All Activity

- Past hour

-

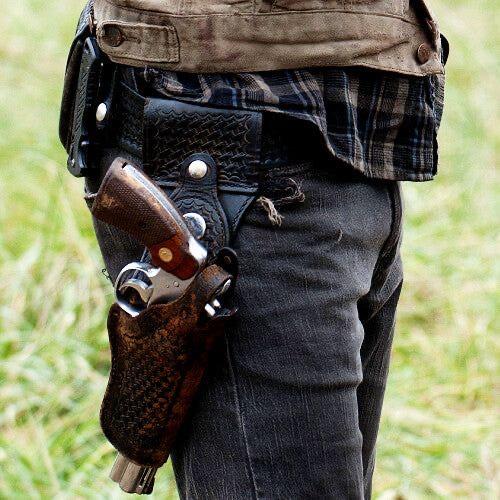

A good holster and a good gun too.

-

This hasn't disappeared; its here, Perhaps you asked in the wrong section and its been moved

-

Post on the front page move down the list as new ones appear but are still in the sub Forum they were created in like a question related to a sewing machine would have been created in the Leather Sewing Machines sub forum but would also appear on the right side of the front forum page. As new topics appear it would move down the list and off the front page but be still listed in the Leather Sewing Machines sub forum. If someone posts a answer to your topic it would reappear on the front page of the forum and then move down the list once again. Your post: Questions on tooling English Bridle is still available in the "How do I do that?" sub forum on page 2 with one response from @TomE. kgg

-

That's exactly how I felt, and I didn't intend to hurt anyone's feelings. I apologize to all who are offended.

-

Most times it is not a problem but have a seniors moment, be distracted, tired or whatever and Murphy's Law is always at the ready to kick in. You screw up and you want to kick yourself in the butt as you just screwed up the work piece. Someone else my not notice but you will. @toxo I agree. Having a simple centre point ruler of any configuration is easier and correct everytime. Also the fractional measurements in the imperial system are not as easily divided in half as compared to the metric system. I did have a digital mic that read in both metric and imperial which is typical but this particular mic automatically showed half of the actual measurement. kgg

-

I'm trying to figure out why my posts keep disappearing. I've asked a couple questions in the past week. First was trying to find out what style of carving was on a belt (I've resolved that on my own) and how to work with bridle leather. Specifically HO English bridle. Both posts disappeared within the day posted. Did I violate any rules here? I really doubt I did. It's been a little while since posting anything in Leatherworker.net only because I've been busy. And it's only a could months or so. I like this site, but if this continues to happen then I have zero reason to be here. I just want to know why?

