All Activity

- Past hour

-

Looks like about $140 US. If I'm going to part with one that I've gone through and made good as new, it takes at least $100 US to pry it away. Most people would rather go the Walmart and drop that same money on a less capable, low end plastic machine. The difference is a couple years of service vs a couple of lifetimes. Here's hoping this works out for you. I've made a lot of denim bags on 237's and similar Kenmores.

-

spring flowers and good food

chuck123wapati replied to chuck123wapati's topic in All About Us and Off Topic

whats interesting is understanding why a certain stitch was used and how they work in that situation. It's rarely mentioned in patterns why the pattern maker used the stitch and how to sew the stitch correctly. In my case, the holes seemingly were way off, but as I tightened the stitches and stretched the leather into place, the holes made sense and the moc formed perfectly. -

Heck yeah, treat yourself !! Merry Christmas, friend!!! You know i have studied your work to death its simply perfect every time.

-

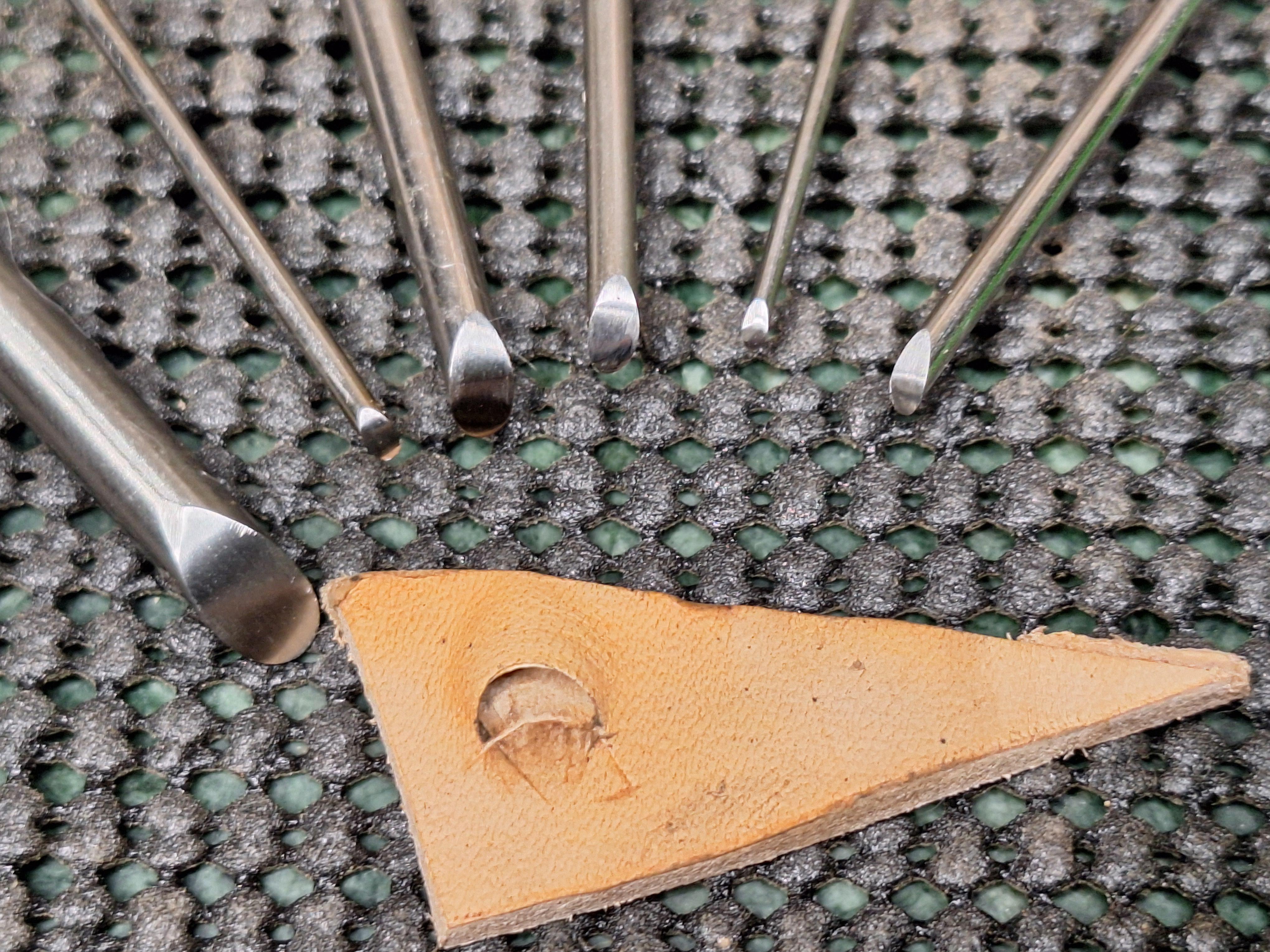

That's a nice set!!! They are better than anything on the net. It's really pretty easy to make a lot of the tools we use. It's too bad more folks don't do it. Back in the day, it was a requirement for most tradesmen apprentiseship was about making your own tools as you learned to use them. Nowadays, folks can barely push a button to order them without two hours of internet research and reading 500 reviews. I made mine from stainless all thread, scrap leather and brass nuts. Chuck up the all-thread in a hand drill and turn it against a belt sander to get the profile and size you want then just polish the tip. Tighten down the brass nuts dope it up with resolene, let it dry, and do the same with the handle, and you're done. I have two double-ended lifters and also a double modeling tool/ stylus i made pretty much the same way. Can you imagine paying 30 40 bucks for a tool you can make in minutes for less than a couple bucks? I also use d2 rod and a map gas torch to forge smaller cutting tools.

- Today

-

