All Activity

- Past hour

-

- Today

-

If i get this tagging right @Johanna will know. You know those ads featuring the most interesting man in the world? In my humble opinion Billy 2-Shews has a claim to that title. Before the days of phone plans I had a couple $100+ phone calls with him, and several chat strings. You never knew when you'd hear from him and it was worth it everytime. Interesting factoid - Leatherworker.net started because of Billy 2-Shews and a pizza baking mama from Ohio.

-

Yes, how many coats of ProResist do you use to insure the antiquing doesn’t “stain” the other dye colors? I end up with a thin coat of antiquing color on parts of my work I don’t want antiqued. I use three coats and I’m not satisfied. Suggestions? Experiences? Thank you for al feedback. David

-

I read about a transfer method on video from Billy 2-shews. I was wondering if that video is still available?? thanks

-

Decorative Stitching/Embossing on a Driving Bridle

BlackDragon replied to TomE's topic in How Do I Do That?

Not sure why I didn't remember using thread as a filler, I do this on the spine when I rebind books. I looked Catrien Coppens up a little and she does some amazing work! That would be so cool if she could do that. Maybe she would be will to do a basic webinar on the embossing. -

Decorative Stitching/Embossing on a Driving Bridle

TomE replied to TomE's topic in How Do I Do That?

Thank you, @BlackDragon! "Trapunto" gives me lots of in roads for exploring. I also found the Stohlman book on embossing leather as a free download at the Tandy website. He describes using linen thread as a filler for small raised designs with parallel edges, but he doesn't stitch around the borders of the embossed designs. Facebook revealed that Catrien Coppens made the bridle in the picture. She's a saddler at the Royal Mews who has won numeous competitions. She does tutoring and will be teaching classes this month at the Walsall Leather Skills Centre. Think I'll get in touch to see if she's willing to do some long distance tutoring. -

Jotr joined the community

-

Didn't think about that. Good idea @chuck123wapati I'm pretty sure my metal working buddy has a sheer and the Guy I'm working for right now I know has a break and a sheer for sure at the work shop. I did find some 1 1/4" metal strapping at HD but just need to see how thick it is. This Nexbelt is only .150 thick. Two pieces of 3/4 oz and .028 Kydex comes out about the same. Curious how stiff it might be if I glue all three pieces together.

-

Find a heating air conditioning shop, they can cut it maby even have something you can use, they cut and bend tin/sheet metal.

-

Thanks for all the input. The Nexbelt I am using has the .028 Kydex (SHC) with a ratchet buckle. I think the Kydex stops at the ratchet track. I can buy that on EBAY. I was thinking of metal flashing. I would be looking for something 1 1/8" wide. Really thin. Not sure how to cut a nice straight piece. I was looking at using two pieces of 3/4 oz. Horween strap leather. The SHC runs the entire length of the belt with the ratchet track set in the SHC. Doesn't really look all that great on the front of the belt. This belt has a 12" ratchet track. I will probably cut it down to 6" or so.

-

Decorative Stitching/Embossing on a Driving Bridle

BlackDragon replied to TomE's topic in How Do I Do That?

I believe it's known as trapunto-style leather stitching. Basically it's similar to making a raised brow band but much more elaborate. You need a core made out of leather or cork, then you mold and glue your leather around the core, then stitch in place. -

