-

Posts

1,806 -

Joined

Content Type

Profiles

Forums

Events

Blogs

Gallery

Everything posted by Matt S

-

Belt cutting machines always slightly narrower than "belt width"?

Matt S replied to nstarleather's topic in How Do I Do That?

My strip cutting machine is only a cheap benchtop one from China, but I have to account for the thickness of the blades when adding spacers. I think the logic goes that the strip is actually the distance between the edges of the blades, i.e. the length of the spacers plus one blade thickness (2*0.5*thickness). Could it be that your machine originally was designed for thicker blades, which have been subsequently replaced with thinner ones? -

Beautiful old machine, fairly rare even in the UK and like an honest politician elsewhere. There's a few threads scattered around discussing them on this forum. The bobbin does look about the right shape for a 45K but without anything to scale it off it's hard to tell. My 45K bobbins are 31mm long and 20mm diameter. If your Pilot bobbins are very close to that I would buy a few cheap ones to try gently in the Pilot. Hartley Sewing in Walsall is one of few dealers likely to have much/any knowledge on these things or parts lying around.

-

I've seen a couple designs similar to this being offered for sale on the usual Chinese websites for a few years. Nothing in the way of actual user reviews though. I would be very curious to play with one but not curious enough to spend my own money if you see what I mean. They appear to be a band knife splitter, but smaller, cheaper and lighter than the industrial standard ones. At first glance that appears to be tempting. I have one of the industrial standard ones, albeit a slightly old-fashioned model. It weighs about 400KG (800lb) and has a 12" capacity. Most of that mass is a couple of chunky iron castings which are used to keep the blade as taught and flat as possible. There's a good bit of weight in the large driving wheels so (a) the knife isn't being pulled round a tiny radius and (b) I guess their mass smooths out the blade's speed (which affects quality of finish). A fair bit of space is tied up with mechanisms to minutely adjust positioning and interactions between various internal mechanisms (and prevent those setting from wandering in use). There's also 4x motors to carefully time and control various functions (knife, feed, knife sharpening and dust extraction) and an automatic knife advance feature. When I was shopping for a splitter I spoke with the UK dealer of Camooga, which are one of the leading brands today. Their current equivalents of the one I eventually bought aren't much lighter because you still need/want a very stiff frame and to be able to control all the same aspects of function. Knowing what I do now I would not buy one of those desktop models if I expected it to be reliable because it cannot physically fit the above features. There's probably/hopefully a solid frame inside that sheetmetal enclosure but looking at how much of its limited realestate is taken up already there's not much space left for stiffness. I'd rather learn to live with using my bell knife skiver, mortgage a kidney buying a "real" splitter, or spend my send my leather out to be split by someone with a good splitter.

-

Apologies for not responding individually -- short of time and sleep and I figure a brusque response is better than none! Veg tanned leather is acidic (i.e. it has a pH of 0-7). From memory it needs to have a pH of around 3-4. Changing it very much in either direction can cause premature degradation. If you don't know what the pH of your treated leather currently is, or what pH you want it to be, dumping it in baking soda is like driving a car blindfolded! I have stuff I blacked with iron sulphate that's years old. Some cracked, some didn't. The stuff that cracked is when I followed the herd advice of "neutralising" in baking soda. The stuff that didn't I just washed it in a couple changes of water, let it dry and applied an appropriate dressing to replace the lost fats and oils. Unless you're using a tiny amount of baking soda (which is alkaline, with a pH around 8) you're going to bring the pH way too high. Whether you neutralise it to pH7 or completely overshoot and make it alkaline is irrelevant -- if you bring the pH above 4ish you're shortening the life of the leather. 10% iron sulphate in water has a pH of slightly less than 4. That's bang in line with what I'd expect a piece of veg tanned leather to be. If anything I'd say that veg tanned leather treated with iron sulphate might have raised its pH (seeing as some of the tannic acid is "used up" reacting with the iron to make black iron lake) and needs slight acidifying rather than having something like baking soda applied! Sorry to hear about your boots Scott. You say you took a pair of dyed boots and struck them with iron sulphate. How else were they treated? Alcohol based dyes can strip a lot of the oils that even "natural" leather has had added. Water based dyes and treatments can affect leather in a similar way. Did you treat them with fat, oil, wax or grease at any point? Veg tanned shoe uppers is unusual these days as other tanning methods tend to produce leathers that are less affected by their environment. Were your black boots worn in the same way as your other boots -- not worn more often or got wet or left in the sun more than the others?