Thanks for the kind words everybody. I was checking the inside veg tan and it is only .8 mm. I have found some Kangaroo to make the insides out of again. The Kangaroo is really soft and has a matt finish. I think I will make myself a new wallet after Christmas.

-

@Wizcrafts Thanks for the tips on the machines Wiz, my issue is one of space however, as I mentioned at the start of this thread, I don't have the space for another machine with it's own table, which is the reason I'm hoping a domestic will serve the purpose.

-

I believe that the Juki LU-1508 series may be too heavy duty for the thinner leather you want to sew. This series is beefed up in order to sew into denser and thicker stacks of material. The DNU-1541(s) is probably a better match. It can sew over thick seams and has a thread range more suitable for thinner and softer leather and broad cloth, or denim. Now, if you will be sewing leather or heavy canvas jackets, with flannel, quilted, or fur linings, the LU-1508NH is the better machine. But, it may eat thin vest linings.

-

Bingo! This is a much overlooked issue among leathercrafters who sew on machines. Some of use have a room full of walking foot machines of varying capacities. I do! One thing they all have in common is their lust for linings and broadcloth lunches! They love to eat these thin, soft fabrics. If you are going to be sewing this kind of cloth, you need a bottom feed machine with a flat foot. The actual machine can be any ancient Singer tailoring machine, like a 31-15, or 96k40. Juki makes some superior high speed bottom feeders that have oil pumps in an oil bath and can sew at 8000 stitches per minute! My first industrial sewing machine was a Singer 96k40. I used it to sew a soft leather vest and a lining. But, when I tried to sew on a panel with fringes, that machine balked. I bought a walking foot machine that was better equipped to go over thicker seams and denser leather. You can often find tailoring machines for sale in local ads or marketplaces. A lot of them will have a clutch motor that you can either learn to feather, or replace with a servo motor.

-

Yeah, I tend to be a bit of a hoarder, but these struck me as relics deserving to be kept.

