-

Posts

2,221 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Store

Everything posted by Uwe

-

Consew 255RB3 breaking top thread in reverse

Uwe replied to sandmanred's topic in Leather Sewing Machines

That’s very likely a hook timing issue. Hook timing is more forgiving when sewing in the forward direction because hook and needle move towards each other. In reverse, they move in the same direction at different speeds, which trickier to get right. I usually tweak timing a bit (advance or retard the hook) to make sure the machine sews well in reverse at max stitch length; that all but guarantees that it’ll also sew great in the forward direction. -

How to identify my Singer model and make it work

Uwe replied to Schlaumeier's topic in Leather Sewing Machines

If you stop the motion by pressing on the foot pedal as it comes up, it’ll reverse direction next time you press down on it. Make a habit of stopping the motion by holding the hand wheel after the pedal starts to move downward again, so when you start again it’ll continue in the same direction. Or use the hand wheel to get the motion started in the right direction and then continue with the foot pedal. -

How to identify my Singer model and make it work

Uwe replied to Schlaumeier's topic in Leather Sewing Machines

Yes, 29K8 is the model number. Here’s a previous topic that has some more details and links to a relevant manual: If everything moves at it should and no parts are missing, you should be able to make it sew without disassembling anything. You can oil and clean many areas without removing parts from the machine. Much depends on the condition of the machine. Post some pictures of your machine, it may help us see if anything’s missing or wrong. The early models like yours had hooks without the hole. Insert bobbin inside the hook and pull the thread into the slot on the hook. Then drop the hook into the arm and leave thread hanging over the arm’s edge. Close the cover plate. If hook timing is good, you should be able to pull up the thread through the cover plate hole by turning the handwheel. If that doesn’t work, upload a short, non-public video snippet to YouTube and post the link to it here. We’ll have to see what’s going on in order to offer remote service advice. -

545 H3 lower foot just goes back and forth

Uwe replied to AKtrapper's topic in Leather Sewing Machines

Pfaff built many subclasses of the 545. Some of them do not have vertical feed dog movement, usually on machines intended for binding operations. While it’s technically possible to replace parts to add that function, the chances of you finding the necessary parts are slim to none. Just enjoy the machine as it is for now. You may never notice the subtle difference in real life sewing. -

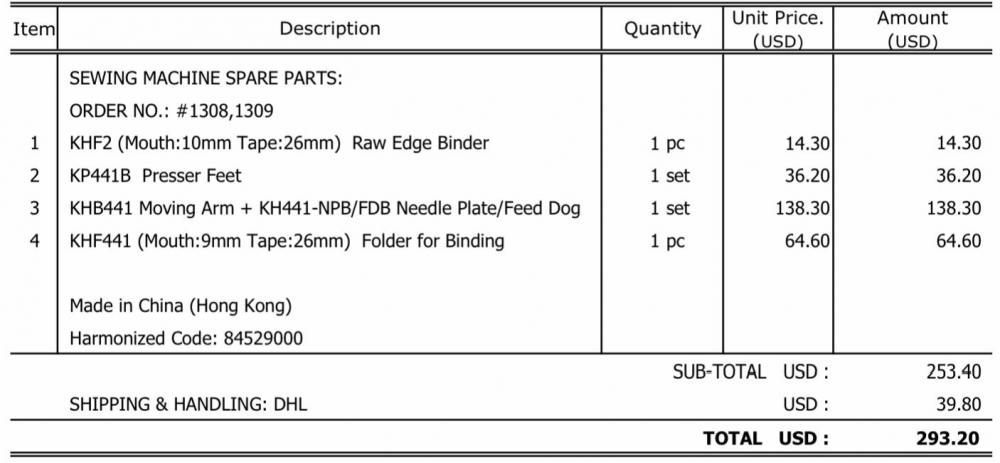

@ZigZag I ask for a Paypal invoice when I place an order. After placing an order, they email an invoice with shipping cost and a Paypal link to send payment. Shipping usually takes less than a week. Works for me. I’ve been buying parts from Kwok Hing for years and my experience with them has been very good, no complaints. @Anubis78 I don’t have a motor hooked up on my Cowboy 3200 at the moment. It’ll be a little while before I get to do actual sewing on that machine. I’ll post a video and photos when I do get to it. @Gregg From Keystone Sewing I’m lucky that both my workshop (sunroom) and my dining room are essentially natural light boxes, flooded with light from multiple sides, especially on a bright day. My iPhone 12 Pro has a wicked good camera that seemingly does the rest. That’s a cute animated GIF!