-

Move along and save or maybe take a risk

Matt S replied to Webicons's topic in Leather Sewing Machines

It looks a lot like the 17s I have owned. Seiko is cloning it to this day as the TE and several Chinese firms too so many parts, as well as needles and bobbins, are readily available. It's about as simple a machine as will sew leather, runs very smooth and quiet. It's quite an old fashioned design so has a few issues with things like bobbin size and reluctance to climb over seams but the things just run and run. Convenient small cylinder arm. Perhaps worth noting, it's a drop-feed-only machine without reverse. Should work with v69/tkt40 thread, might do v138/tkt20 but don't bank on it. Intended for sewing lighter leather and fabric items without too many changes of thickness. Wallet not holster. The wheel presser can be changed out for a regular foot IIRC but is better for doing rapid and smooth changes of direction. Probably was setup for closing shoe uppers. You might get some dog marks on the back, but these are often easy to deal with or hide. From memory the shuttle driver will be pinned to the shaft so about the only timing adjustment will be needle bar height. Simple so long as nothing's damaged, a nightmare if it's banjaxed. For a few $hundred if it turns over I'd break the seller's hand off. -

Sorry mate, autocowrong struck. For "roasted" read "raised". Here is the relevant thread. Some of it is specific to using croc but the principles are more generally applicable. Here Brian skives the edges of the top layer as well as the filler layer, giving a fairly radiused rather than stepped raised effect.

-

Some products have a thin layer of foam or similar between the outer and the lining to give a bit of bulk or squashiness. This can also give the impression of thicker leather without the weight and cost increase that using thicker leather would entail. Cardboard and paper components get a hard time from many leather crafters but they have a very long history of use. Greyboard/millboard/strawboard (the grey coloured card you get at the back of notepads) is a popular choice because it's easy to work, inexpensive, and available in a range of suitable thicknesses. It's basically compressed recycled wood pulp. Cardboard liners can increase the bulk but also add a little stiffness. Moisture and repeat flexing can break down the fibres of the card over time, which is where higher-tech stiffeners like those produced by Bontex and Texon come in. These tend to use cellulose fibres like card, but are bound together with a moisture resistant resin, making them far harder wearing in use. These are very popular in shoes to increase stiffness in certain areas with minimal weight. Thin wood also works, and is how things like attaché cases hold their rigid shape. Bag bottoms are often reinforced with thin wood. Again you have to choose what you use carefully by the application -- usually hardboard, MDF or plywood. Often though on small items that "bulk" is an effect called "raising", where a piece of leather is skived (thinned) at its edges and sort of moulded down to create a raised centre and thinner edges. This is particularly popular on dress belts and traditionally seen as a sign of skilled work. Sometimes a thin piece of leather is moulded over a thicker core. Brian ( @RockyAussie) has very kindly documented his hybrid approach that he uses to produce *raised* belts commercially.

-

Is it a specific pattern of holster for a PPK you're after or just "a" flap holster for a PPK? I may have seen one to fit a PPK in one of the Stohlman books. It occurs to me that the PPK is a fairly flat pistol and not very large. All else failing you could print a 100% scale picture of one, cut it from some wood of the same thickness or a bit more, ease the edges, and you'd have a fairly accurate dummy to pattern off.

-

As it happens, I knew Mark and Marie when I lived in Exeter over a decade ago. Mark got me started in leather and showed me how to saddle stitch. I am eternally grateful to them for giving me my start and glad that they have continued to run a sustainable business on a relatively simple product line. It's a very neat belt you've made. Not sure I'd come to you for business advice but a very neat piece of work!

-

It's an industry term for things like vinegaroon, where colour is introduced by a chemical reaction rather than a pigment or dye. The most common is the grey-black-blue one you get from iron. There are others but they aren't as spectacular and use less common ingredients.

- 52 replies

-

- vinegaroon

- roon

- (and 10 more)

-

I read that advice a lot. What acidity levels are you getting, and what do you "neutralise" to? My experience is that vinegaroon can be of many different pHs (acidity levels). Veg tanned leathers are acidic with an average pH around 3 from the tannery, which I presume to be the "correct" pH for best longevity. Basic/caustic conditions are well recognised as being just as detrimental to leather as excessively acidic ones. This also matches my experience -- when I first tried vinegaroon I followed the common "neutralisation" advice with baking soda and "burned" the leather, cracking almost immediately whilst uncoloured pieces from the same hide went years without cracking. I did some informal testing and found that for the leathers I use washing the 'rooned leather in plain water brought the pH back very close to its "tannery fresh" level, while washing in a baking soda solution raised the pH significantly. I have found that pieces so treated don't tend to crack like those I have washed in baking soda.