-

@kgg I hear you on the needles, I also have #140 needles but it seems to produce a good tight stitch on most things I sew with the 130 so I stick with those unless I move onto firmer leather. I have a table attachment for switching to a more flatbed orientation. The main reason I wanted a lighter machine is for sewing light stuff, it tends to bunch up with the heavy threads. Obviously on a site called leatherworker asking about sewing fabrics is maybe barking up the wrong tree, but I know the expertise of the people who hang out here is respectable, I have often dug through the archives to answer any questions, regarding not just machines. Thanks to everyone for taking the time to reply.

-

Wanted to do some petal lifting, making the leather look more 3d by stretching up certain sections. Mine are in NC, didn't want to buy an expensive set. For under 20 dollars and an hours work here we are. Pretty happy. The items, Stainless rods, handles, super glue, I found a set of stainless rods 1.5mm to 8mm x 60mm long these were 8.99, the handles are file handles got 12, 6 large not used and 6 small, 6.99. Put the rods in the handles, for the small ones wrapped painters tape around the top for a snug fit then used some super glue down the hole to fix them. The grinding to shape can be done many ways bench grinder, files, dremmels, the angle isn't precise we are after a cutting edge. I like the angle around 45 degrees with the heel radiused. Used a course grinder to get shape and then went to a finer belt grinder. Then used sharpening stones to clean up the scratches, finished with 2000 on the stones and then used a strop with polishing compound to bring a mirror polish, we want it to be razor sharp at the tip as it is a cutting tool..

-

Nicely done, very clean.

-

Bringing this thread back to life. Which of these models could someone recommend for making leather jackets? I use an .8mm and a different 1mm cowhide mostly and will start to use horsehides soon. I also will run some horween veg 5oz or less through it some times. Jackets will be the primary and my vintage Adler 167-373 has trouble getting over thicker seams.

-

Finished a second mousepad that's been on my to do bench for months. Both backed with 1/8th neoprene for heft and to help it not slide so much. First one I made a few months ago: And the one I just finished (sadly the leather quality is a bit lower) : Finished with a resoline coating. Both were airbrushed with dye by my wife as her first projects. Honestly I think they both turned out really well.

-

Depends. If it's a personal item and I can't fix it, I might live with it. If it's a sale item and I can't fix it, I'd start over.

-

I guess we need a Cobra guy to come along and say if it's right or wrong.

-

Gotcha, I misunderstood your question. That does seem a little odd.

- Yesterday

-

I lightly case the leather and mark with my wing dividers, and typically run over the groove 2-3x for a nice deeper groove without cutting through, so only my irons (and maybe my awl) actually pierce the grain. — AZR

-

Yes but I don't see a slot on the Cobra. It's where it goes after the tension spring that's got me puzzled? There's no way my thread can double back after coming out of the tension spring and go through the little notch on the bobbin retainer on the top like it is on the Cobra.

-

Yep. The bobbin thread runs through a slot/notch and under the tension spring on the bobbin case. EDIT: I'm not sure what machine you have but when you drop the bobbin in, there will be an angled slot somewhere in the case. The bobbin thread will go into that slot *in the same direction that the slot is angled up*. That notch you refer to should be the top end of the slot. Pull the bobbin thread up and out that notch. The bobbin thread then changes direction and passes under the spring. Every machine I have operates this way.

-

Damn I love you all and this community... Any kind of advice is good I really appreciate it . Seems like some people that are also starting are getting and providing some knowledge from this thread. For sure I will show you some of the work i make once I start. Thanks for the advice on the knife sheat I work in a kitchen so I think would be nice to make some sheats for my knives of even a knife roll (yeah ). Thank you all.

-

Very good advice. Making all your rookie mistakes on the first project.

-

When you say groove line are you meaning an indentation with something like a compass or an actual groover where you're taking off the top layer of the hide? If it's the first one I would do it as Bruce said. You may be able to undue the indent and it won't be noticeable. If it's the second I'd start over. I would keep that belt for myself or someone that doesn't mind a blemish but I wouldn't give that to a customer that's paying top dollar for a belt

-

Keep a straight stitch line and remember to watch the groover next time. I would rub out the errant groove line as best I could and regroove it before I stitch.