-

Posts

2,372 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Store

Everything posted by immiketoo

-

EDC multiple holster

immiketoo replied to Akers's topic in Gun Holsters, Rifle Slings and Knife Sheathes

I’ve made many things out of necessity as well. The concept is usually the most challenging part! Sometimes I have one or two prototypes in the scrap bin before it’s the way I want it. my only worry is that if you lean on it, the tools will push into your phone screen and crack it? maybe it’s far enough apart, but I can’t tell in your pics.- 8 replies

-

- leatherman

- flashlight

-

(and 1 more)

Tagged with:

-

Something simple.

immiketoo replied to immiketoo's topic in Gun Holsters, Rifle Slings and Knife Sheathes

Thank you. As to the flap, it is molded around the tool slightly to keep it out of the way yet still provide easy access for opening. Additionally, the tool is also wet molded low into the case with a very snug fit. You can shake it upside down and it doesn’t come out. maybe if you did hand stands? Lol... Besides, I hate the way those pointy belt end flaps look. -

I enjoy making simple items sometimes. They require both less and more work than complex tooled and colored items.

-

You’re right, Fred. The blade is the most important, but you need someplace to hold it these will accept all major blade makers blades except leather wranglers, which you have to ask them for specifically, but can get.

-

Glad you enjoyed it!

- 26 replies

-

- bevelingislife

- celtic

-

(and 1 more)

Tagged with:

-

In these images, the border lines were cut after the dividers, then smoothed with a modeling spoon to round them off.

-

Seems like this is pretty will covered, but I’ll add this. Part of your problem is that you’re cutting too deeply. These line borders don’t have a lot of support once you cut both sides, and the grain can start to “peel” up on the cut edges. for the most part, I don’t cut these borders anymore, rather I use a wing divider to score a deep line and leave it at that. those push bevelers and beader blades are really difficult to control and it’s easy to mess up a piece of leather in a hurry. The wing dividers afford a lot more control, and if you do need to cut them in, there’s a sweet channel to guide your swivel knife.

-

Absolutely. Just make sure you test on a piece similar to your work piece and of course, make sure everything is fully dry.

- 24 replies

-

- youcantresistthis

- frisket

-

(and 1 more)

Tagged with:

-

There's guy here in Greece that makes them. Last summer the group we work for gave me a bag of swords and I am steadily working through sheathes for them.

-

Its WAY too soft and you risk damaging your knife. You need a sheet of HDPE or UHMW plastic like they use in professional kitchens. You'll be amazed at the difference you feel. You can get a small piece from Woodcraft or you can do a search for restaurant supply in your area. And, if you have a really sharp knife you can cut right through those mats. They aren't suitable for round knives.

-

Nice to see someone else who gets it. I too just bought a half dozen Dieselpunk patterns. I am willing to do this because it cuts down my learning curve significantly, and I get a great product that I can then modify or use to create my own as needed. I am also a member of Nigel's page because he's just so darn cool and filled with knowledge. You make an excellent comparison to tool money. People buy a lot of tools and then have no idea how to use them BTW, we can't share the armor pattern as they are the property of the company who ordered the armor sets. Sorry dude

-

Hey dude, thanks a lot. It is SUPER niche. We missed the boat on AC Oddesey because they had to be so secret about it. They couldn't even tell us what it was for until it was too late, but the group is also tapped for a lot of movies, so hopefully it will happen. As for patterns, I haven't ever considered it because who would want one? LARP and SCA folks are not willing to spend the money on full custom sets like ours most of the time and the casual larper probably couldn't make one. I'll talk to the boss though and see what she says

-

Well, that's ancient greek armor, if stylized quite a bit. Our armor was used in the research for that game and the company we make it for was consulted heavily. Unfortunately, ours wasn't ready in time to be digitized, but hopefully, we'll have future opportunities. Can't wait to see what you're doing with your set.

-

Yeah, the pic of me wearing it didn't load for some reason. :/

-

The entire thing is covered in linen. With a few leather trim pieces.

