All Activity

- Past hour

-

you know a person can do either stitch by hand, so my question is how many of you use the lockstitch when sewing by hand? I've never even had the urge to try.

-

Google AI "A 794 S needle is a leather point needle. Specifically, the "S" stands for "spear point" or "narrow cross point," which is a cutting point designed to create straight seams in leather and other thick, non-woven materials." See attached needle / thread size chart that will be handy for you later. Looks right for your current leather. If you start using hard dense leather often needs a size larger.

-

These heavy duty harness stitchers usually ship with high thread tension and foot pressure because they are typically used to sew hard, dense leather. You will need to dumb down your machine to sew soft leather. Start by backing off the bobbin tension screw until there is just a slight amount of pull required. Next, back off the top tension to balance the knots. Next, back off the top foot pressure screw on top of the right end of the head. Use just enough force to keep the leather from lifting with the threaded needle and the bobbin thread locked around the needle. This setup won't work as well in dense leather, so try to make a mental note about the initial setup tensions and pressures. Finally, adjust the stitch length a little shorter to minimize the warping of the material.

-

Yes, many things going on at the same time. I remember my learning curve and finally getting the balance of needle, thread and settings right was very satisfactory. This all takes time to build experience and confidence, like when learning the guitar, don't rush and try to force things.

-

I remember years ago, someone on a gun forum said he always took high res pics of his new used guns. He said the photos showed way more than the naked eye. I bet these don't show up as well in person as they do in the pics. Also, it seems obvious that one end is a smaller diameter. Should you decide to take the plunge, it should be easy to tell which end to hit. That thing is a monument to industrial manufacturing of a bygone era. Obviously neglected, 122 years old and still quite a viable sewing machine. I'm going to go oil something ...

-

Yes, that is probably a tapered pin. Be sure to drive it out from the small end. I would measure the ends with a vernier to determine the small end. Support the shaft end well and drive it out with a drift punch. As others pointed out, proceed with caution as not done correctly could end poorly.

-

Thanks @chuck123wapati and @DocReaper I appreciate it

- Today

-

Okay I see it now. As though they pounded a pin in, then ground the ends off. That would explain the surrounding texture. Here's a view of each side

-

I haven't adjusted the presser foot at all, but I will definitely take a closer look. I'm using the needle that the machine arrived with. It's a 794 S size 25 needle. I increased the top tension and am getting slightly better results, but the stitching seems abnormally tight, like it's sinking too far into the leather. Going to do some more tinkering today.

-

From what I can see, it looks like your presser foot pressure is too high and pushing leather into the feed dog needle hole. Also, are you using a leather point needle? It looks like a lot of 'blow out' due to using a conical point meant for textiles is being used. Both of these affect appearance besides the thread tension adjustments.

-

Moved your post to leather sewing machines. I think more sewing machine guys will see it here than in suppliers (which was a logical choice too).

-

The edit window is only open for an hour or two, so you have done what you need to do to add or edit. One item needs to be clarified, is the table/stand included?

-

I see it now, too. Sort of a brown circle, midway of the shaft on the left. It's a tapered pin and I can't tell you which way. Are y'all talking about the two brown patches on opposing sides of the shaft, as seen in the video? 27-arm-shaft.mp4

-

One-piece casting: sturdy!

-

These are works of art, looks like you could use it to do pull-ups with. I'm impressed with the look more than the function

-

It's nice, in both art and gesture.

-

I see it now, too. Sort of a brown circle, midway of the shaft on the left. It's a tapered pin and I can't tell you which way. I'd also concur with leaving it in...

-

-

Yes, lots of trends to follow, and with social media everyone's an expert.

-

Finished Up A Couple Of Single Point Slings.

chuck123wapati replied to BattleAx's topic in Show Off!!

great job!! A bit heavy leather, IMO, but hey, they look fantastic and should work well. I would suggest,using these clips made specifically for the job if you do any more of them. I have had the ones you used snag the thumbpiece and open just on my suspenders. https://www.ebay.com/itm/171369888626?var=0&mkevt=1&mkcid=1&mkrid=711-53200-19255-0&campid=5338590836&toolid=10044&loc_physical_ms=101688&customid=32c1eb99c2f11fb7b82f83561eeeacea I always liked the 3-point sling for tactical carry, and I use the M1907 rifle sling on all my long-range guns, so they all fit the same. -

excellent work for a very worthy reason!! great job on the hair texture.

