-

Posts

5,975 -

Joined

Content Type

Profiles

Forums

Events

Blogs

Gallery

Store

Everything posted by fredk

-

How do I paint or draw on leather (waterproofed leather)

fredk replied to c.c.1315's topic in How Do I Do That?

Paint pens work well. The pens must have either an oil based or acrylic based paint I use them for the details on my gaming boards The paint pens cost about $1 each and are sort of meant for detailing autos, especially the tires -

Need recommendations for steel bar plate for work bench

fredk replied to desullivan's topic in How Do I Do That?

I'd go for at least 6mm (1/4 inch) thick aluminium. No chance of corrosion / rust ruining leather. About 4 inches wide and about 15 to 18 inches long. Counter-sunk brass screws to hold down. Should be able to cope with most projects -

Give thanks for whatever God shoves your way Don't; drink too much, eat too much, fight your relatives too much Do; hug those relatives, eat well, drink wisely, have good time

-

simple and does the job, whats not to like?

-

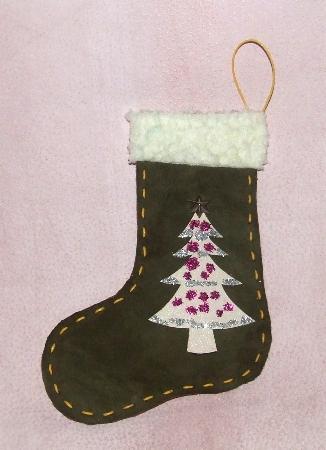

Christmas trees & stockings to hang on a tree or somewhere. Personalized with peoples initials on the other side I made a bunch of these a couple of years ago. Maybe about 20 The year before I made Christmas trees. About 4 to 6 inches tall. Again, made about 20 I don't seem to have photos of the trees, or I can't find them On a couple of the stockings I left the top unsewn and put some sweets (candy) in I used red & green chrome tan (and scraps of faux fleece) but brown or other colours will work just as well HTH

-

We don't have Aldi here but Lidl might have something similar in sometime I don't need one . . . . . but its another toy for the toy box so I'll probably buy one if they come my way

-

Yup, did that a few times last week. Not concentrating on what I was doing, talking too much

-

Not knowing what the console looks like or is made of; maybe staple or tack it in place?

-

You can also add varying amount of talc into resolene which will give varying degrees of mattness. Talc added to any paint or varnish in small-ish amounts acts as a matting agent

-

Try a final buffing with talcum powder

-

All working fine at my end but, there have been reports that the Russians have been interfering with Western communication satellites and although its been going on for more than a year in recent months they've stepped up the interfering

-

what did you miss at the pendelton leather show video

fredk replied to chuck123wapati's topic in Leatherwork Conversation

Thanks for posting the video. A great presentation and a great show. Its nice that one company felt confident in the honesty of folk to leave all that brass (?) work unattended on one of the busiest days of the show. I wish I could attend one of these shows as we don't have anything like them here. But my credit card is happy I wasn't there - I would have maxed it out, and the max is very high number! -

I only sand to even up the edge, to take out bumps made by my bad cutting, or similar. I sand by hand. Depending on how bad the edge is I'll start with an 80 or 120 grit, working thru 240, 320, 400 to 600

-

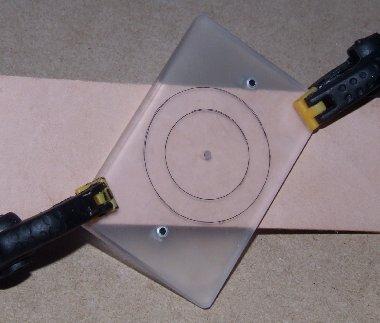

I use these ; Two pins with a hole centred on them. Fits virtually any size of strap or belt. Just put each pin against the belt and the hole is the centre of the belt. I've made 3 of them, just for handiness sake Swivel it and the centre of the strap or belt can be marked. The circles are at 1/2 inch and 3/4 inch. If you want 3/4 inch between holes move the guide so that the 3/4 circle is over your last hole

-

Besides books, especially by Al Stohlman my other things are; A Tandy Pro-Press. I use it a lot, for pressing stamps, as a clicker press, for making sewing holes with chisels Sets of sewing chisels with different spacing; 3mm, 4mm, 5mm, 6mm and my stitching pliers and lacing pliers A couple of sewing clamps; a light-weight one for taking out to places and a larger heavier one for use at home base My special stamping table Which is adaptable for various jobs

-

BBC caught with its knickers down . . . .

fredk replied to fredk's topic in All About Us and Off Topic

Ah, but they haven't. Only the two top dogs resigned but those responsible for the wrongful editing remain in their jobs -

The BBC has been caught Certain people at the BBC edited Trump's speech and the images of the January 6th 2020 event to make it look like he incited the people to riot It has only come to light because a newspaper was accidentally sent an email of a memo between BBC execs Donald is threatening to sue the Beeb for a $billion Rightly so

-

I have a few I can share with you I'll PM them to you later

-

Help with square corners on wet molded pouch

fredk replied to bigsig11010's topic in How Do I Do That?

Try using a small spring clamp on the corners; to pull the sides together. Use pieces of scrap leather between the clamp and your piece to avoid the spring clamp leaving an impression of its jaws on your piece One of these, that depending on the size of your piece. but I'd go as large as possible But you'll not get perfectly tight corners without cutting the leather -

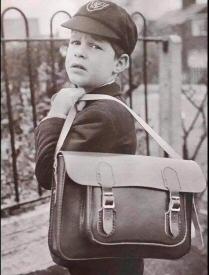

When I was a small boy going to Primary school (Grade school?) one of my mother's annual rituals was to take me to a shoe shop a week or so before the school start after the summer break to buy me a new pair of shoes and a new school satchel, aka a school bag. Even though the last year's school bag was still good a new one had to be bought. ( see below, first image) Every child in Belfast had one of these school bags. Made of good stout leather and always brown. Since those times I've come to believe the bags were made by disabled WW2 veterans in some sort of work programme Thats not me, just a photo off the internety Last year I was passing a top women's fashion shop in Belfast and spotted what looked like a school satchel for sale. So I wandered in and had a look. I soon retreated when I saw the prices - £360( $475 USD / $665 CD) and some were reduced to 'only' £250 ( $330 USD / $460 CD). They were almost exactly the same as my old school bag, but available in a range of fashionable colours, eg bright blue, yellow, bright red, grass green and so on This is a picture from the shop's website. Except for the fancy strap on this one can you tell the difference. And below it is a genuine school satchel being sold on ebay for £65

-

Halloween; I prepared a large orange bucket with plenty of sweets (treats). I also included a few baby potatoes, as a sort-of 'booby' prize The childer came to my door. I got the bucket and told them to dive in and take lots. One we lassie got a spud. She laughed as she exclaimed 'I got a potato'. Then all the others cried they wanted one too. I tried to tell them it was a trick but they weren't listening They all crowded round the bucket and would you believe it the buggers err, the wee darlings all got a spud each! and were really happy There goes my Sunday dinner spuds

-

Wrap each bottle in bubble wrap. Make sure its very warm when you do tho. Bubble wrap is a fine insulator; it'll keep things cold or warm, but it depends on the temperature when the item is wrapped. I use medium sized bubbles, not the small ones nor any of the larger. This will help keep the bottles warm for a while but you may have to go out to warm them and re-wrap them