-

Posts

247 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Store

Everything posted by gordond

-

Hi Jimi PM sent Cheers

-

Same question re: W&G Straw hat machines ..was meaning to ask but didn't want to clutter forum with non leather machines.... Not my interest as many know..this was thrown in with a sale -free - broken ...but just a bent needle bar...just need parts/schematic and threading diagram (other's have different tension loop set up).

-

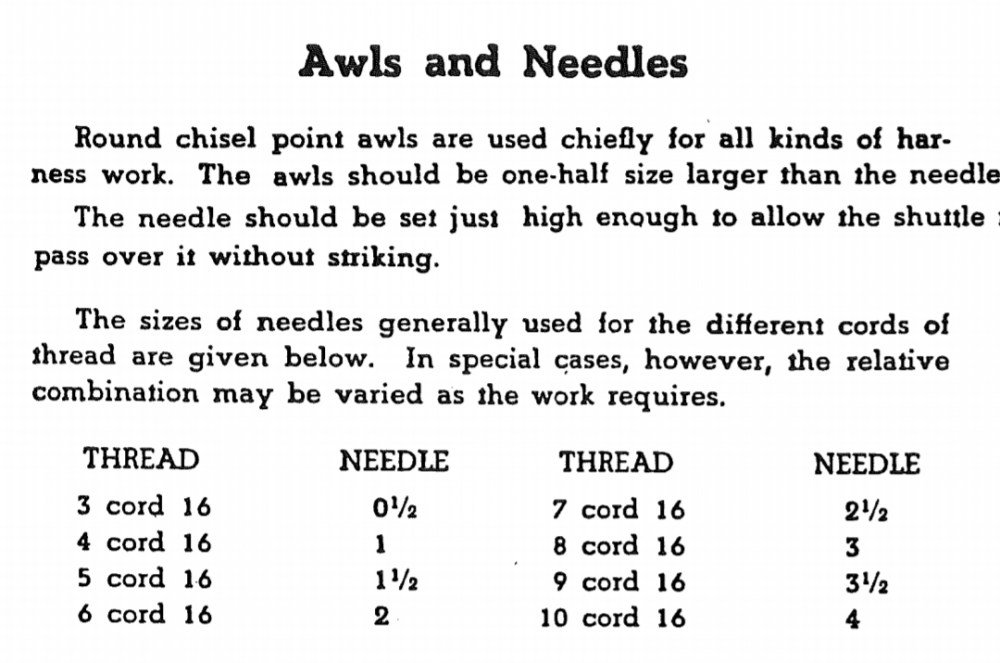

Campbell Randall awl/needle/thread sizing

gordond replied to gordond's topic in Leather Sewing Machines

I am going to contact them in due course.. good advice on the appropriate needle vs thread type - that's what I was looking for (& suspected) ..thanks Wiz -

Hi all I have finally set up a new power train on my Campbell Randall (750 servo + speed reducer)..control and stitching all good. But the previous owner only stitched with fine thread (looks like a 207 - non bonded poly - he ran it through lube)... and only needles supplied with this machine are 0.5 with a limited amount of 1.5 awls (have a range of awls in different forms/sizes - blade forms to 3.5 chisel points).. So seemingly straight forward when I checked my manual to select the correct needle/awl/thread size..am I correct in assuming that a 5 cord thread (346) needs a size 1.5 needle with size 2.0 to a size 2.5 awl ? I am considering using linen (left twist) - up to 346 ... but already have a good quantity of bonded polyester (207 to 346)... would appreciate opinions of polyester vs linen in this machine and appropriate needle/awl. Thanks

