathes

Check out his shoulder rig lol, the shirt is cut to hide the strap.

.thumb.jpg.4ed1dbae8dada980d06392d599329b6e.jpg)