suzelle

Members-

Posts

490 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Store

Everything posted by suzelle

-

Big Barb - The Consew! (255 RB2 - I think!)

suzelle replied to suzelle's topic in Leather Sewing Machines

Constabulary, Okay, I'm not crazy! It's the motor, it is crazy fast! The guys in the shop I'm working at are both on Juki machines, they tried my machine out and didn't like how fast it was. LOL. They like fast cars but the sewing machines, not so much! LOL. Yes, gonna have to get a Servo. Think I'm headed in that direction. Thank you! Oh, and also thanks for mentioning the Singer 211G and 211U. I will put those machines on my list too, for parts. -

Big Barb - The Consew! (255 RB2 - I think!)

suzelle replied to suzelle's topic in Leather Sewing Machines

Northmount, Thanks for doing the math for me. Makes me feel a bit better, you came up with same approximate difference in speed reduction that I was figuring. I agree, probably I won't notice much difference. -

Big Barb - The Consew! (255 RB2 - I think!)

suzelle replied to suzelle's topic in Leather Sewing Machines

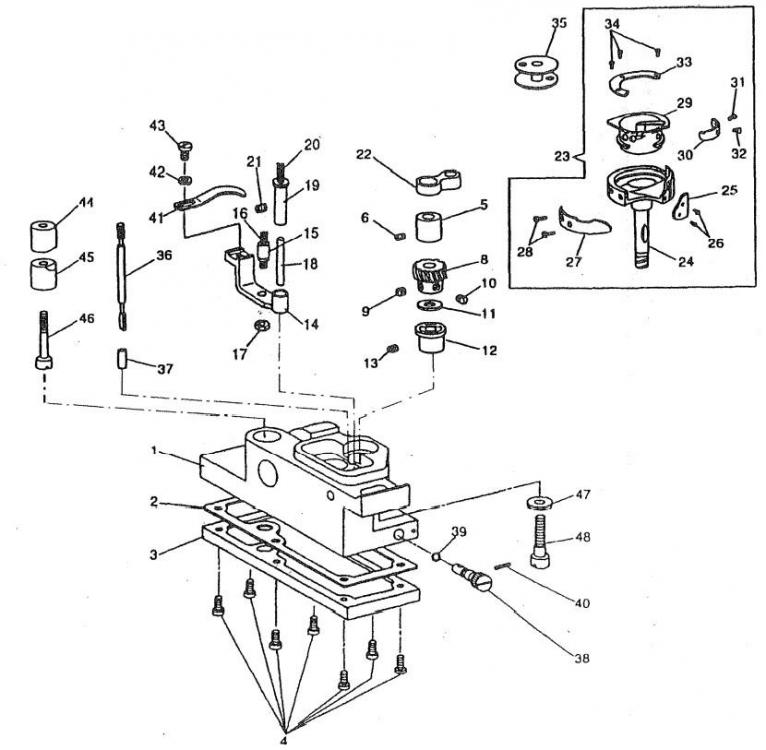

Part Numbers below. Let me know if there is a better diagram somewhere. Oh, and regarding the motor, I am going to put the smallest pulley I can find on it. The machine really races. I'm accustomed to a clutch motor, so that is not the issue. It's just that this machine runs so smooth that it flies! My shaft is 3/4 inch, and the outer diameter of the pulley is about 2.25" approximately. I found a new pulley on Ebay that was 3/4" shaft, with a 2" pulley. Not sure if it's going to make much of a difference, but it is the smallest pulley I could find. I do need to get better educated on clutch motors. I have included the specs on the Camsew motor. It says 3450 RPM, is that a faster motor than the other clutch motors available? What about the 3.4 AMPS? I may have a slower or less powerful motor I can pull off a machine I'm not currently using. If you can shed some light on that stuff, please do. LOL. I am not an electician. I'm thinking I can adjust the belt a bit to accomodate the new pulley when it gets here. If that does not make it slow enough, and/or I don't have a less powerful motor around here somewhere, I'll just get a servo motor. If anybody knows of a smaller pulley that will take a v-belt or if another pulley and belt combo is better, please share. Much appreciated! -