- Today

-

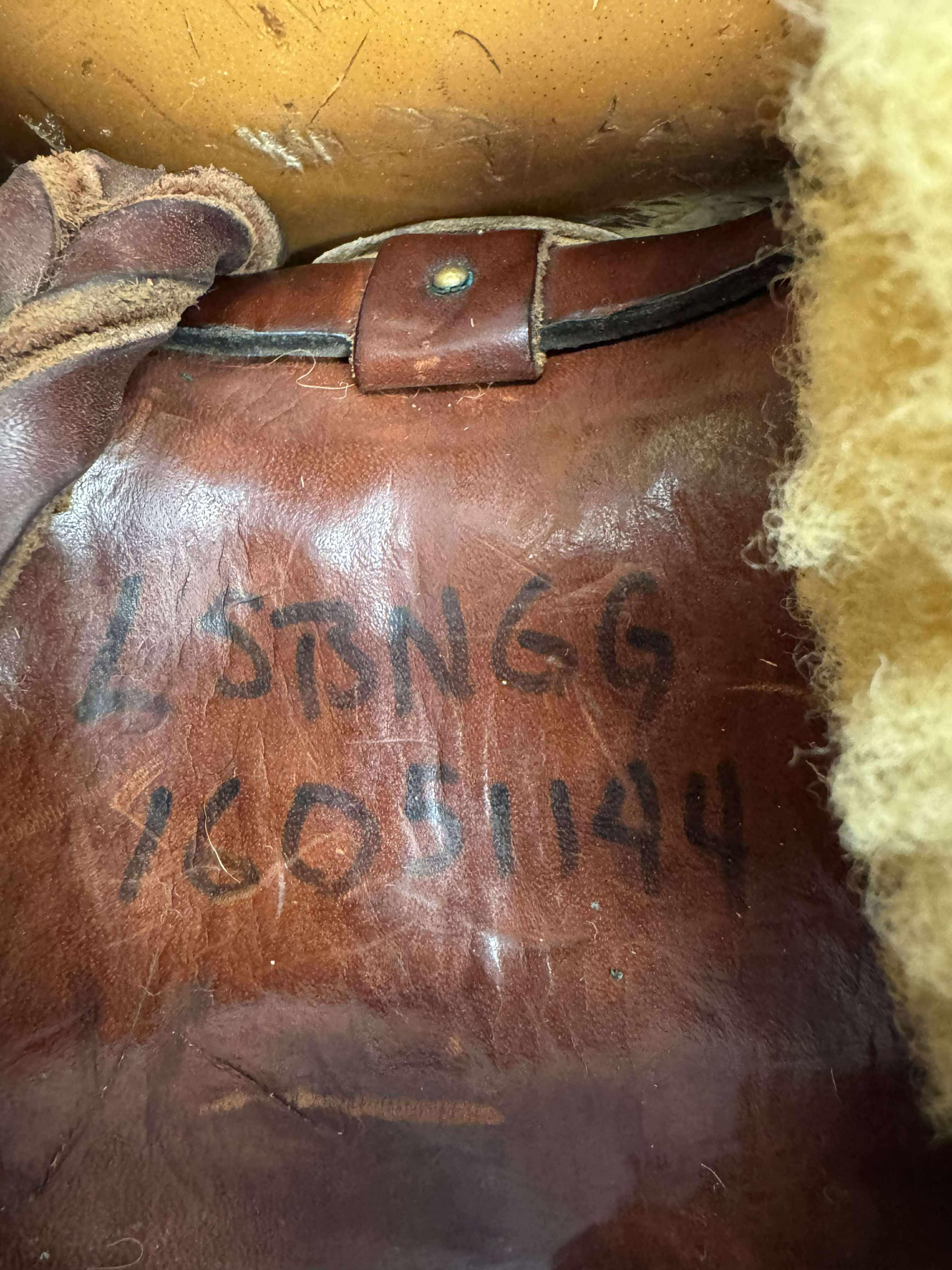

I found a saddle that is, from Legacy Saddlery. It only has black marker four a number on the underside of the pommel/ horn. It is stamped legacy, salary behind the horn, and it also has n "L" stamped on the outside of the stir up leather above the stirrup. An extensive search on the internet, nothing. I'm trying to figure out the maker of this saddle.It's very well made. Its very wide flat bars.

-

@Samalan made it a math lesson, but I have a center finder.

-

This is not a math lesson. Go buy a centre finder.

-

Well, the Big Dogs are going to have to solve this one. I'll watch and learn.

-

7/8 + 24-1/2 = 25-3/8 ...you got ahead of yourself. 24-1/2 + 3/8 = 24-7/8

-

I saw this video. It’s a good idea. I just want to see if I’m doing something wrong first so I can correct it.

-

It feeds the material through at an angle.

-

Finding the center of a line should be in your head, almost instantly, especially in leather work. Except for that rare time when the measurement needs to be closer than 1/32" Let's do one 50" divided by 2, what comes to mind instantly, 25 . Let's do another 50 and 3/4" divided by two, half of 50 = 25, and half of 3/4= 3/8", so it's 25 and 3/8" So let's do one a bit more difficult, 49.3/4" divided by two. Just think what's half of 40" = 20", then what's half of 9"=4.1/2" add them together and that's 24.1/2" all that's left is the .3/4" and half of that is .3/8" add that to the 1/2 and you get .7/8" add the .7/8" to the 24.1/2" and you get 24.7/8" When I first started in my trade, over 50 years ago, a big part of my job was measurement. My boss was a tough man, and that's being nice. After a few years, I went to him for a raise. With his gruff look and voice, he said, "Raise. What makes you think you deserve a raise?" Before I could say anything, he spat out, "How many thirty seconds in nine sixteens?" I said, "I don't know." He said, "Come back when you do know, and maybe I'll give you a raise." I was very mad, but I also knew he was right. I should know that. After a very short time, I came back, and I did know and trust me, if I can figure it out, you can too, and that's for sure. In a very short time, that stuff should be second nature to you, no special rulers or any of that. You should see the measurement and boom, the center is in your head. Sorry for the story, but what's half of 9/16"? If you had to think for more than "one half" a second, you need practice! In fact, you should not have to think at all for the answer to that.

-

This is a great resource! Thanks @NerdyLeather for taking the time to do this. And thank you @Johanna for turning it into a PDF.

-

Questions on tooling English Bridle

TomE replied to DoubleKCustomLeathercraft's topic in How Do I Do That?

A Google search of this site turns up a number of threads about tooling/stamping bridle leather. "site leatherworker.net tooling bridle leather" I use a fair amount of HO bridle leather for making English tack, and appreciate that it is firm and has a smooth "moss back." In my limited experience, Wickett and Craig bridle leather has a softer temper. If you're seeing loose fibers that might not be the best part of the hide. I find that typically more than half a side of HO bridle leather is firm, smooth backed, and suitable for straps. Bridle leather is stuffed with fats/waxes that impair water adborption so it won't case like regular veg tanned. An alternative to carving/stamping would be to carve designs without stamping. Jean Luc Parisot has some nice examples on his Instagram account. -

AH Hillbus joined the community

-

If it's not a lot of trouble, a pdf should be a lot more compact. I know we have a lot of those military manuals for sewing machines floating around and even a high res scan is under 10 megs. 11x17 would probably be larger. If it's as easy as swinging past an office supply place in your travels, and it can be done without damaging the original, it would be a fantastic thing to preserve. I saw a copy on ebay that sold for $50! I would at least chip in for the expense.

-

Looking good dikman but I didn't realise it was the railway steel you were wanting to bend Now you have to form the roundy bits and the pointy bits that get the job done. Looking forward to seeing the results.

-

Progress! Much cutting, grinding and welding later and I have something that just might work. The handle is a bit long but it gives plenty of leverage and the linkage works better than I expected. The potential down-side to pushing down on the handle is the force may cause the front to lift, we'll see. It needs a bit of fine-tuning with the grinder and the next thing is to make some bending tools to actually try it on the banding steel.

-

Tandy sells this one on their website Japanese Heavy Duty Holster Slot Punch

-

Southpaw Jim joined the community

-

MamiaGirl joined the community

-

MarianV joined the community

-

So you want a scanned to pdf file of all of the pages?

-

Fonlandlaser joined the community

-

I found a similar document, but from the RCAF and focusing on physical fitness. When I asked the Feds (air force) about it, they said it was out of copyright. I posted it online to share, after scanning and manually entering the text. You could likely get similar permission here, and as Al Zilla offered, several of us may be willing to help out. Looks like a terrific resource! Thanks for posting.

.thumb.jpg.6e903dd66163ad5672f00f144058c571.jpg)