-

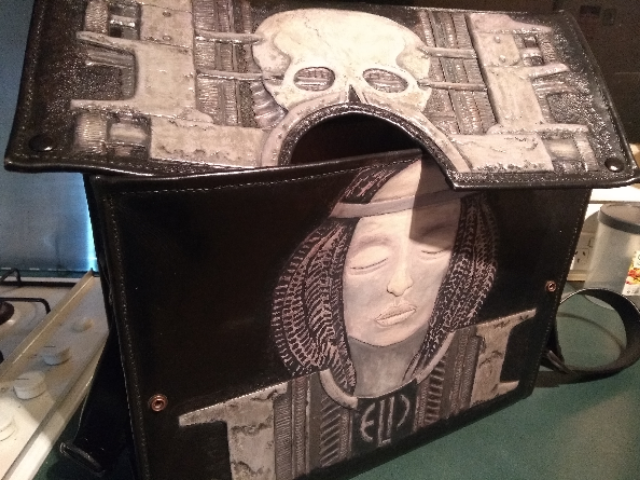

Album cover bag

gordond replied to gordond's topic in Purses, Wallets, Belts and Miscellaneous Pocket Items

Thanks very much All for the compliments Having issues with the gallery function on the forum was hoping to post more photos there before I replied here .. I think the admins are quite busy with certificate issues. (error ext 1064) ...I probably broke it?!! Background on this project : an icebreaker on many levels. I haven't carved leather for a few years and no Embossing in over 30 years (even then just a one off and a very small job). this was test of my own and machinery capabilities... Well sure did identify the gaps between imagined vs reality - lol! Biggest one - I need a bigger workshop! (plus sharpen everything..repair this that and also everything else..lol!) The other unexpected icebreaker was the reaction to this bag by some famous musicians in my autograph quest..... "wow - what's that!".. certainly had some entertaining discussions. -

Album cover bag ... made recently and taken on board this year's "Cruise to the Edge" - autograph collecting (another of my interests) Solid 2 layer sculptured plugs ... ~ 1.5mm top leather... turn back edges .. hand stitched... black oil dye (plus commercial black refinish) Colour - acrylics .. resolene sealer plus wax sealer .. Inner supports - 3mm hardboard with soft liners ... simple shoulder strap.. line snap closures (least obtrusive fitting - which did work well) Nb: posted on some FB pages also

-

Looking for one particular part for a Pearson No.6

gordond replied to HollyMac23's topic in Leather Sewing Machines

I'm awake... Just contact- email- me in Auckland or Steve in Aus- 7 replies

-

- pearson no.6

- parts

-

(and 1 more)

Tagged with:

-

From the album: gordond's Machinery NewZealand

Album cover bag. made recently and taken on board this year's "Cruise to the Edge" - autograph collecting (another of my interests) Solid 2 layer sculptured plugs ... ~ 1.5mm top leather... turn back edges .. hand stitched... black oil dye (plus commercial black refinish) Colour - acrylics .. resolene sealer plus wax sealer .. Inner supports - 3mm hardboard with soft liners ... simple shoulder strap.. line snap closures (least obtrusive fitting - which did work well). Nb : also Posted on FB -

-

Can't help with spares.. but some photos of what you need.. appears you need approx 5 parts(and bolts) - balance wheel .. bottom drive arm plus shaft.. drive shaft/cam connector...and wood pitman arm The foot lift pedal is just one piece - axle - bolted to the frame. (Pedal shown LHS photo # 3 .. with bottom drive arm RHS) My first one had no stand but I acquired an original style frame but missing the major parts .. long story - but ended up welding / building them - reference was photos online (measured and scaling).... And as fate has it .. about 18 months later I found a #2 machine with a complete stand ..lol!

