All Activity

- Today

-

Speed reducing that 66 was my first thought but I wanted to see what others offered. Here's a pic of a speed reducer for an industrial. A little big but it illustrates the concept. You can also homebrew a unit with a couple of pillow blocks, 2 pulleys and some bar stock. Reducing the speed also increases the torque. I've got an industrial that I can run as low as 11 stitches per minute. Way too slow but very controllable as it increases in speed. If that 66 can be controlled enough to work for you, it lets you work while you decide on and fund a genuine glove machine. You could go here https://www.blocklayer.com/pulley-belteng and play with the potential speed reduction. I guessed at a 1/2" motor pulley, driving a 4" pulley that in turn drives a 1" pulley and then a hypothetical 3" hand wheel pulley. Driving the motor at 300 rpms gets 13 stitches per minute. Obviously, you can change any of that. It's the 3rd calculator down on the page. If you do something like this, I'd make sure the foot controller is 100%. Those things can cause a lot of problems.

-

spring flowers and good food

chuck123wapati replied to chuck123wapati's topic in All About Us and Off Topic

Maybe a circle instead of a diamond with the same-sized edge on both sides of the stitches. -

WhizzleSTIX joined the community

-

Thanks for your reply and linking to your post. I am thinking this may be my next approach whilst I see what other suitable machines are available over here. I love how you have solved your issue without it being too difficult to manufacture or source parts. I’m thinking I may try a 3d print a larger wheel to suit 😊

-

Max of 8mm? That thing is definitely overkill, it's a 441-class machine, a harness stitcher!! It's too late now but you should have found out what options the seller has then ask here as to suitability. They should never have sold you a machine like that for what you are sewing.

-

A 205-64 is not a walking feet (-370) but a needle feed sewing machine. One of the best made in the class of super heavy arm machines.

-

What other working sewing machines do you have in your shop?

-

@DarkHorseFarm As a starting point you could check what motor (how much horsepower) and what gear reduction (4:1, 5:1, 10:1) is being offered by the folks at Campbell.

-

Hello to whoever reads this. I’m considering buying a 205-64. It needs the walking foot worked on. I’ve been told there are shims that are needed to keep it working in line. Its sews fine and could be used as is. I know it’s an old machine with its limitations and I certainly don’t need it. That being said the asking price is $500 and I do wonder if it might be worth it to have I’m my shop or possibly repair and resell. Though I never seem to sell anything. I’d like to hear opinions from those who know more about this machine than I. Thanks Jonathan

-

My girlfriend says I can get a reduced sentence if I paint the pulley 😀

-

I would have thought the 869 would be a better machine for the job also. thickest leather I will sew is 8mm.

-

Jisela joined the community

-

One curse of the 7x3 needle system is they are so long. This means they will flex more when using narrow sizes like the 140Nm you mentioned. The needles are also more expensive, and available from fewer sources.

-

It is along the entire length of the bottom edge.

-

What sewing machine should I purchase?

AlZilla replied to J Kellar's topic in Leather Sewing Machines

You'll get plenty of good feedback here. For the moment, let me direct you to an epic thread on this very subject that should get you started: -

I have a few questions regarding machines. I mostly sew wallets, belts, and knife cases, but I would also like to do bags at some point. As far as belts and sheaths go, I use Hermann Oak Saddle Skirting Leather. Should I use 207 or 277 size thread, or both? Is the Cowboy 797 from Tandy powerful enough to sew through 2 layers of 10-11 oz Hermann Oak without pre-punching the holes? If not, what machine should I look for? I've looked at the CB3200 and the Cobra Classes 3 and 4 sewing machines, but those are a tad out of my budget for now.

-

As you say, many years of use. I would obtain some U shaped brass channel and affix it to that bottom edge oh, question, is just the corners or the whole length of the bottom edge seam or what exactly?

-

I have been asked by an older gentleman who is really attached to this bag if I can address the edges. I didn't take a picture of the bag, but found one for demonstration purposes. The entire edge on both sides is rolling inward when the bag is set down on a solid surface. The leather is in good shape, supple, but also very soft. I think over the 40 years it has been used, it has created a memory and will always go back to that position, even when I pull it out. Any ideas on how to fix the bag so the edges don't roll under the bag? Thanks!!

-

Singer 18-2 Problem with part 3037

Constabulary replied to Ghoust6's topic in Leather Sewing Machines

maybe you can post pictures and give us some more detailed information cause no one knows what parts 3037 is except we download a parts list an look through it until we find the part you talk about 😉 -

Doubie joined the community

-

This wouldn't have been my first choice of a machine mainly due to the hole it would punch through the material, 2.5mm diameter unless you are sewing items above 1/2"(12.5mm) in thickness or saddles. I would have probably gone with a Juki LS-1341 or clone with a speed reducer as it would use a smaller diameter needle the system 135 x 16 x needle size for leather. My understanding is the 969 is a class 441 machine that takes the system 7x 3, 794 or 1000 needles (Schmetz). There are needles available for 7x3 or 794 from #19-#27 (120-220) for V92 to V415 thread. I would talk to the dealer to track down the needles if you are going to keep the machine and maybe discuss exchanging the machine for something like a 869 which would take the system 135 x 16 needles . kgg

-

Carlos Asse joined the community

-

Ever hear of J.Z. Horter Co?

