All Activity

- Today

-

maybe this https://www.ebay.de/itm/385670072955

-

no facetime but I may be able to hep when you explain the problem and post some pictures. What model do you have?

-

Yes i pretty sure there is binders for the class 26. Let me look 2mrow, but I am pretty sure i bought a set.

-

landis 5 in 1 Landis 25 - Landis 5 in 1

GraceAVD replied to GraceAVD's topic in New and Refurbished to Like New

Aww, thank you! And yes, sanding and painting is was two whole weeks of full time attendance. You kinda have to wait before you turn the pieces to coat every crevice and corner, and then you have to wait like a day or two to let every layer dry hahaha. Also I was surprised to see that the Montana Gold Metal primer was a darker red colour. Didn't expect that, thought it would be white-ish. Thanks again for the appreciation 😄 Grace- 2 replies

-

- landis

- landis model 25

-

(and 2 more)

Tagged with:

-

Hi Shoepatcher

I have been chatting with Constabulary and he recommended getting in touch with you.

I have a Patent Elastic boot patcher that is missing the shuttle. The rest of the machine is in good order as far as I can tell and I am keen to get it going. Would you possibly have or know of where I can purchase a small shuttle for this machine?

Any help would be much appreciated.

Regards

Smileyfaces

-

I moved your post to leather sewing machines, You are much more likely to get some answers here.

-

I moved your post to leather sewing machines. You are much more likely to get answers here.

-

@BaroqueLeatherGal, you could tag @terrymac to get their attention.

- Yesterday

-

Chui2022 joined the community

-

Hello, I am looking to make duffle bags using a cobra class 26 and finish my inside edges with binding. Is there an attachment that works well with the cobra class 26?

-

Help Wanted: Leather Tooling Artist

BaroqueLeatherGal replied to BaroqueLeatherGal's topic in Help Wanted

sure whats your email? -

Hello, I am looking for an industrial sewing machine Mechanic, who is experienced with fixing Claes Patchers, it has to be through Face Time. I contacted Landis International they could not help me with the issues, I was surprised. Willing to pay. I’m in desperate need of having two Claes Patchers fixed. 603 952 4818. Northeast time zone.Thank you.

-

-

Will this work for a singer 111w154 ?

AlZilla replied to outaluck's topic in Leather Sewing Machines

It takes some research but you can find cheap servos with a start speed of 100 rpms. In my case, with the small pulley and a speed reducer, I can get down to 11 stitches/minute. There's a whole rabbit trail of slow speed versus cooling. But I think at the hobby level we're not running these things for prolonged periods of time, so it's probably not a giant issue. 11 spm is ridiculously slow. -

Jeff B joined the community

-

Will this work for a singer 111w154 ?

friquant replied to outaluck's topic in Leather Sewing Machines

Plug this one into the wall, and see how fast the pulley moves at its slowest setting. You can put a piece of tape on the pulley so you can count revolutions as you time it with a stopwatch. That will inform the slowness this one is capable of. By the way, how fast is your old motor? -

Reommendations for Getting into Saddle Repair

Tove09Tilda replied to Samer's topic in Saddle Supplies, Tools & Trees

Hey, as BlackDragon has already pointed out, saddles are a sensitive piece of equipment. The idea of toring saddles apart is nice, but also try to get your hands on books and stuff by Jochen Schleese and saddlefit for Life to understand the basics. I really never get tired of recommending Schleese (also the saddles, as well as Albion), as he has great insights into: 1. saddles and why they have to be constructed as they are 2. Biomechanics and why a saddle has to fit a certain way 3. The work of a saddler (he was trained by Passier and Sohn but now lives in Canada) And believe me, you need those things to understand saddlery and therefore how to repair things. If you want to learn the basics, there you get a very good foundation, so you can offer a real benefit to your customers. He also writes in some articles about western saddles and what to take into account for them and why don't fit every horse, despite most saddlers (at least here in Germany) trying to make them work on every horse. I can't say much about Stohlman and Gonzales, but they seem to be great for observing how it is done. Schleese, gives you the why it is done in accordance with science. As a scientist and a soon to be saddler apprentice, he is my best weapon and also helped me to prepare for my upcoming try outs, so I can ask informed questions instead of dumb ones. Best Tove. -

This is a home made knife, slightly larger that the Tandy round knife. This blade actually cuts as well or better than my commercially made knives. Ther4 handle can be replaced by pretty easily. I just never had the need. Comes with the slide on cover shown. $40 plus shipping.

-

This knife is in good condition and is very sharp. It has no name on it, but looks like a clone of Tandy's Stohlman knife. $45 plus shipping.

-

I have 2 of these that have little to no use on them except for stopping. $50 ea. plus actual shipping costs.

-

Yes and No. My two cents: i) Looks like the cooling fan is incorporated in the motor pulley. So getting a smaller motor pulley with the cooling fans maybe limited. ii) Appears to be a 550 watt 6 coil brushless servo motor which would probably work. A 12 coil 550 watt would be better but would cost more (2X). iii) The start up speed could be as high as 500rpm which will give you startup jerk. A speed reducer would help eliminate that or go with a brushed servo motor rather then the brushless servo motor. iv) Make sure the operating manual comes with the setup. v) Like @AlZilla has mentioned the control box is going to be in a awful location under the table so you are going to be down on your hands and knees to change the settings. kgg