-

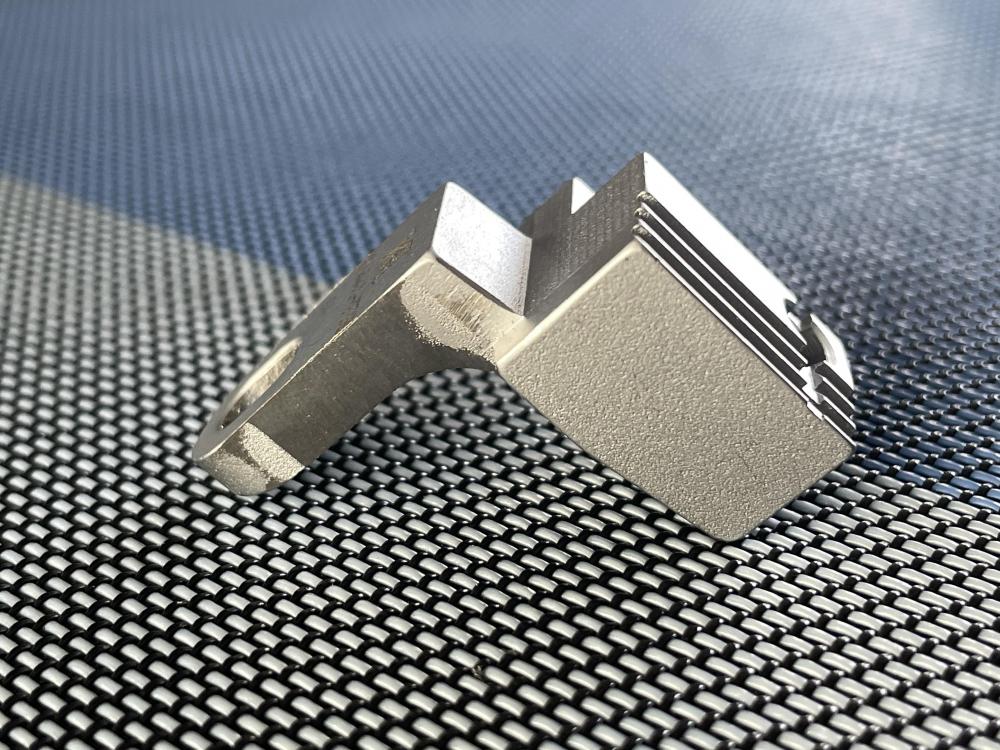

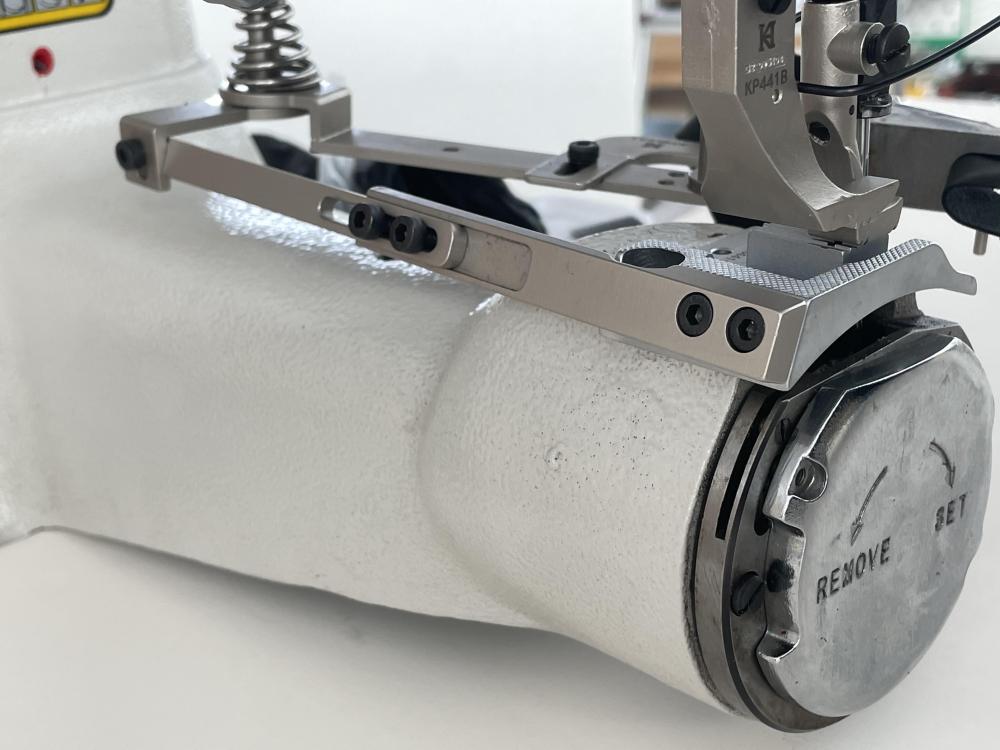

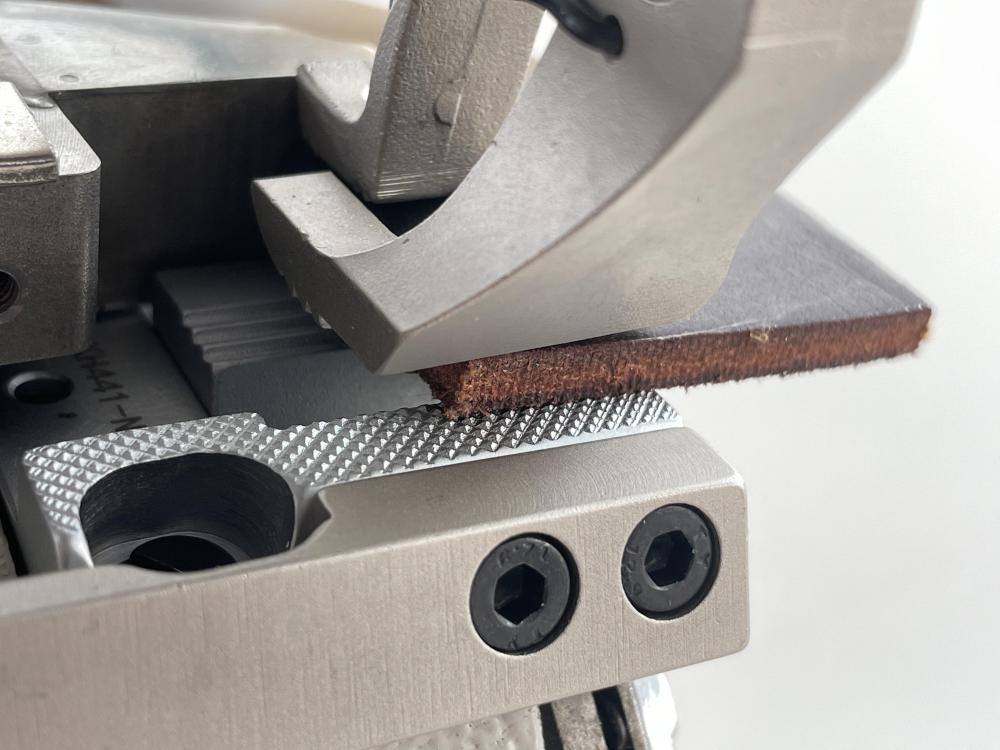

My invoice pic above shows a KHF2 tape folder that may not work well with this combo. I recommend using the KHF441 tape folder, which was designed to be part of this set.. I had to make three small modifications: filing about 1mm off the tip of the arm to clear the ridge on the 3200 (should not be required on other 441 machines; the ridge is unique to the 3200 design). The thick shim piece under the tape folder also needed one edge filed down a bit to line up properly with the mounting slots on the tape folder. The feed dog also was a fraction of a millimeter too wide to fit the mounting slot on my 3200 - this may also be a 3200-only issue. I filed it down a bit and all was well. I ended up using two 20mm long M4 screws to attach the tape folder to the arm. The included screws weren’t quite long enough.

-

For the Cowboy CB-3200 this is the most promising binding setup I have found. I just now installed it on my CB-3200 for the first time - I haven’t sewn with it yet. It’s made and sold by Kwok Hing. It’s the only synchronized binder setup I know of for the CB-3200. It should fit any Juki TSC-441 class machine and, surprisingly, also the Durkopp Adler 205.

-

New Tech Motor and Needle Positioner Config

Uwe replied to jackalopes's topic in Leather Sewing Machines

I missed the speed reducer detail. It’s more of a function of the controller software. It will do only a certain number of motor revolutions trying to reach the target position before it gives up. It’s a safety feature, really. Each controller model is different, there’s no standard. If you let up the pedal just before it reaches the target position, it may work just fine. If you let up just after it passed the target position, you may get some fixed distance from wherever you let up. -

New Tech Motor and Needle Positioner Config

Uwe replied to jackalopes's topic in Leather Sewing Machines

Make sure the position sensor is firmly attached to the hand wheel and that the position sensor itself (the plastic housing) does not rotate. If the wheel mounting adapter is loose, or the sensor collar that attaches to the adapter is loose, you’ll get random stopping points. Just check to make sure you can’t rotate the sensor collar against the hand wheel. Hold one try to rotate the other. If it rotates, things are loose. -

Neither the Pfaff 335 nor the Adler 69 are well suited for what you’re trying to do, especially the handles. If I were you, I’d look for a used Durkopp Adler 269 or, better yet, save up for a new Durkopp Adler 869. The links point to SIECK in Germany; they likely deliver to Ireland.