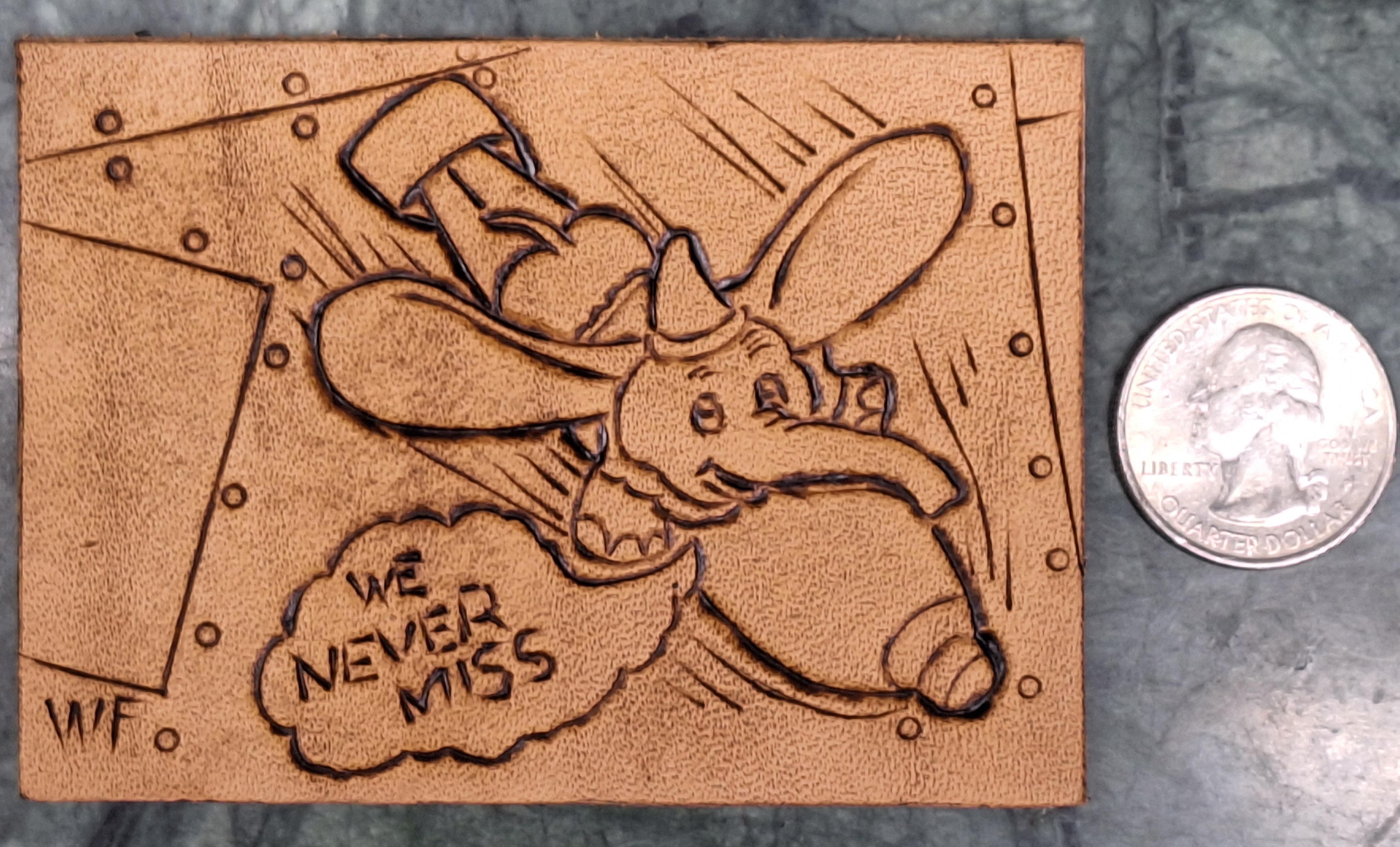

Had a small offcut, why not do a nose art tradinng card. This was from WWII and what Al Stohlman would have seen on planes in the Pacific. I wasn't sure about painting, the actual nose art is without much shading so kept to original.

- Yesterday

-

Need a part for Singer 17-30

Cumberland Highpower replied to docpugh's topic in Leather Sewing Machines

That's pretty tough. You're essentially going to have to find someone with a junk 17-30 that can supply you with parts. How handy are you with tools? If you have a drill press and belt sander/grinder you can made an adapter for it, something that can screw down with the large screws and then fit a needle plate from a different variant on top of it. For example, a needle plate from a Seiko TE series machine. (Chinese needle plates for the TE can be found fairly easily and not expensive). I've made/fit needle plates a few times over the years, it's not as hard as it sounds. You might also be able to change the shuttle race plate with one for a TE Series machine and then use a TE needle plate. But I don't know if they're fully interchangeable between a Singer and a Seiko? Of course that may not be something you may not be interested in, or maybe, I don't know. Then again, it may not be really worth any serious investment? I don't know what your machine is worth to you. I could see $200 worth of parts/labor on a $30 machine being a deal breaker. -

Thank you, it would be cool my skills aren't there yet.

