All Activity

- Today

-

LACING OR THONGING A MITERED BOX CORNER

Chipster99 replied to MikeF's topic in Leatherwork Conversation

That’s some pretty spiffy tooling work right there…very nice job! -

Often times it is better not to tag onto an 8 year old post. Find the same forum and make a new thread with your post. Some pictures may be of great help too. Need to be able to see what you are describing. Our ESP doesn't reach that far

-

.thumb.jpg.6e903dd66163ad5672f00f144058c571.jpg)

How to search for single word with three characters

Northmount replied to friquant's topic in Computer Help

Use a Google search. Their indexing is better, and the servers are very fast. Use the following format: site: leatherworker.net vfd The site parameter restricts the search to a specific site. The search parameters like "VFD" follow the site parameter. -

How to become a Contributing Member

friquant replied to friquant's topic in Feedback and Suggestions

-

Is there something preventing small search queries from running? I'm trying to search for the word "VFD", but it's coming back with no results. I tried adding a filter for "posts only by one particular member" but still no results. I'm also having trouble searching for "tig"

-

go to the homepage leatherworker.net

-

How to become a Contributing Member

friquant replied to friquant's topic in Feedback and Suggestions

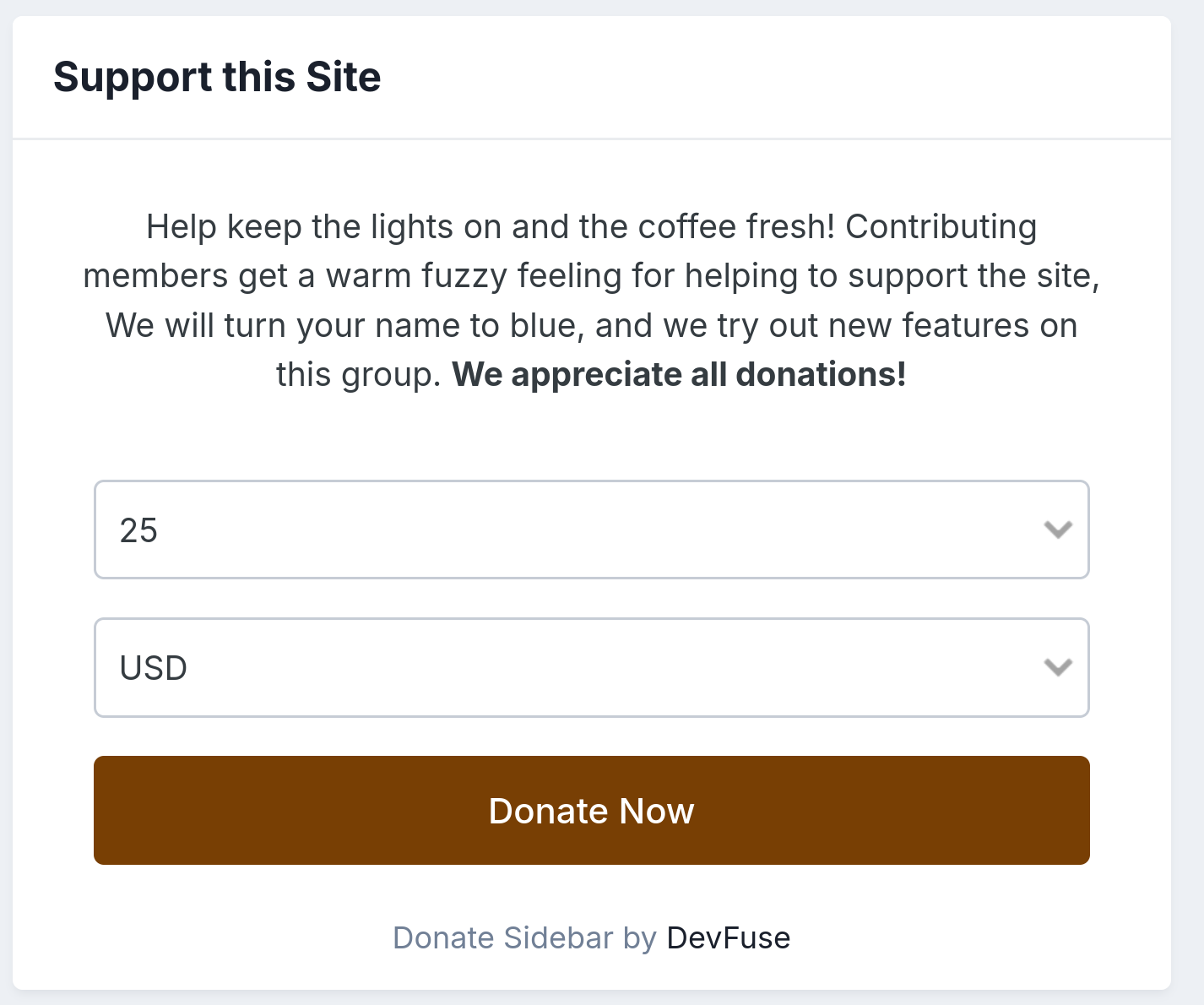

Yes that sounds good! I'm not seeing the "donate" box. Here's a screenshot of the lower right of my screen. -

Thank you!

-

Locked and moved to old and sold archive for non-compliance.

-

Very Nice...

-

Something else that makes edging the flesh side easier is slicking your leather. I know, I'm old school. Basically for vegtan you case or at least dampen the surface then run a glass or wooden slicker over it a few times. I slicked flesh and grain side. On a cosmetic note slicking makes the bottom side appearance smoother and more pleasing. Functionally - slicking will compress the fibers, smooth the grain a bit, take some stretch out. it helps to prevent paired straps from stretching unevenly. It will also make your bottom edging feel almost like grain side edging. For chrome tan leathers like latigo, you can use something like saddles soap, BlackRock, gum trag or Tokonole on the flesh side and then slick to lay down fibers and allow some compression. Slicking will also let you use some of that leather you all are throwing or giving away. Cut the flanks out of the bellies and save the bellies. Case them and slick the snot of them. They will compress and make a nice piece for things like card cases or leather that molds easier for sheaths depending on thickness. You can work at it and slick a belly up to almost resemble shell cordovan.