Carlos Asse replied to Kelloggkid's topic in Saddle Identification, Restoration & Repair

J.Z. Horter was an American businessman in the 30s/40s in the city of Habana, Cuba. Diego Velazquez de Cuellar founded the city 'San Cristobal de la Habana' in 1514. Habana with a 'b' is the correct spelling. Americans began to spell it, Havana, I have no idea for what reason. Mr. Horter was a representative of agricultural machinery, and electric motors and lamps. The saddle you have may very well be something that he had made for himself, or something given to him as a gift by some of the sugar cane companies with which he dealt. Since he probably went riding a horse to some sugar cane fields. This is just my assumption. Since I do not believe he had anything to do with leather goods. There is a three story building with his name on it in the middle of 'old Habana' (Habana Vieja). I just bump into your inquiry while doing other research. I hope it helps you with your inquiry! -

spring flowers and good food

Darren8306 replied to chuck123wapati's topic in All About Us and Off Topic

Thanks guys. The stitches are layed out in the die, and the stamp couldn't have been stamped any harder (short of breaking my hardwood stamp). One of the other problems, pointed out by a stranger who didn't see it, is the quality of leather. Bought some cheap from Tandy, to try as liner. It dyes weird, is strange to handle and probably has problems I am unfit to describe well. The 'stranger' was 'Armitage Leather' on youtube. He has a 2h sewing presentation, and early on, he told me something I've known a long time, and keep having to be told. Buy quality. Leather of high quality, he says, works consistently and that limits the errors to the worker, simplifying troubleshooting. This leather, as I said, is the opposite. I think it will be worth going back to Hermann Oaks, or whatever other quality stuff I can find in Canada. It's better, and the errors are more often 'mine'. I will try to make tension consistent, and avoid the backstitch, so thanks for that. I'll be banging out a few of these crappy ones, while meditating on some of these issues. The quality stuff will be after I've got a better result, as I do still have some HO scraps around somewhere. As a side note, it seems to be too slow to include sealhide in this fashion. Also, the hairs look too long for this size of project, I think. Anyhow, onward and thank you guys. -

Those are BEAUTIFUL! And the messy bench makes me less ashamed of mine lol. (currently a similar mess on the kitchen table, while Sweetheart is away)

