All Activity

- Past hour

-

The top thread on a machine stitch saws back and forth something like 50 times. Remember that the tension arm way up at the top of the machine is letting it get pulled around the bobbin each rotation and then yanked back up. I was surprised when I first heard it. You are correct about the bobbin thread having an easy time of it. I'm glad this post finally got some traction.

-

Well said Fred.

- Today

-

I would dispute that simplistic statement 1. I like to saddlle-stitch. It is NOT for novelty value. Knowing how to saddle-stitch is good for any sort of leather work. I can s/s some items up faster than it takes me to set up any sewing machine 2. Poverty - NOT, I have numerous usable sewing machines and a few speedy-stitchers. The right tool for the right job. All in the leatherworkers armoury. I am neither poor nor rich

-

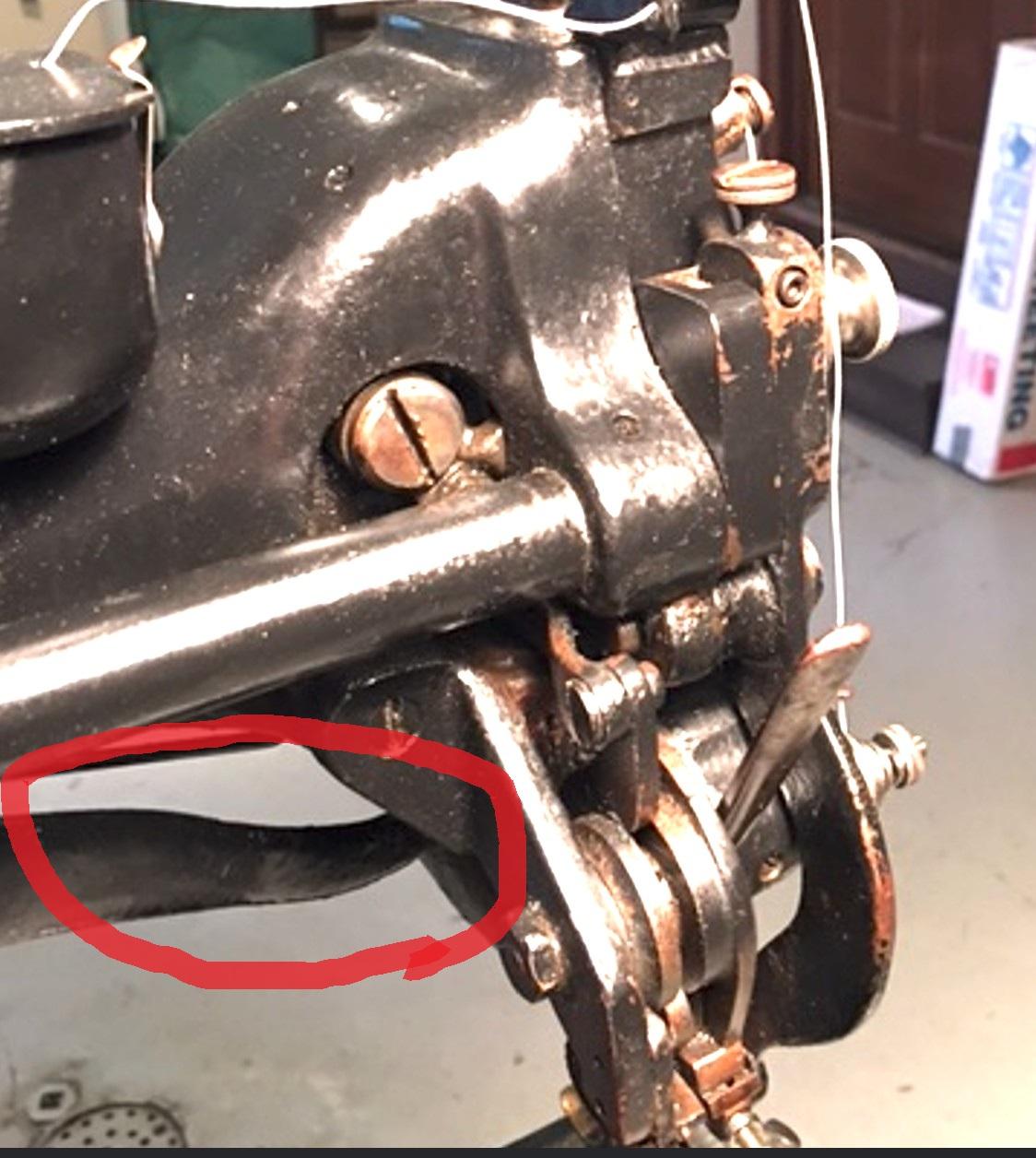

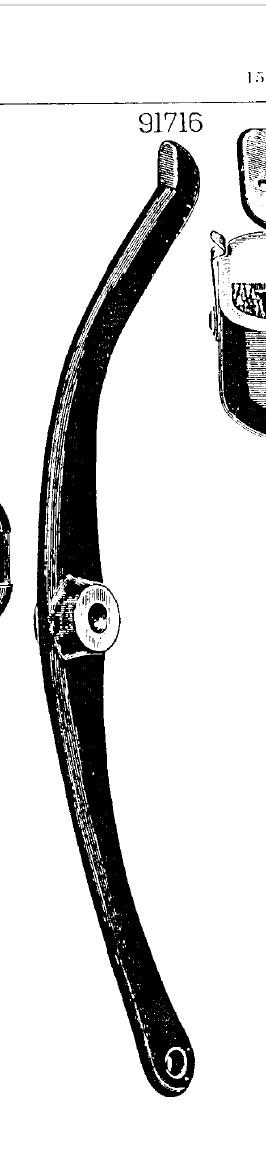

Hello, I have a question about my 45k53 machine, Since I couldnt find parts list for 45k53, I dont know how it would be but, I want to rebuilt foot lifter lever . I have also one 45k25 and I have completed rebuilding for 45k25 . From this topic , I have seen this photo with lever system And also I want to share my machine photos, I just want to learn the shape of part,in order to produce a utilizable replica of it. I think it should be a bit diffrent from the one 45k25.(part code 91716) If possible, Could you please share the photo of foot lifter lever for 45k53 (or part code of it) Thanks

-

Tall Post Sewing Machines?

nylonRigging replied to Cumberland Highpower's topic in Leather Sewing Machines

Not a Tall extra high post, but the slight shim tilt forward modification to the sew head is more comfortable on sitting behind with eye-hand, and you dont find yourself leaning forward as much . - - -