Big Barb - The Consew! (255 RB2 - I think!)

suzelle replied to suzelle's topic in Leather Sewing Machines

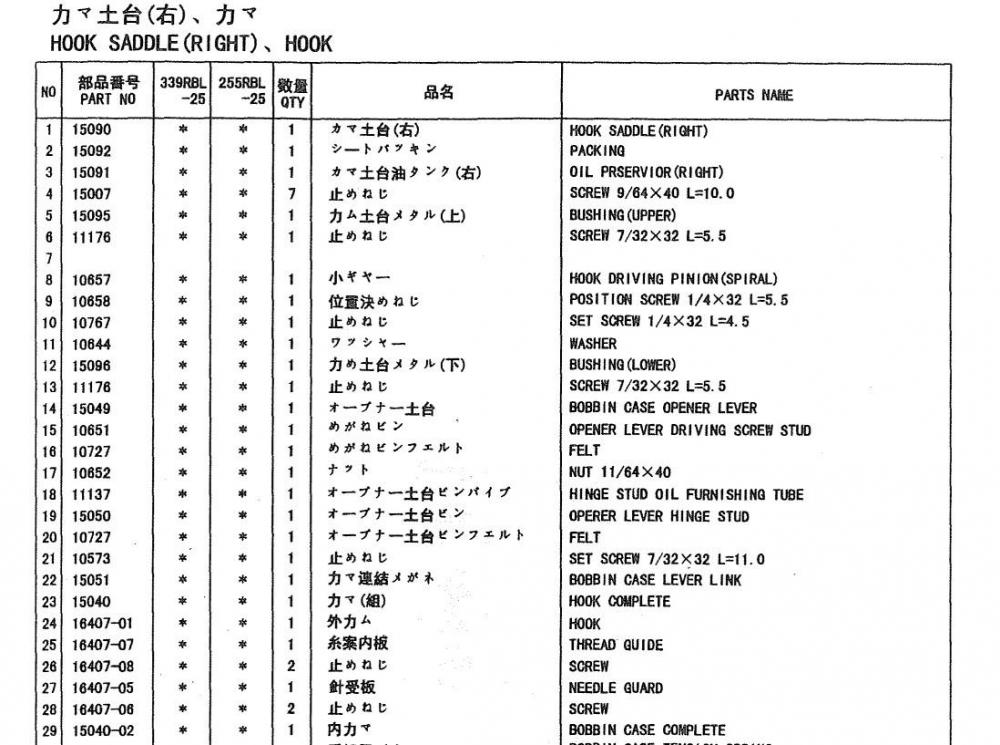

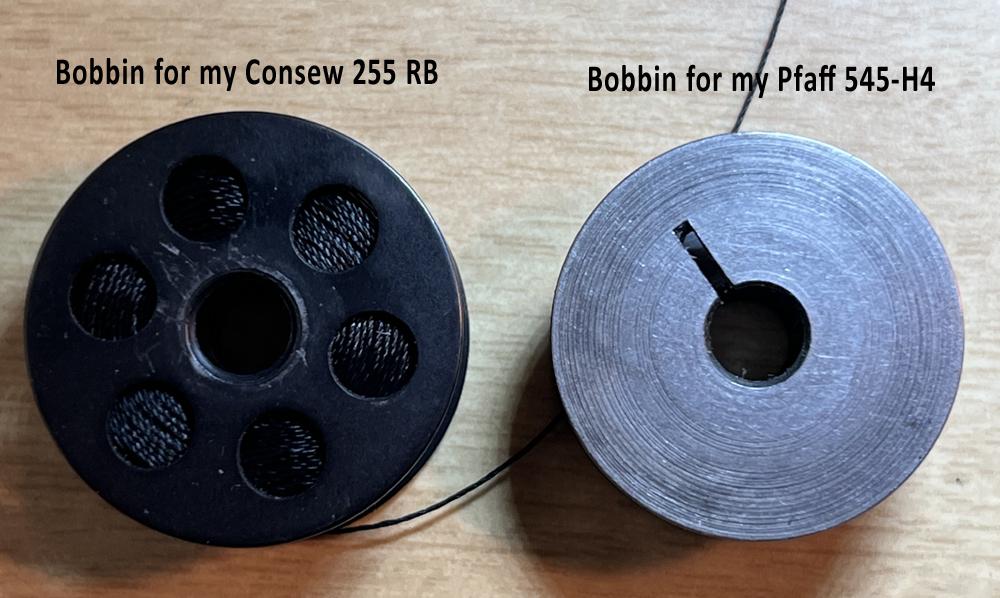

Here's some information (from Double needle 339 RBL) that has same parts in the right side (saddle and hook) as my machine. I'm hoping to see a real photo of the dip stick/oil check thing. Does anybody still have that part in their machine? I am wondering if it would look something like an ice pick or a screwdriver? Are there several parts that are all connected to make it? Asking because there are quite a few parts in the parts list. I have just a hole in my bobbin area where it used to be. I'm thinking it's not a part that I have to have, but would be nice if I could find one. Machine runs without it and I can oil without it, right? Any advice is much appreciated. -

Big Barb - The Consew! (255 RB2 - I think!)

