-

Posts

1,039 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Store

Everything posted by Big Sioux Saddlery

-

And a Sight Feed Spotter and a Landis 3 and what looks like a bobbin winder for something. I don't know anything about a Puritan machine. . . I know that some are chain stitch machines. . . tell us about yours. Man, you've got some goodies!

-

And another honey of a machine to the right of that big maple block. . . Pearson #6? Really like that solid old table too! And the rounder, and the knives. What's that machine in the upper left hand corner, partially out of sight? And the one to the left of that?:-)

-

Most of my tables are 4 x 8 and about belt buckle height, whatever that comes out to be. Back when I was starting, a guy told me that was the rule of thumb for height. I can see where that would be nice for some items that you want to hang. I have a 20' x 24' area that will be retail and finished goods for display, so I think the slatwall will work better there. The back wall of the work area is nearly all pegboard, where I intend to hang my hardware inventory and other things, depending on how much room is available. I hung slatwall behind and to either side of my clicker to hang my dies. The first couple days after I got them all hung up, I had to just stop and look at them every once in awhile. I've had a clicker for going on 15 years, and never had enough room to hang all my dies in one place. Some would permanently end up on my tables, some in boxes under a table, some in boxes in my basement.

-

Finishing Harness Leather Edges

Big Sioux Saddlery replied to Alexis1234's topic in How Do I Do That?

HO black harness is not the easiest to get good edges on. For me, W & C produces better edges, as well as a nicer grain side finish for dressier grades of harness. HO is a more rugged, work type of harness IMO. However, I know there are guys making fancy harness from HO, but I can get a finer finish on the Wickett. -

I did get the slatwall second hand from a lady who closed a retail store in town. I also got a bunch of pegboard with the framing system and shelves, which I really like. There is nearly enough between the slatwall and pegboard to cover all the available wall space in the building. Of course half of one wall is taken up by shelving for leather. I should take some pictures and share them also, but it's just such a dang mess right now!

-

None better, and most others don't even come close!

-

As I looked at the first couple pictures, I was thinking "Pretty nice set-up", and then I saw your stitcher, Landis 3 or Randall? Couldn't tell. But super sweet! I'm in the process of putting up some slatwall in my new shop, and am really looking forward to being able to hang something wherever I want. Handy stuff.

-

I think mine is made by The Tubular Rivet Company. I can't even find a mention of the company on the internet. But there are others that I'm sure work as well. It is the design of the jaws that hold the rivet that I think makes a difference. On your heritage presses, what adjustments do you make other than anvil height? I took the rivet setter off my heritage press long ago and use it solely to punch holes, so I can't remember exactly what it looked like, but I don't remember there being anything I could really change other than anvil height. I sure understand what you mean about dreading messing with adjustments though: the same goes for stitchers and automatic spot setting machines. Once I get them set to a specific task, I don't want to touch them. A fellow harness maker that I know runs 4 Union Locks. He has each one set to sew a certain type of work, and then there's no messing around changing back and forth and not being able to get it set back to where it was. Edit: If I think about it, I'll take some pictures of my riveter. The jaws hold the rivet tight until the head slips through the jaws, at which point they spread apart to release the rivet. Busy days coming up, so I'm not sure when I'll get a chance.

-

I'm going to have to disagree with you on this one Toot. The jaws have to hold the rivet solid enough so that when it comes through on the anvil side, it hits the point of the anvil pretty much dead center. If it doesn't, it is going to miss a large percentage of them. From what I've seen, none of the new riveters hold the rivet steady enough. Old timers (older than me) have told me that the Rex's and Best Yet type bench riveters never did do that great of a job. They were made for farmers to have in their farm shop to do an occasional simple harness repair job back when that task was a necessity. I've occasionally come across some old stock rivets that set better than anything I buy today. And stainless is not a nice material to work with in the first place. It's hard to peen when using a solid rivet, and brittle. Stainless steel spots chew up the anvils on my spotters and do not set as easily as brass or NB. It IS very important that the length of the rivet is right for the work, but it is not the only affecting the poor setting of the rivets available to us today.

-

Part of it are these dang stainless steel rivets. I have the MT900 press from Weaver, as well as an older Heritage brand press, neither one of them set perfect, in fact depending on what I'm riveting, they'll miss as many as 5 out of 10. Extremely frustrating. I have an old Rex type bench top riveter that I bought a splash anvil for years ago, and it doesn't do any worse or better than the presses. And if I'm setting SS rivets, I have to use a maul on the handle too! The best riveters are the old ones (like from 75-100 yrs old) IF you can find them. They sell crazy high on auctions, and I've seen a bunch of them sell, and I always thought "I can go buy a new one for just a little more". Well, I finally realized why they sell high, because they work. I also finally bit the bullet and bought one of these old ones last spring on an auction. Paid way more than I wanted to, but it DOES set rivets way more consistently than any of my others. SS can still be a bitch though, and I'm not so sure it isn't the rivet design as much as the material. I think they are thinner walled than they used to be, which makes them crush rather than set properly if the point of the anvil doesn't hit the hole exactly dead center. So no it's not just you, I cuss when I set tube rivets. Edit: And I gave up on trying to set them with caps.