-

Those are some nice looking edges! You're right, English-style bridle leather can be a right swine to dye and burnish, what with the tallow and the tight fibres. I'm curious what's in that edge solution. Over here the saddle industry has been using diluted water-based glue as a burnishing compound for well over a century. Many will work but traditionally gum arabic or hide/pearl glue were used and nowadays it's usually normal white PVA. Often a powder dye is added so it stains and burnishes in one step, and a drop of dish soap for penetration. Finishing is done with either beeswax or tallow. I like those edge irons. I've never had much success with mine and tend to just use a power burnisher for wax. To level out multiple layers before burnishing you can scrape with the edge of a piece of broken glass (once very common in the shoe and carpentry trades too).

-

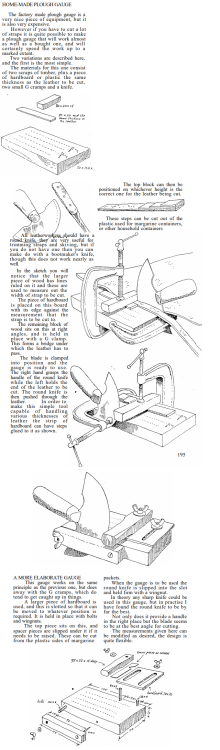

I borrowed these pictures from Ron Edwards' excellent book on Australian bush leatherwork. It can be chucked together in minutes from common materials. It's probably as cheap as you can get if you already have the knife. A Stanley/boxcutter blade would probably also work. He also shows an even simpler jig with a knife stuck in the benchtop and a block of wood nailed down as a fence.

-

Black strikers like iron sulphate and vinegaroon give a darker or lighter effect based on the amount of tannin left in the leather. There's a chemical reaction which occurs within the leather where tannic acid oxidises the iron in the iron-containing solution into black iron tannate. The less tannic acid left in the leather after tanning the less pronounced the effect. Tannins (and so the blacking effect) can be increased, usually with a solution of black tea. In South America they strike rawhide black using this method (rawhide, being untanned, has no tannins). Solution strength and contact time also affect how deep a shade is produced. It's not unusual for black-struck leathers to look blue-grey until some grease or oil is added. I think that there may also be some variation based on how much grease/oil is in the leather, as that would reduce the ability of a water-based solution to contact the leather fibres. Even natural/russet/tooling leather often has a small amount of oil or grease added during production.

-

Sorry about the delay replying, had a busy few days. Frankly, I think it may be. The 3600 seems to only have one advantage to you over you Adler 69, i.e. a larger bobbin. Your Adler is a far higher quality (i.e. reliable and repairable) machine than that Tysew-badged one. When I was having troubles with my 246 clone I called in a technician and he pointed out that any parts that need replacing (which can happen due to wear, accident or desire to upgrade) are not always compatible with clone machines. I nearly had a boat anchor after a slight mishap. If you want different parts for your Adler 69 (like a an add-on flat table, or a narrow needle plate) they are widely available as that model has been an industry staple for decades. Let's put it this way: Tysew sells used Adler 69s for about the same price as a /new/ Tysew 3600. Since they are broadly similar machines in terms of features and capacities the only way that would work is if Adler. Tysew's offer is to take 2x machines with a sale value of ~£2K off you in exchange for a machine worth ~£1K. No wonder they're keen.

-

If you want a similar effect without the hassle and guesswork of producing vinegaroon, dissolve iron sulphate in water and use that instead. Iron sulphate is sold for gardening purposes and a saturated solution has a very similar pH to veg tanned leather. Or take Will Ghormely's approach and marinade your leather in a barrel of rusty water.

-

Leather can certainly change size or shape after different processes. I'm sure we've all had straps which suddenly get unstraight as soon as they get cut off the hide -- just from relieving some of the internal stresses. I've had straps where the stitching can stretch the leather (a curve develops if you stop having stitched just down one side Putting a piece through a machine like a splitter can stretch it too, as can even hand skiving an edge on certain leathers. If any potential stretch/shrink/warp is likely to cause problems I tend to cut the initial pieces oversized and trim down once most of the work is complete. Linings can be trimmed to the edge of the "main" piece, or both pieces of leather deliberately cut slightly oversize and the outer edge of the entire lamination cut to final dimension. Yes it's a bit of a waste but I figure it's less wasteful than throwing out multiple large pieces cos they don't fit.

-

Weaver sells something similar, and Tandy has done but I think they were discontinued. Sometimes called a tipping press (cos it punches the holes and cuts the tip). Alternatively you can have a clicker die/press knife made to your specs. Brian (@RockyAussie ) has a great thread that shows how he uses these professionally, including a couple of ways he builds a locating jig. If you just want the holes punched buy a handful of punch tubes and drill and tap them into a piece of strap iron or heavy box section.