suzelle replied to suzelle's topic in Leather Sewing Machines

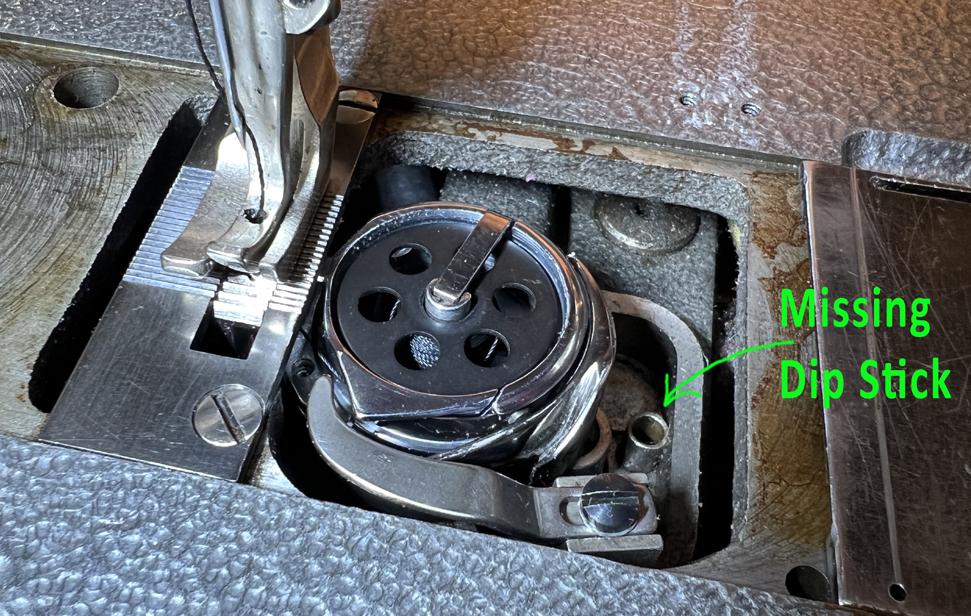

I called Seller Monday Morn., she said she would be home all day Friday, or I can come look any evening. So Friday it would be. Before buying, I called the Consew Company to ask questions about 206 vs. 255 machines, new and used. I was advised that the machine (If it was a Consew 255 RB2) would have a "U" sized bobbin in it. The guy tells me that if it's a running Consew 255 RB and a good price, he said I should run and get it. He said Auto Upholsterers love these machines. So... after speaking to Mr. Consew, I called the Seller back and told her that I thought it was the machine for me, and picked it up that night, Monday Eve. Okay, I bet you want to know the price, she listed it at $400, I gave her no less. Decided it was worth every penny, no dickering. The Seller was not sure about the bobbin size, and I thought it may be a bit bigger than my Pfaff 545 bobbin, but wasn't sure since I didn't have one with me for comparison. I decided it didn't matter about the bobbin size, it was at least as big as my Pfaff and knew I wanted at least an "M" size, no smaller. When I began to shop, I was looking for either a New Consew 206RB or New Juki DNU1541S, or anything used that comes close to the specs on these two machines. Luckily, I found one! Huge savinigs over a brand new machine and I really have not had to do much to it, other than oil, grease, adjust. I love to fix and fuss with stuff, so that machine was for me!! With no name badge on the machine, I really don't know if it is officially a 255-RB2, so I'm including the serial number on the machine. Its seems kind of hit and miss about what information can be gathered on serial numbers that correspond to the year of manufacturing on these machines, maybe there is somebody on the forum here who can take the mystery out of it and tell me what year the machine might be. Thankfully, Wiz (thank you Wiz) was able to share some of his wisdom about the machine and it's bobbin size. I'm not sure if the "U" bobbin was added to the machine later or if it came like that from the factory. Doesn't matter, it's no smaller than "M" size, and now that I've gotten it home to compare, I know it's a "U" bobbin. Missing from the Lower (bobbin) area is the oil check thing, I think it is probably like a dip stick in a car. It gives you the reading of the oil level. If anybody has one they can show me photos of in their machine, I'd appreciate it. I'll find the parts manual and post a pic of that area as well. Thanks for reading and for any potential info. you may have about my Mystery Girl, Big Barb! I named her after the previous owner who passed away. Her daughter sold me the machine. She said her Mom was a Big Lady, so that was quite alright that I wanted to name the machine Big Barb. She got a chuckle out of that. Told her I'd love the machine like her Mom did. -

