-

Posts

2,221 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Store

Everything posted by Uwe

-

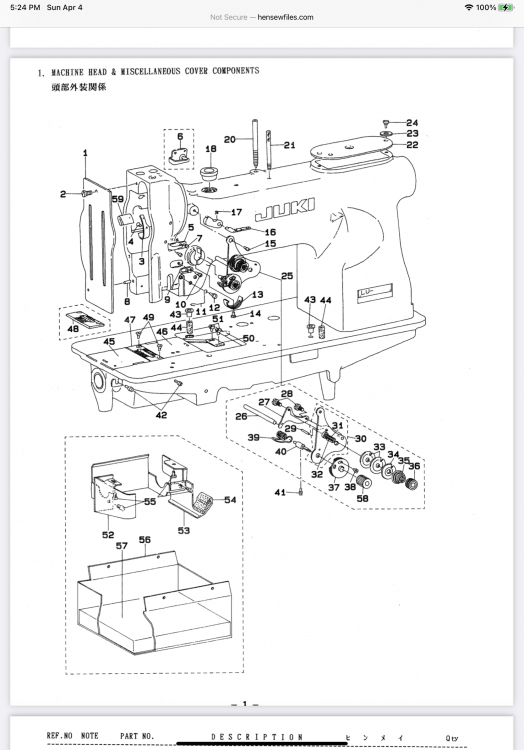

You can manually oil the machine, that’s not a problem. The automatic oiling is just a small reservoir or pan that sits under the hook. The pan usually has a sponge/felt inside and is filled with oil. With that reservoir installed, the bottom of the hook shaft dips into the oil. There’s a spiral grove in the hook shaft that moves oil up to the bushings, but only if the bottom of the shaft sits in a pool of oil. The oil gets flung to the sides by the rotating hook and hits the black metal side shield you still have installed on your machine. From the side shields the oil drips back down into the reservoir pan. The sponge/felt just traps dirt to prevent it from getting sucked up by the hook shaft. You can make your won oil reservoir if you’re handy - it’s just a rectangular box, nothing special. But you don’t really need it unless you sew at full speed for several hours at a time. For hobby use, a quick manual oiling before you start sewing is fine. This page from the Juki LU-563N Parts Manual shows the oil drip pan (part 56) which normally attaches to the table. Don’t disassemble anything unless you have to, or you know what you’re doing. A good cleaning with a cotton rag or tooth brush and some oil will likely get things moving very nicely. I wouldn’t recommend using a chemical paint stripper on the machine unless it’s totally disassembled. Just scrape off the flaky bits and use some sand paper to smooth the edges. Use a vacuum to pick up the sanding dust to keep it out of the moving parts of the mechanism. There’s a few topics on here where people discussed re-painting their machines. Getting 3-phase power installed (or getting a rotary phase converter) may be more expensive than getting a brand new 230V servo motor. If that 3-phase motor is a clutch motor, I’d recommend getting a new servo motor. Best of luck with new machine! The Juki LU-563 are a really nice design and should last a long time if you take care of it. Here’s a video that goes over some basic adjustments on these machines:

-

That depends on which motor and controller you install. If you Install a $1,000+ modern EFKA motor and controller like the EFKA DA321G (https://www.efka.net/en/products/control-box/da321g/) or other high-end system that is designed to be used with this machine, then the automation functions likely can be made to work. It won’t be a trivial undertaking and you still need 220V. If you install a basic sub-$200 servo motor, none of the automation functions will work, and you will have trouble operating basic functions like foot lift or reverse, because the machine is configured with pneumatic cylinders to perform those function via switches and valves. There may simply be no manual reverse lever, for example. I have on of these machines and built a rotary 220V 3-phase converter to run it. Works like a charm and is a joy to use. Ready-to-use rotary phase converters like the American Rotary AR-5 run $475. Not exactly cheap, but you can run the machine the way it was intended to be run. Cheap static 3-phase converters do NOT work in this application, I tried. If you install a basic motor without automation functions, it’s still possible to add pneumatic switches to control functions like foot lift and reverse manually via pedal or knee switch. I used a pneumatic switch that replaces the pedal linkage to add pneumatic pedal-heel foot lift functionality to a machine once. In any case you’ll need a small air compressor to operate any pneumatic features of the machine. Here’s a sewing demo video I made with my machine a few years back running on 220V 3-phase, just to show you how it works in full-function mode. Also, make sure you read this topic - it contains a lot of wisdom about the Adler 467:

-

The manual for the Consew 18/118 might be useful: https://www.manualslib.com/manual/1273358/Consew-18.html Here’s previous topic on the Consew 118: The threading is the same as the machine in this video:

-

The Consew 2206RB-14-7-DD looks like an interesting, fully integrated machine. I’d never even heard of it before today. It certainly looks impressively big and makes a nice stitch in the various YouTube video demos. The only downside I can extract from the spec sheets is that it’s Top+Bottom feed only, no Needle feed. Not a show stopper in itself, just something to be aware of before pressing that buy-it-now button.

-

I’m just speculating here, but it looks like Pfaff changed their serial numbering scheme some time in 1967. The serial numbers in the chart above jump from 9,000,000 in 1967 to 29,000,000 in 1968. It’s unlikely that Pfaff suddenly produced 20,000,000 sewing machines in 1967. The change in serial numbering may have prompted a change in how they are marked on the machine. Perhaps the full serial number is now split between embossed casting and a stamped plaque. Perhaps the plaques were a transitional method until they finalized the new numbering scheme. Some manufacturers didn’t assign a serial numbers until the top casting was joined to the bottom. The various parts were, well, just parts, and they didn’t become a serialized machine until the major parts were joined together. The same top could be joined to flatbed, post bed, or cylinder bed, etc. to make various machines. In any case, I suspect that both of your machines are of late 60’s vintage. Just the paint color rules out anything pre-1940 in my book. Nearly all sewing machines were black until the 1930’s. Little happened in terms product development in the 1940’s due to the war. Then they got production going again in the 1950’s and started experimenting with colors other than black. Perhaps somebody will stumble across some information that allows us to make full sense of your apparent serial number plates. Until then, just enjoy your vintage machine as it is.

-

The short answer unfortunately is “No, you can’t get there from here.” You probably mean the Juki CP-180 control panel. The CP-180 control panel only works with specific Juki OEM motor controllers on machines equipped with full-function features. The external control panels are just a convenient user-interface to change motor controller setting (essentially an external keyboard and bigger display.) The control panel itself does not add any functions to the machine, it just make it easier to control existing functions. For example, installing a control panel that has back-tack buttons would not add that feature to the machine. In general, everything you can do on the external control panel, you can also do directly using the buttons and display directly on the motor controller. Conversely, if the motors and control can’t already do it, adding the external control panel does not help. So, unless your machine already is a full-function machine with pneumatic or solenoid-driven actuators and the OEM Juki motor controller (your LU-1508 is NOT one of those machines) then looking to add the CP-180 control panel makes no sense. This Juki Series 1500 product sheet shows which models are available with full-function options (Juki usually uses the -7 extension in the model number): https://www.juki.co.jp/industrial_e/admin/pdata/filedata/333/lu1500n.pdf Adding automatic thread cutting capability to a basic machine is also not a practical option because the feature requires several other automation options to be present as well. You can have automatic back-tack without a thread cutter, but you cannot have a thread cutter without automatic back-tack. If you need these automation functions, your only practical option is buying a full-function machine that already has all that (e.g. Juki LU-1510N-7.) Attempting to add full-function features to a basic sewing machine is not a practical undertaking (there are some rare exceptions for machines that are “prepped” to add automation features with upgrade kits after the machine leaves the factory - the Durkopp Adler M-Type 867 comes to mind.) One “easy” automation feature you can add to a basic machine by means of a servo motor is needle positioning.

-

That plate number in your picture may not be the serial number. My Pfaff 545 has the serial number stamped directly in the casting: The serial number 8435866 on my Pfaff 545 dates it to 1965, according to this Pfaff Serial Number Dating chart I came across long ago:

-

I’ve not seen a service manual dedicated to the Pfaff 545. Here’s a past topic that goes over certain adjustments for the Pfaff 545 and also has a link to a Pfaff manual with a service instructions supplement:

-

It’s not really the hook timing per se, but rather needle bar height that you need to adjust in order to change between the two needle systems. The tip of the hook arrives at the needle at the same correct moment, but the eye of the needle is not at the correct height if you change to a longer or shorter needle. To change needle systems in your case, bring the needle bar with the system 134-35 needle in it to the highest position. Measure or mark the height of the needle EYE above the throat plate. Then insert the system 190 needle and adjust the needle bar height to bring the needle eye to that exact same height. The machine should now sew as it did before. The H4 versions have an extended needle bar stroke. If you use the shorter system 134-35 needle, the lowered needle bar may touch the fully raised presser feet in certain situations, causing a bind. I’d recommend using the needle system the manual calls for unless you have a specific reason not to.

