-

Posts

941 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Store

Everything posted by gottaknow

-

Best machine for non leather application

gottaknow replied to stickandtin's topic in Leather Sewing Machines

On a drop feed machine, only the feed dogs advance the fabric. The needle moves straight up and down. With a needle feed, the needle bar and feed dogs move together to advance the material. Much more positive feed and helps prevent ply shift with stickier materials (vinyl). It also helps when crossing seams. On my 211G157's, I set the presser foot lift for 1/2". They'll go higher, but I've never needed them to. Regards, Eric -

It appears they put money into a table and motor, but that head is old. The hook is gear driven and I would be leary. It's more suited for belts than holsters. With a clutch motor, you may have issues with the speed. If it were me, I'd pass at that price. Regards, Eric

-

I could make my old 241's do this too, but first off, it's a drop feed machine. Then there's the small bobbins that you mentioned Uwe. I do know that with this size bobbin, you can sew about 7-8 yards with T135. That's it. After modifying the basket and shaving off the needle guard, you could never sew the fabric it was intended to, not to mention you can bend a needle bar pretty easy on both this series and the 281's. And most of all, your stitch length is going to be all over the place. In the opening segment, he was pushing and pulling the material through. He also didn't cross any seams. The 241 series were a decent garment machine in their day. I still keep a couple set up in our training school. Guys like this tend to annoy me because they get other folks butchering their perfectly good machines with so-so results. Maybe I'm just grumpy today after a nice 3 day weekend. Regards, Eric

-

Downloaded and printed Mike. Thank you so much! Nice to have so much help around when you need it! Regards, Eric

-

I'm loving the new direct drive Juki motors. I have about 35 of them in service. Not a single issue so far. Really cleans up the whole machine. Regards, Eric

-

Hey folks, I'm trying to locate a manual for my Pfaff 342-6. It's a double needle cylinder machine. Pfaff says it's out of print, but perhaps some of you across the pond has one in a pdf file. I just need the parts manual. Thanks in advance! Regards, Eric

-

Best machine for non leather application

gottaknow replied to stickandtin's topic in Leather Sewing Machines

The 211G157 has reverse and is a needle feed. It's standard needle class is 135x17. The Juki DDL550N is a drop feed that is certainly a nice machine. It won't sew the thickness of the 211G157 because of the needle length and not being a needle feed. In light to medium weight woven material it will sew really nice. Regards, Eric -

I'm with Wiz on this one. I don't think that's the appropriate machine. It may take if for a bit, but it's the components you can't see that will likely be damaged. Regards, Eric

-

Best machine for non leather application

gottaknow replied to stickandtin's topic in Leather Sewing Machines

There are some older Singers which you may want to check into. The 211G151 and the 281-22. Both are needle feed, the 211 has a vertical hook and the 281's have a horizontal hook. The 211 will handle more thickness. The 281 series has several other subclasses that are drop feed, so stick with the -22 subclass. These machines are widely available because so many factories used them. They also run forever and parts are available and cheap. The 281's use an oil sump, the 211's have a small oil reservoir in the top arm and the hook saddle. There is some hand oiling required, but nothing major. The heads of both models are worth $200-400 depending on condition. The 211's are easier to find. Regards, Eric -

Gave up on the antique Singer; bought refurbed Juki!

gottaknow replied to horselady21's topic in Leather Sewing Machines

Thanks Suzelle! Nice to hear someone reads my rambling. I see you're in the Nortwest. If you're ever over by Spokane, the factory is in Post Falls, ID. Give me a heads up and I'll show you around. Regards, Eric -

Best machine for non leather application

gottaknow replied to stickandtin's topic in Leather Sewing Machines

The 9010's were the follow up to the 5000 series needle feeds. We're still using the 5410's, which are still a good machine. Like most garment machines of that age, they require running at high speed to pump oil to the top shaft. A few bobbin windings at speed accomplish this. The new 9010's have Juki's new dry head system which is a series of small reservoirs for a lightweight grease. This is to reduce the oil spotting on textiles. My 9010's have top shaft mounted DC motors which are very strong. No belts, no table mounted motors. I don't know if they offer the machine without this, using a conventional motor setup. The control box is their 920 series which has every feature known to man with more than 100 programmable options. Low speed is decent, and even new operators have no trouble getting used to it. We sew 26oz. heavy wool, (Pendleton) and with a size 21 needle will easily sew 6-7 ply. We have the A series, which is the heaviest, but with a feed dog change (finer tooth) and matching throat plate you could easily sew two ply of nylon. They will tension T90 bonded easily, down to T35. They use standard presser feet so the options are many. The needle class is 135x7. We use size 14 thru 22. I like Juki's for the simple reason that parts are so available and cheap. My Japan made 5410's have endured 15 years of heavy factory use. They use a sump reservoir for oil, where the 9010's have a closed oil system for the lower shaft and feeds. Regards, Eric -