-

Help! Singer 111w155 stripped / stuck screw

Constabulary replied to matthew123's topic in Leather Sewing Machines

how about a screw extractor. not sure if it works but IMO it one of the last options you probably have. There are other model video show just a random one. -

Hello from Germany - New Member Introduction

Mulesaw replied to Tove09Tilda's topic in Member Gallery

Hi Tove Welcome from the north-western part of Denmark. I am looking forward to seeing some of your creations here. Brgds Jonas -

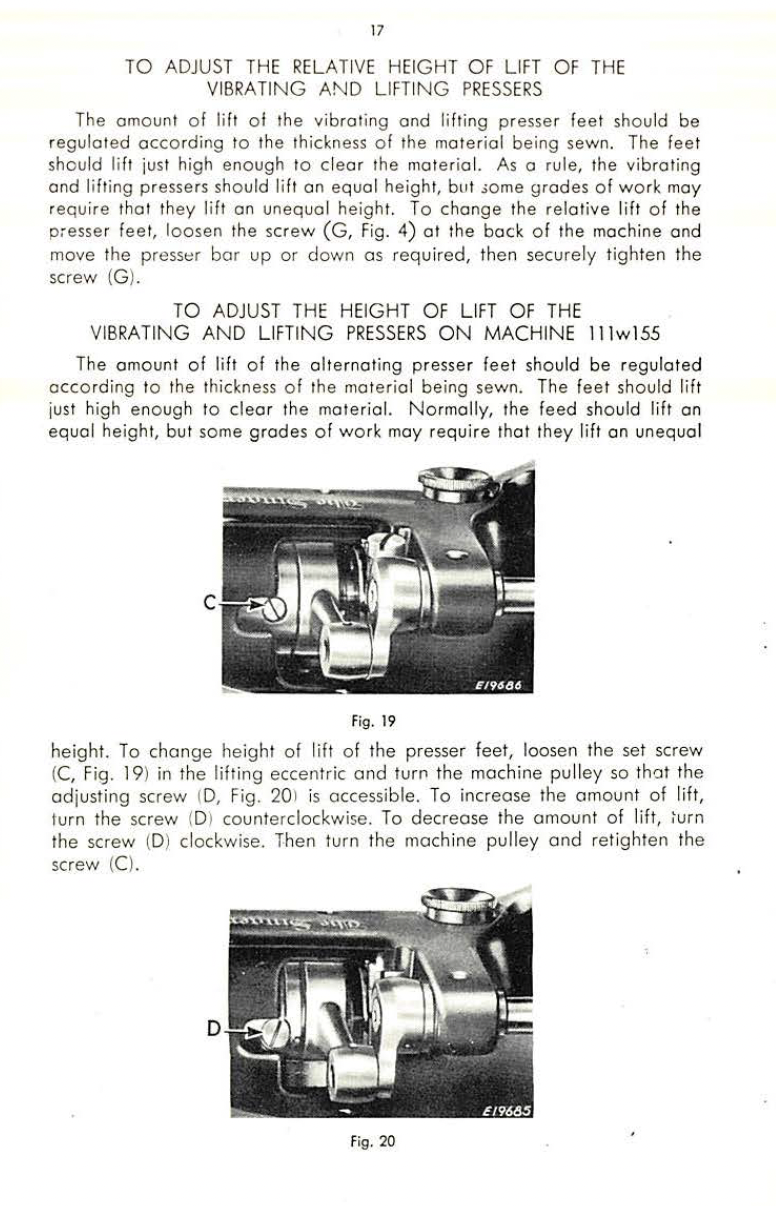

Hi All! First I just want to say how grateful I am for this forum. I've learned so much from you all. Thank you for sharing your knowledge and expertise! I just picked up my first compound feed machine, a Singer 111w155. It sews OK, but the outer presser feet don't lift up enough to accommodate thick material. Based on the manual (see pic attached), it seems that to adjust the relative height of the outer foot with respect to the inner (needle) foot, one has to use the lifting eccentric. However the set screw is stripped and very stuck. See the pic attached. I believe the stripped screw is "C" in the manual screenshot. I also noticed that screw "D" (which I think is the one people call the worm screw) spins freely, which seems weird. It appears someone may have ground away part of the machine casing to get better access to this screw in the past...can anyone confirm from the pic? So far I have tried: spraying the screw with PB blaster nightly for a few nights using a Dremel with a small pineapple burr to deepen the flathead groove gently tapping the screw with a screwdriver and hammer heating it lightly with a mini butane torch I got the screwdriver to bite better when I drilled out the groove, but when I applied force, it again started widening the screw groove again and eating away at the screw head. Can anyone offer other suggestions? I am considering taking it to a local machine shop to see if they can rescue me. I am hesitant to try a left hand drill bit and screw extractor, because the option of deepening the flathead groove further with the dremel seems like a good one and I don't want to burn that bridge. Help!! Am I missing something? Thanks! Matt

-

if it is not necessary to remove the shaft better leave it where it is. such actions sometime cause more damage on parts that most likely are no longer available. My 2 cents.

.thumb.jpg.6e903dd66163ad5672f00f144058c571.jpg)