All Activity

- Past hour

-

Perth 4wd joined the community

-

La- J joined the community

-

Re: Dyo spot remover for fabric, suede and leather replacement: Noticed they are out of business (Dyo Chemical Co, Hutchins, Texas). I used Dyo spot remover for many years but now I can not find it anywhere. Can any one recommend a product that would be a great replacement.

-

Thanks Dave9111!

-

Hello fellow leather workers. I have a seiko skz-6b for sail making and the needles that came with it are for leather work, DDX2. Don't need leather point cutting the sail cloth. My question is, what round point needle is the equivalent? Thank you in advance!

-

a personal comment suits better here I´d say. I never hit any like or dislike button - no matter where. But I´m Generation X and not very social media affine anyway.

-

You need to tone down a notch or two. Keep it civil.

-

I don't know, I think if someone doesn't know much about a thread that's posted, but likes the content of the thread, a like button would let the original poster at least know someone read their post. Having to quote and then add a comment or emoji, tends to lengthen threads out soo far that most just get forgotten or just someone not wanting to read multiple pages of two word replies.

-

Hey all, question for those smarter than me… Is there a way to adjust the color of the edge paint to a more desirable shade? I’m stuck somewhat housebound for the time being, so I’m trying to work with what I have… (Insert “first rodeo” line here…) AZR

-

Has been requested long ago. Apparently there is no provision for one in the forum software. Maybe we are better off not having one as pointed out by Mulesaw.

-

Help Needed:About wiping the glue and edge paint

ThisIsMyFirstRodeo replied to kellyswanson's topic in How Do I Do That?

Mask off the edges with tape, making sure that the edge being painted/glued is pressed down tightly. If you get an overbrush, give it a quick wipe with a damp rag. Take the tape off quickly before it dries to keep the edge line sharp. If it dries, it may pull some of the paint away. It might as well still be my first rodeo, but it’s what has worked for me so far… AZR -

I moved your post to Leather Sewing Machines. This is where the machine guys hang out. Secondly, your photos are too small to see details. Resize photos (JPG or PNG) to 800 pixels in the longest dimension. That will produce files with enough detail and still meet the size restrictions on this site.

- Today

-

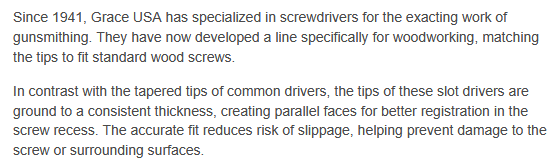

These are for wood screws, so not the correct thickness necessarily. The important part is the faces are parallel rather than tapered. So won't cam out as easily, less damage to screw heads.

-

@bsshog40 I think it could be a deliberate choice to not have a "like" button. An old horse forum in Denmark pretty much died within a month or two after adding "like / dislike" buttons. Suddenly nobody commented on threads anymore, all the discussion was lost and that sort of took the charm out of the forum. So I tend to do like @chuck123wapati simply just reply a short remark that you like the content :-) Brgds Jonas

-

https://chapmanmfg.com/

-

Dear KGG Thanks for Your reply pls look at my photo below, this "onewaywheel" blue arrow can be activated by pressing the "red arrows" it's a rubber bottom, and here is what it's look below Reverse, 2'nd photo in the lever that the yellow arrow are pointing at, it go reverse by pushing it down, and stitching length are adjusting by a shiny nut in the lever,, I hope it make any sense 🙂

-

-

Thanks a lot!

-

I would say those made in Switzerland then either those made in Japan or Germany. The problem is getting screwdrivers that seat and fit properly as well as being durable so sometimes you need to go with metric sized screwdrivers to get a better fit to avoid screw head slop. kgg

-

Look at tippman from Brownells

-

Don't mean to sound snarky but the best screwdriver is the one that fits. You might have to shop around for some, might try a gunsmith supplier? Guns usually have odd size screws that get marred if not using the correct size. Only other suggestion is to be very careful with what you do have on hand.

-

Adler 205-370 presser foot supplier

ChristopherC replied to ChristopherC's topic in Leather Sewing Machines

I don’t and never have stitched up harnesses, but It seems this machine was set up to do heavy work. It had a 250 needle and 446 thread on it when I bought it I’m exploring what the machine can now do on the lighter side with a 120 needle and 135 thread. -

The green arrow points to what looks like a oiling port for the internal parts similar to the Juki LU-562 & 563. The red arrow points to the stitch length adjuster as I don't see a stitch length adjusting dial or it is a safety clutch to protect the hook assembly when you jam up the machine. If you want to wind just a bobbin: Here is a link to pretty good video from the 9:00 minute mark ( i) remove thread from needle otherwise you will jam the machine up. ii) the winder needs to be set so it trips out when you get about 80 percent of the bobbin filled. iii) install empty bobbin on winder shaft. Most bobbins have holes on the sides of the bobbin so a) the end of the thread from the spool of thread you are using to fill the bobbin through the winders tension discs then to the inside of the bobbin outwards through a hole b) push the bobbin trip lever towards the rear of the machine to engage the winders drive wheel up against the machines drive belt c) hold the end of the thread in your hand d) hit the go pedal e) hold the end of the thread until you have at least two complete rows wound on the bobbin. iv) you really should have two spools of thread one for the top thread and one for the bobbin thread so you don't have to unthread the machine just to wind a bobbin. kgg

-

Does this forum have a "Like" button?

chuck123wapati replied to bsshog40's topic in How Do I Do That?

i do dis lol -

Adler 205-370 presser foot supplier

dikman replied to ChristopherC's topic in Leather Sewing Machines

Ahh, that makes sense, although I've never come across it before. I can see why it's problematic on thin leather with finer thread. They obviously expect the machine to be only used with heavy stuff. -

Adler 205-370 presser foot supplier

ChristopherC replied to ChristopherC's topic in Leather Sewing Machines

Thank you, exactly what I was looking for👍

.thumb.jpg.6e903dd66163ad5672f00f144058c571.jpg)