Best machine for non leather application

gottaknow replied to stickandtin's topic in Leather Sewing Machines

I'm a big fan of the Juki 9010 series. Needle feed with several sub-classes. The differences between them is really just the feed dogs and throat plate. The "A" sub-class is the heaviest. Regards, Eric -

puckers in waxed canvas stitching

gottaknow replied to georgeandgracie's topic in Leather Sewing Machines

Unlike leather, the bottom stitching on woven fabric should not appear much different than the top. The white discoloration you see is the wax. It will "heal" itself as the oil wicks back in and the material is handled. We will often sew inside out, say on the rolled hem of a jacket. I have to make sure the tension is balanced, probably the most common adjustment in the factory. We don't allow the operators to make tension adjustments. In our waxed fabric, needle holes are permanent and the garment becomes a second. i would keep your other machine. About the time you think you don't need it, you will. There could be times when you need it, say for binding. We'll sometimes bind the edge of our waxed canvas with a heavy cotton twill. I put the word out to some dealers I know who will keep an eye out for a 211g157, people I trust. Regards, Eric -

puckers in waxed canvas stitching

gottaknow replied to georgeandgracie's topic in Leather Sewing Machines

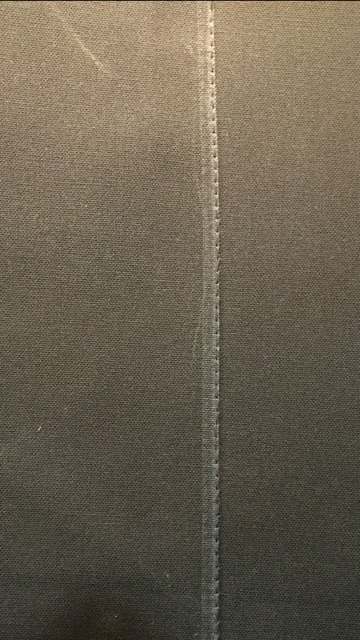

Here's another sewn sample with the same waxed canvas but using T70 bonded nylon, same size 18 needle. No tension adjustment. I edited this to add a picture a rolled hem which was shown in the original post. Regards, Eric -

puckers in waxed canvas stitching

gottaknow replied to georgeandgracie's topic in Leather Sewing Machines

I finally had a chance to sew a sample of our waxed canvas on one of my Singer 211G157's. The thread is T60 polyester core/cotton wrap. The needle is a 135x17 size 18 with a round cloth point. I simply folded over a piece and topstitched it down at about 1/16". I really like the way a needle feed handles the waxed canvas. As I said before, the only time I'll use a walking foot machine is for binding. Regards, Eric -

That is a nice looking 563! Regards, Eric

-

puckers in waxed canvas stitching

gottaknow replied to georgeandgracie's topic in Leather Sewing Machines

That's way too high. Head only in good shape $400 tops. Regards, Eric -

puckers in waxed canvas stitching

gottaknow replied to georgeandgracie's topic in Leather Sewing Machines

The 211A series were made in Japan. There were a few Singers of that era that were designated A as well, but were made in Germany, likely under contract from Adler. Regards, Eric -

puckers in waxed canvas stitching

gottaknow replied to georgeandgracie's topic in Leather Sewing Machines

Our thread is custom made by one of the worlds leaders. (I can't say) Two years ago I did extensive testing for them which resulted in a new finish formulation to solve some undesirable attributes. That said, I've worked with A&E thread a lot and it's a very good thread. D-core is good for anything cotton. If you want something stronger, try the Perma core which is poly wrapped poly. I've used their thread on everything from denim to Lycra. Regards, Eric -

puckers in waxed canvas stitching

gottaknow replied to georgeandgracie's topic in Leather Sewing Machines

Great looking etsy shop! Looking at your product lineup, I think holding out for a needle feed with reverse would serve you well. Again, great looking stuff! Regards, Eric -

puckers in waxed canvas stitching

gottaknow replied to georgeandgracie's topic in Leather Sewing Machines

I'll check out your store when I get to my home computer! I really wouldn't use a double needle unless you want to use it for that purpose. My 211's are the backups for my Juki 9010A's. I do have a lot of 211W151's that don't have a reverse, and those are everywhere around the country. I'd still hold out for a single needle with reverse. I'll look at your products and see if I can come with other ideas for you. Regards, Eric -

puckers in waxed canvas stitching

gottaknow replied to georgeandgracie's topic in Leather Sewing Machines

Bonded poly is better than nylon for puckering. I don't think I caught what you were making with the waxed canvas. That will make a difference in the size and type of thread you're using. You can use a double needle by removing one needle, usually the left one. The 212 is the two needle version of the 211. I'd hold out for a reverse if you can. I'm going to sew up some samples and photograph them for you here so you can see for yourself. Regards, Eric -

Yeah, that's pretty steep for that machine. Someone will end up with it at that price though. People are so eager to get a walking foot machine they'll pay about anything. That is unless you spend time on the forum here and learn their realistic value. Good luck! Regards, Eric

-

Gave up on the antique Singer; bought refurbed Juki!

gottaknow replied to horselady21's topic in Leather Sewing Machines

My Juki LU562 does have reverse and uses a "G" sized bobbins, same as the Singer 111's and 211's. Glad you got a good machine. My 562 gets a lot of binding work in a factory, and we don't sew slow. Uwe really sounds like a good egg. I'd love to have him kick around the factory with me some weekend. You too Wiz. Regards, Eric -

puckers in waxed canvas stitching

gottaknow replied to georgeandgracie's topic in Leather Sewing Machines

That is very true. Our company has been around since the late 1800's. The waxed canvas we use isn't far from the original. It was designed for miners and loggers working in the rainy northwest. Gore Tex is nice for a lot of active sportswear applications, but if you get it muddy, it will leak like a sieve. It offers little abrasion resistance as well. With waxed canvas, you can hose it off, scrub it with a brush and re-wax it. We use high quality Wickett and Craig veg tanned bridal leather for our luggage, combining it with waxed canvas or heavy cotton twill. Our duffle bags are amazing. Our loyal customers want time tested products that don't fail under heavy use and stress. As you said, many of our techniques are over a hundred years old simply because there's nothing better. Regards, Eric