-

Posts

525 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Store

Everything posted by Chief Filipino

-

That video was specific to finishes...... it's been awhile so I can't remember if he also talked about paints and finishes....

-

I mainly use dyes. I've made a few things with acrylic paint, not the leather type of acrylic but just regular acrylic paint. A few of them came out nicely, but for some reason the white paint cracked. Which from what I hear is a common issue. I use acrylic resolene to seal it. I haven't heard back from the owner so I have no idea how well it has held up. I bought some Eco-Flo Cova-Color during a Black Friday sale but haven't played with them yet. Since this is actually going to go onto a helmet and will see all the hell that fire fighters deal with daily, I would recommend not using acrylic paint at all. In that case the total black would last longer. From what I have seen, experienced, and heard in my research is that acrylic resolene is the closest you can probably get to a "waterproof". I've also heard the same with wax/oil mixes. Maybe Red House Shields is willing to share what they use. Here's a looooooooooooooooong video but I thought he did a good job of showing the properties of each finish. https://www.youtube.com/watch?v=zyTg_hfpNUM

-

Leather vest and a whole lot of braiding

Chief Filipino replied to DS STRAPS's topic in Clothing, Jackets, Vests and Chaps

Nice. So the black diamonds along the bottom just come from the way the Mexican braid is done? -

My First Leather Hat

Chief Filipino replied to Bodean's topic in Purses, Wallets, Belts and Miscellaneous Pocket Items

Do you remember the website? I am looking to make my own not for others. -

My First Leather Hat

Chief Filipino replied to Bodean's topic in Purses, Wallets, Belts and Miscellaneous Pocket Items

Nicely done! Would you mind sharing how you went about getting your measurements? Please -

Leather vest and a whole lot of braiding

Chief Filipino replied to DS STRAPS's topic in Clothing, Jackets, Vests and Chaps

Nicely done! I like the design you made along the trim with the lacing. Could you get a close up shot of it or did you already give it to your brother? -

I like the design! I think you should be able to redye it with black, though in my opinion that would drown out your details. Maybe you could do some antiquing? Or apply a second coat of the Eco Flo smoke and that should darken it some more. To me (though I'm far from professional/expert) your tooling doesn't look too bad. I would say the biggest thing would be consistency of depth (something I'm working on too). The bottom middle right of your triskelion is an example of inconsistency. Your letters are lined up fairly well though I'm having trouble trying to figure out the look you are going for. They aren't centered, and I personally feel like they should be, but maybe that isn't the look you were going for? Overall I like the design and symbolism. What did you use for your blue-ish and red?

-

First Leather Binder

Chief Filipino replied to Chief Filipino's topic in Books, Journals and Photo Albums

Thanks! Ya he was a new guy so I'll cut him some slack, hopefully I'll get the same since I'm a newbie too -

First Leather Binder

Chief Filipino replied to Chief Filipino's topic in Books, Journals and Photo Albums

This is a perfect explanation! Awesome! Thank you so much! I just had a request for a journal cover and plan on using this for it! Thank you! -

First Leather Binder

Chief Filipino replied to Chief Filipino's topic in Books, Journals and Photo Albums

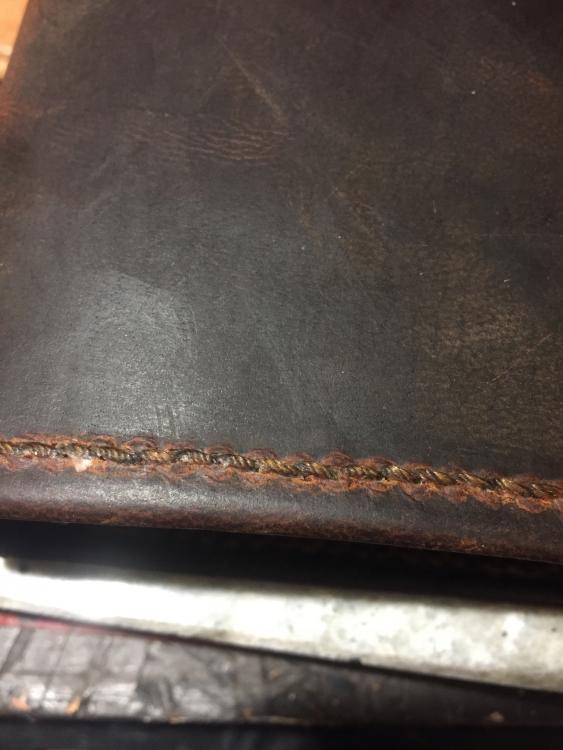

I did everything but skive the edges. Thanks for the info. I thought sanding and scoring it with my scratch awl would be enough but obviously it wasn't. I will skive the next one. I did have luck with one side of it though because I clamped a metal ruler over the whole thing and left it over night because I was tired and went to bed. It held long enough for me to get some holes in it to stitch. I thought about 45-ing the edges and I agree it would probably be better. Any tips on 45ing corners? I didn't go the extra mile on this one because it is for a friend of a friend who didn't want to pay big bucks for a leather binder, but wanted hand made. So I took it as a learning opportunity, but wanted it done so I didn't spend a gagillion hours on it. -