-

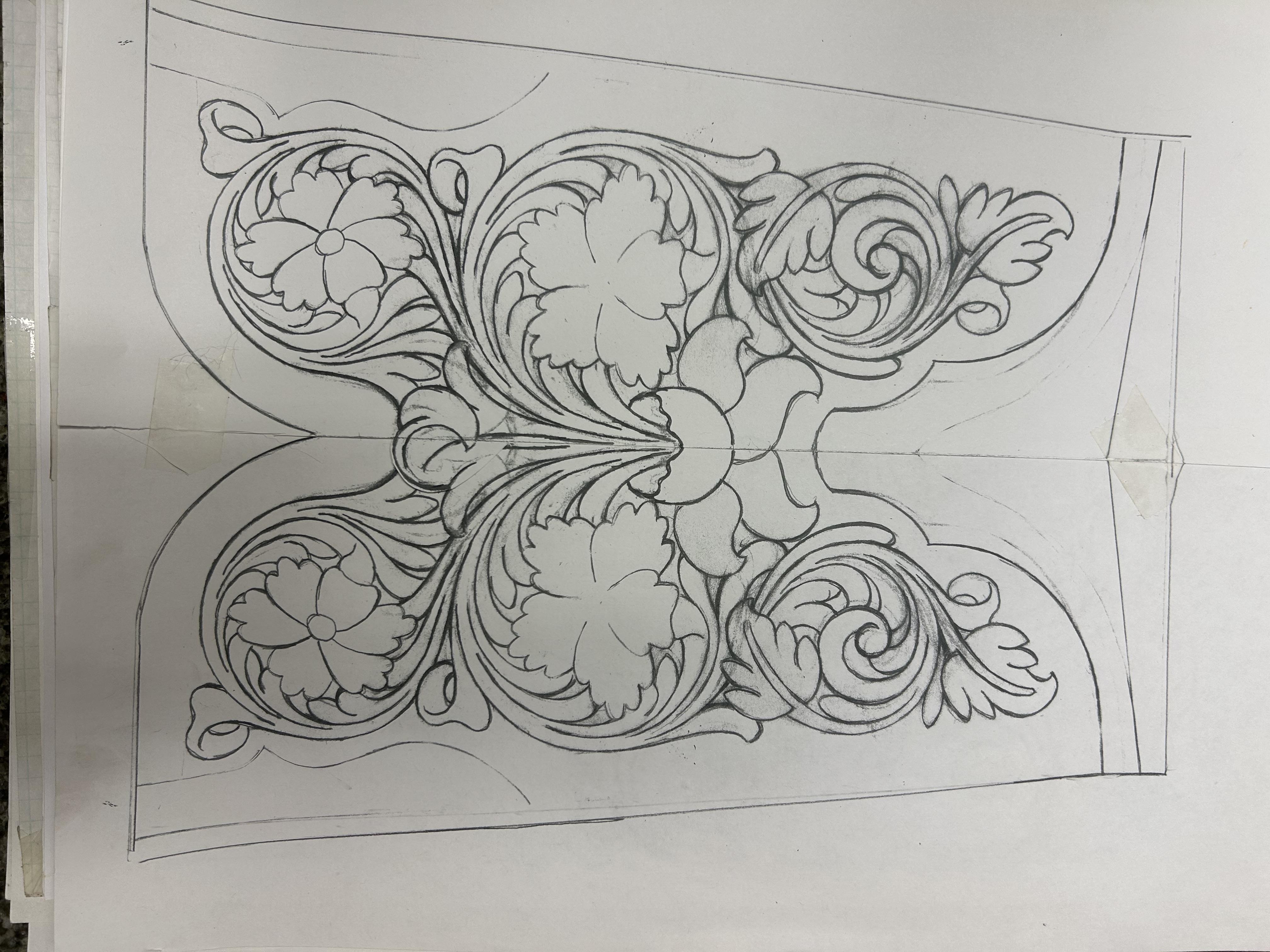

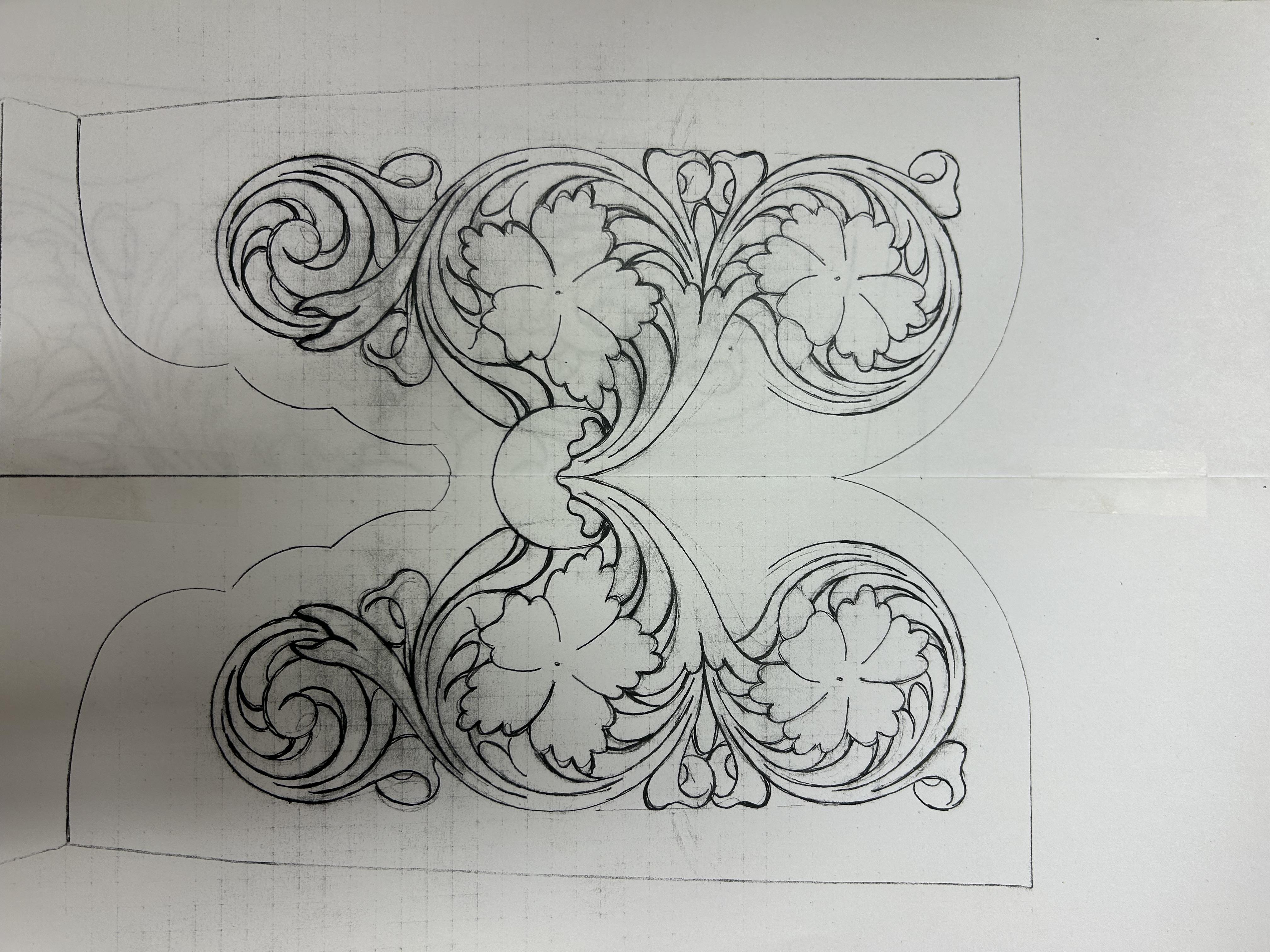

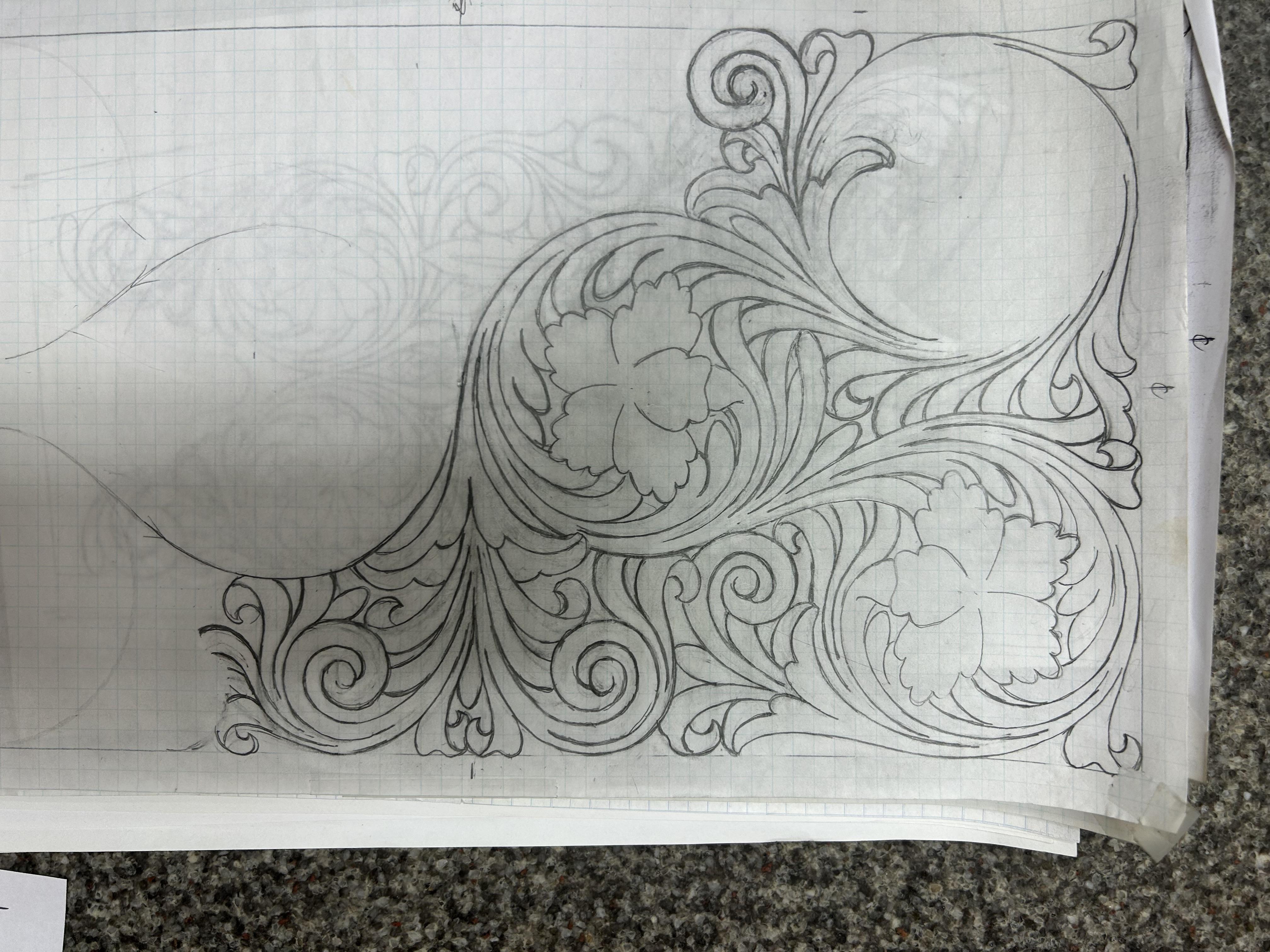

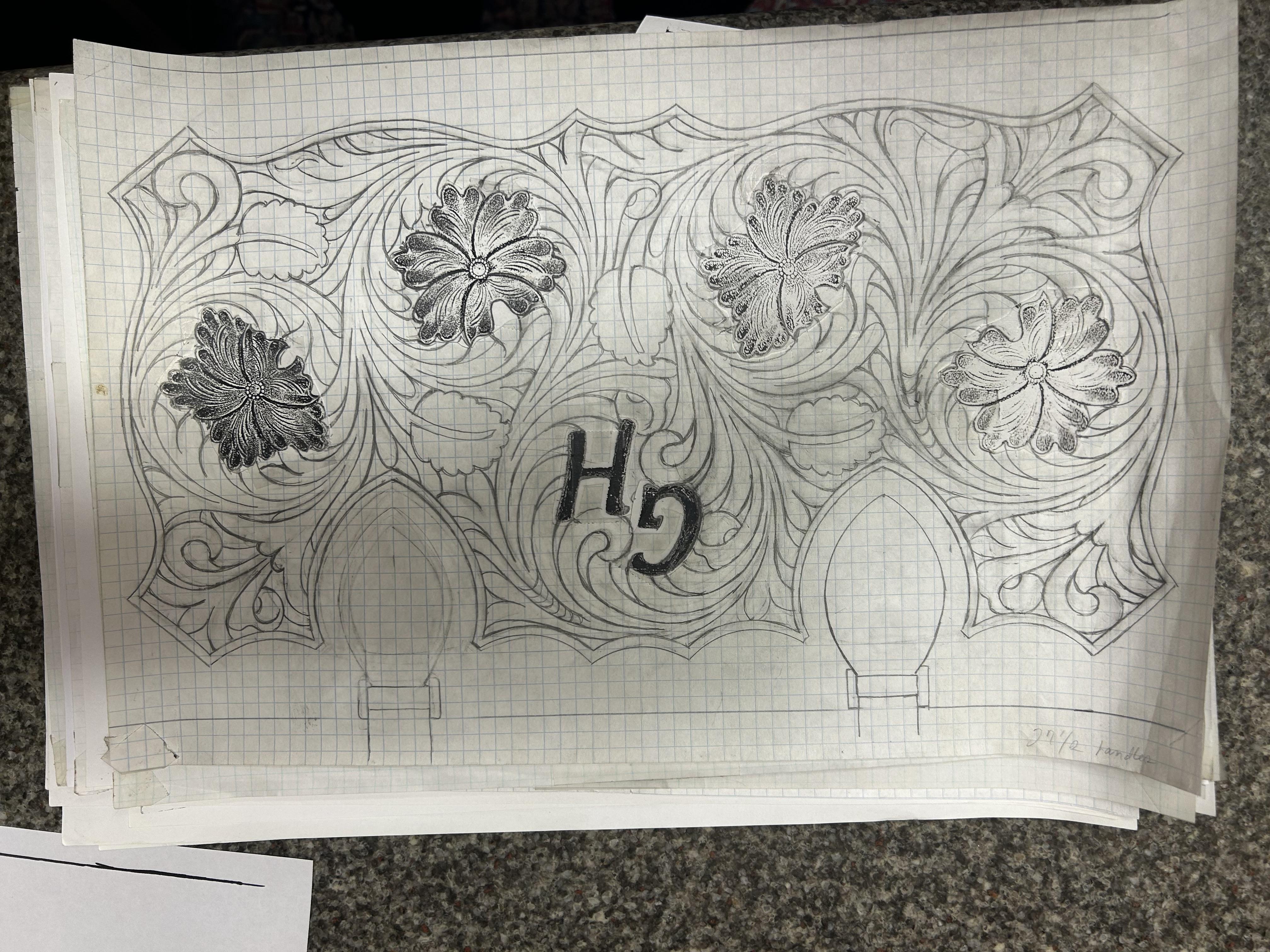

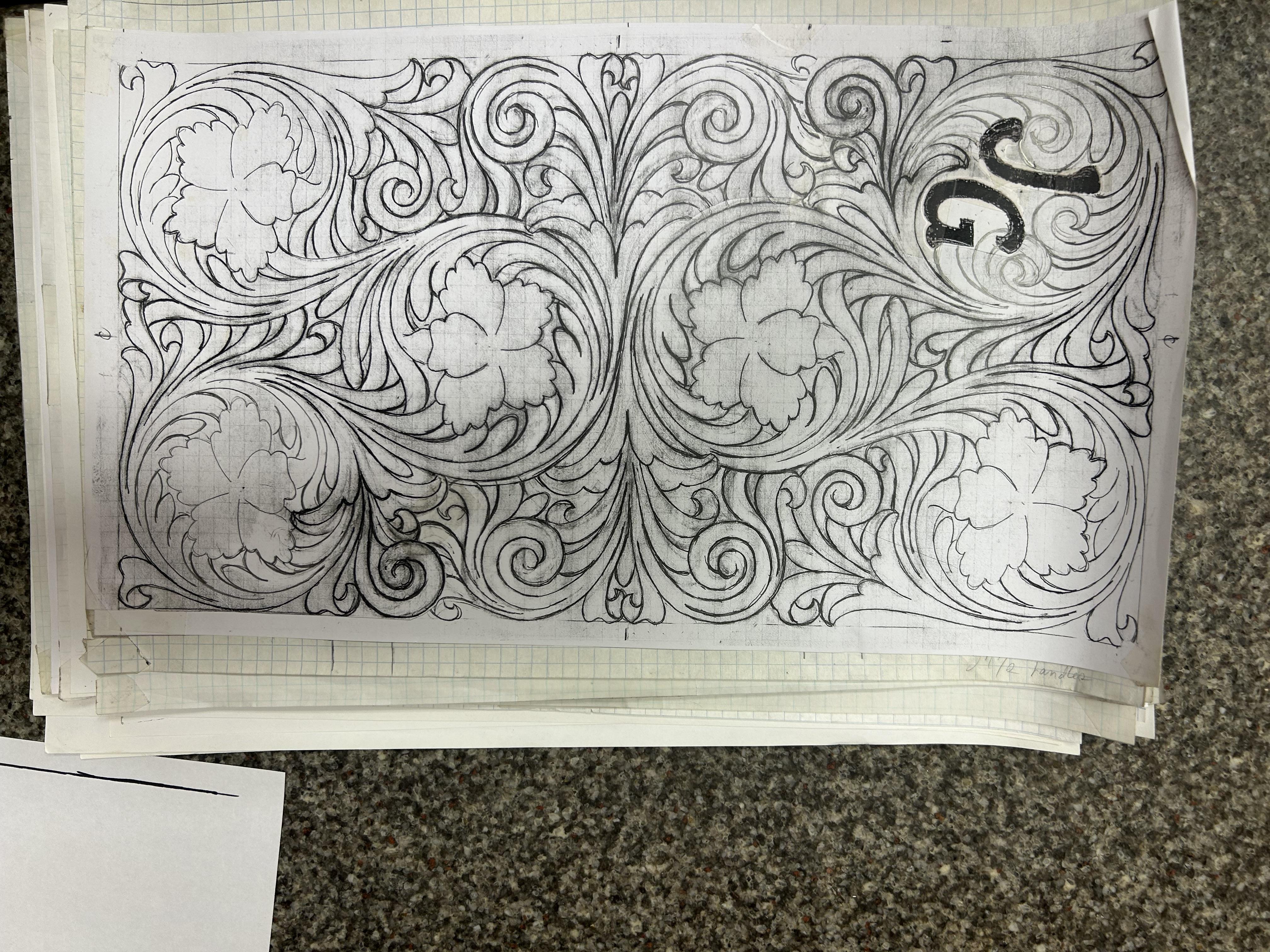