-

From the album: gordond's Machinery NewZealand

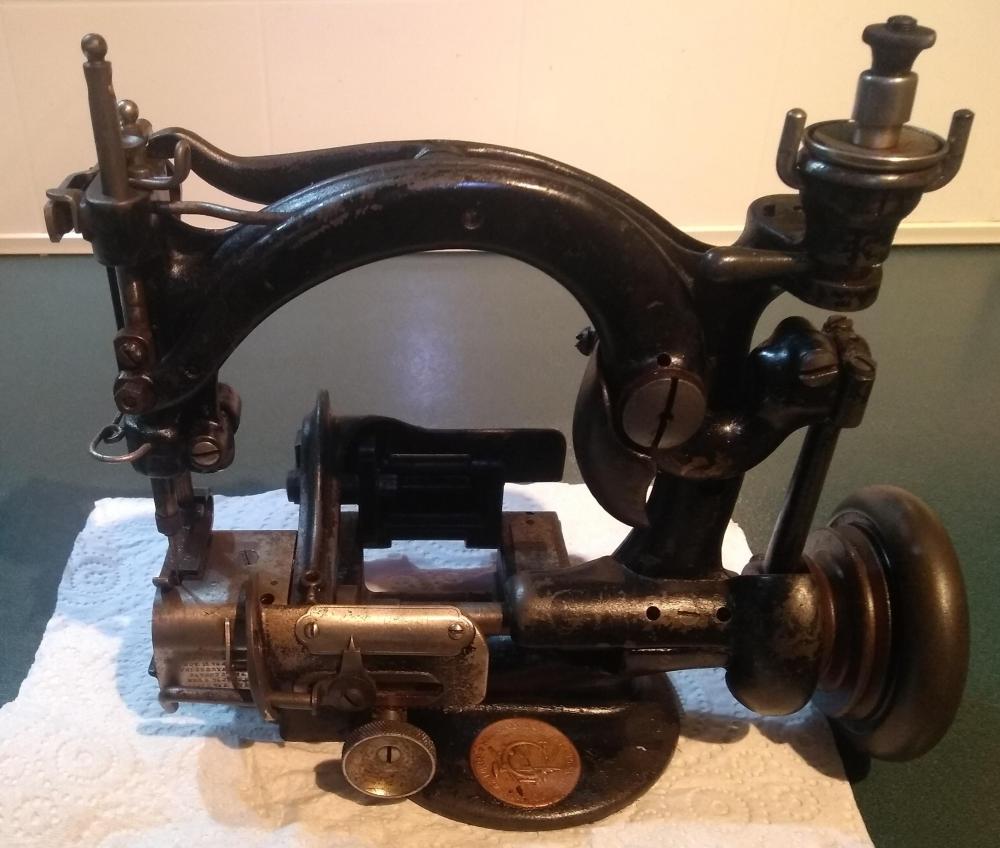

BUSM #HM6 ... serial no : 7114 ... restored© gordondnz2018

-

-

19th century Hugo Werteim shoe patcher

gordond replied to RichardPorley's topic in Leather Sewing Machines

Thanks Richard That's it... err ...I think the spring flew off somewhere during moving it ... easy enough to replace.. thanks again -

19th century Hugo Werteim shoe patcher

gordond replied to RichardPorley's topic in Leather Sewing Machines

Hi Richard Yes still have it. Have an issue with a missing part within the lever arm which governs the stitch length - was working when I purchased it but for the life of me it's just gone . And I have forgotten what it looks like -lol! .. So any photos would be gratefully appreciated of the arm end where it is actuated by a cam - there is meant to be something between spring tab and the main arm. I'll post a photo later if this doesn't make sense. -

The water heats the wax - the needle dips into the wax bath so hot liquid wax. But I use mainly bonded polyester so in this case - cold lube.. A picture of the wax bath that fits below the needle (not my photo + I don't have this unit) Easy machines to work on ... Tried and true function.. nice stitch including rear of work - not mirror perfect but close.. Bear in mind that only up to a few years ago there weren''t a lot of machines that were suitable for heavier work

-

These machines were originally fitted with an elaborate heating system -water baths to the wax pot below the needle - the thread and needle were quite warm

-

19th century Hugo Werteim shoe patcher

gordond replied to RichardPorley's topic in Leather Sewing Machines

Excellent job!.. Love the red highlights! -

Dont get carried away with collecting sewing machines

gordond replied to chrisash's topic in Leather Sewing Machines

Hi Gregg Yes I'm afraid so... whilst I have a half a stories worth.. you have 4 !!! -