-

Consew 206-RB4 oiling mechanism and sewing speed?

suzelle replied to sojourner999's topic in Leather Sewing Machines

Thanks for explaining Wiz! Glad to know! -

Consew 206-RB4 oiling mechanism and sewing speed?

suzelle replied to sojourner999's topic in Leather Sewing Machines

kgg - all good points! I think you are right that the reason is they like the look of the larger thread on the top. I think you are also right that they like the idea of getting more thread on the bobbin to reduce having to change the bobbin. I was told that they felt they didn't need the exta stength of the thicker thread in the bobbin, that #92 was strong enough. -

Consew 206-RB4 oiling mechanism and sewing speed?

suzelle replied to sojourner999's topic in Leather Sewing Machines

Hello JHunter, thanks! Glad you like her! Good question aboout the thread weights used! The newly acquired machine (Big Barb) is my machine, but I have set her up at at a Friend's shop to help him get caught up with a sudden flood of work. He's got his machines set up with this thread combo, and since I know that is what he prefers to set up his own machines, I set mine up that way in his shop. Yes, I have my own shop too. At my own shop, I have used #92 bonded, and #69 bonded pretty regularly. #92 top and bottom for Aircraft covers and Banners. #69 top and bottom for lighter stuff. Any Auto Upholsterers here? Please chime in and answer that one for JHunter if you have the same thread arrangement used in your shop (#138 top and #92 bottom). I'm pretty new at Auto Upholstery too! Have done a little Aircraft Seat Upholstery too, but using #92 top and bottom. Thanks JHunter for your question! -

Consew 206-RB4 oiling mechanism and sewing speed?

suzelle replied to sojourner999's topic in Leather Sewing Machines

Hi Wiz, appreciate your input!!! Since I don't want to hijack Sojourner's thread, I'll just create a new thread in the near future for Big Barb, with detailed photos of everything and you guys can identify what the heck Big Barb is made of. LOL. I'd love for you to really look her over and share your thoughts. I got so busy yesterday with this Auto Upholstery job I am on that I could barely even think of taking pics. The photo I attached is just the one the Seller used for the Ad. -

