-

Content Count

596 -

Joined

-

Last visited

About LeatherLegion

-

Rank

Leatherworker

Contact Methods

-

Website URL

http://www.leatherlegion.com

Profile Information

-

Gender

Male

-

Location

Brampton ON. Canada

LW Info

-

Leatherwork Specialty

leather dog collars

-

Interested in learning about

wallets, bags, holsters, knife sheats...

Recent Profile Visitors

19,953 profile views

-

Make sure the motor pulley or the belt doesn't touch he cover

- 6 replies

-

- leather

- leatherwork

- (and 7 more)

-

The color is off too. Tokonole is white....yours looks yellowish...maybe it's just the picture though

-

Under the burnished surface , you still have a "spongy" substrate . If you don't have a high fiber density on the flesh side , you can't really do much about it

-

Craftool® Hand Press - Huge Problems

LeatherLegion replied to MonsieurHidan's topic in Leather Machinery

This is the set of line #24 dies i am using ...- 7 replies

-

- tandy leather

- hand press

-

(and 1 more)

Tagged with:

-

Craftool® Hand Press - Huge Problems

LeatherLegion replied to MonsieurHidan's topic in Leather Machinery

Judging by the firs picture , it looks like you are not pairing the dies /snaps properly- 7 replies

-

- tandy leather

- hand press

-

(and 1 more)

Tagged with:

-

Yes

-

There is one available in Mississisauga store , along with a class 4 , two class 17 and two NP4 skiver All these machines are on the floor and out of the boxes...I am sure the staff can demo the class 26 for you

-

How to answer the question "How much is it?"

LeatherLegion replied to Leatherinspire's topic in Marketing and Advertising

Welcome to the board . Interesting and helpful read -

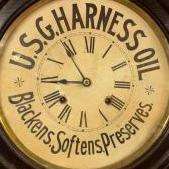

Quick Googke search came up with this

-

I have the same press but in green. ...i think i posted some pictures way back. You have to turn the round plate to adjust the height...very fine thread so it's a bit of work , but once you set it and use the same dies , you are good. The press is extremly heavy and has to be bolt it down...i have mine bolted to the floor . I also had a Lucris MA III and the green one seems to have more umph The plate's diameter is arounf 11in . Way better option than one of those hydraulic shop presses in my opinion. If it doesn'y have any cracks and everything moves smooth it'll do the job just fine Hope this helps Eddie

-

Bought a left/center smooth foot set few weeks ago for a 111 type machine. I had to drill a bigger hole in the left foot to make it fit. All good now

-

Can you please post a more clear picture of the tension discs with the thread ran through?

(1).thumb.png.25742175a180b0f23164a3b91a47f4df.png)