-

I suggested the 1508-10H because that’s the design I’d likely choose for myself if I were to buy a flatbed machine right now. There are hundreds of sewing machine candidates, both new and used, that have been discussed in thousands of topics here on LW. Some of the popular flatbed candidates are: Pfaff 145, 545, 1245 Adler 67, 167, 267 Juki LU-562 or LU-563, 1541, 1508 Consew 225, 226 Singer 111W155 Seiko STH-8B . . . And scores more. There are lots of clone options as well. A clone is essentially a copy of an original designs, manufactured by other companies after patents expired, and sold under various brand names. Common clone brands include Artisan, Cowboy, TechSew, Thor, Cobra, Typical, Consew, Titan, and many more. I recommend spending a little quality time on this forum. If a candidate pops up for sale locally, you can search for previous discussions on Google using a search term like this: ”Site:leatherworker.net Juki 1541”

-

I’d recommend a machine that had triple feed, meaning it has an upper walking foot, bottom feed dog, and needle feed, all feeding the material in unison at the same time. The 1797AB machine you’re considering only has upper and bottom feed, but no needle feed, according to spec sheet here: http://artisansew.com/pdf/specs/1797_AB_LTHR.pdf It’s workable, but not ideal. If you’re going to invest money to buy a machine that can handle your projects with ease, get the best you can afford. Unless you’re on a very tight budget, I’d go for a new machine like the Artisan 1508-10H. This machine is a very good design and won’t be struggling with any of the projects you mentioned. Perhaps plan a road trip to visit Artisan to try out the machine in person and potentially pick it up.

-

$300 for a Singer 111W153 head seems reasonable to me - if it‘s complete and serviceable. You’ll likely have to learn how to service the machine yourself anyways. It’s a good starter machine in that regard - they’re easy to work on. Common parts are generally still available for these machines and they’re cheap. Beware of sellers who have no clue about how to properly package a head for shipping. If you put a 70lbs head into a cardboard box with foam peanuts, you’ll all but guarantee that it’ll get destroyed during shipping. Find a local pick-up deal if at all possible.

-

We’ll need to see some pictures or ,better yet, a video (upload to YouTube, post the link here) of super slow motion hand-turned stitches of the hook area to have chance of figuring out what might cause your reverse stitch issues. Thread tension is only one of a dozen possible culprits, and not the most likely one.

-

I looked into using a VFD drive a few years back. I bought a nice VFD and a 3-phase motor and set it up on a test stand with a pedal for speed input. Alas, I soon abandoned that project - it was just not a practical solution in my mind. I highly recommend going the brushless servo motor route instead.