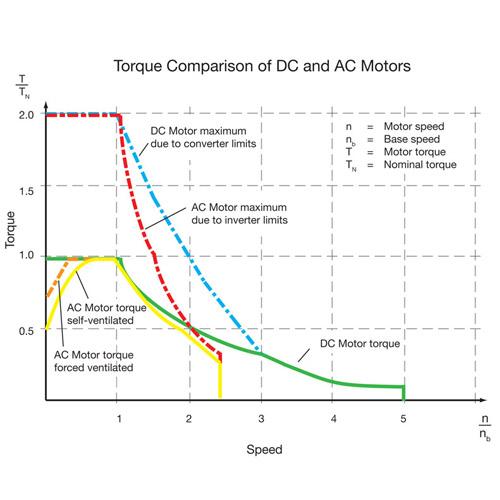

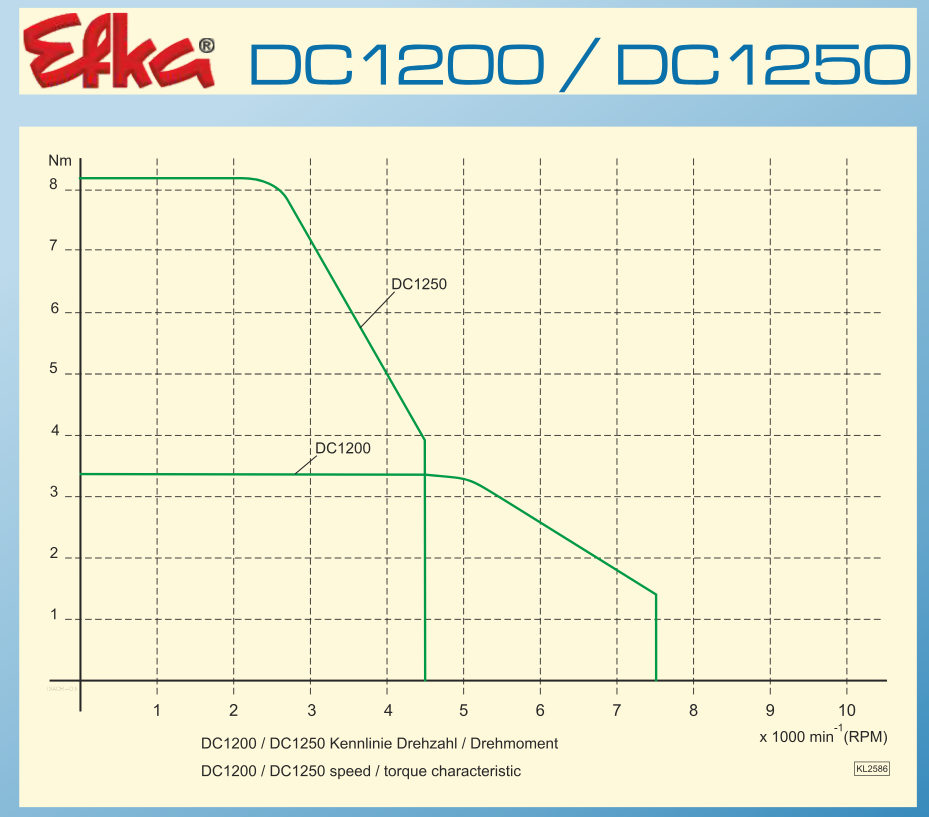

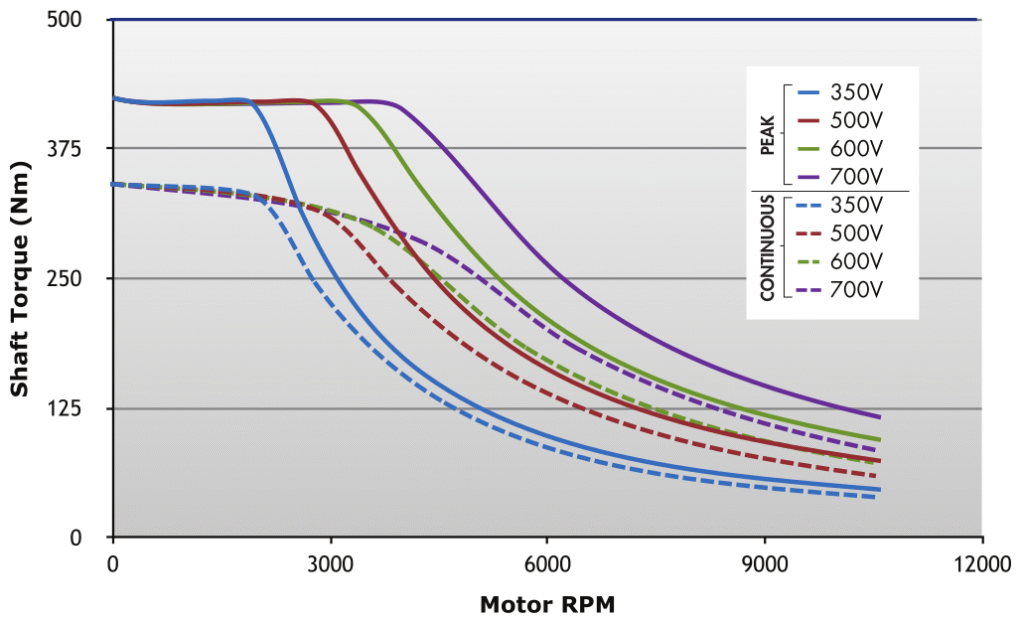

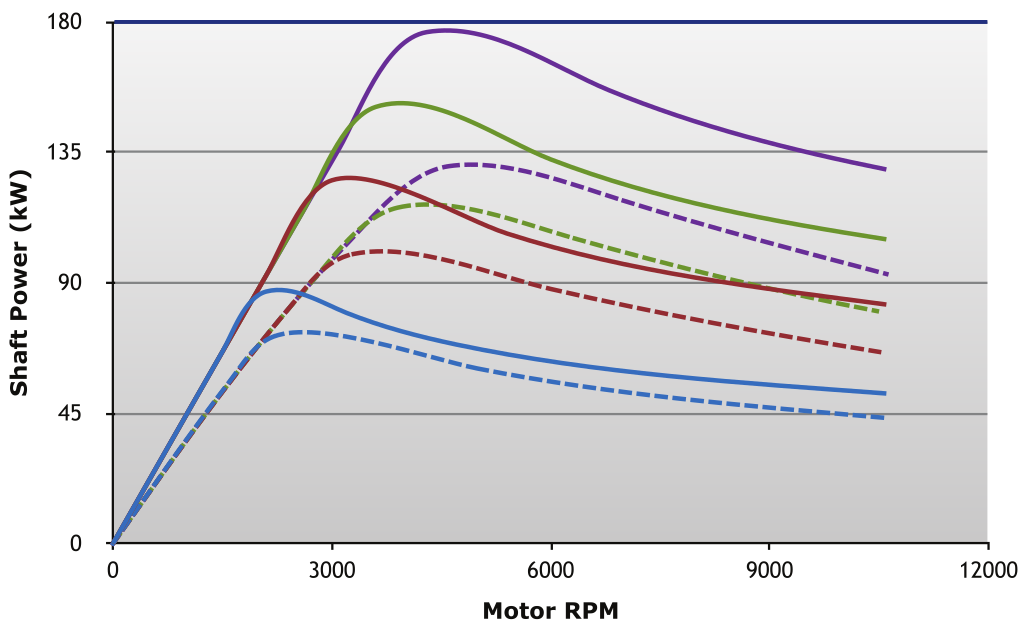

I guess the problem is with the minimum speed to start. Which is I guess an engineering characteristic of the motor, but this is beyond my limited knowledge of electric motors Regarding torque of different types of motor I found this:

-

Nay, with any hand stitching one keeps the thread well waxed to stop any abrasion by the leather and thusly by the thread itself

-

I've started to distinguish between digital servo motors and universal motors with triac speed controllers. Unfortunately, both are marketed as "servo motors".

-

Oddly, most everything I've seen about the cheaper servos is that they lack torque in the low end. I don't know ...

-

Those are very informative charts. I'd really like to see the same data on lower end servos.

-

of course they have, this is from Efka site: which shows that torque is more or less flat in the lower part of the rpm. It also shows that they have two different servos, one built for speed and the other built for torque. The power is function of speed and torque: P [kW] = (T [Nm] · ω [rad/s]) / 1000 in lower speeds where torque curve is flat the power is increasing constantly with speed. Later it can decrease slightly (depends on the turning curve of torque). Of course when the speed is 0, power is also 0. And because of engineering reasons the motors have minimum speed at which they work.

-

@WMages Good question, I guess it depends on how you want to make your holsters. There is a skiving knife on a 5 in 1 that will make a skived edge alongside a curved edge, so that could be a solution if it is something you already do, or perhaps it could be something that can set your holsters apart from others? The cutting wheel like you mention could potentially help. Could you perhaps borrow the 5 in 1 from your friend, and make a couple of test pieces to see if it is something that would suit you?, make a scabbard and a couple of holsters and try to use it for all those things that you can think of, if the completed item looks better than your normal product, or if you found it easier, then I'd say go ahead. But if it just ad complexity to the process and no real gain, then you have tried it and knows that it won't work for you. Another thing that you might consider, is that you can always try to sell the 5 in 1 again if you don't like it. you might loose a bit of cash, but I think the value of those machines won't change much even if you use it for a couple of months. Brgds Jonas