-

Luberto #9 and Old Leather Stamps for Sale

Big Sioux Saddlery replied to Cmartin1336's topic in Old/Sold

Decent enough deal for someone starting out and needing it. -

I'm just wondering what everyone is charging for rifle slings. I've never made one but am getting some requests for estimates. I'd like some insight ranging from a simple, single thickness, plain strap to a lined and stamped one. I know there are a lot of variables when stamping, so show me some examples of your work and what is a fair price. Also, looking for input from people who are making them to realize a profit, AFTER getting paid for time and materials. Gifts are great, but there are no hunters in my family for which to make one as a gift, and I don't make near enough money to gift them to customers! I know I could make up a sample one to see how much material and time I get into one, but right now I don't have the time to make up a sample just to find out it's going to take more time/material than I can get back out of it. No sense in looking at retail prices at Scheels, etc, because they're mostly overpriced junk. Thank you very much to all who reply!

-

I would have to see proof of that before I'd believe it's worse than mine right now. . .I'm still in the process of moving and I'm about to pull my hair out from frustration.

-

Add to the above comments (which I agree with) that the value of the Union Locks has dropped considerably in the last 5-10 years. Have seen quite a few sell in the $1500 range, some for less.

-

I always rolled a round braid between two boards, I think I saw it in Bruce Grant's book or something. It works pretty good.

- 8 replies

-

- round-braid

- bracelet

-

(and 1 more)

Tagged with:

-

Precision/neat work with Landis 1

Big Sioux Saddlery replied to Alexis1234's topic in How Do I Do That?

Thank you both for your compliments on my work. And you are welcome OldNSlow. We all start at the beginning, some are lucky enough to have someone to teach them the tricks of the trade, others have to muddle along on their own, driven by a fierce desire to master the craft. I think the day that I believe my work is perfect will be the day that I hang up my knives for good. -

Precision/neat work with Landis 1

Big Sioux Saddlery replied to Alexis1234's topic in How Do I Do That?

Thanks guys, much appreciated!! Some of my fondest very early childhood memories are of when my dad would put me up on the bare back of a horse. To this day I remember the smell and the warmth and the feel of that live horse underneath me. My other family members were never really "horse people" and I'm the only one that has stuck with it. I've only had heavies the last 15 years or so, it was just saddle horses up until that point. My grandfathers both used horses to farm way before I was born, and like nearly everyone else made the switch to tractors when that time came. I often feel like I am living in the wrong time period, and wish I could visit with my grandfathers about the days when they farmed with horses. So much information has been lost on that subject that will never be regained. -

Precision/neat work with Landis 1

Big Sioux Saddlery replied to Alexis1234's topic in How Do I Do That?

Thank you very much Tom! I have devoted 4/5 of my life to learning this trade. I'm 51 now and started when I was 11. While I feel like there is no such thing as a perfect piece from ANY artist, (sometimes only the creator will know where the flaws are) I continually do my best, strive for that perfect piece, and never, ever stop learning and looking for better ways to do things. My thanks also to those who maintain and contribute to this site, as it is a valuable resource to not only those starting out in our craft, but those of us who having been doing it most of our lives. -

Precision/neat work with Landis 1

Big Sioux Saddlery replied to Alexis1234's topic in How Do I Do That?

The Campbell/Randall would be the machine of choice for that type of work. The 441 clones don't do raised work very well. It all depends on the style you're building. This harness was sewn on a Landis One, but it isn't narrow strapping. There's no way you'll get that look with a 441 clone, but they will sew narrow work ok. I've sewn a lot of half inch stuff on my Cowboy 4500, but I sewed a lot on my Randall too, and I much preferred the look of the stitch of the Randall. The clones don't do round work, the Landis One will (if you have a knife and the guides and know how to set it up). If you are sewing harness for minis, POAs, etc, the 441 clones might suffice, but if you are making Hackney pony style, almost Freedman level high end stuff, you better pony up the bucks for a Cambpell/Randall. Sorry, couldn't resist:-) -

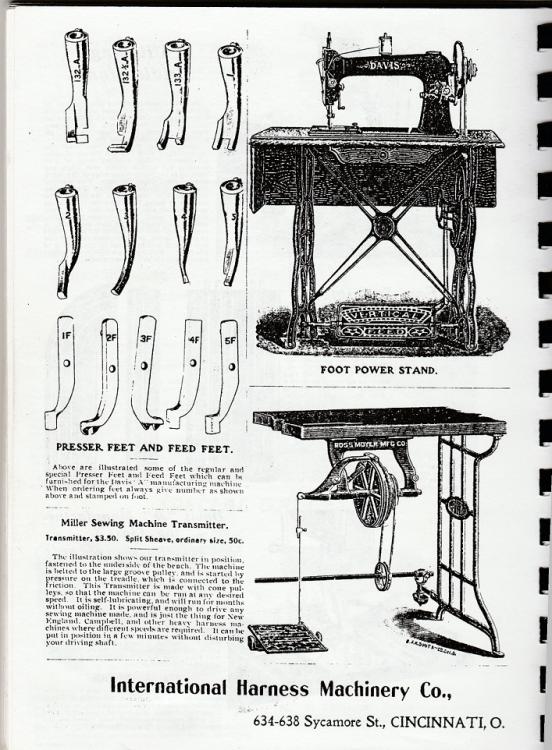

International harness machine

Big Sioux Saddlery replied to shoepatcher's topic in Leather Sewing Machines

I guess I'm done for tonight. There were a few more I wanted to show, but it keeps telling me the file is too big, even though it's only about 194KB. I'll try again tomorrow.