-

We made another set of armor, this one from the Mycenaean era. Leather wrapped in linen with some embellishments. Natalie handled most of this project, while I was hired for my stitcher abilities and as a model :)

-

Another way that many people use is to cut square strips and then bevel the edges at 45 degrees. Moisten the strip and roll them on a flat surface with a smooth plank of wood or other smooth rigid item. Apply pressure as you roll back and forth and this will eventually make a round, although its more time consuming than using a rounder.

-

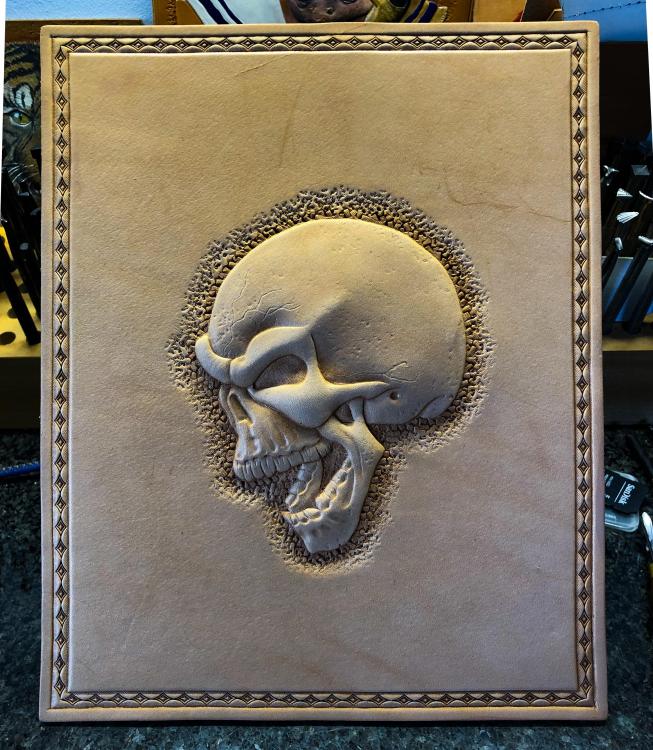

You are correct. Good eye. The piece is a letter sized piece of paper. Skull is 4x4 ish? That’s a great idea! Thanks, dude. Thank you. No idea on the skull’s origin, I just made a tutorial of it for a guy on Facebook and I liked how it turned out. Yes the diamond is a BK.

-

-

That was probably my video about the low angle blade. As to the exact geometry of the blade, I don’t know what it is, but the angle of attack, is very low. It almost looks like a straight blade from the side. The grind of the edge is also very wide compared to other blades, think wide low roof as opposed to steep church steeple angles. Another thing to consider is the thickness of the blade as that will also have great impact. These blades are narrower than your standard blade and that’s part of what gives it its feel in the leather. honestly, you could just message Peter and buy one for 40 bucks. Having never seen one, you’d just be guessing at the angles etc. your call though. Let me know if you need help ordering as Peter is a friend of mine and can be busy much of the time.

-

Not at all surprising, Jeff. In fact, I would have been shocked if you had taken the opportunity to put your money where your mouth is, but I wanted to offer you the platform anyway in the spirit of professionalism and promoting the craft. That's what I do.

-

If you have been complaining about this for two years and still aren't satisfied, why don't you do something about it and make one yourself? Better yet, I am willing to host a live class with you as the instructor. For FREE, since you like that word a lot. That way you can answer questions in real time and put the complaining to rest. I will make the video available to anyone who wants it at any time. What do you say?

