johnv474

Members-

Posts

664 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Store

Everything posted by johnv474

-

I have tried 3-4 of the flat braided waxed polyester threads available on Amazon. All of them are quite nice, especially considering the price. From what I've seen you are limited to 0.8 and 1.0mm thread (unlike Tiger thread) but for general purposes it works quite well. Outside of very fine stitching I think it would do the trick for most people.

-

I hear good things about Fabri-Tac, as far as not gumming up needles. Otherwise, ensure glue/cement is dry (1 hour minimum, overnight is better)m

-

Here is an Instructable I came across, showing a full walkthrough of making a leather Messenger Bag: http://www.instructables.com/id/Handcrafted-Leather-Messenger/ Link to Handcrafted Messenger Bag on Instructables

-

Painting Natural Veg Tanned Leather White

johnv474 replied to LouraLeather's topic in How Do I Do That?

Leave enough time to do more than one thin layer of the paint. Often it takes more than one application for the white to completely cover the color behind it (depending on the paint). -

How about coating your thread? After you wax it, if not prewaxed, burnish the wax into the thead by rubbing along it with a paper sack several times. Then, you could probably coat it by running it through diluted 50:50 water:Resolene to give an acrylic "shell". When done, brush the project to clean up the threads. I've also just used saddle soap to clean up after dyeing and sewing, to clean up thread.

-

A lot of soft leather jackets are lambskin. They last relatively well for that, so I think you'll be okay with your camera case. Since camera cases carry valuable equipment they aren't usually abused so I think either approach would have worked.

-

Veg tan (no dye), how to stop water or gum trag stains?

johnv474 replied to CJW306's topic in How Do I Do That?

If you don't want to use dye but you want your leather to be stain/water-resistant, you can try using a few non-darkening products. A word of warning that "non-darkening" is not entirely true, because adding moisture nearly always makes the natural color richer, and may be a shade darker. To avoid water stains I would do these steps before making the wallet itself. Clean with saddle soap. Buff lightly. While still damp, apply a light coat of Lexol conditioner. While still damp, apply another light coat. Buff lightly. While still damp, apply a waterproofing paste such as Sno-Seal (requires heat) or Huberd's Shoe Grease--light coat. Give a few minutes, wipe off excess, then another light coat. Give a few minutes, wipe off, then apply Leather Balm with Atom Wax, very light coat. Buff to a light sheen. It won't fully buff until the leather is dry. Apply a very light coat of very diluted Resolene (3:1 water:Resolene ratio), then apply another very light coat. Since some of these will have touched the edges, you'll want to sand the edges slightly before burnishing to expose fresh fibers. Voila, natural veg tan that is water/stain/fade-resistant and looks beautiful. Undyed veg tan with nothing on it is quite porous and will quickly disfigure and stain when exposed to moisture, dirt, and pressure. -

One way to keep track of your idea that *is* accepted by courts is to use the proper methods for your details, drawings, etc. A website called Scientific Notebook Company, snco.com, sells notebooks for just this purpose, and includes instructions on how to use them in a way that will hold up in court. Basically, you keep all of your ideas and notes about the product on the dated pages and have others sign as witnesses to the date/work.

-

If the purpose is to simply make the leather smoother and denser, you may want to look into getting leather soling strips. I believe these are generally run under a press because they are much firmer/denser than regular bag/belt veg tan. They can be bought in 4" and 13" wide strips for $15-30.

-

You'll want to look at some automotive upholstery books. There are probably some leatherworkers who do upholstery work, but it is a bit of a trade in itself. To answer your question with my limited knowledge, you need to make sure the leather on the inside of that curve remains flat. Since "the inside of a doughnut is shorter than the outside of a doughnut", if you sew the outer rim and use the same amount of material on the inside, it will necessarily bunch up. If, instead, you keep the inner curve relaxed (not taut) but flat, then you pull and stretch the leather for the outer curve. You don't want the iner curve taut to leave as much stretch-ability as possible. Hope this helps some. That's about the extent of what I know.