-

LS-1341 forward and reverse stitch misaligned

Uwe replied to palvim's topic in Leather Sewing Machines

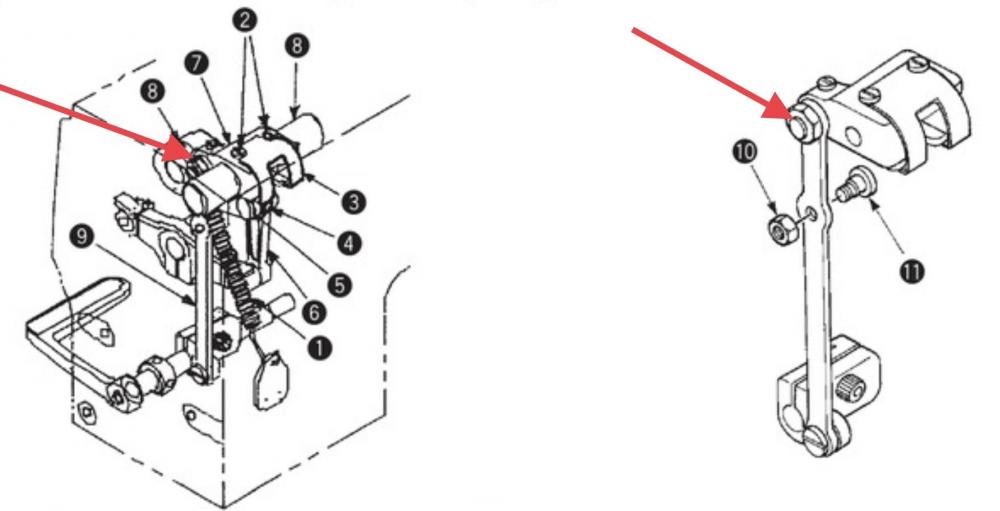

Yes, I added the red arrows to point at the part shown in your original diagram. The part they want you to rotate will be an eccentric bolt (an off-center bolt, it “wobbles” as you rotate it.) When you rotate it, you will in effect lengthen or shorten that connecting arm a very small amount. Mark the original position off the eccentric bolt with sharpie pen before you make any changes. This way you can move it back to its original position if you need to. Here’s a picture of what an eccentric bolt looks like The picture is NOT your exact bolt, just an example. -

LS-1341 forward and reverse stitch misaligned

Uwe replied to palvim's topic in Leather Sewing Machines

I don’t have the machine to take a photo, but this diagram shows where that part is located inside the machine. You’ll have to remove the top cover panel to get access to it. -

Whoa, that planetary gear setup is quite something! The Singer 151W and also the Singer 108W are compact triple feed machines, weighing in at around 35lbs, compared to nearly 70lbs for the full size Singer 111W155. With a modular servo motor setup, you have a great deal of flexibility for arranging the components in a small table-top footprint. I replaced the motor on my serger with such a setup to make a compact, portable table-top solution for sewing masks. Works like a charm. A similar setup could be used for the compact Singer for a rather portable solution. The motor below is a 1,500W motor, way more powerful than you really need for this Singer. Just for illustration purpose a few pictures of a mock-up with a Singer 151K3. Imagine a cutout in the plywood box to sink the machine into. Lift the machine out for two-part transport, each piece weighing 35lbs or less.

-

The Singer 111W155 is the default choice for leatherwork. There’s a compact/stubby version called 151W which might be a good candidate for creating a luggable table-top setup. Quite capable for small projects like wallets, belts, perhaps even sheaths, I suppose. I have some in storage but I don’t have that bottom part shown in the picture for table-top operation. I’ve made similar table top setup out of plywood for testing full size machines.

-

Search Ebay or Amazon for “1245 feet” and you’ll see dozens of presser foot options that will fit your machine. Look for feet with at start with “KP” in the part number, they’re good quality feet. Pfaff models 145 146 195 335 345 540 545 1240 1245 all use the same feet. Almost nobody shows Pfaff 345 in their listing description. You can also order good quality parts directly from a manufacturer at http://khsew.com (search for “1245” to see feet or “345” for throat plate and feed dog.) Thread path looks okay from what I can tell on those small pics. I’d recommend tweaking the hook timing a little to see if it makes a difference. Very often a small adjustment makes all the difference between snapping thread and buttery smoothness.

-

The Sailrite machines are okay for certain projects, they’re even perfect in certain situations (e.g. repairing a sail on your boat in the middle of the Atlantic). They are comparatively cheap and certainly portable. They enjoy great marketing. But you get what you pay for. They are not on the same level as other true industrial machines in terms of design and build strength.I doubt you will find a Sailrite in an actual factory (save for the occasional car upholstery shop.) If you can make them work you, then you can a save a little money and a lot of space. Alas, you won’t find too many glowing reviews of Sailrite machines here on LW.