-

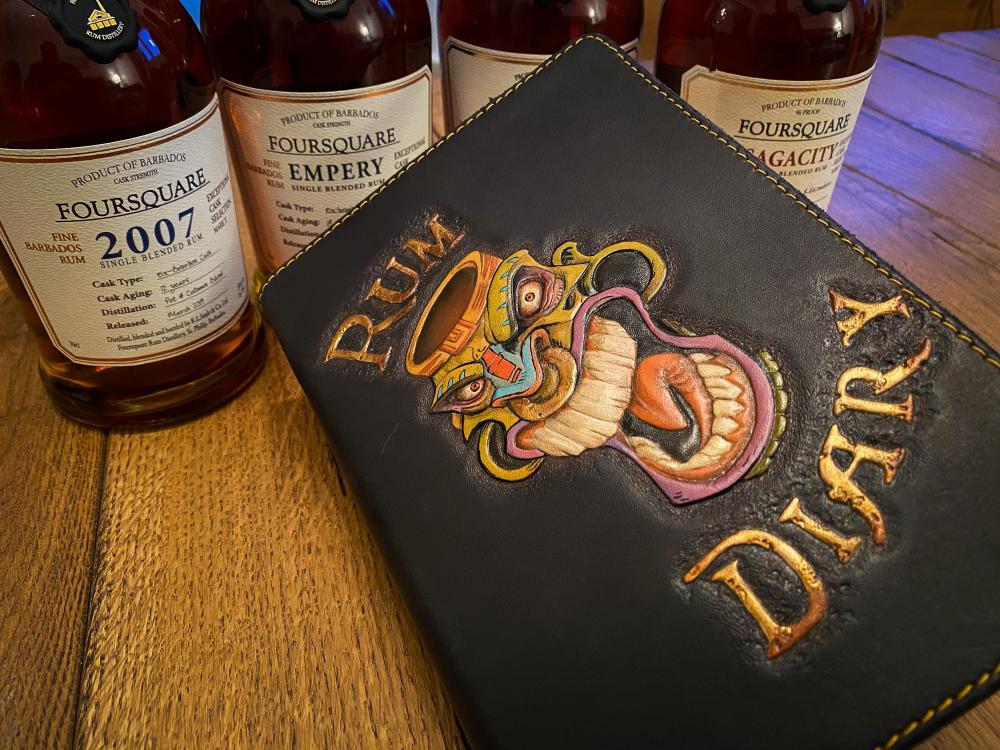

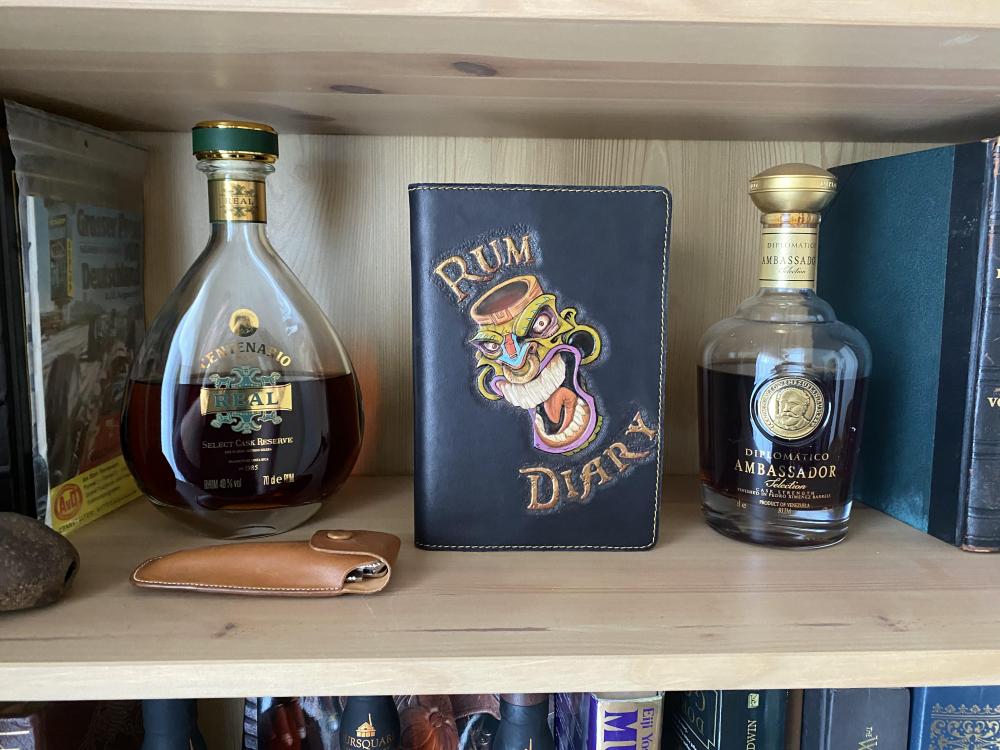

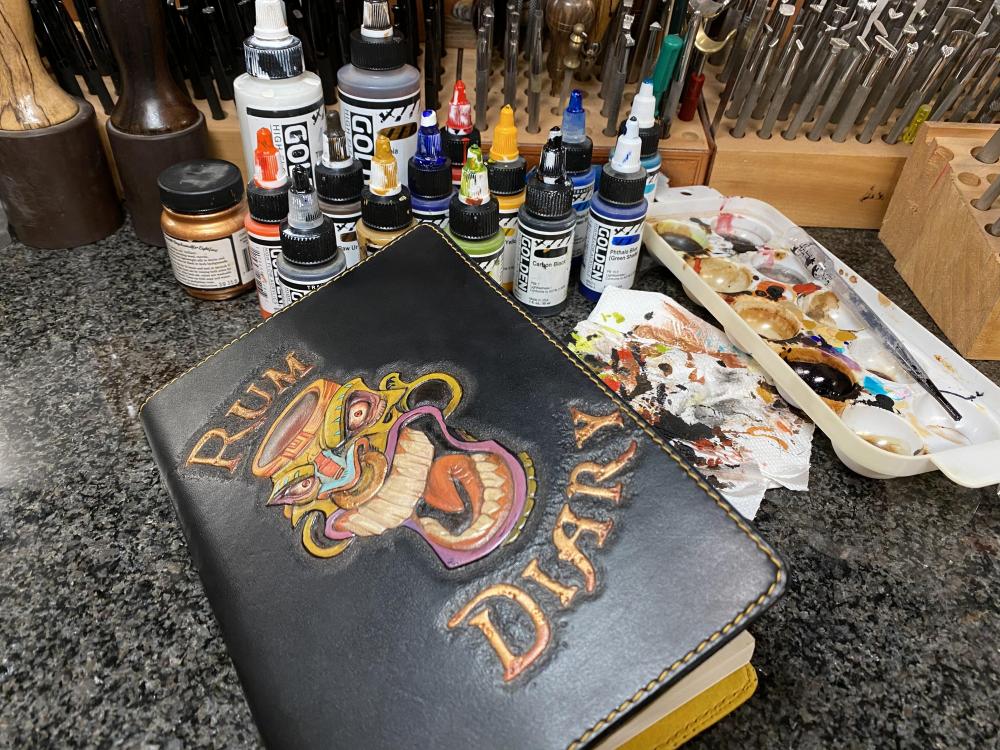

Thank you. I try to make it as perfect as I possibly can. The front is tooled first, then lined, then the front and the back composites are glued together and stitched. The Gold is acrylic paint, made by Lumiere.

-

The only way to make this work is to do a laser scan and make a point cloud of the weapon. That requires a considerable investment in equipment and even more so on the skill of the operator. To make an accurate scan, the technician must have a thorough knowledge of the software in order un understand if the point cloud is correct. And, because the scans need to be put together to form a 3D printable object, there is a LOT of margin for error. THEN, there's the output. If the file is manipulated at all the dimensions will be off. I have a P30 that has an oval barrel because someone stretched the dimensions on one axis and the person who printed it didn't catch it. Then, there's the cost of the 3D printer and, and, and. Blue guns are more durable, more accurate (at least for a lot less $$$) and cheaper for now.