-

In some cases, buying leather with the flesh side unfinished and unsanded is desirable or tolerable. When it is not, you can find cowhide (veg tan or chrome) that is of a consistent thickness with the flesh side sanded to be quite nice, or finished like some bridle leather is.

-

Thanks for sharing this.

-

If you use a head/round knife or rotary cutter, start with the blade directly above the corner and push straight down, then push/pull toward the next corner, but not all the way. Do the same thing at the next corner and come back to meet your cut line. Do the same thing perpendicular to the first cut for your 90 degree corner (assuming you have good square here). That is not how I cut my corners, but it should work. The idea is that the leather can't stretch out of square if it's not being pulled/pushed by your blade.

-

The fastest way to know is to try some tooling on the very end of the belt blank. The majority of belt blanks are cut from veg tanned leather. Beyond that, the factor that will matter is what else besides dyeing was done to the belt blank. If it was waxed a lot, for example, it won't absorb water as well, which will make tooling a bit more challenging. I'd try moistening the very end (just an inch or so) and then testing out tooling. That will be the most direct route to getting the correct answer.

-

Do you know whether the other piece was dyed with Eco-Flo? Are all of these samples and the original cut from the same piece of leather? Dye is not opaque but translucent, so among other things the color of the leather beneath the dye will affect the end result. Do you have other colors of the same dye?

-

Does the source of the leather provide any description of it, such as whether this is vegetable tanned? Much tooling is done on undyed vegetable tanned leather, but leather that is vegetable tanned and also dyed can be tooled as well. Other leathers besides vegetable tanned can be tooled, but generally with less success.

-

How to smooth out wrinkles from bunching up?? - pics included

johnv474 replied to 180sx's topic in How Do I Do That?

Once the cover is in place I don't know of any solution because the material is already there. The closest you might get is with a combination of heat, moisture, and pressure. A hot washcloth held in the corners and pressed down with a bone folder/fingers might help. It will likely smooth out some with the heat of the sun and pressure from fingers (over time, that is). Before the material is applied the only way I know is to use a stretchy enough material to lay the inside edge smooth and pull the outside longer. However, since this is perforated leather that could throw off the perforation pattern some. My mentor always reminds me that the "inside of a doughtnut is shorter than the outside of a doughnut". In this case you are trying to get the same amount of material over both distances. To aid in stretching there are liquids/sprays called "shoe stretch" that will make leather stretch (while wet, then stays extended while dry), and that could be of help in future projects. I wish I knew of a better answer for you. Nice work, by the way. I'd be proud of it as-is. -