First Leather Binder

Chief Filipino replied to Chief Filipino's topic in Books, Journals and Photo Albums

I will keep that in mind though with this thickness/oiled hide I was even having trouble with the contact cement. It didn't want to stay down when I turned/rolled the edges. I had to clamp it down for a long time before it would stay. Maybe rubber cement will work better? -

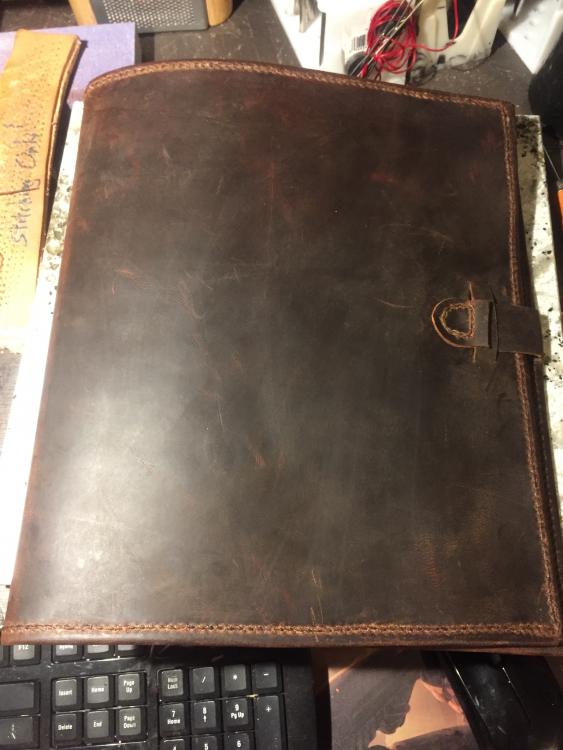

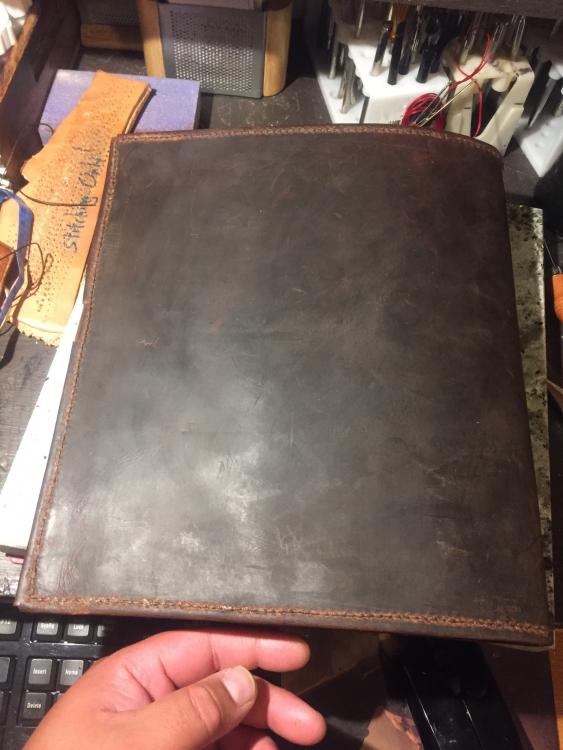

Hi Everybody! Here is my first binder I've ever done. I like it a lot, though as always there are things that could be done better. For example one section of my stitching wandered a bit, but through the power of censorship I didn't include that in my photos . It is made of two layers of some sort of calf skin. It isn't veg-tan, and it's not an oiled hide... well it kind of is.. I am not sure it feels like it's somewhere in between. Maybe stone oiled? The guy at Tandy didn't give me too clear of an answer, at least not one that stuck in my head hahaha. This is my first rolled edge project as well and it was definitely a learning experience... I got a little too liberal with the contact cement in a couple spots. Any and all comments or critiques are welcome. Yes, I know I'm not supposed to ask for critique here but I didn't want to do two separate posts and I really do feel like showing this one off. Let me know what you think! ..... wait... is it called turning the edge or a rolled edge?

-

Leather Guild Start Up Tucson, AZ

Chief Filipino replied to Chief Filipino's topic in Leatherwork Conversation

Thanks! Hopefully it goes well. There are some really great crafters out here! -

I am not an expert and have never refurbished a leather piece but my thought is to maybe redye the whole thing? Perhaps there is a spot that has been rubbing that hasn't been re-coated. That might end up costing quite a bit though. Perhaps the inside needs re-dying and re-coating with acrylic resolene? Are the smudges only coming from the edges of the jacket? Or is it coming from the inside?