-

Thanks!

-

I got the old girl sewing like a champ. I had a CB4500 but really wanted a Landis 16 needle and awl machine. Eli really dialed her in I called him to get some pointers on how to sew with this machine. Still learning but this machine really sews a beautiful stitch on both sides of the leather. I us the machine for the sides and corners of my tote bags the leather is 5 to 6 OZ. The little Consew 206RB-5 I bought from Bob over at Toledo Industrial Sewing Machines and the CB4500 I sold that to a saddle maker in the Columbia SC area. I use the Consew for the Marine Canvas and boat upholstery work. I have a booth at the Cottage in Georgetown SC for all my leather works make a lot of ladies purses. I needed another heavy leather stitcher for my leather work. I just love these old machines..

-

spring flowers and good food

chuck123wapati replied to chuck123wapati's topic in All About Us and Off Topic

Life is good, my friend 🍺 On both sides of the planet. It's been a ride, though, and not one I care to repeat for a while. I am slowly catching up to my chores and starting to relax a bit. Went shooting the other day just for kicks and picked up some more clay. Ive processed about 30 lbs so now i have enough to play with if my kids don't use it all up. A great thing is taking place here now, folks are buying more and more US-made products and more and more small family businesses are making a comeback, finally. I can see my kids actually being able to work for themselves and make a living if they want to go that route in the future. Anyway have a great day and say hi to pops for me!! -

Edge beveling 101

RidgebackCustoms replied to ThisIsMyFirstRodeo's topic in Leatherwork Conversation

"They be more what you call guidelines than say actual rules" Since the fibers on the flesh side are a little looser and harder to cut cleanly, I tend to cut it first. The presence of the full width of the leather supporting the cut makes it easier. I can push down slightly as well as forward and the fibers don't tend to smush down as I run the line since they're fully supported. -

What a grand old lady . The machine i mean .lol Did anyone else notice the wear on the outer foot pedal in photo 5 ? That probably took 30-40 years to get it like that . When i look at old machines like that i can't help wonder . Some one has made a living using it , bought a house and raised a family sent their kids to college and retired . The machine gets passed to a new worthy owner and the cycle starts again . I am sure the old girl has heard laughter and felt tears and no doubt being a Landis many a curse word has been spoken to it and in its presence . Still going though and by the looks of it still loved. makes me smile