-

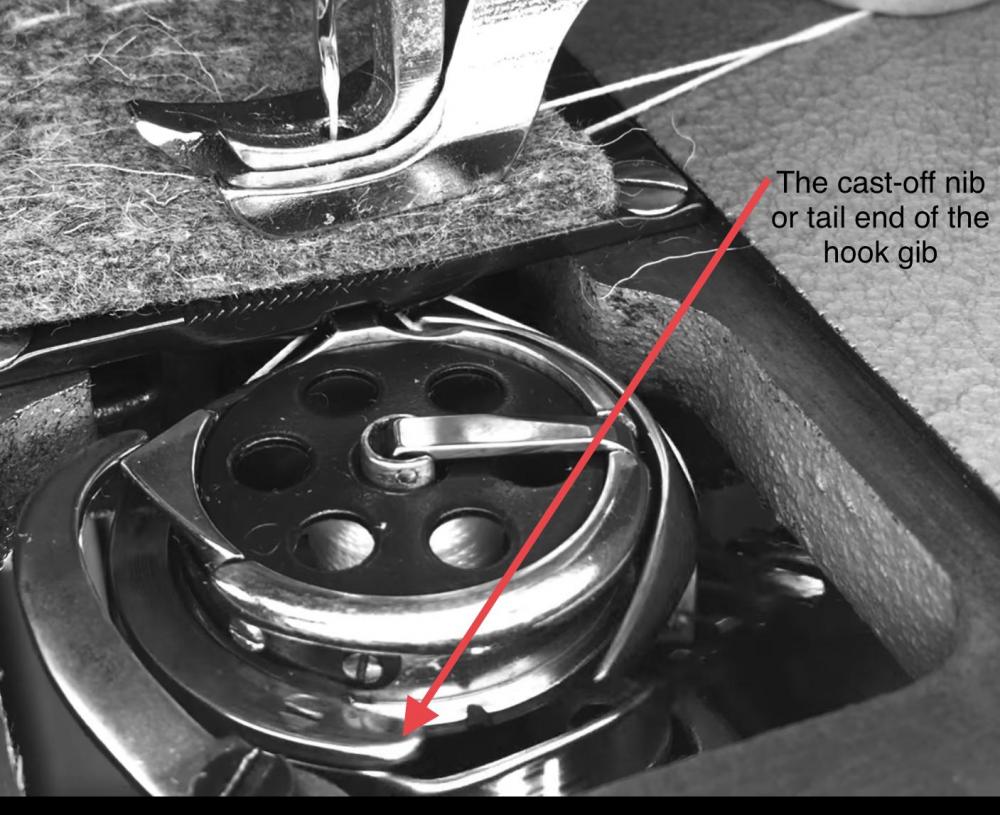

There are a few things going on here that don’t seem quite right. The main issue may indeed be a hook timing issue. It seems like the thread snags on the tail end of the hook gib (called the cast-off nib) because the hook is a little too late letting go of the thread. Advancing hook timing a little, i.e. making the tip of the hook arrive at the needle a little bit earlier may help with that issue (because the hook gib will also let go of the thread a little earlier.) Essentially the take-up lever is fighting against the hook. This photo points to the cast-off nib: This video show the same problem on a different machine (caused by a retarded hook timing). In that case advancing the hook timing resolved the issue: Your top thread tension also appears to be excessively high. Especially in reverse the top thread pulls the bottom thread straight to the top and then some, despite the leather being pulled up with the thread. Check your upper thread path to make sure it’s right. The presser feet are not doing a good job holding the leather down close enough to the needle as it pulls the knot tight. The left toe foot is too far away from the front foot and needle. If the leather gets pulled up while it’s trying to pull the knot into the leather, that normally causes the knot to stay below the the leather. On your machine the knot gets pulled to the top anyways. Please take some photos of your thread path.

-

The Juki LU-1508NH may be a machine that can cover the projects you describe. The original is available from Juki and there are clones/copies of this design available under various brand names. There are several versions of the basic 1508 design (N, NS, NH, etc.)- you want the NH version. It may not be the cheapest design, but it sure would be cheaper than two separate machines. Since you have space limitations, this might be a good candidate to investigate. The video below shows the Titan branded clone, and they demo sewing both Tex70 and Tex277 thread, very few machines can handle that wide of a range. That should cover wallets to belts and likely knife sheaths, depending of what type of leather you intend to use. A good servo motor and speed reducer will be essential. Artisan is another clone vendor. They are based in California and call their version the Artisan 1508-10H: http://artisansew.com/walkingfootmachine.html Perhaps Artisan are in day trip distance from you. Buying a machine from a local-ish dealer is kind of a big deal, especially when it comes time to service it. Being able to try out the machine and pick it up in person is just priceless.

