-

Posts

308 -

Joined

-

Last visited

Contact Methods

-

Website URL

http://www.leatherbyjohan.com

Profile Information

-

Gender

Male

-

Location

Twin Cities, Minnesota, USA

-

Interests

Tooling and design / Braiding / Finishes / Publishing / Bookbinding / Teaching

LW Info

-

Leatherwork Specialty

Everything

-

Interested in learning about

Everything!

-

How did you find leatherworker.net?

Surfing

Leerwerker's Achievements

Member (2/4)

-

Welkom! Ek was lanklaas hier op die forum. Ek woon in die VSA, maar het met my leerwerk begin in SA in 1978.

-

I was contacted by a lady whose husband had hunted 13 white tail deer. He then had them tanned at Uber Glove Company in southern Minnesota. They are just not going to be able to make use of them and decided to sell them to anybody who could make good use of them. She wants $75 per hide. She described them as 11 buckskin color, 1 grey and 1 more yellowish. She can be contacted at Mary Brau 651-455-7706 She lives in Inver Grove Heights, MN Please reply here if you bought them from her, then I can remove this post so that she does not get too many phone calls.

-

I had a leatherworking friend in South Africa called Bill Stockill. He did amazing art work on leather with a method he developed of transferring images to leather. I am experimenting with a similar technique now and want to demo it to our guild. But I also want to tell them about Bill Stockill. I cannot find any photos of his work. Can any body help with that? I know there was also video of him showing his technique, but all I can find now is a horrid one that shows him but the sound is bad and just not worth it.

-

-

I acquired these three as part of old batches of tools I bought (one box containing this was even mailed to me via usps!). Does anybody have an idea what I can thin the old Neatlac out with? Anything I can buy in a hardware store? JOhan

-

-

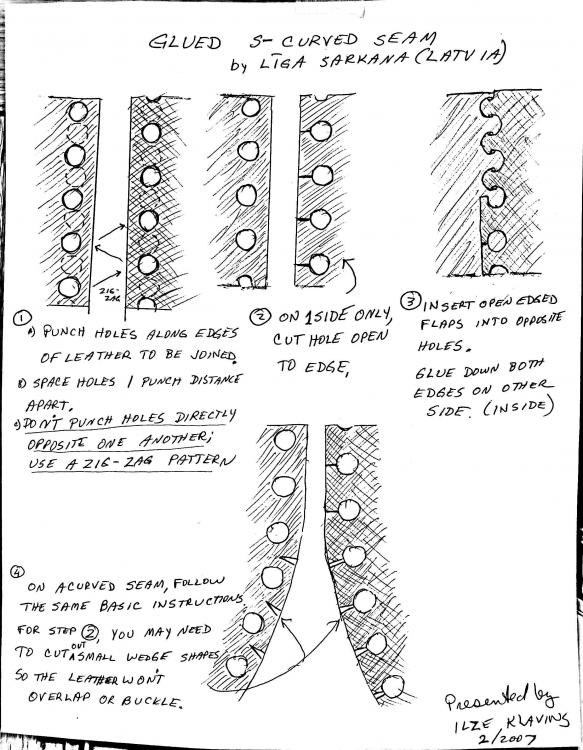

Need help learning this construction method please? Interlocking?

Leerwerker replied to ddct70cc's topic in How Do I Do That?

-

Thank you! That gave me all the information I needed and now the guy is going to make his own drive belt! Johan

-

I was approached by someone to make a three inch wide drive belt - 140" long. So, I will have to attach two or thee straps end to end to achieve that. The old belt the guy had, had a very specific hinge setup that looked like a row of staples that allowed two straps to be attached end to end and make for a smooth belt. Does anybody know if and where that hardware can be found?? Has anybody made this type of drive belt? Johan

-

I just acquired a Singer 29K60 Long arm big bobbin patcher today. The little motor runs and drives the machine! Most of my stitching is by hand or on my Tippman Boss. I have read all the threads about the 29K60 on this forum and made notes. So I hope my questions will be fairly few. I could not find a manual specific to the 29K60. Does anybody have a copy for me maybe in .pdf? I don't want to fiddle too much with the machine before making sure everything is where it should be.... The little motor has just about 12" of cord attached, and when you plug it in, it starts running. How are you supposed to start and stop the machine? Thanks! Johan

-

Grey dye

Leerwerker replied to glockanator's topic in Dyes, Antiques, Stains, Glues, Waxes, Finishes and Conditioners.

Vinagroon is a surefire way - it might take some testing to get it weak enough to produce grey and not black immediately. Just one warning : I suggest not to do the backing soda bit - raising the pH much above 4 will start to de-tan the leather. I have a blog post about it at http://www.johan-potgieter.com/ll/?p=148 -

I made this very successful pair of minimalist flip flops for myself and therefor could measure them on my feet for my feet. Now someone else asked for a similar pair. Is there standard lengths for the straps that would work for all feet or how would I go about it?

-

Antonia, You cannot stamp on treated leather - unfortunately it is that simple.Any impressions you get will be temporary. Here is my short explanation: First the veg tan leather comes to you you dry from the tannery - you make it damp and this makes the fibers of the leather stick to each other as you stamp on the surface - you let it dry and the impressions are still there - now you add a conditioner or sealer and the impressions become permanent and the smooth parts of the leather cannot be stamped any more, because you cannot get the leather fibers sticky any more. It applies to all the steps in leatherwork, but especially to colouring and finishes: test every step on the cut off pieces of leather! So, dampen the untreated veg tan, stamp your maker stamp, let it dry, dye the piece of leather, put on a conditioner / finish and see what it looks like. Variations for a more visible maker logo might be to cut them out of the undyed leather and sew them onto your project or consider the old type of block dyeing that the hipies did in the 60's and 70's. (You can see my blog post on this topic to get a better idea: http://www.johan-potgieter.com/ll/?p=117)

-

This is my latest pair - on the road now for two weeks and very happy with them. The improvement on this pair was that I glued a rubber bottom sole to the leather sole - all my previous shoes just had a single piece of leather as the only layer between me and the ground and I only use them indoors - with these I wanted to be able to walk on damp surfaces outside. The bottom plastic sole is a sheet I bought at Tandy - does anybody know of suppliers that would sell sole materials on a small scale?

-

For my third pair of shoes my son convinced me to try a turned shoe - stitched inside out and then turned so the stitches was on the inside. Not too uncomfortable, but not my first choice - you do feel the seams on the inside against your feet.... Unlike my other shoes, I stitched these on my Tippman. The pieces were held in position with narrow strips of double sided glue tape. For all my other shoes, the holes are already indicated on the patterns and I sew them by hand.