-

Hey, Dwight! I'm your Huckleberry! I've been sewing patches for bikers for a decade now. I use a patcher, a flat bed and a post machine depending on how the sewing needs to be done. Here's the breakdown. If the patch is on the back, or upper fronts, and there is no pocket or zip open liner behind it, I use a long bed flat bed Singer 139. It doesn't have reverse, but I sew all the way around the patches. No reverse is needed as the starting stitches are covered by at least 6 to 8 going over them. If the vest (cut) or jacket has a pocket to deal with, I use my Adler 30-7 long arm, big bobbin, high lift patcher. It easily gets into pockets and zip open linings. If the sewing is around the vicinity of the arm holes, I tend to use a post machine. It's much easier to turn the vest around the post with the excess hanging down that to fight with a flat bed or patcher. An example of when I use the post machine is when I'm sewing flags or club names, or office positions onto the upper shoulder, in the narrow area between the front and back seams. I use double-sided leather tape from Wawak to hold the patches in place for sewing. If the back is extra flimsy, or is made of denim, I also use a long body office stapler to keep the patch and material lined up. Next, I prefer to use #69 bonded thread with a #18 needle, unless it is on a jacket or padded vest. Then I'll use #92 with a #19 needle. As for the needles, I have learned to use round point needles when sewing any patch that has a serged or embroidered edge. This is because a leather point needle will slice the closely sewn edge thread whereas the round point just goes between them. The leather under the patch doesn't care about the needle. It is garment leather. If your machine takes a needle system that is available in titanium coated needles, buy those whenever possible. This really comes in handy if you are sewing through double-sided tape. I also keep a little can of Goof Off and a dauber near my machines so I can clear any glue or tape residue off the needle. If your patcher has a lube pot, fill it with clear liquid silicon to keep the top thread from sticking to the eye of the needle. While at Wawak, buy some steel thread snips. Put magnets on the body of your machines and let them hold the snips and threaders, bobbins, etc. Wind extra bobbins in advance so you don't have a lot of downtime when you run out of bobbin thread. Prewounds go a long way if they are available for your machine(s). That's all I've got to say about tha-at!

-

spring flowers and good food

Handstitched replied to chuck123wapati's topic in All About Us and Off Topic

If my memory serves, years ago , mum had a few tubs of clay in one of our sheds, 2 different types for different applications. They were hermetically sealed , and still soft ready to use, heat and moisture kept them preserved. I might try to find them . I wonder ? 🤔 I also have her potters wheel, tools etc. Had our last visit to the hospital this arvo (hopefully) just another video conference to go. All that I've been doing seems to have paid off , according to the nurse, can't thank them enough for their help. And yes, not a period to be repeated. Take care HS -

Those look great! I bought me some of those clips a couple years back but have never used them. I noticed you used screws to secure them. Are the holes in the leather just punched for the screws? Stabilized in any way? Great job again!!!

-

Everything I read about digital servos says they have high torque from a standstill. My digital servos with 200 rpm minimum speed start with lots of torque. It would be educational to have a digital servo that was fully programmable so we could try some experiments at very low speed. The control box on my "stitchman" digital servo has what looks like a 9-pin serial cable, but I have not checked to see if it's actually sending serial (UART) data across the line.

-

I have no experience with hand stitching, but a possible weakness with a saddle stitch might be that you keep pulling the same thread through the leather, abrading the thread and making it slightly weaker with each hole you pass. By the time you reach the fiftieth hole, the thread has been pulled through fifty holes. With a (machine) lockstitch only a short amount of (top) thread gets pushed through the hole and pulled back, while the bottom thread doesn't get pulled through at all. So any bit of the top thread at any moment in time has been pushed through the leather only a couple of times and so has only worn down a little bit. Increased thread abrasion with manual stitching is offset by typically using thicker thread sizes as far as I can tell (so they there is more material to abrade before the thread becomes too weak) and waxing the threads for lubrication (so they abrade less when pulled through holes). On the other hand, the threads in a lockstitch basically make a 180 degree U-turn and as has been said before, that sort of a concentrated pulling point might be a weak spot. That said, now I wonder where a thread usually breaks when it does: in the exposed bit along the leather (in which case it doesn't really matter which stitch type you use), or in the hidden bit inside the leather where the threads are either locked (lockstitch) or where they pass each other (saddle stitch). Also, to be fair, one should compare apples with apples: so we should compare different stitch types using the same thread type/size and leather and that could be hard. Running a thick waxed thread through a machine would require a heavy duting sewing machine and using an unwaxed machine thread while hand stitching for any serious length would probably wear away the fibres in the thread... In the end I think both stitch types are comparable in strength and it would largely depend on thread thickness, thread material, and the way in which an item is used how soon a stitch would fail.