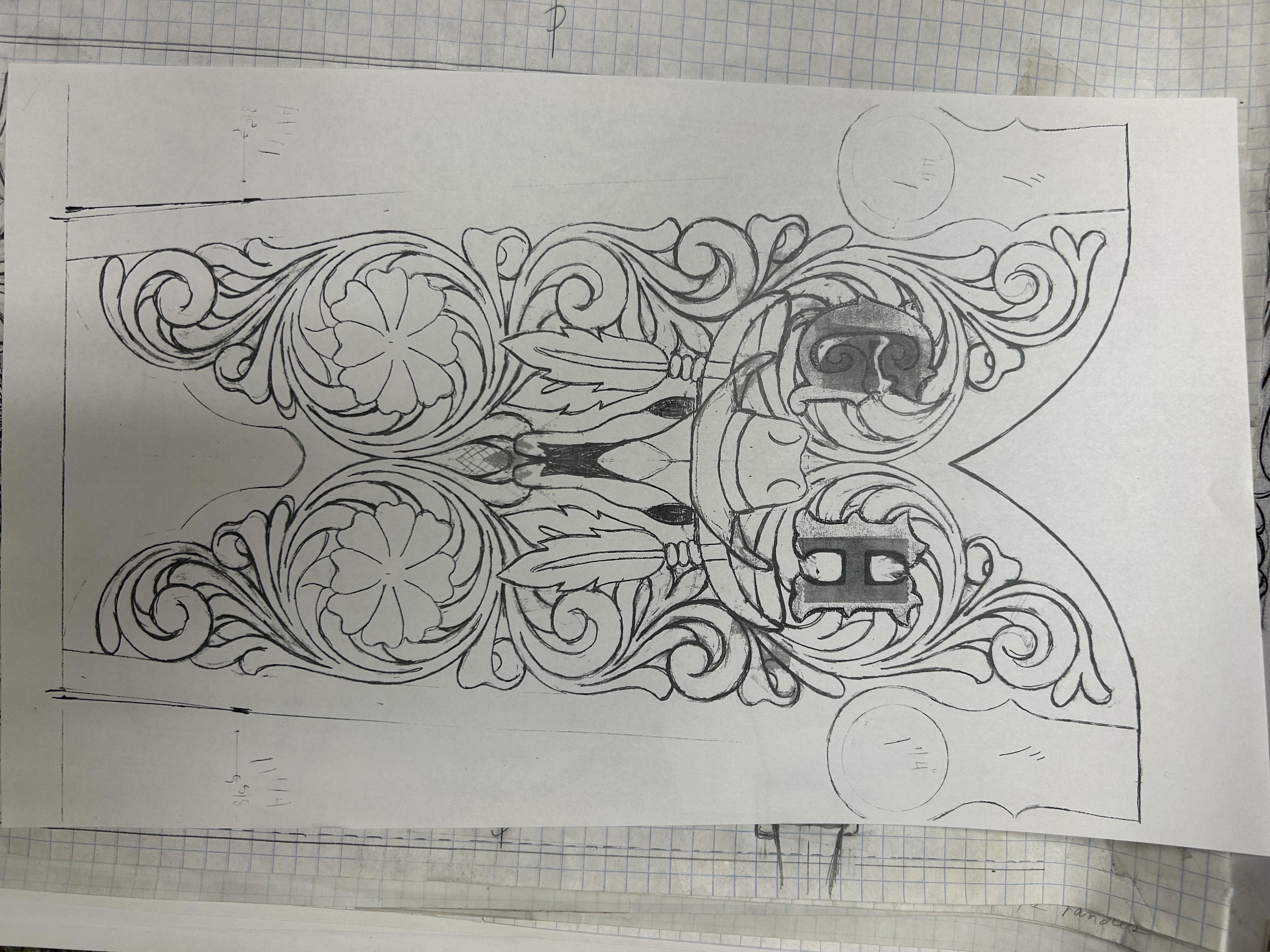

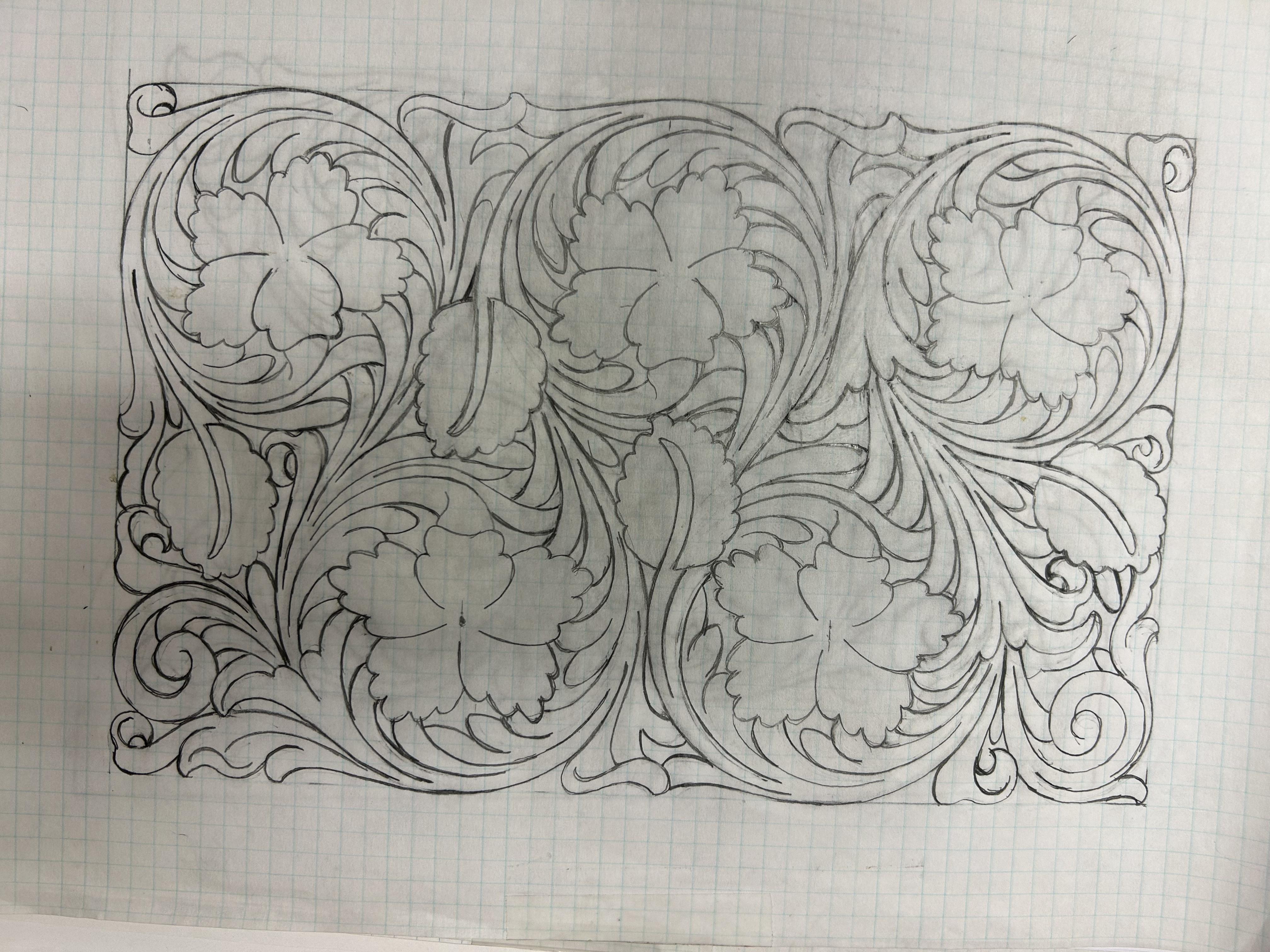

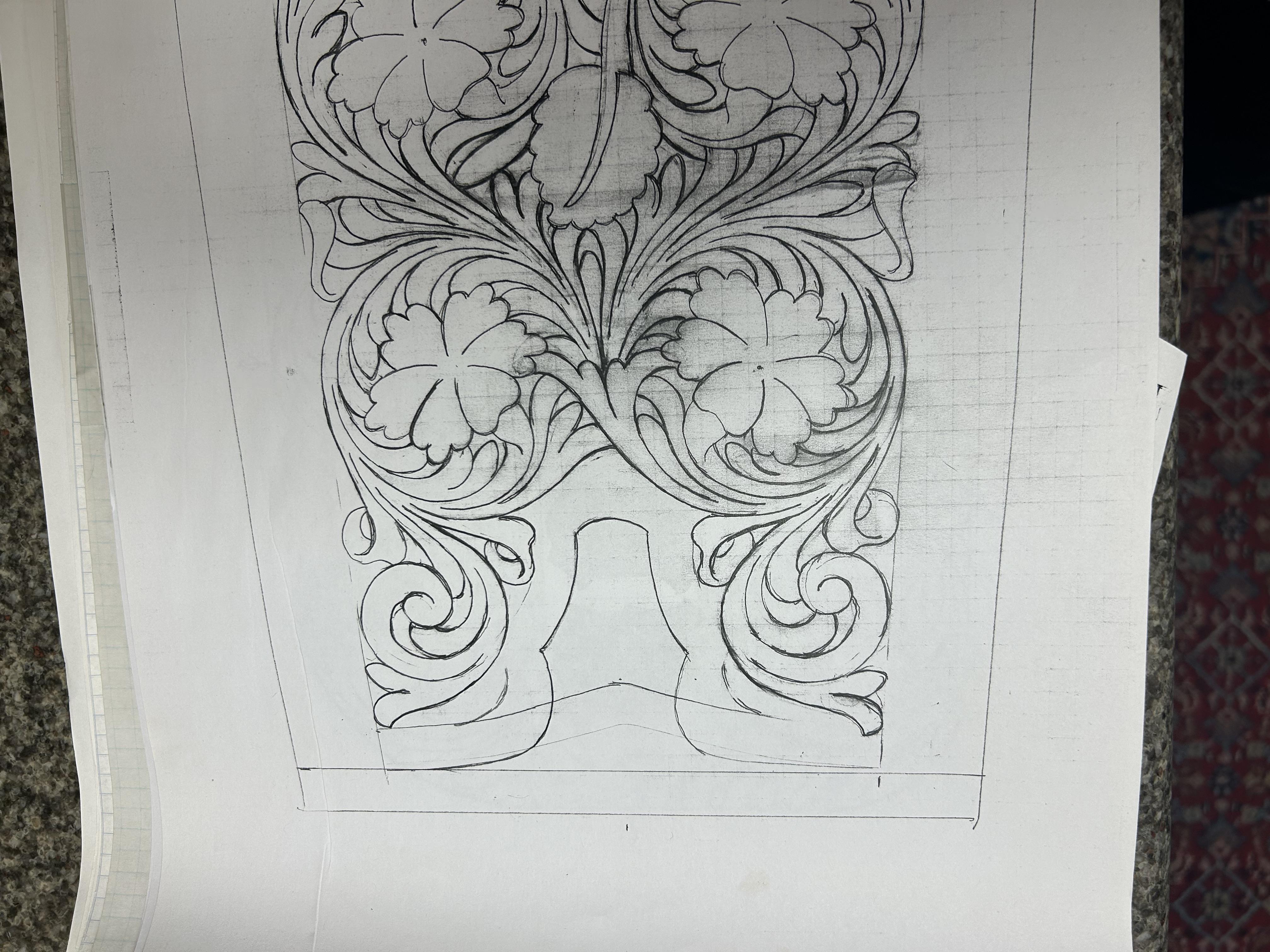

Help completing sheridan style pattern

Tim Schroeder replied to jstern's topic in Floral and Sheridan Carving

-

@Ghoust6 I slid you over to the sewing machine sub forum. We'll probably get more attention here.

-

Len Tortorella joined the community

-

If clutch not engaging, probably your synchronizer not conected... It is worth if its working and complete machine, if it have some major parts missing, it can be a nightmare to assemble. parts can be very expensive! If its just electronics, just throw in Chinese servo, make a foot lift (if it automatic) and happy sewing. 50 bucks is cheap!

-

Hello, I have a problem with my singer 18-2. I have no idea how to disasemble part number 3037. I did unscrew it but it still hold like hell to the parts that regulate the stich lenght. I wiuld be thankfull for any clues and pictures/videos. Thanks to all of you !!