-

Does anyone know what this style of decorative stitching is called and how it is done? I'm interested in how they created the relief in the decorative design. Any resources for learning this technique? This example is from the Society of Master Saddlers national saddlery competition. Thanks for looking.

-

limegreentouque joined the community

-

Is backstitching with a leather point needle a problem?

kgg replied to Gymnast's topic in Leather Sewing Machines

I have on occasion had this happen but only when I am sewing leather using multi layers say 6 oz that has not be glued together first. My thought is it was probably my fault because: I didn't hold the layers tight enough together so a layer moved slightly or the needle wasn't the correct size for the thickness leather I was trying to sew or the needle bent slightly when I tried to push the sewing thickness limit of both the machine and or the needle. I have stop using the servo motor to do reverse stitching and just handwheel the machine in reverse for those couple of stitches. Also if you do the typical forward few stitches then reverse to lock and then continue to the seam you are basically have a lot of bulk in those holes. To help reduce that bulk start and reduce possible cutting of the thread set the needle in about 3 stitches and Reverse then go forward. Another factor is the individual machine, maybe the forward and reverse are not properly setup. A simple check to that is put a piece of paper or cardboard under the presser foot and without thread in the needle do a few stitches forward and then do a reverse. If the machine is setup properly the needle will fall into same holes made when forward stitching. kgg -

.thumb.jpg.7b83907b17613afe0cdc856f1257806a.jpg)

Special Holster for Special Friend

tsunkasapa replied to Dwight's topic in Gun Holsters, Rifle Slings and Knife Sheathes

Very nice. I need to make a 1911 holster for a friend that's wrong-handed. I need to keep my mind on it when laying it out. I already have a right-handed one. -

Special Holster for Special Friend

Samalan replied to Dwight's topic in Gun Holsters, Rifle Slings and Knife Sheathes

Looks pretty cool to me, I'm sure your friend is going to love it. -

Is backstitching with a leather point needle a problem?

Samalan replied to Gymnast's topic in Leather Sewing Machines

Passing anything through the thread where the lockstitch forms is not helping; that's IMHO -

Is backstitching with a leather point needle a problem?

Samalan replied to Gymnast's topic in Leather Sewing Machines

I generally use them on nylon strapping, but yeah, they don't slice the leather like a leather point. I'm not saying they are the best thing to use, but anything that separates threads isn't a good thing; even a round point can compromise thread strength if you're sewing a shirt, no big deal. If you're sewing a holster, now you want all the thread strength you can get. -

Is backstitching with a leather point needle a problem?

Samalan replied to Gymnast's topic in Leather Sewing Machines

Yes -

Is backstitching with a leather point needle a problem?

friquant replied to Gymnast's topic in Leather Sewing Machines

Are you saying diamond point is less susceptible to cutting threads in a backstitch than a slant needle? -

Is backstitching with a leather point needle a problem?

Samalan replied to Gymnast's topic in Leather Sewing Machines

Definitely not trivial, it depends on what you're sewing. If it's in a stitching groove, you don't need that slant look anyway. I did a holster one time at the very end. I cut the thread in half. I now use diamond or round point on almost everything, unless I need the look you get with a leather-point needle, then I'll backstitch by hand. It's easy, and I get a better job. The problem is that when you use a leather point, it's designed to slice through leather, and it will slice through thread just as easily. -

I would use a thin carbon fiber strip. You can sew through it, punch holes in it, and it's very strong.

-

Is backstitching with a leather point needle a problem?

Gymnast replied to Gymnast's topic in Leather Sewing Machines

Thanks for the answer. I think it is not entirely trivial to find out the problem, if the thread is only partially cut. One possibility is to make tests with many stitches, and then pull the thread out and see if it has been damaged. The type of leather tip on the needle can probably also be important. -

Kinda makes me wish I needed a notebook.