-

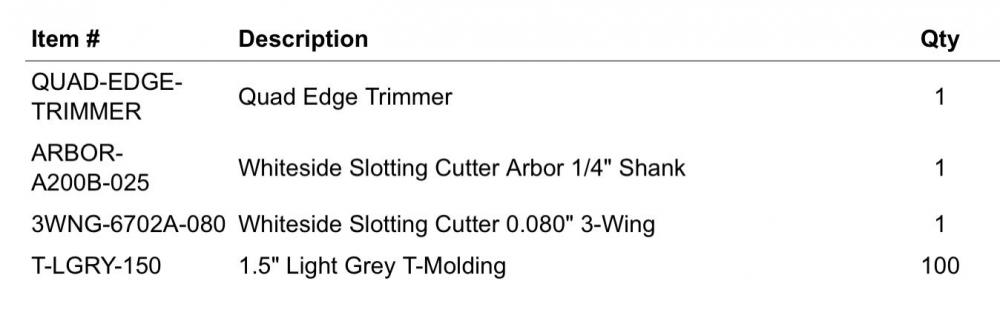

@sandmanred I got mine from https://www.t-molding.com They also sell the slotting router bits and other edge banding supplies. Here’s the parts I had ordered for my table top. You only need about 12’ of edge banding for one 2’x4’ table top.

-

@sandmanred Love those welded aluminum legs and that huge pedal on your table! @Parfektionisto There’s different approaches. If the wood itself looks nice and isn’t bowed, you can just sand it down and give a few coats of clear varnish. If you don’t like the wood look you can glue on a new layer of laminate like @Doxnet did. I’d use a hand-held trim router and a laminate trim bit to follow the contours of the inner cutout and the outside edge. To finish the edge itself, you can get some T-molding. Buy the T-molding a bit wider than the actual table edge. Use a T-molding router bit, you can cut a slot along the outer edge, install the the T-molding and the cut off the overhang with a sharp knife. Here’s an example of a table I made this way. Mine used new plywood, but there’s no reason you can’t use this approach with an existing plywood table top.

-

@327fedThe needle in the video was a size 22 regular point - all the details are in the video subtitles. @Pintodeluxe No modifications, just everything adjusted to spec.

-

My Consew 225 managed size 207 thread reasonably well, even with a less than ideal needle. You may have to tweak some adjustments a little, but the hardware itself can handle it. I made this video a few years ago:

-

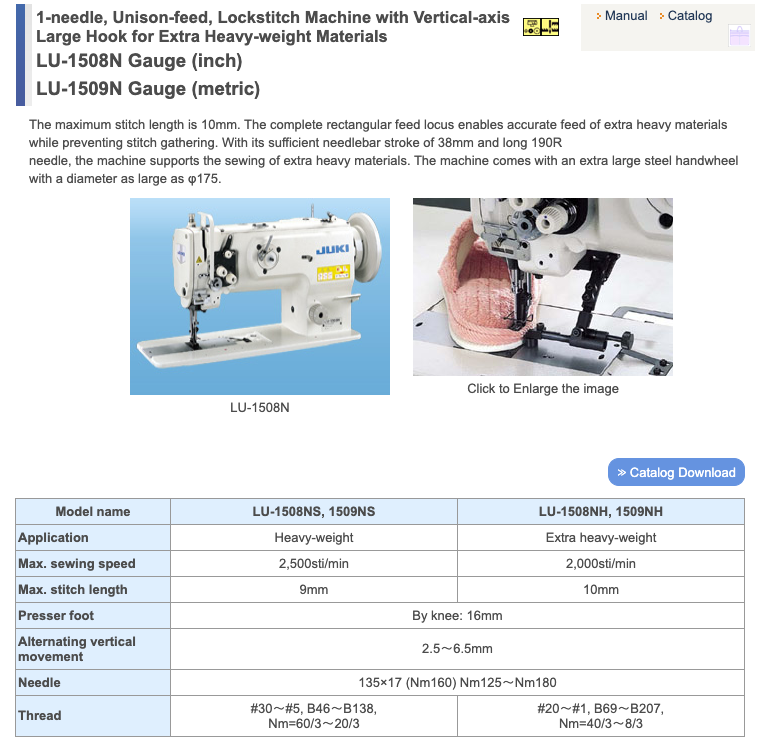

I’d say the Juki LU-1508NS is very close in certain design elements and capability to the Singer 111W155, likely better in several aspects, definitely better in terms of usability and convenience. The 1508 should be able to sew anything the 111W155 can sew. As for the max thread specs on industrial sewing machines, they really mean that you can run that thread in the machine at full speed all day long in a high-volume production setting at a factory. Sewing a handful of projects per day at count-along speeds isn’t going to stress out the machine. The Juki LU-1541 is a very different design internally from the LU-1508, even though they look nearly identical on the outside. The LU-1508 runs about $1K more than the LU-1541. The LU-1508 design is available in various clone versions from several vendors (Cowboy, Artisan, TechSew, etc.) The Artisan 1508-10H might be worth a look - it claims to sew up to size 277 thread. Artisan is located in California, too, which might make logistics easier. Being able to pick up a machine in person is priceless.

-

The Juki LH-2800 series is another candidate that accepts Singer style feet. The 2800 is quite imposing when you sit in front of it, compared to the 1508 and Singer 111W155. [rant mode ON] These machines likely run between $4K-$7K, depending on model and configuration. Not everybody wants the cheapest possible tool for a job. Some want the best possible tool they can afford. The cost of a Singer 111W155 a hundred years ago wasn’t all that different, when you account for inflation. $5,000 in 2021 is roughly the same value as $400 back in 1920. Another example, the Adler 205-370 cost $5,000 back in 1990 (that’s $10,000 in 2021 money,) but many people nowadays think it’s insane that a modern, improved version of that machine should cost about the same (e.g. the DA 969-H Type.) The availability of cheap vintage machines and mass produced clones are distorting the perceived value of these machines.[rant mode OFF] There’s fairly detailed discussion of both Juki machines in this topic:

-

-

Amann Serafil Ticket No. 20 is the same size as Tex No. 135 (138). Tex thread sizes are used in the USA https://www.amann.com/products/product/serafil/ We really need to see a video snippet of what is actually wrong. We’re all just guessing as to what’s really happening. Upload a video snippet to YouTube and the post the link here.

-

Here’s a PDF guide by Groz Beckert on the various leather needle types and their respective stitch lines: needle_points_leather.pdf

-

Just for reference, here’s a demo video I made some time ago that shows how my Adler 467 works: Ter referentie, hier is een demovideo die ik enige tijd geleden heb gemaakt en die laat zien hoe mijn Adler 467 werkte:

-

Here’s the page of the service manual that talks about the thread cutter: Hier is de pagina van de servicehandleiding die over de draadafsnijder gaat: https://www.manualslib.com/manual/464955/Duerkopp-Adler-467.html?page=16#manual

-

Since the thread comes out of the needle at the end of sewing, it may be a problem with your automatic thread cutter. Thread doesn’t come out of the needle at the end of sewing unless you cut it. Adjusting an automatic thread cutter is not simple. It seems nearly impossible remotely and with a language barrier. Aangezien de draad aan het einde van het naaien uit de naald komt, kan dit een probleem zijn met uw automatische draadafsnijder. De draad komt aan het einde van het naaien pas uit de naald als u deze afknipt. Het afstellen van een automatische draadafsnijder is niet eenvoudig. Het lijkt op afstand bijna onmogelijk en met een taalbarrière.

-

If you try to remove the material while the hook has a hold of the top thread, you get those threads pulling out of the feed dog. The proper way to remove the material is: keep turning the handwheel until the thread take-up lever is in the very top position, then remove the material. Side note: Those loops on the underside are a problem, too. They indicate that the thread snags at some point as the hook wraps it around the bobbin case.

-

I'm thinking the hook timing may need to be advanced instead of retarded, but it's hard to judge without sitting in front of the machine. There's some trial and error involved. Also, the check spring is an often-ignored, yet key component in this issue. It's supposed to keep just enough tension on the thread as it wraps around the hook and, ideally, take up any slack that may occur. So while the modification does work, there may be simpler solutions via basic adjustments. The topic below has the full details for my arbor shim solution and also a neat custom solution by another user on page two. Keep in mind that your hook is slightly larger than the ones we were working on in that topic. Dimensions will vary slightly on your hook.