-

Stitch strength heresy - Lock vs Saddle

Cumberland Highpower replied to AlZilla's topic in Sewing Leather

Saddle stitching mostly still exists for either of 2 reasons: 1) Novelty 2) Poverty. Novelty as in Hermes or other high end makers that are selling the work of skilled artisans and a high end/luxury item. Poverty as in you can't afford a stitcher, yet. Even when I hand stitch that rare item I don't use a saddle stitch anymore. (I use a speedy stitcher). the stitches look about the same and the strength is close enough. (Your hands are only going to last so long, don't wear them out fiddling with stitches). There are a very few times when saddle stitches are used by an equipped shop. Repair, someone just wants it done a certain way or reproduction of goods designed before machine stitching. -

Just to sew them on shirts . . . jackets . . . vests . . . etc. May God bless, Dwight

-

The machine has been listed on the estate auction.

-

Tall Post Sewing Machines?

Cumberland Highpower replied to Cumberland Highpower's topic in Leather Sewing Machines

RockyAussie thanks for the reply. How do you find the overall ergonomics? Are these high posts comfortable machines to operate sitting down or do you feel your knees crowded and having to reach excessively upwards to work? Probably not as bad as I'm visualizing sitting here, but wanted to ask. Makes sense about the post offset. -

Leatherworking is a great winter hobby—quiet, creative, and very satisfying. You can definitely do it all by hand, no machines needed. People have made stunning leather goods by hand for centuries, so you're good to go with just basic tools and patience. I recommend "The Art of Hand Sewing Leather" by Al Stohlman (great for stitching techniques) and "Leatherworking Handbook" by Valerie Michael for a broader overview of tools, types of leather, and project ideas. Starter Tool Kit (for your projects): Knife: A skiving knife and a utility knife (like L’indispensable) will cover most tasks. Pricking irons (3.0–3.85mm) – better than chisels for finer work. Stitching awl and needles (John James) + waxed linen thread. Edge beveler (#2 or #3), edge creaser, adjustable groover, scratch awl – all very useful. Don’t forget a cutting mat, ruler, and burnisher (wood or bone). Look into European suppliers like Decocuir (France) or Le Prevo (UK) for quality tools without crazy shipping costs. And yeah, it’s true—finding a job nowadays can be tough in most fields unless you're using special services or platforms to boost your chances. So having a productive hobby like leatherwork is a solid idea!

-

This is the reality, and i agree completely. The sewing machine is one of the greatest inventions man has ever made IMO and the lock stitch has worked for a long time too.

-

That's just it a saddle stitch doesnt create a knot while a lockstitch is basicly a series of knots. Visualize your threads. Saddle stitching is basically using two threads spiraling them together with leather in between with no tension built by the threads pulling against each ohter. while lockstitch is two pieces of thread wrapped around each other in every hole, pulling against each the oposing thread on the other side of the leather

-

That's an interesting point, Chuck. It seems the ability to use a sewing awl is a dying art, driven in part by the ability to market expensive punches and irons. I've been an advocate for the efficiency, versatility and esthetics of awl sewing - holes always line up, can sew odd shapes that are difficult to punch, the hole size matches the thread. I'll add strength of the stitch to the list. Strength is tested on a regular basis with horse tack. I haven't seen many examples of failed stitching. It's usually the leather breaking where it wraps around hardware. I have seen linen thread rotted out after many years.