Consew 206-RB4 oiling mechanism and sewing speed?

suzelle replied to sojourner999's topic in Leather Sewing Machines

Sojourner, Okay, This is Big Barb! LOL. I think she is a Consew 255 RB2, not absolutely sure though, since her badge is gone. I'm really putting this machine to use daily. Got the stitch perfect with #138 thread on top, #92 thread in bobbin. What's been real nice is that the bobbin is "Large" which is the "U" sized bobbin. I am pretty thrilled with that. This lady is a smooth stitcher! -

Consew 206-RB4 oiling mechanism and sewing speed?

suzelle replied to sojourner999's topic in Leather Sewing Machines

-

Consew 206-RB4 oiling mechanism and sewing speed?

suzelle replied to sojourner999's topic in Leather Sewing Machines

sojourner, Very nice! That looks like one Beefy machine! I'm sure that is going to give you a lifetime of great sewing. I really like the way the table is set up! I've been thinking of creating something like that around my table. Yes, I'll post pics of mine as well. She is at the shop, got her all cleaned and tuned and adjusted last Thursday and Friday. Then was able to finish up an upholstery job I had to set aside when my Pfaff quit on me. I'll post those photos later today. Thanks for posting yours! -

Consew 206-RB4 oiling mechanism and sewing speed?

suzelle replied to sojourner999's topic in Leather Sewing Machines

Thank you sojourner999! Hey, can you post pics of your new Machine? Would love to see it. -

I got the 97-10 up and running on its own power

suzelle replied to coma44's topic in Leather Sewing Machines

-

Consew 206-RB4 oiling mechanism and sewing speed?

suzelle replied to sojourner999's topic in Leather Sewing Machines

-

I had been looking at buying that table myself. Their ad on their website reads: Complete unit table and legs Short table for industrial sewing machines Table Top measurements: 32" x 20" ( refer to pictures) I would have pressed for the legs too, no additional charge. Says it's "complete unit table and legs" (??)

-

Thanks for this info Eric!!! I am working on tuning up an old Consew 255 RB machine. I think it is probably 40 years old. Guessing on age and model, as it is missing it's label on front with model #. I got my can of grease out (for my SWF Embroidery machines) and lubed the shaft to the motor, also loosened bolts on the pitman rod and pedal and cleaned/oiled there. Also, found there were some parts in foot pedal that were put in the wrong position, and made the straightest path I could from the pedal to the rod, and to the motor. This made my pedal operate so smoothly that I'm probably not going to take the next step, which was to put a smaller pulley in. I'm pretty happy now. Much safer too! Before these adjustments, she took of like a crazy wild horse. Now she trots like a well trained little pony, lol.

-

I'm late in hearing this, also offering condolences to Gregg's family. He made a difference here, he will be greatly missed!

-

Joe, thank you for letting me know that. What a wealth of knowledge he left for all. I agree, huge loss. Have a wonderful day Joe!

-

Gregg, I know this is an old post. Even so, I wanted to say Thank You! This will help me a bunch since I'm going to work on my old clutch moto. Much appreciated!

-

JJN, I'm so glad you posted the pic of this old Consew. It looks almost identical to a machine I just bought. But the one I have is missing it's label saying if it is a 256 or 255. Seller told me the machine was 255RB, and provided Operating Instructions with it (bad photo copy) that featured a Consew 255RB-2... But many of the Consew machines are also listed on the front, including 254BTC, 255BTC, and a list of others beginning with those same digits. I do have what I think is a serial number on my machine, but no idea of it's date of manufacturing. I'll try to do a new post to show my own machine and answer questions about it. I got the machine set up and stitching perfect yesterday with 135 thread on top, 92 thread on bottom. Getting her ready to do some Auto Upholstery work. I'm thrilled with how smoothly she runs after oiling and tuning!