-

I personally think of what the use of the item will be, the conditions it will experience , and pricing. I am trying to make a bunch of key fobs to get rid of some scrap so I don't want to spend a ton of time/effort on these. They will be cheap so why use my good rivets on them? Is the purse I am making something I want to last a lifetime? If yes then I will use brass or copper rivets. That will increase the price though. Since you live in Ireland you have those weather conditions to deal with so that may actually limit your choices. I live in dry/hot conditions so I really have a lot of options. So if you sell locally and not internationally that may limit your choices as well. I personally haven't seen much difference between rivets and stitching, except when I screwed up putting a rivet in. That being said, I feel like items that I have screwed up the stitching on have still held well. I have a pair of tabi (ninja boots) that I made and they see the harshest conditions I can put an item through. They are stitched and have held up even when portions of the stitching have failed. They were like the second thing I had made out of leather and really didn't know what I was doing. I have a belt I have made and held together a part of it with contact cement and rivets. One of the rivets has popped out and the cement is starting to give a bit. So long rambling cut short, if you are making an item that will last years I recommend either brass or copper rivets and on cheaper/less important items use the jiffy rivets.

-

I have a press from Harbor Freight. It doesn't have a hole yet and it has served me well. I have a set of stamps from Tandy as well as others. If I end up using a stamp repetitively I will definitely want to drill a hole into it but for now I infrequently use stamps so haven't taken the time. If you do a search on youtube there are a bunch of vids showing you what others have done. For example:

-

Any fellow crafters in the Tucson and surrounding areas: The local Tucson Tandy Leather has offered their space as a meeting spot for leather crafters to start a guild for the Tucson area! They are inviting crafters to the first meeting next Tuesday, May 23, 2017 from 6pm-8pm. I think it would be great to meet with people and see what they have done. It's like a leatherworker.net in real life! I am pretty sure I will be able to attend and I will pass on this site to anyone who would like more information. I truly appreciate all of your input! Here is the info from their flyer: Tandy Leather Factory 3455 S Palo Verde Dr. #167 Tucson, AZ 85713 Please RSVP: 520-519-0750 Please bring a project that you have finished or one that you are working on. We will be meeting to get your input on developing a leatherworking guild for the Tucson area. This is a great opportunity to share skills and knowledge with fellow leatherworkers of all skill levels from beginner to professional. If you are interested in leadership please let Kathy at Tandy know. Please know that Tandy would love to house all future guild meetings, but that this guild will be established and maintained by those who attend. Tandy will be open during whatever hours your establish for guild meetings.

-

Welcome Ron!

-

Tanning A Python Skin Help

Chief Filipino replied to Chief Filipino's topic in Exotics, Reptiles, Furs and others

awesome! I will see if I can get ahold of some of that stuff. Right now my biggest concern is the smell. It has disappated some but do you know if that will go away? Does the lubristretch help with that? -

Has anyone attempted to tan their own snake skin? I've been researching through youtube mainly and found that practically all the tutorials are on rattlesnakes. I recently purchased three python skins from a taxidermist who only wanted the bones. I am attempting to tan them myself. So far I have only started with one to see if I can figure it out. Has anyone tanned both a rattlesnake and a python? The skins I got were not exactly "tube peeled" and so there is a very large band of tissue running down the spine. I tried to flesh it as best as I could. I got the fascia off for the most part but this band seems to be something else. At times I was able to get a bit lifted up and peeled off but in some areas no matter how much I scraped it would not come up. It was getting to the point where I began cutting some holes in the skin. I ended up leaving it on and I'm hoping that it works out. I put it in the tanning solution (50/50 isopropyl/glycerine), shook it twice a day for a week, and just pulled it out today to dry. In the video I watched the guy mentioned that when I pull it out I shouldn't smell anything but the isopropyl alcohol. I smelled the alcohol but there was also a hint of ... a death smell... not rotting, but dead. Have I totally messed it up? Should that smell have dissipated in the alcohol/glycerin solution? Here's the vid I watched on the solution portion:

-

Chelsea Leather Food Reviews?

Chief Filipino replied to Chief Filipino's topic in Leatherwork Conversation

Are you here in the United States? It sure sounds like the US regulations. -

Awesome! Thank you! I would love to get into saddle making but I do not ride and I'm not part of the culture so I don't know that I'd ever make them to my satisfaction... plus I know nothing of saddles other than they are made of leather, have padding, and are beautiful. I appreciate the input! Awesome thank you! I will go see if I can find some leather that my dad has and see what that is like. He is horrible at maintaining things other than his truck and lawn mower lol.

-

Hello Everyone, I am trying to find a decent and easily accessible leather conditioner to perhaps start selling along with my products. I have personally used Chelsea Leather Food over the years and I feel like it works. I do not have your vast experiences, how decent is it? Also, since I don't have the time/knowledge at the moment to make my own beeswax/oil conditioner is there one that you personally use? Does anyone know of a wholesaler that I can buy small quantities from? I am not doing this full time yet. Thanks for the assist!

-

Also, being a newbie to this I don't know that I could tell the difference between leather that has been taken care of the proper way, and leather that has been mistreated/conditioned improperly. I would love to give a lifetime guarantee too, but I don't know that I am at that level yet. Does it just take experience to know? How would I even start researching what it looks like?

-

Awesome NV thank you! However my question pertains more to the finishers/sealers that I am using. So for example would I use the same process you describe regardless of whether I use resolene, super shene, or carnauba creme? I have been using acrylic resolene on my masks to try to give them some waterproofing. Does the resolene seal the leather off so thoroughly that it will take some time/use before any neatsfoot will even soak in?