-

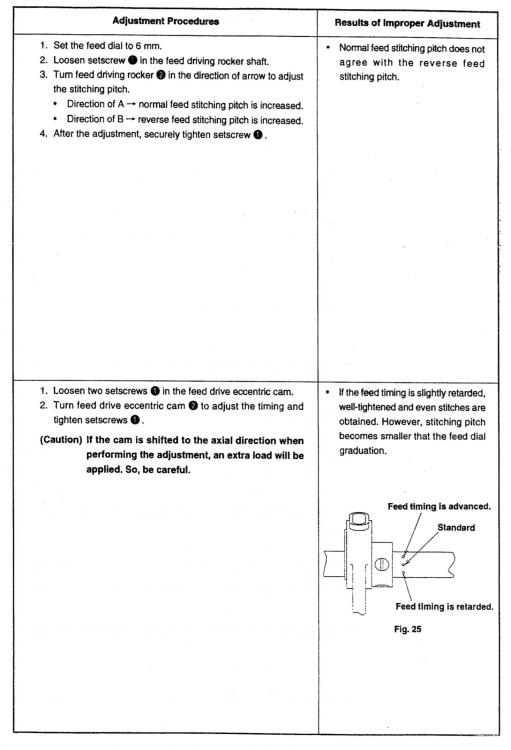

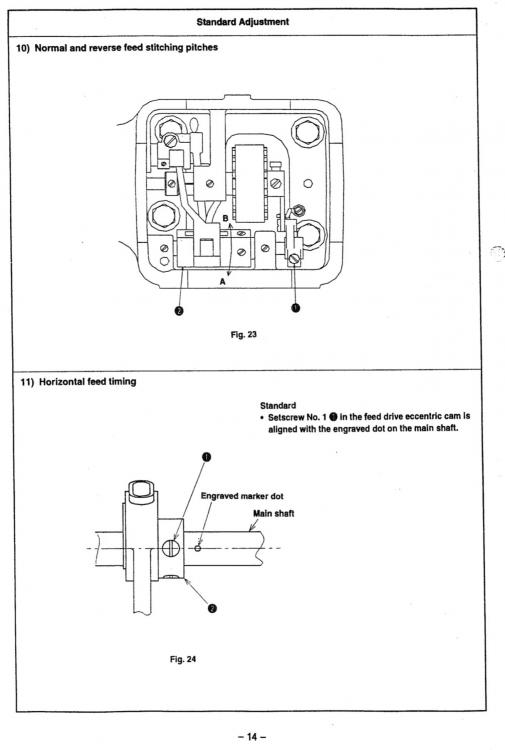

You’re not far off now, it seems. I don’t see or hear anything glaringly wrong other than perhaps some thread snapping perhaps due to the hook gib not letting go of the thread early enough (advancing hook timing might resolve this.) Please elaborate on what you actually do. “I adjusted the stitch length adjuster” doesn’t really give us enough information about what you actually did. Which screws did you loosen, what parts did you move in which direction? Others reading this topic in the future will want to know what to do, or what not to do. I’m not sure what manual you get with the TechSew, but the Juki LS-341N Engineering manual describes how to balance forward and reverse stitch length on pages 14 and 15 (see images below). The TechSew may be a modified/enhanced clone since it apparently can do 9mm long stitches. The original Juki LS-341N can only do 6mm. I have a feeling multiple planets have to align and all relevant adjustment have to be spot-on to squeeze 9mm stitchlength out of that design. I’d be curious to know how TechSew accomplished that. Make sure the feed dog movement is perfectly centered in the throat plate opening. At 9mm stitch length there is no wiggle room at either end (unless they use a significantly shorter feed dog.) Below are the two relevant pages in the Juki engineers manual that describe how to balance forward and reverse stitch length and adjust feed timing. Your machine may not have the engraved markings the Juki manual refers to. It would be interesting to see if and how the TechSew manual differs from the Juki manual.

-

Well, it sounds like at least one adjustment is not at the factory setting. Which manual were you using to make the adjustments? It’s hard to offer advice without knowing what you actually did to the machine and without actually seeing what’s going on. Pictures and video help. I also wonder why the bobbin case opener needed to be replaced on a brand new machine. I strongly recommend NOT running the machine under motor power until you get it adjusted right. You can do a lot of damage in a matter of seconds if you run it under power while something is loose or adjusted incorrectly. Remove the motor belt until the machine makes perfect hand-turned stitches. Don’t take it personal, but there’s a good chance that you inadvertently caused most of the problems you’re experiencing with the machine. Getting your machine back to a working state may not be a simple task.

-

Single toe feet are useful for sewing very close the edge or when using an edge guide, and also for sewing zippers or near an edge or step.