-

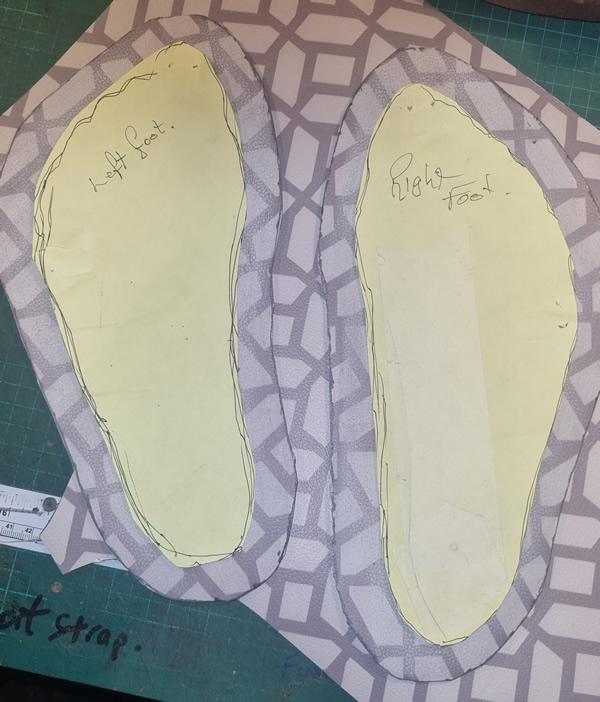

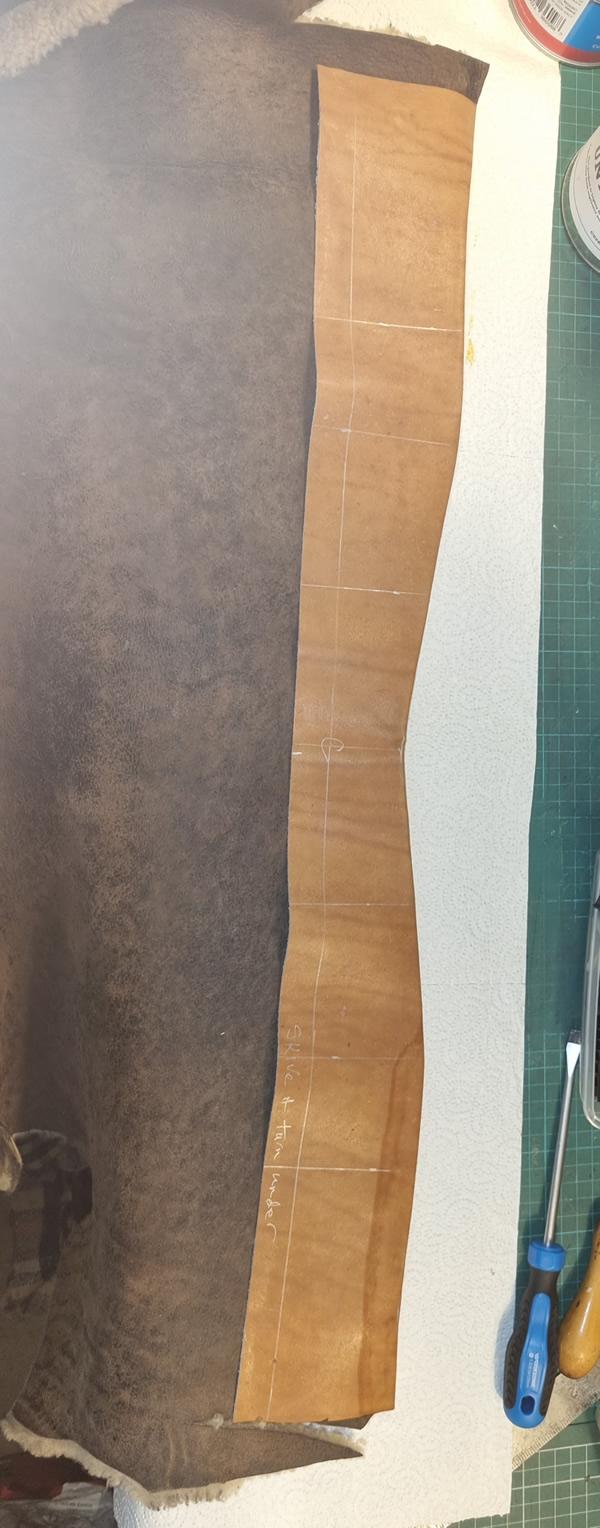

Been threatening to have a go at slippers for quite a while because I have the leather and a bit of sheepskin and at the moment I'm stubbornly walking on holes. I couldn't find any cheap outsoles and I found a cheap vinyl mat with a good textured back and I immediately thought glued back to back would make a decent sole for a pair of slippers. Draw around feet and cut out. Oversize because I intend to make things easy by sewing and binding around the outside. Rough up and glue. Work out the shape you want. I was very pleased that the 801 skiver took the sheepskin in it's stride. Top level glued and turned. Feet cut out. First try for fit. Cosy or what? That's where we're at now. More to follow.

-

I have never seen anything like that - I have no clue! 🤔 I´m not questioning the quality of Pfaff machine but Pfaff IMO made a lot of thing way tooooooo complicated. It it was a Singer 236 I would have a belt driven roller foot.

-

@Mocivnik Moved your post to Dyes, Antiques, Stains, Glues, Waxes, Finishes and Conditioners. And to comment on NFO, it is a conditioner used to replace natural oils lost due to dyes and other treatments. It is not a finish. Also finishes (acrylic or lacquer) seal the surface of the leather. It helps prevent loss of natural oils, fats, etc. and blocks addition of oils, liquids, and other stuff that may damage the permanently degrade the appearance of the leather. It can wear off if the article is subject any type of abrasion over time. So a wax is often used to protect the finish and is normally buffed to remove any excess.

.thumb.jpg.6e903dd66163ad5672f00f144058c571.jpg)