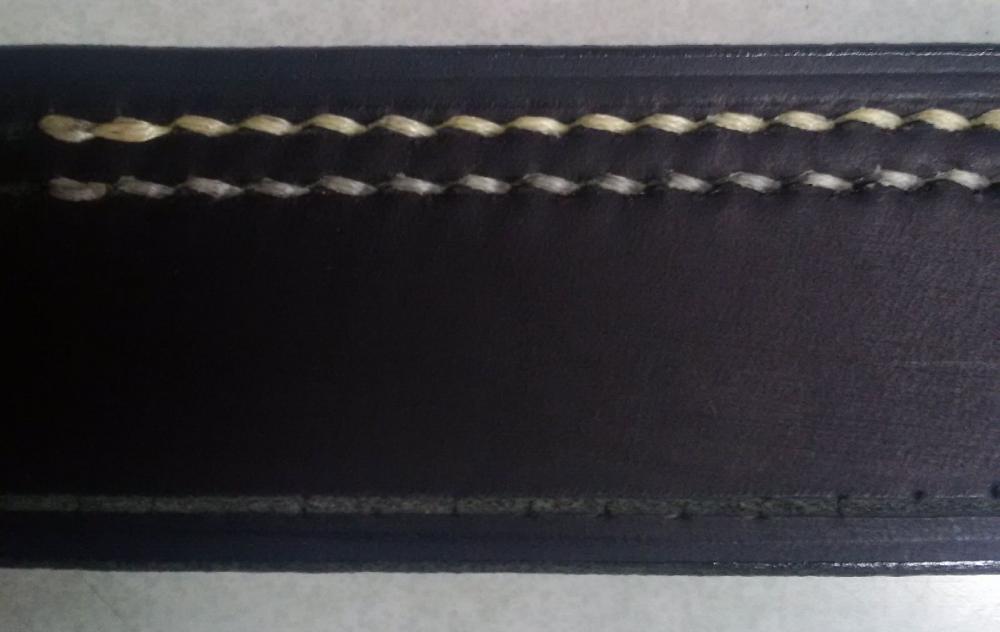

A 4mm punch (if measured tip to tip) should give about 6 stitches to the inch. I recommend 5-6 for general holsters and such so that size is fine. Maine Thread is a waxed polyester twist thread. Their 0.040 size is good for 4-6 stitches per inch. Their 0.030 thread is good for 6-8 spi. Braided waxed poly thread like Ritza 25 (aka Tiger Thread) would look good at 0.8mm or 1mm at 6 spi. There are cheaper alternatives like Twin Eagle thread, Soledi, and Flexzion, and most are about 1mm so they would be fine, too. I did some test stitching with braided generics yesterday at that thickness/spi. I'll see if I can post a quick photo. EDIT: here's a photo of some quick testing done at 6 spi using 1mm waxed poly braided thread, to give you an idea.

-

Hand Sewing Thread Comparison - 10 Threads In A Row

johnv474 replied to Wicked Welts's topic in Sewing Leather

Thank you for posting this. I have tried out a handful of these threads but just received my non-Ritza poly braided thread and I'm anxious to try it. The last version I bought performed terribly. As for linen thread, it can look extremely fine/nice. It tends to have a softer curve than the polyester or synthetic threads, and this can be very appealing especially while stitching bridle leather or thin/stiff veg tan. I use both, but mostly use linen for my own stuff because it can fray easier. People tend to expect thread to look perfect for a long time so I use synthetic, even if it looks more plasticky. -

This was posted on Instagram, in case anyone here would want one: Osborne 155 punches on Instagram EDIT: I work there, so thought I'd mention the listing here.

-

Most of those cheap sandals are made with EVA foam, which does adhere to leather (and rubber) with contact cement such as Master All-Purpose Cement, Barge, etc. I do not remember what Weldwood is made up of, but it would likely work too. Clean the sandals, then sand (40-80 grit) enough to rough up both surfaces. Then swipe with thinner or another solvent to remove surface waxes/oils which interfere with adhesion. Apply cement thinly to both sides. Let dry completely. Apply cement thinly again, let dry about 5-10 minutes, then apply the two together with pressure. Then, leave them for an hour or more before trimming, sanding, or any finish work. You should be good. Optional: several drops of super glue around the outside of the leather immediately before pressing the contact cemented pieces together.

-

Typical stitching horses range from $50 on the low end at an auction, up to $200+ when sold at an antiques mall or retail location (or some overpriced Ebay listings). I'd say somewhere around $75-140 is a typical sale price (different from asking price). If I found one made of very nice wood, in exceptional condition, I would pay upwards of $150, to give an idea... but fully functional ones can be had for $100'ish.

-

Dye will be translucent, so the color behind the dye will show through/affect the color the dyed piece is. Some people paint (white, for example) and then apply dye, but I have no direct experience with that. Paint will/can be opaque, so it will want to cover the base layer's color. For truly bright colors, I think "acrylic dye" aka paint is the way to go.

-

People put a lot of time (and money) into finding good slogans and catch phrases. Any great suggestions here would get snatched up by other readers, losing exclusivity. It also depends on what you are hoping to describe. I wouldn't describe Gucci or Louis Vuitton the same as I would describe a heavy saddle or tool pouch. For a bridle belt: "created by Nature to withstand the elements, tailored by man to suit you perfectly", or for a fine leather purse, "Elegance incarnate"

-

I've seen a stitching horse with metal jaws, but it didn't look like that. That might have been custom/user-made. If the jaws are steel, be aware of rust and subsequent staining of light leathers.