-

Hi, I'd be interested in that. I'm in Harrow so not far away from you. I've had a look at your current range on your website and that all seems well within my skillset. Normally for things like this I agree a piece rate with the client rather than charging per hour. My rates for piecework/trade work depends on things like quantity, who provides the materials and tooling, etc. If you're interested drop me a PM, or I can email you. We can chat about a few details and if things seem right for both of us we can discuss how to move things to the next stage, which is usually that I submit samples to you for approval. Best Wishes, Matt

-

I believe that's a moderate quality Chinese clone of the Juki 245 or 246. I used to have a 246 clone from another rebadger (probably the same manufacturer) and while it has some advantageous features would prefer to have your Adler for its quality and reliability. I wouldn't put my money into another one. Two layers of 3mm leather should work fine in your Adler. If you want to sew 2x layers of 6+mm you'll have to upgrade to something significantly heavier like an Adler 205, with a going rate around 3-4x your Adler. If you want something with similar capacity to your Adler but a larger bobbin there's a few options for about 1-1.5x the price of your Adler. Seiko LCW-8 and Juki 1341 would be good options, and usually go for under £1500 used.

-

The only machine I can recall with a locking reverse was the Tippman Aerostitch, which is years out of production, a rare bird on these shores, and temperamental. If you can make do with a larger cylinder arm (3" diameter) there are a few options available to you. I have a pair of Seiko LCW-8s, which use large U-size bobbins. If you need to stay with a smaller cylinder arm like your 69 there are a lot fewer options, but you might want to look at the Juki 246 which has a 2" diameter arm but takes a (IIRC) M size bobbin which takes more thread than the one on you Adler. Most machines in this weight class will probably struggle with anything over 10mm total thickness though -- it's simply not what they're designed for. If you're stitching 2 layers of 8mm veg tanned leather regularly you'd be best looking at something in what I call the harness weight class -- Singer 45K, Adler 205, Juki 441, that sort of thing. Most of those have large cylinder arms but on the plus side their bobbins are far larger than the G size on your Adler 69.

-

Veg tanned leather is mildly acidic -- usually around a pH of 3 in my experience. I'm no tanner but I'd be willing to bet that there's a good reason behind that. In the trade certain premature degradations of the leather are associated with low pH ("red rot") and with excessively high pH. For comparison human skin is around pH5.5, regular vinegar pH2-3, distilled water neutral at pH7 and a saturated solution of baking soda mildly basic at pH8-9. I think it's a very good idea to keep leather as similar as possible a pH as it came out the tannery when we're mangling it, for longevity. I don't remember the pH of iron acetate (the active component of vinegroon, i.e. the result of reacting iron with acetic acid [vinegar]), nor can I find it from Google. The pH of any particular batch of vinegroon might be anything within a wide range though, dependant on things like the amount of unreacted vinegar present. The simple version of the chemistry of vinegroon and other similar strikers is that excess tannic acid in the leather (left over from the tanning process) reacts in the presence of water/moisture with iron to form iron tannate, which is a blue-black in colour. Iron tannate is not water soluble, so can't wash out of the leather. This same reaction is used on tannin-containing wood like oak and chestnut. There's nothing magic or unique about vinegroon -- many different ways of getting iron to react with the leather work. Iron filings are a common accidental reaction in workshops and tanneries. Blood is also common, though usually again an accident. I've used iron sulphate crystals from the garden centre before, and have heard of good results from dietary iron supplement tablets (same stuff). Will Ghormley simply uses a barrel of rusty water. I greatly prefer the idea of using either largely neutral reactants (like rusty water) or consistent off-the-shelf components like ferrous sulphate, for which there is no brew/wait time, are consistent in their behaviour, whose pH can be predicted, measured and controlled. (Incidentally a 10% solution of ferrous sulphate in water has a pH of around 3.5, which is very similar to veg tanned leather.) Immersion of leather in basic solutions of unknown or uncontrolled strength doesn't seem like a good idea to me. I've tried it as the "received wisdom" way to "neutralise" a vinegroon bath and ended up with stuff that seemed fine initially but cracked and split far too early. No amount of grease will knit broken leather fibres back together.

-

Glue diluted in water has been standard in the UK for over a century. Traditionally gum arabic or hide/pearl/rabbit glue but these days normal white PVA wood glue is more common. It works very quickly, is very long-lasting and so cheap it's pretty much free.