-

@acem77 Below is a link to an English shoe making tool manufacturer called George Barnsley The catalogue is from the 1920's . Barnsley tools were probably the best in their field at the time and still used today . I still use vintage Barnsleys's everyday . I think the catalogue with help you identify what you have . But we still want to see photos . https://archive.org/details/barnsley-and-sons-shoe-tools-catalogue-1927/page/n1/mode/2up?view=theater Click the link and download . On the bottom right you will see left and right arrows .click the arrows to turn the pages . In there you will find a version of just about every shoe making tool and what they are called . Other makers have variations of the same tool but are generally named the same . I use the catalogue as a reference source but i am pretty familiar with most of it . I think i may even have a bout 70% of what is pictured , not because i use them but because i collect them . For those that a wondering what a welt mill looks like ,below is a photo . The teeth on the mill correspond to a height or thickness of leather . A skiving knife is held across the chosen teeth and the leather strip pulled through cutting it at the desired thickness . Essentially it is a leather splitter . Its not a big tool

- 23 replies

-

- shoe making machinery

- cobbler techniques

- (and 2 more)

-

Vais Sewing machine in Brooklyn should be able to get it going.

-

I am intrigued please do post some photos . Brass welt mils were made of brass so they would hold up better in the salt water . Most other tools would be made of steel with wood handles . It would be interesting to see how these hold up over time . I would be fascinated in the the background story . Where were the tools found and what year did the ship sink . Where did it come from and where was it going . You would be surprised with the meticulous records kept by shipping companies . If you can find the records you can find out a full cargo list . ,where it came from and where it was going . I get excited when i find old tools in a long forgotten shed or in the back of an old shop covered in dust . Its like finding treasure . But actually bringing them up from a shipwreck is about as good as treasure hunting gets . The fact that you found a welt mill tells me a few things . Good year welting became fairly normal around the 1850's so it would be some time after that that there would have been a market for a factory produced welt mill . I have seen new ones for sale on etsy i think , but there would be limited demand for them now days . To be honest i i have never seen one come up for sale on Ebay in the last 10 years . I think the tool is so obscure that no one really knows what it is so mis-identify it. There was one owned by the master shoe maker who taught me but i never saw him use it because we would buy welts pre made in various thickness and widths . If i ever do come across one in the flesh i would not hesitate to buy it to add to my collection .

- 23 replies

-

- shoe making machinery

- cobbler techniques

- (and 2 more)

-

LACING OR THONGING A MITERED BOX CORNER

SouthWales replied to MikeF's topic in Leatherwork Conversation

This is beautiful work Mike. ive been thinking about doing wraps on speakers etc with tooling but wanted to learn about spanish braids on mitered corners etc. -

I have a "thing" for these old Landis machines. Now I need a 16... I like the safety sandals, they say "This will work out perfectly..." and it sure looks like it did! Nice machine and space!

-

A beautiful holster for a great side arm!

-

Hand sewing is another level for sure! I bought it from Tandy, 4 oz "Crazy Horse". It’s interesting and nice to work with. The vinyl lining gives it some body when the bag is done.

-

The ABLE290 is available again. I am now a full time caregiver for a disabled partner so it is just a sideline. The machines from China are much better in terms of paint ant chromed parts but still need most of the same modifications as five years ago to make them a viable sewing machine that won’t slice into your finger the first time you open the needle plate. Due to changes in US customs I doubt it is worth importing a $AU350 machine as it will get hit with the Chinese import duty.

-

@friquant I'm going to be going through Little Rock in two weeks going to the Heart of Texas show in Waco, sponsored by the Leathercrafters Journal. Wanna have a cup of coffee? If anyone wants to donate to the site to get a warm fuzzy feeling, and a few extra permissions, you can use the "donate" box on the right side, bottom, of the page. (It's just a widget for PayPal to admin @ leatherworker.net. The most important contributions to the site are your comments, pictures, experiences, warnings, triumphs, lists and participation, and I am humbled by the way our community will jump in to help others. There are some great people in Leather Land, and they are willing to share what they know so the next generation can learn. We are 19 years old now, older than FB and X, and have collected the most useful leather info available on the planet. God bless you all. ~J