-

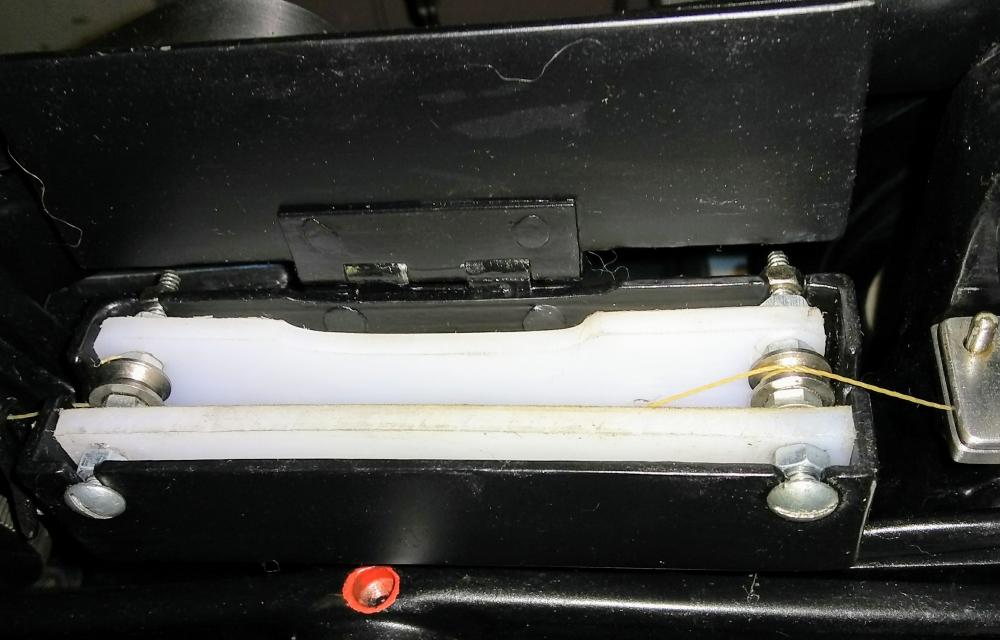

Congrats on your purchase! I too was shy of a wax pot ... Figured i wasn't going to find one so welded one up. No reference at the time so guessed and devised a thread track (vee bearings held in a UMPTE cartridge... Ok not classic at all but it works).. this was my "first" #6 machine of which many more have followed.

-

Hi Didn't get notification of your question..do excuse my delay in responding. . Not sure about the manual for this particular machine ..only have some loose pages which are just an overview of a different but similar styled machine...that is a Bradbury. .. That doesn't show details of any accessories such as the table There are members here that have the Bradbury and I have seen tables on the machine. ..but I can't remember who they are. .. Suggest you post a question the sewing machine section ..I'm sure you will get a response as this has been discussed before particularly with the Singer K patchers. Cheers

-

PM'd you

-

Busm & Pearson Hm6 Needle Clamp Screws Size/system

gordond replied to gordond's topic in Leather Sewing Machines

sorry taken so long to get this sorted ...I took out the screws out of 4 machines and took them to work to size before sending to Al. but they are all different !@!.an array of retapped metric [4mm] ,maybe Whitworth and munched up odd screws...everything from 3.5 - 4mm Conclusion: ?? -without knowing if they have been altered - it's really a best guess to fit something [not the answer we were looking for but if this is the state of affairs[altered] - then ordering an "original" is going to be hit and miss with these antique machines] -

Busm & Pearson Hm6 Needle Clamp Screws Size/system

gordond replied to gordond's topic in Leather Sewing Machines

Thanks Al - will send you one that is "intact"-- we put 3 screws over all our gauges at work and no match on common BSW... thought they might be a very old BA system- but we don't have a gauge here is one that has been stretched and basically cross threaded -

Busm & Pearson Hm6 Needle Clamp Screws Size/system

gordond posted a topic in Leather Sewing Machines

Hi all in conversation with Constabulary about needle clamp screws for the BUSM HM6- what screw system are they? none of mine line up with BSW [or BSF] or any other system.. I believe Al has been through this before and ordered some offshore - but they didn't fit? just putting this out in the public domain 'cause no doubt; it will be asked again [unless it has been already!]

.jpg.4f75dabb04834689d7214bc68c5cc61a.jpg)

.thumb.jpg.1e5806d9f4ff60a4944b94794e2bc410.jpg)

.thumb.jpg.2daf66e097952feb405cf3a6f971de00.jpg)